ELGO Electronic P40-000 Series User manual

Operating Manual

SERIES P40-000

Programmable 1 or 2 Axes Position Controller

Position Controller for 1 or 2 Axes

Manual, Single or Program operation

LCD display with 7 menu languages

16 freely configurable inputs & outputs

Optionally with 12 bit analog output

Useful functions like referencing,

tool offset and batch counter

Simple and intuitive handling

Integrated diagnosis mode

Optional RS232 interface

Quick panel mounting

799000347 / Rev. 10 / 2018-07-23

Translation of the original operating manual

Contents

- 3 -

1Contents

1Contents ............................................................................................. 3

2General, Safety, Transport and Storage ........................................... 6

2.1 Information Operating Manual .............................................................................6

2.2 Explanation of Symbols ........................................................................................6

2.3Statement of Warranties.......................................................................................7

2.4 Demounting and Disposal....................................................................................7

2.5 General Causes of Risk........................................................................................7

2.6 Personal Protective Equipment...............................................................................7

2.7 Conventional Use ...............................................................................................8

2.8 Safety Instructions for Transport, Unpacking and Loading ..........................................8

2.9 Handling of Packaging Material ............................................................................8

2.10 Inspection of Transport ........................................................................................8

2.11 Storage .............................................................................................................8

3Product Features ................................................................................ 9

3.1 Essential P40 Features .........................................................................................9

3.2 Operating Modes ...............................................................................................9

4Technical Data ................................................................................. 10

4.1 Identification ....................................................................................................10

4.2 Dimensions......................................................................................................10

4.3 Technical Data Controller .................................................................................. 11

5Installation and First Start-Up......................................................... 12

5.1 Operating Area ................................................................................................12

5.2 Mounting / Installing ......................................................................................... 12

5.3 Activation of the Device .....................................................................................12

6Design und Function ........................................................................ 13

6.1 Key Functions...................................................................................................13

6.2 Display Functions..............................................................................................14

7Handling & Operating Modes ......................................................... 15

7.1 Operating Modes .............................................................................................15

7.2 Referencing an Axis ........................................................................................... 18

8Menu Structure and Parameter Levels............................................ 19

9Axis Menu......................................................................................... 20

9.1 Parameter Axis: Distances...................................................................................20

9.2 Parameter Axis: Times........................................................................................ 24

9.3 Parameter Axis: Settings .....................................................................................26

9.4 Parameter Axis: Analog - optional .......................................................................32

9.5 Parameter Axis: Measuring System - optional.........................................................35

Contents

- 4 -

10 System Menu.................................................................................... 36

10.1 System: Setup...................................................................................................36

10.2 System: System-Times ........................................................................................39

10.3 System: I/O Configuration..................................................................................40

10.4 System: Default Parameters ................................................................................44

11 Password Menu................................................................................ 45

12 Contrast Menu.................................................................................. 45

13 Diagnosis / Error Messages Menu................................................... 46

13.1 Diagnosis ........................................................................................................46

13.2 Error Messages and Error Handling ..................................................................... 46

14 Parameter Lists ................................................................................ 47

14.1 Parameter Axis: Distances...................................................................................47

14.2 Parameter Axis: Times........................................................................................ 47

14.3 Parameter Axis: Analog - optional .......................................................................48

14.1 Parameter Axis: Measuring System - optional.........................................................48

14.2 Parameter Axis: Settings .....................................................................................49

14.3 System: Setup...................................................................................................50

14.4 System: Times...................................................................................................50

15 I/O Configuration Notation Tables.................................................. 51

16 Connections...................................................................................... 53

16.1 Plug Arrangement .............................................................................................53

16.2 Pin Assignment ................................................................................................. 54

16.3 Connection Example Diagram ............................................................................56

17 Disturbances, Maintenance, Cleaning............................................. 57

17.1 Fault Clearance................................................................................................ 57

17.2 Re-start after Fault Clearance..............................................................................57

17.3 Maintenance.................................................................................................... 58

17.4 Cleaning .........................................................................................................58

18 Type Designation ............................................................................. 59

19 Accessories....................................................................................... 60

20 Index ................................................................................................ 63

Contents

- 5 -

Image Directory

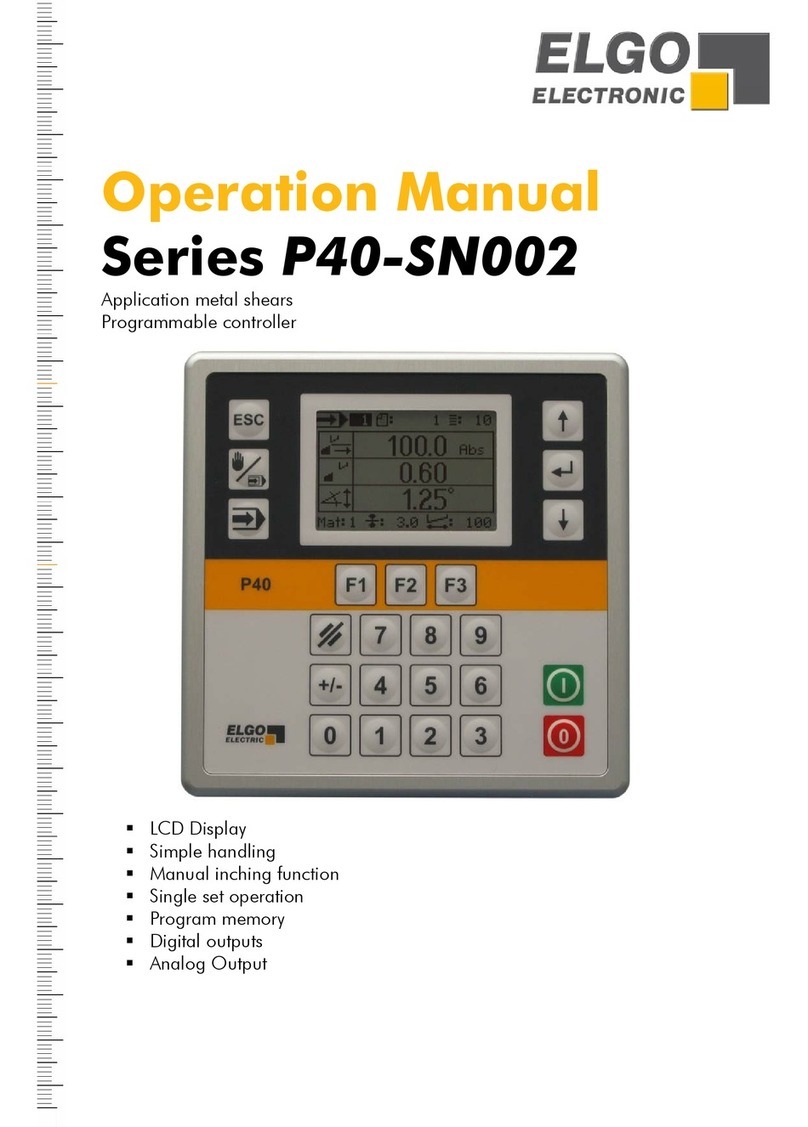

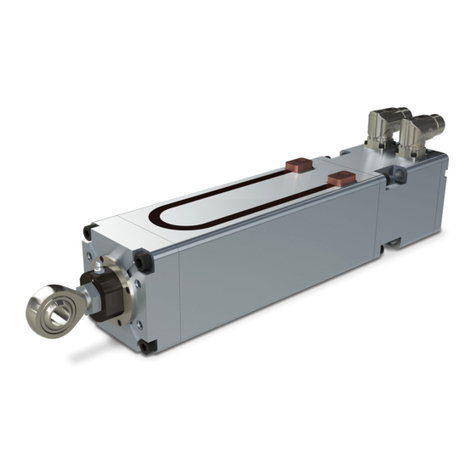

Figure 1: P40-000 controller with panel housing ......................................................................................... 9

Figure 2: Dimensions of the P40 controller ............................................................................................... 10

Figure 3: Key Functions ........................................................................................................................... 13

Figure 4: Display Functions...................................................................................................................... 14

Figure 5: Manual Operation.................................................................................................................... 15

Figure 6: Single Operation ...................................................................................................................... 16

Figure 7: Program Operation .................................................................................................................. 17

Figure 8: Correction stop with 2 speeds .................................................................................................... 21

Figure 9: Correction stop with 3 speeds .................................................................................................... 22

Figure 10: Assigning an analog output to an axis ...................................................................................... 33

Figure 11: Assigning an analog input to an axis ........................................................................................ 35

Figure 12: Analog Input Calibration ......................................................................................................... 35

Figure 13: Input assignment .................................................................................................................... 43

Figure 14: Output assignment ................................................................................................................. 44

Figure 15: Plug arrangement ................................................................................................................... 53

Figure 16: Connection example diagram.................................................................................................. 56

Table Directory

Table 1: Error Messages and Error Handling............................................................................................. 46

Table 2: Axis parameter list: Distances...................................................................................................... 47

Table 3: Axis parameter list: Times ........................................................................................................... 47

Table 4: List of analog parameters ........................................................................................................... 48

Table 5: Calibration of analog Inputs ....................................................................................................... 48

Table 6: List of general axis parameters .................................................................................................... 49

Table 7: List of system parameters: setup .................................................................................................. 50

Table 8: List of system parameters: times .................................................................................................. 50

Table 9: Notation table for input configurations ........................................................................................ 51

Table 10: Notation table for output configurations .................................................................................... 52

Table 11: Measuring system connections .................................................................................................. 54

Table 12: Input connections .................................................................................................................... 54

Table 13: Output connections ................................................................................................................. 54

Table 14: Analog / PID output connections Table 15: Power supply connections..................................... 55

Table 16: Analog output / motor drive controller MCC.............................................................................. 55

Table 17: Accessories ............................................................................................................................. 60

General, Safety, Transport and Storage

- 6 -

2General, Safety, Transport and Storage

2.1 Information Operating Manual

This manual contains important information regarding the handling of the device. For your own safety and operational safety, please ob-

serve all safety warnings and instructions. Precondition for safe operation is the compliance with the specified safety and handling instruc-

tions. Moreover, the existing local accident prevention regulations and the general safety rules at the site of operation have to be observed.

Please read the operating manual carefully before starting to work with the device! It is part of the product and should be kept close to the

device and accessible for the staff at any time. The illustrations in the manual are for better demonstration of the facts. They are not neces-

sarily to scale and can slightly differ from the actual design.

2.2 Explanation of Symbols

Special notes in this manual are characterized by symbols. The notes are introduced by signal words which express the magnitude of danger.

Please follow this advice and act carefully in order to avoid accidents, damage, and injuries.

Warning notes:

DANGER!

This symbol in connection with the signal word “Danger” indicates an immediate danger for the life and health of

persons. Failure to heed these instructions can result in serious damage to health and even fatal injury.

WARNING!

This symbol in connection with the word „Warning” means a possibly impending danger for the life and health of

persons. Failure to heed these instructions can result in serious damage to health and even fatal injury.

CAUTION!

This symbol in connection with the signal word “Caution” indicates a possibly dangerous situation. Failure to heed

these instructions can lead to minor injuries or damage of property.

Special safety instructions:

DANGER!

This symbol in connection with the signal word “Danger” indicates an immediate danger for the life and health of

persons due to voltage.

Failure to heed these instructions can result in serious damage to health and even fatal injury. The operations may

only be carried out by a professional electrician.

Tips and recommendations:

NOTE!

…points out useful tips and recommendations as well as information for an efficient and trouble-free operation.

Reference marks:

Marks a reference to another chapter of this manual.

Marks a reference to another chapter of another document.

General, Safety, Transport and Storage

- 7 -

2.3 Statement of Warranties

The producer guarantees the functional capability of the process engineering and the selected parameters.

2.4 Demounting and Disposal

Unless acceptance and disposal of returned goods are agreed upon, demount the device considering the safety instructions of this manual

and dispose it with respect to the environment.

Before demounting, disconnect the power supply and secure against re-start. Then disconnect the supply lines physically and discharge

remaining energy. Remove operational supplies and other material.

Disposal:

Recycle the decomposed elements: Metal components in scrap metal, Electronic components in electronic scrap, Recycle plastic compo-

nents, dispose the remaining components according to their material consistence

CAUTION!

Wrong disposal causes environmental damages!

Electronic scrap, electronic components, lubricants and other auxiliary materials are subject to special refuse and can

only be disposed by authorized specialists!

Local authorities and waste management facilities provide information about environmentally sound disposal.

Safety

CAUTION!

Please read the operating manual carefully, before using the device! Observe the installation instructions!

Only start up the device if you have understood the operating manual.

The operating company is obliged to take appropriate safety measure.

The initial operation may only be performed by qualified and trained staff.

Selection and installation of the devices as well as their embedding into the controlling system require qualified

knowledge of the applicable laws and normative requirements on the part of the machine manufacturer.

2.5 General Causes of Risk

This chapter gives an overview of all important safety aspects to guarantee an optimal protection of employees and a safe and trouble-free

operation. Non-observance of the instructions mentioned in this operating manual can result in hazardous situations.

2.6 Personal Protective Equipment

Employees have to wear protective clothing during the installation of the device to minimize danger of health.

Therefore: Change into protective clothing before performing the works and wear them throughout the process.

Additionally observe the labels regarding protective clothing in the operating area.

Protective clothing:

PROTECTIVE CLOTHING

… is close-fitting working clothing with light tear strength, tight sleeves and without distant parts. It serves preliminari-

ly for protection against being gripped by flexible machine parts.

Do not wear rings, necklaces or other jewelry.

PROTECTIVE GLOVES

…for protecting the hands against abrasion, wear and other injury of the skin.

PROTECTIVE HELMET

…for protection against injuries of the head.

General, Safety, Transport and Storage

- 8 -

2.7 Conventional Use

The product described in this manual was developed to execute safety-related functions as a part of an entire assembly or machine.

The ELGO position controller P40-000 only serves for positioning applications.

CAUTION!

Danger through non-conventional use!

Non-intended use and non-observance of this operating manual can lead to dangerous situations.

Therefore:

Only use the device as described

Strictly follow the instructions of this manual

Avoid in particular:

Remodeling, refitting or changing of the construction or single components with the intention to alter the

functionality or scope of the device.

Claims resulting from damages due to non-conventional use are not possible.

Only the operator is liable for damages caused by non-conventional use.

2.8 Safety Instructions for Transport, Unpacking and Loading

CAUTION!

Transport the package (box, palette etc.) professionally. Do not throw, hit or fold it.

2.9 Handling of Packaging Material

Notes for proper disposal: 2.4

2.10 Inspection of Transport

Check the delivery immediately after the receipt for completeness and transport damage.

In case of externally recognizable transport damages:

Do not accept the delivery or only accept under reserve.

Note the extent of damages on the transportation documents or delivery note.

File complaint immediately.

NOTE!

Claim any damage immediately after recognizing it.

The claims for damage must be filed in the lawful reclaim periods.

2.11 Storage

Store the device only under the following conditions:

Do not store outside

Keep dry and dust-free

Do not expose to aggressive media

Protect from direct sun light

Avoid mechanical shocks

Storage temperature (4) needs to be observed

Relative humidity (4) must not be exceeded

Inspect packages regularly if stored for an extensive period of time (>3 months)

Product Features

- 9 -

3Product Features

The position controller of the P40 series is used for simple positioning applications, e. g. with wood or sheet

metal processing machines. The main advantage of this controller is the simple, easy and fast entry of required

positions and quantities. The actual value, target value and quantity are displayed by a well legible LCD display

in the control panel. After entering a target position value and a quantity, the positioning process can be started.

The P40 has an internal program memory for a maximum of 1,000 blocks. For the positioning procedure, three

different versions of output signals are available:

1. Switch-off positioning with up to 3 speeds via digital outputs.

The assignment and logic (active HIGH/LOW) can be parametrized.

2. Optionally (18) via unregulated 12 bit analog output (±10 V).

3. Optionally (18) via regulated 12 bit PID analog output (±10 V).

The P40 controller is with 24 VDC (+10 / −20 %).

For an alternative supply with AC-voltage, an external power pack is available (19)

3.1 Essential P40 Features

Available as Single or Dual Axis-Controller

Analog output or digital outputs for 1 - 3 speed operation

16 free programmable digital in- & outputs

(8 instead of 16 digital I/Os optionally, see 18)

Program memory with up to 1000 program blocks

Figure 1: P40-000 controller with panel housing

3.2 Operating Modes

The P40 consists of three general operation modes:

Manual: Inching operation moves the individual axes manually by operating the keypad.

Single: A whole set can be processed.

Program: In the program mode, data sets can be strung together or programmed.

This program blocks are then processed sequentially. The program consists

of several different data sets.

Technical Data

- 10 -

4Technical Data

4.1 Identification

The type label serves for the identification of the unit. It is located on the housing of the sensor and gives the

exact type designation (18) with the corresponding part number. Furthermore, the type label contains a

unique, traceable device number. When corresponding with ELGO please always indicate this data.

4.2 Dimensions

Figure 2: Dimensions of the P40 controller

144

144

0123

+/- 4 5 6

789

F1 F2 F3

0

I

144

33

136

136

ESC

37

3

Technical Data

- 11 -

4.3 Technical Data Controller

Technical Data P40-000 (standard version)

Mechanical Data

Housing

panel housing

Housing material

front plate: aluminium

housing: galvanized steel sheet

Front plate dimensions

W x H = 144 x 144 mm

Panel cutout

W x H = 138 x 138 mm

Keyboard

membrane keyboard

Installation depth

37 mm (without connectors)

75 mm (with connectors)

Electrical Data

Display

LCD dot matrix 120 x 80 pixels with white background lighting

Hardware

32 bit microcontroller with 1 MByte Flash and 56 KByte RAM

Program memory

up to 1.000 blocks (more on request)

System accuracy

± 1 increment

Power supply voltage

24 VDC +10 / -20 %

Current consumption

24 VDC: max. 150 mA (unloaded);

permitted tot. current incl. self-consumption: 1 A

Encoder supply voltage

24 VDC or 5 VDC (order designation 18)

Encoder load

max. 130 mA

Input signals (encoder)

HTL, TTL, analog (order designation 18)

Incremental input channels

A, B, Z resp. A, A', B, B', Z, Z'

External inputs

16 x digital PNP inputs with free programmable

assignment and switching logic (active HIGH/LOW)

Input current / pin

max. 10 mA

Pulse time for inputs

min. 300 ms

Input frequency

max. 100 kHz (higher on request)

Analog inputs (option)

1 … 2 analog inputs (12 bit) at 3.3 V sensor supply (18)

Output signals

16 digital PNP outputs with freely programmable

assignment and logic (active HIGH / LOW)

Output current

max. 150 mA per output / 500 mA total current across all outputs; the

outputs are durable short circuit proof (no multiple short circuits)

Freewheel clutch / outputs

for inductive loads integrated (clamping voltage at the output max. −45 V)

Analog outputs (option)

optional: ± 10 V PID or ± 10 V unregulated (each 12 bit) (18)

Interfaces (option)

RS232 (18)

Connections

industry standard plug-in terminals (3.81 mm grid, lockable)

and additional RJ45 sockets (depending on version)

Power down memory

E²Prom (service life: 1.000.000 switching on/off cycles or 40 years)

Further options

8 = 8 instead of 16 digital inputs and outputs

C = screw terminals instead of plug-in terminals

Environmental Conditions

Operating temperature

-20 … +50° C

Storage temperature

0 … +45° C

Humidity

max. 80 %, non-condensing

Protection class (front)

IP43 (installed state)

Protection class (rear)

IP00

Installation and First Start-Up

- 12 -

5Installation and First Start-Up

CAUTION

Please read the operating manual carefully before using the device! Strictly observe the Installation instructions!

In case of damage caused by failure to observe this operating manual, the warranty expires.

ELGO is not liable for any secondary damage and for damage to persons, property or assets.

The operator is obliged to take appropriate safety measures.

The first start-up may only be performed by qualified staff that has been trained and authorized by the operator.

5.1 Operating Area

WARNING!

Do not use the device in explosive or corrosive environments!

The device must not be installed close to sources of strong inductive or capacitive interference or strong electrostatic

fields!

CAUTION!

The electrical connections must be made by suitably qualified personnel in accordance with local regulations.

The device may be designed for switchboard mounting. During work on the switchboard, all components must be de-

energized if there is a danger of touching the energized parts!

(protection against contacts)

Wiring works may only be performed in the de-energized state!

Thin cable strands have to be equipped with end sleeves!

Before switching on the device, connections and plug connectors have to be checked!

The device must be mounted in a way that it is protected against harmful environmental influences such as splashing

water, solvents, vibration, shock and severe pollution and the operating temperature must not be exceeded.

5.2 Mounting / Installing

For the installation of the device, a panel section must be cut into the respective control panel. The cutout di-

mensions must correspond to the measurements defined in the technical data (0).

The device is fastened into the panel cutout by using two studs with swiveling flaps which are already attached to

the housing. For installation, only a screwdriver is necessary.

5.3 Activation of the Device

After connecting the power supply voltage, the device is switched on and ready for operation.

Design und Function

- 13 -

6Design und Function

6.1 Key Functions

Figure 3: Key Functions

Switchover between “Manual” and “Single” mode

Operation mode “Program” (only if program mode is activated)

To enter the parameter level (press for 3 seconds) and

to exit the parameter level or a submenu (press shortly)

Select or confirm (ENTER button)

Cursor navigation „down“

Cursor navigation „up“

...

Functional keys (depending on menu level and operating mode)

Delete or reset an entry

Sign switchover

...

Enter a target position or a parameter value

Start positioning

Stop positioning

0 1 2 3

+/- 4 5 6

7 8 9

F1 F2 F3

ESC

Escape

Operating mode

Input field

Menu navigation

Functional keys

START

STOP

0

ESC

F1

F3

+/-

0

9

0

Design und Function

- 14 -

6.2 Display Functions

Figure 4: Display Functions

NOTE! The display elements can vary depending on operating mode and configuration.

Program number

Symbol operating mode

Absolute- / incremental

position

Browse through data blocks

Program block

number

Target position

Piece counter

Program counter

Actual position

Options

Handling & Operating Modes

- 15 -

7Handling & Operating Modes

7.1 Operating Modes

Depending on the parameter setting, the screen display and assignment of the function keys can vary.

7.1.1 Manual Operation

In this mode the axes can be moved manually (manual inching). To do this, select the corresponding axis with

the cursor and change the position by using the functional keys F1 / F3.

Figure 5: Manual Operation

Displays the actual position of the respective axis

Moves the axis in negative direction

Moves the axis in positive direction

Referencing of the respective axis: Use the cursor to select the

desired axis and press the F2 button longer than 2 seconds.

Note!

The parameter axis times (9.2) “manual change”can be used to define a time. In

case of manual operation, there is a change from creep speed to fast speed after the expi-

ration of the time adjusted here.

See also table in section 14.2 parameter axis times “manual change”

Referencing:

see chapters: 7.2 “Referencing an Axis”, 9.3 “Parameter Axis: “

and table in section 14.1 “Parameter Axis: Distances”

342

1

1

2

F1

3

F3

4

F2

Handling & Operating Modes

- 16 -

7.1.2 Single Operation

This mode allows moving all active axes simultaneously after entering the desired target values and confirmation

by the START key.

Figure 6: Single Operation

Displays the actual position of the respective axis

Incremental positioning:

target value is an absolute position

target value is an incremental position +

target value is an incremental position −

Displays the target value of the respective axis

Input field for quantity

Referencing of the respective axis: Use the cursor to select the

desired axis and press the F2 button longer than 2 seconds.

NOTE!

Incremental Positioning:

Select corresponding axis with the cursor and change positioning mode by pressing the E

ENTER nter-Key (see chapter 9.3 “Parameter Axis: “)

Referencing:

see chapters: 7.2 “Referencing an Axis”, 9.3 “Parameter Axis: “

and table in section 14.1 “Parameter Axis: Distances”

3

4

2

1

1

2

F1

3

F3

4

F2

Handling & Operating Modes

- 17 -

7.1.3 Program Operation

When using the program mode, the user has the possibility to summarize several program blocks into one pro-

gram. Depending on the configuration, different program sequences are possible.

Figure 7: Program Operation

Enter and confirm a program number

Incremental positioning:

target value is an absolute position

target value is an incremental position +

target value is an incremental position −

Shows the actual program block and the program end (example: 3E = 3 last program block)

Displays the actual position of the respective axis

Displays the target value of the respective axis

Input field for quantity

Previous program block

Next program block

7.1.3.1 Create a Program

Press the program key to activate the program mode. Before a program can be created, a program number

must be assigned and confirmed with the ENTER key. The corresponding data sets (blocks) then will be assigned

to the defined program number. In order to navigate through the various program blocks, the keys F1 and F3

are used. It is also possible to select a program block directly, by entering the block number in the correspond-

ing input field and confirming with ENTER.

3

4

6

21

7

5

1

2

3

4

5

6

F1

7

F2

Handling & Operating Modes

- 18 -

After entering the required data sets, the program end has to be marked. For this, the F2 key must be pressed

during the cursor is in the input field for the block number. The defined program end will then be marked with

the letter “E”behind the block number.

7.1.3.2 Processing a Program

The program mode can be selected directly by using the PROGRAM key. First, choose a program by entering a

program number and confirm it by using the ENTER key. The keys F1 and F3 can be used to scroll through all

the program blocks. The positioning will start automatically when the START key is pressed. Now, all data sets

will be processed in dependency of parameter settings until the end marker of the program is reached.

The positioning process can be interrupted by pressing the STOP key at any time. In this case, the program re-

mains in the current block. To continue the program, press the START key again.

NOTE!

The end of program is necessarily needed for the automatic run.

In case of missing end of program a warning is displayed.

Incremental Positioning:

Select corresponding axis with the cursor and change positioning mode by pressing the

ENTER key.

9.3 “Parameter Axis: “

7.2 Referencing an Axis

The axes can be referenced in the manual mode and single mode. Depending on the setting in

parameter axis X-/Y-axis settings reference mode the following applies:

Mode 1, 3, 5, 7: The F2 key must be pressed for minimum 2 seconds.

With a dual-axis controller, the reference symbol of the corresponding axis has to be displayed

- in the manual mode the corresponding axis needs to be selected,

- in the single mode the target value of the corresponding axis needs to be selected.

Mode 2, 4, 6, 8: for referencing, an external input must be activated

Mode 1 or 2: the value deposited in parameter axis X-/Y-axis distances referenceval.

will be taken as the current actual value for the respective axis

Mode 3 or 4: the value entered for target position will be taken as current actual value

Mode 5 or 6: referencing to the positive switch end-position with index pulse (see next section)

Mode 7 or 8: referencing to the negative switch end-position with index pulse (see next section)

7.2.1 Functionality of Referencing

The controller moves the axis that needs to be referenced in dependence of the parameter setting in parameter

axis X-/Y-axis settings reference mode. The output “reference drive run” is set. If the corresponding

input (switch end-position positive or negative) is activated, the controller will stop. After a dwell time the control-

ler moves in the opposite direction.

As soon the appropriate input (switch end-position) is disabled, the index pulse will be released. With the next

zero pulse, the controller stops and the reference value stored in parameter axis X-/Y-axis distances

referenceval. will be transferred into the actual value window.

Menu Structure and Parameter Levels

- 19 -

8Menu Structure and Parameter Levels

Operating modes

manual mode

single mode

program mode

NOTE!

The service mode with the parameter levels can be accessed by keeping the ESC key

pressed for minimum 3 seconds. Most of the parameters - if not marked otherwise -

can only be changed after entering the password resp. PIN code.

PIN CODE: 250565

Service (press ESC for 3 seconds)

parameter axis

system

password

diagnosis

contrast

X-axis

distances

times

analog (optionally)

measuring system (optionally)

settings

Y-axis

distances

times

analog (optionally)

measuring system (optionally)

settings

setup

system-times

I/O-configuration

input function

input logic

output function

output logic

default parameter

inputs

outputs

keyboard

version

Axis Menu

- 20 -

9Axis Menu

9.1 Parameter Axis: Distances

This menu is used to set relevant distances for the X- and Y-axis separately.

A detailed description of these parameters can be found on the next pages...

Distances.

Access to parameters concerning distances e.g. speeds etc.

Times

Access to parameters concerning times e.g. position reached, zero speed monitoring, rotary encoder etc.

Settings

Access to the general axis parameters

Slow forward

Creep forward

Correction stop forward

Slow backward

Creep backward

Correction stop backward

Tolerance window

Manipulation

Spindle compensation

Forced loop

Reference value

Retract length

End position Min

End position Max

Factor

Displacement

Tool correction

Fix position

Sägebla

Table of contents

Other ELGO Electronic Controllers manuals

Popular Controllers manuals by other brands

Burger & Brown

Burger & Brown SMARTFLOW WDT2-S3-P3 operating instructions

NovaStar

NovaStar NovaPro UHD user manual

Timeguard

Timeguard PDFM1500N Installation & operating instructions

Hobby-Wing

Hobby-Wing XERUN XR10 STOCK SPEC 1S user manual

IMG STAGE LINE

IMG STAGE LINE 25.5780 instruction manual

Clear One

Clear One Conference Controller quick start guide