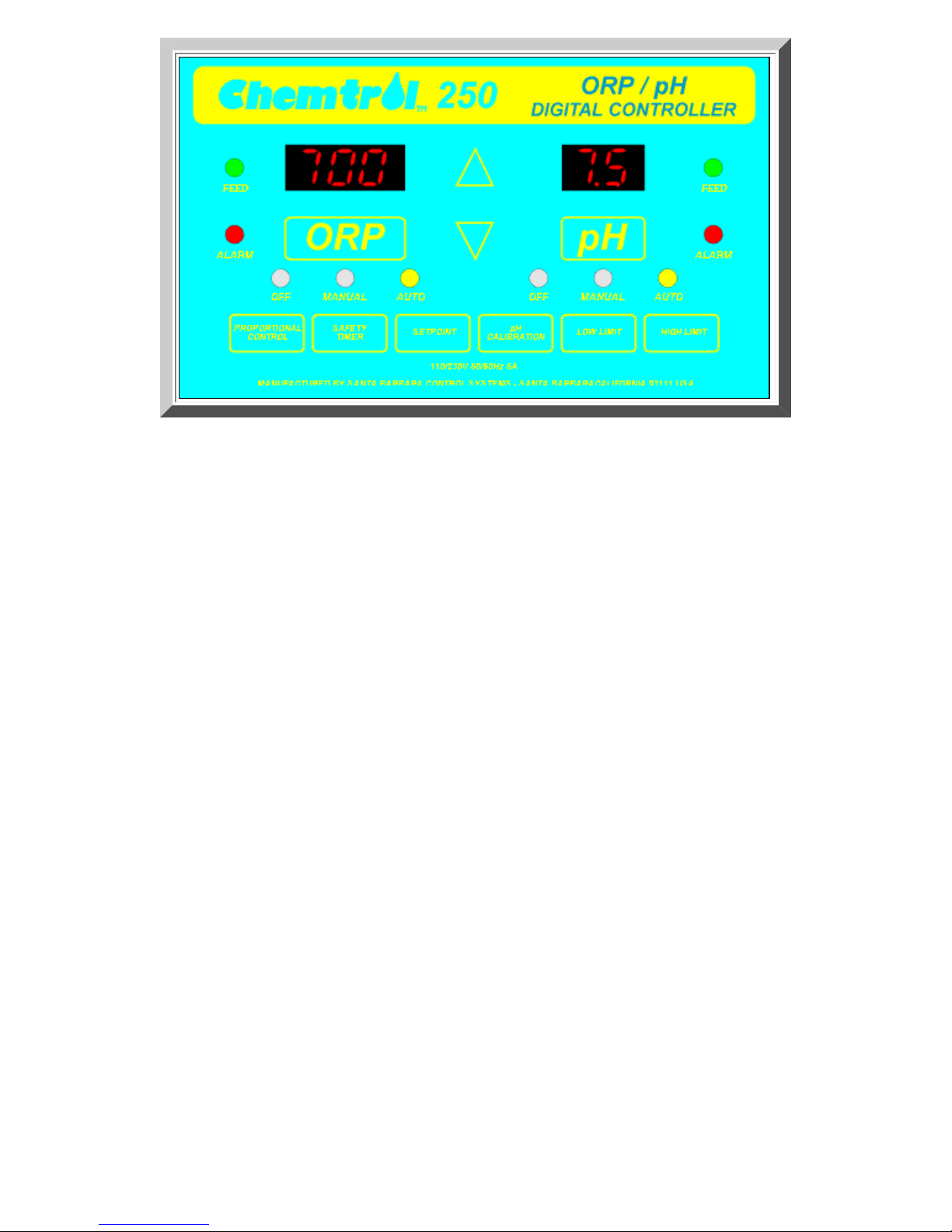

Chemtrol 250 User manual

Table of contents

Other Chemtrol Controllers manuals

Popular Controllers manuals by other brands

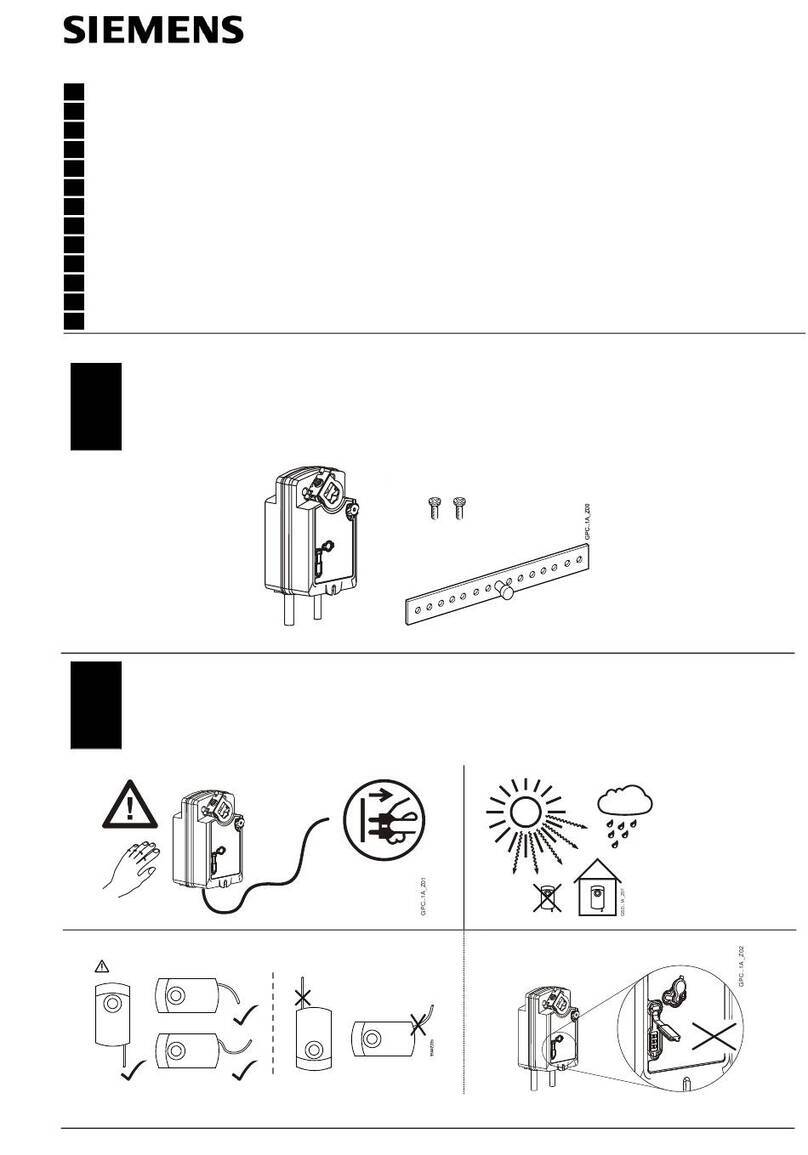

Siemens

Siemens GPC 1A Series Mounting instructions

Siemens

Siemens RDF870KN manual

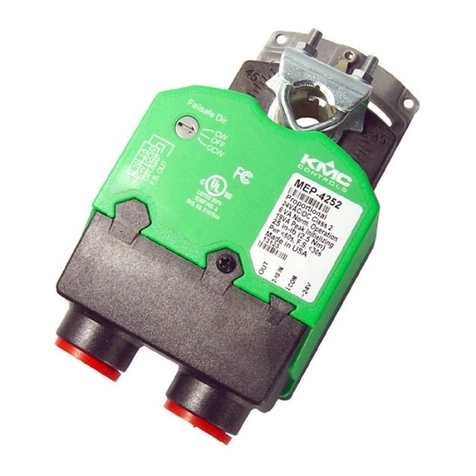

KMC Controls

KMC Controls MEP-4 Series Application guide

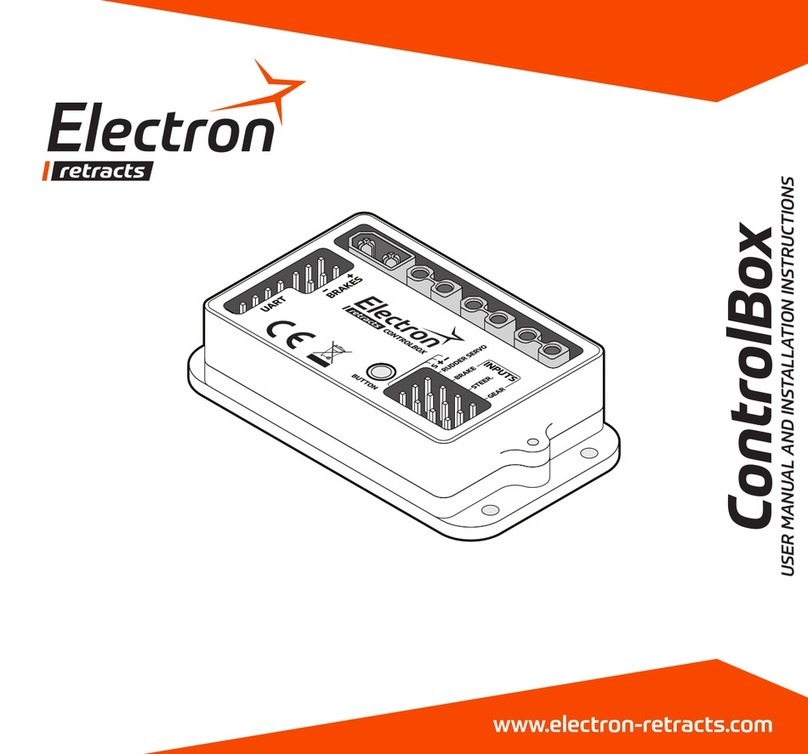

Electron retracts

Electron retracts ControlBox User manual and installation instructions

MORITEX

MORITEX MLEK-A120W1LRD instruction manual

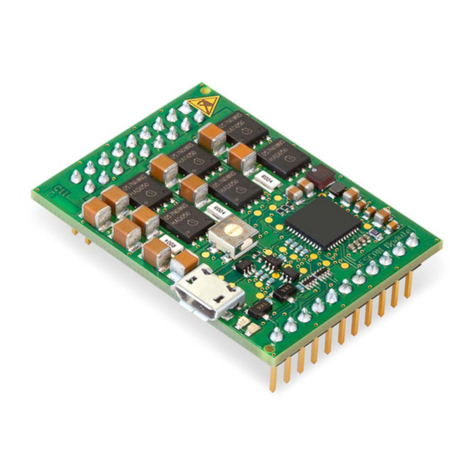

maxon motor

maxon motor ESCON Module 50/5 Hardware reference

Autogrow

Autogrow IntelliDose Installation and user guide

Kohler

Kohler K-7124 Installation and care guide

SOMFY

SOMFY Animeo KNX RS485 operating manual

Steca

Steca Tarom 4545 Installation and operating instructions

Fujitsu

Fujitsu AIRSTAGE UTY-ALGX instruction manual

Emerson

Emerson dixell WING XW260K Installing and operating instructions

Pivot

Pivot THC-M user manual

ALEXANDER ENGEL

ALEXANDER ENGEL TMAX V2 Installation & operation

JUMO

JUMO exTHERM-DR operating manual

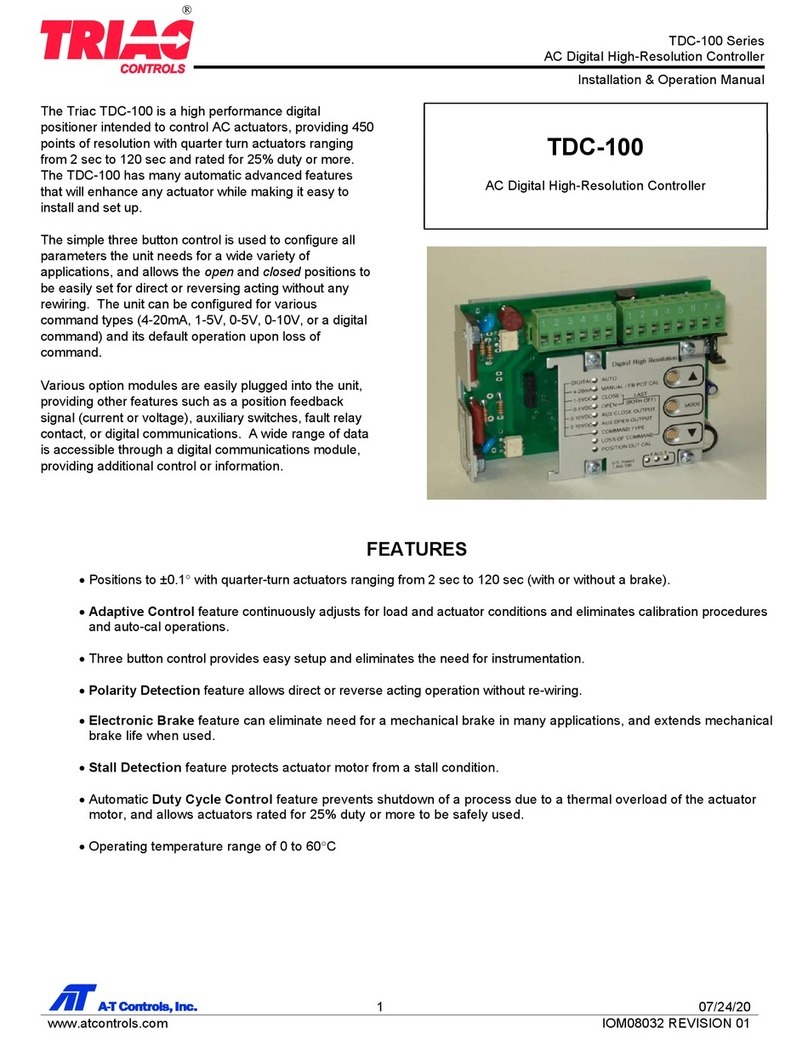

A-T Controls

A-T Controls TRIAC TDC-100 Series Installation & operation manual

Regulus

Regulus UR1 A-DT Installation and operation manual

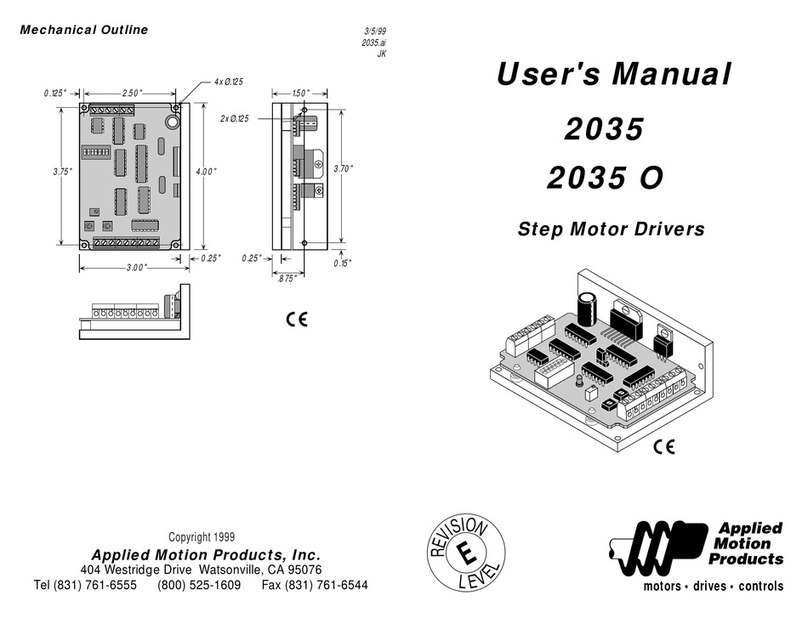

Applied Motion Products

Applied Motion Products 2035 user manual