Trouble(s) Solution(s)Possible Causes

1. No power was supplied to the ESC.

2. The ESC switch was damaged.

The throttle cable was reversely plugged into

the TH channel or plugged into wrong channel on the receiver.

1. The (ESC-to-motor) wiring order was incorrect.

2. Your chassis is different from popular chassis.

1. The receiver was influenced by some foreign interference.

2. The ESC entered the LVC protection.

3. The ESC entered the thermal shutdown protection.

1. The throttle neutral position on your transmitter

was actually in the braking zone.

2.Setthe“RunningMode”improperly.3. The ESC was damaged.

1. Some soldering between the motor and the ESC

was not good.

2. The ESC was damaged (some MOSFETS were burnt). CheckifallESC&batteryconnectorshavebeenwellsolderedorfirmly connected.

Plug the throttle cable into the throttle channel (CH2) by referring to

relevant mark shown on your receiver.

1. Swap any two (ESC-to-motor) wires if you are using a sensorless motor.

2. There is nothing you can do if you are using a sensored motor and your

chassis is different from popular chassis.

1. Check all devices and try to find out all possible causes, and check the

transmitter’s battery voltage.

2. The RED LED keeps flashing indicating the LVC protection is activated,

please replace your pack.

3. The GREEN LED keeps flashing indicating the thermal protection is

activated, please let your ESC cool down before using it again.

1. Recalibrate the throttle neutral position. No LED on the ESC will come

on when the throttle trigger is at the neutral position.

2.Setthe“RunningMode”to“Fwd/RevwithBrk“.3. Contact the distributor for repair or other customer service.

1. Check all soldering points, please re-solder if necessary.

2. Contact the distributor for repair or other customer service.

1. Change another pack with great discharging capability.

2. Change a low-speed motor, or increase the FDR.

3. Set the punch/start mode to a low level.

1. Check if the sensor cable is loose or poor contact issue exists.

2. Hall sensor inside the motor is damaged.

The ESC was unable to start the motor, but the

RED LED on the ESC turned on solid.

The vehicle ran backward when you pulled the

throttle trigger towards you.

The ESC was unable to start the status LED, the

motor, and the cooling fan after it was powered on.

The motor stuttered but couldn’t start.

The vehicle could run forward (and brake),

but could not reverse.

The motor got stuck or stopped when increasing

the throttle during the starting-up process.

TheRED&GREENLEDSontheESCflashedrapidlyat the same time when the throttle trigger was at

the neutral position.

The motor suddenly stopped or significantly

reduced the output in operation.

1. Poor discharging capability of the pack.

2. The RPM of the motor was too high, or the FDR

was too low.

3. Set the "Punch/Start Mode" to a high level.

(When pairing with a sensored motor) the ESC

automatically switched to sensorless mode

when it detected incorrect signal from Hall sensor.

1. Check if the wiring order is A-A, B-B, and C-C.

2. Contact the distributor for repair or other customer service.

The motor stuttered but couldn’t start. 1. The (ESC-to-motor) wiring order was incorrect.

2. The ESC was damaged.

08

Trouble Shooting

09

Guidance

Option 2: Auto

In Auto mode, the ESC adjusts the Boost Timing dynamically as per the throttle amount. Only at full throttle, the actual Boost Timing is the value you had previously set.

4C. Boost Start RPM

This item defines the RPM at which Boost Timing is activated. For example, when the Boost Start RPM is set to 5000, the ESC will activate the corresponding Boost Timing when the

RPM goes above 5000. The specific value is determined by the Boost Timing and the Boost End RPM you had previously set.

4D. Boost End RPM

This item defines the RPM at which Boost Timing (you specifically set) is applied. For example, when Boost Timing is set to 10 degrees and the Boost End RPM to 15000, the ESC will

activate the Boost Timing of 10 degrees when the RPM goes above 15000. The ESC will adjust the Boost Timing accordingly as per the actual RPM when the RPM goes below 15000.

5A. Turbo Timing

This item is adjustable from 0 degree to 64 degrees, the corresponding turbo timing (you set) will initiate at full throttle. It’s usually activated on long straightaway and makes the

motor unleash its maximum potential.

5B. Turbo Delay

When“TURBODELAY”issetto“INSTANT”,theTurboTimingwillbeactivatedrightafterthethrottletriggerismovedtothefullthrottleposition.Whenothervalue(s)isapplied,

you will need to hold the throttle trigger at the full throttle position (as you set) till the Turbo Timing initiates.

5C. Turbo Increase Rate

Thisitemisusedtodefinethe“speed”atwhichTurboTimingisreleasedwhenthetriggerconditionismet.Forexample,“6degs/0.1sec”referstotheTurboTimingof6degreesthatwillbereleasedin0.1second.Boththeaccelerationandheatishigherwhenthe“Turboincreaserate”isofalargervalue.5D. Turbo Decrease Rate

After the Turbo Timing is activated and the trigger condition turns to not be met (i.e. vehicle slows down at the end of the straightaway and gets into a corner, full throttle turns to

partial throttle, the trigger condition for Turbo Timing turns to be not met), if you disable all the Turbo Timing in a moment, an obvious slow-down like braking will be felt and cause

thecontrolofvehicletobecomebad.IftheESCcandisabletheTurboTimingatsome“speed”,theslow-downwillbelinearandthecontrolwillbeimproved.Warning!BoostTiming&TurboTimingcaneffectivelyimprovethemotorefficiency;theyareusuallyusedincompetitions.Pleasetakesometimetoreadthismanualandthensetthesetwoitemscarefully,monitortheESC&motortemperatureswhenyouhaveatrialrunandthenadjusttheTimingandFDRaccordinglyasaggressiveTimingsandFDRmaycauseyour ESC or motor to be burnt.

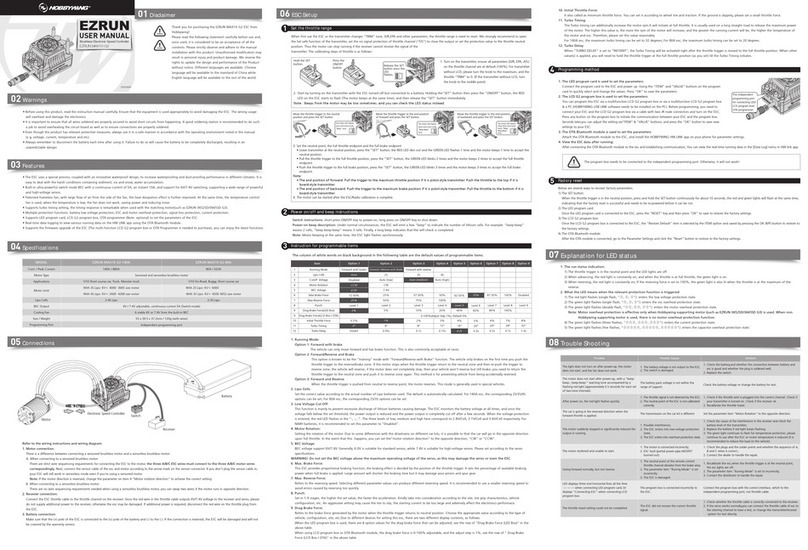

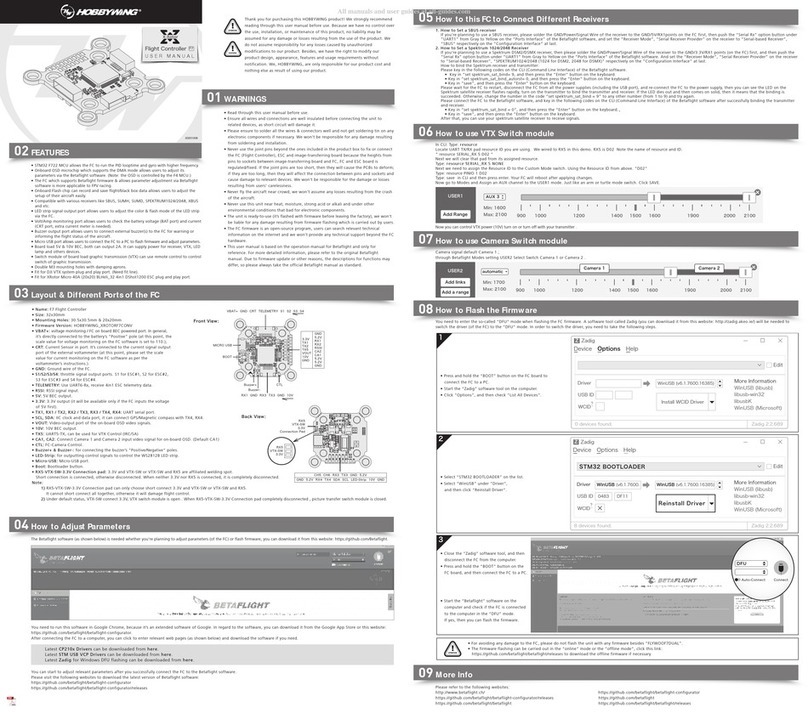

1) Program your ESC with a multifunction LCD program box

YoucanprogramthisXR10STOCKSPECESCviaamultifunctionLCDprogramboxorviaamultifunctionLCDprogrambox&aPC(HOBBYWINGUSBLINKsoftwareneedstobeinstalled on the PC). Before programming, you need to connect your ESC and the LCD program box via a cable with two JR male connectors and turn on the ESC; the boot

screenwillshowupontheLCD.PressanybuttonontheprogramboxtoinitiatethecommunicationbetweenyourESCandtheprogrambox.Secondslater,“CONNECTINGESC”willbedisplayed,andindicatesthefollowingparameters.Youcanadjustthesettingvia“ITEM”&“VALUE”buttons,andpressthe“OK”buttontosavenewsettingstoyour ESC.

2) Program your ESC with a WiFi Module

The XR10 STOCK SPEC ESC can also be programmed via a WiFi module along with smart phone devices (HOBBWYING WiFi LINK software

needs to be installed on the smart phone). Before programming, users will need to plug the programming cable on the WiFi module into the

programming port on ESC and switch on the ESC. For detailed information about ESC programming via WiFi module, please refer to the

user manual of Hobbywing’s WiFi Express.

Attention! This ESC has a separate programming port. Please don’t use the throttle control cable (also called Rx cable) on the ESC to

connect the program box; otherwise the program box won’t function.

3) Data Checking

The ESC is able to record the maximum ESC temperature, maximum motor temperature, minimum battery voltage and maximum motor speed in operation. It automatically saves

the recorded data to the designated area when you turn off the ESC after a run. You can check those data via a multifunction LCD program box whenever necessary.

UsersneedtoswitchontheESCafterconnectionbetweentheprogramboxandtheESChasbeenestablished.Pressthe“R/P”buttononany“item”pagefollowedbypressingthe“R/P”buttonagainmultipletimes.Thefollowing5itempageswillbedisplayedcircularly:Mode→ESC Temperature→Motor Temperature →Min Voltage→Max RPM.

Attention!

•Pressthe“VALUE”buttononanydata-recordingpagecangetyouintothenextpresetmode.Pleasenotethatimproperoperationwillgetyouintootherpresetmode(s).•Pressthe“ITEM”buttononanydata-recordingpagecangetyoutotheparametersettingpageofthecurrentpresetmode;pressthe“R/P”buttonifyouwanttoreturntothe data-recording page

07

Explanation for LED Status

1. During the Start-up Process

•The RED LED turns on solid indicating the ESC doesn’t detect any throttle signal or the throttle trigger is at the neutral position.

•The GREEN LED flashes rapidly indicating the neutral throttle value stored on your ESC may be different from the current value stored on the transmitter. When this happens,

re-calibrate the throttle range.

2. In Operation

•The RED LED turns on solid and the GREEN LED dies out when the throttle trigger is in the throttle neutral zone. The RED LED will blink slowly (to confirm with ROAR’s Sportman

(or Zero Timing) rules) if the total value of Boost Timing and Turbo timing is 0.

•The RED LED dies out and the GREEN LED blinks when your vehicle runs forward. The GREEN LED turns solid when pulling the throttle trigger to the full (100%) throttle endpoint.

•The RED LED dies out and the GREEN LED blinks when you brake our vehicle. The GREEN LED turns solid when pushing the throttle trigger to the full brake endpoint and setting the

“maximumbrakeforce”to100%.•The RED LED dies out, the GREEN LED blinks when you reverse your vehicle. The GREEN LED turns solid when pushing the throttle trigger to the full brake endpoint and setting the

“reverseforce”to100%.3. When Some Protection is Activated

•TheREDLEDflashesashort,singleflashandrepeats“☆, ☆, ☆”indicatingthelowvoltagecutoffprotectionisactivated.•The GREENLEDflashesashort,singleflashandrepeats“☆, ☆, ☆”indicatingtheESCthermalprotectionisactivated.•TheGREENLEDflashesashort,doubleflashandrepeats“☆☆, ☆☆, ☆☆”indicatingthemotorthermalprotectionisactivated.•The RED&GREENLEDSflashashort,singleflashandrepeats“☆, ☆, ☆”atthesametimeindicatingthedrivemodehasbeenautomaticallyswitchedtosensorlessmodefromsenored mode because of abnormal sensor signal when pairing the ESC with a sensored motor.

T Count

10.5T

13.5T

17.5T

21.5T

25.5T

KV

3800KV

3000KV

2300KV

1900KV

1500KV

FDR (1/10th Touring Car)*

4.5-5.5

4.0-5.0

3.0-4.5

FDR (1/10th Buggy)*

6.5-8.0

6.5-7.5

5.5-7.0

Applications

1/10th Drift, Stock class racing.

1/10th Stock class racing (popular racing in Europe and Asia).

1/10thStockclassracing(popularracinginUSA).1/10th rock crawler and Stock class racing.

1/10th rock crawler and Stock class racing.

Note 8: AlltheaboveFDRsaretheFDRsrecommendedfor1/10thscalevehiclesusinga2SLiPobattery,zero-timingESCfirmwarewithBoostTiming&TurboTimingarenotactivated.Ingeneral,theFDRshouldbeincreasedaccordinglywhentheBoosttiming&TurboTimingareactivated.

RPM (Motor Speed)

Actual Boost Timing

<10000

0 Degree

10001-11000

1 Degree

11001-12000

2 Degrees

12001-13000

3 Degrees

13001-14000

4 Degrees

14001-15000

5 Degrees

>15000

5 Degrees

Note: this section is applicable to the situation when the motor limit is regulated and the ESC timing is not regulated.

1) You can get a higher top end speed via the following methods:

•Decrease the FDR (by using a bigger pinion within the reasonable range)

•Increase the Timing. If you only want to increase the top end speed on straightaway, you can increase the Turbo timing. If you want to increase the speed at different sections of

the entire track, you can increase the Boost timing.

•Change another battery with higher discharge capability.

2) You can get a higher acceleration via the following methods:

•Increase the FDR (by using a smaller pinion within the reasonable range).

•Increase the throttle acceleration.

•Increase the Boost Timing.

•DecreasetheBoostStartRPM&theBoostEndRPM.•Decrease the Turbo Delay.

•Increase the Turbo Increase Rate.

3) You can get a lower motor temperature and a longer run time via the following methods:

•Increase the FDR (by using a smaller pinion within the reasonable range)

•Decrease the Timing

•IncreasetheBoostStartRPM&theBoostEndRPM.•Increase the Turbo Delay

•Decrease the Turbo Decrease Rate.

Note: Please adjust the FDR and other parameters slightly (feel and test the ESC and motor temperatures after every adjustment.), keep trying different settings until you get the

“satisfactory”speedandtheacceptablemotor/ESCtemperature.Youcanalsosavethe“setting”forfuturereferenceoruse.

Basic rules on power system adjustment for OPEN STOCK class of touring car racing

2

Recommended Power Configuration

1

ESC Programming

5

•Restore the default values with a multifunction LCD program box

AfterconnectingtheprogramboxtotheESC,continuetopressthe“ITEM”buttonontheprogramboxuntilyouseethe“RESTOREDEFAULT”item,andpress“OK”tofactoryreset your ESC.

•Restore the default values with a WiFi module (& WiFi Link)

AfterconnectingtheWiFimoduletotheESC,opentheHOBBYWINGWiFiLINKsoftwareonyoursmartphone,select“Parameters”followedby“FactoryReset”toresettheESC.

Factory Reset

6

What is COAST?

Whenavehiclehasalargerfinaldriveratio,thetendencyofhavinga“drag”feelishigher.The“COAST”technologyistoallowthecartoroll(coast)evenwhenthefinaldriveratiois high. The Coast function brings better and smoother control feeling to racers. Some drivers will refer to this to the traditional brushed motors.

Note 5: The“Coast”willbevoid(evenifyousetittoanyvaluebesides0)iftheabove“dragbrake”isnot“0%”.2E. PWM Drive Frequency

The acceleration will be more aggressive at the initial stage when the drive frequency is low; a higher drive frequency is smoother but this will create more heat to the ESC.

2F. Softening Value

It allows users to fine-tune the bottom end, change the driving feel, and maximize the driving efficiency at different track conditions. The higher the "Softening Value ", the milder

the bottom end. In some class, drivers often feel the power of the bottom end is too aggressive. Little throttle input usually brings too much power to the car and make it hard to

control at the corners, so HOBBYWING creates this softening function to solve the issue.

Note 6: You can increase the motor mechanical timing accordingly after you set the softening value. Every time you increase the softening value by 5 degrees, you can increase the

mechanical timing by 1 degree. For example, if you set the softening value to 20 degrees, then you can increase the mechanical timing by 4 degrees. Please note that you will never

increase the mechanical timing by over 5 degrees.

2G. Softening Range

It'stherangetowhich"SofteningValue”startsandends.Forexample,0%to30%willbegeneratedwhentheuserpre-programsthe"SofteningRange"atavalueof30%.3A. Drag Brake

It is the braking power produced when releasing from full speed to neutral position. This is to simulate the slight braking effect of a neutral brushed motor while coasting. It’s not

recommended for buggy and monster truck.

(Attention! Drag brake will consume more power and heat will be increased, apply it cautiously.)

3B. Max. Brake Force

This ESC provides proportional braking function; the braking effect is decided by the position of the throttle trigger. It sets the percentage of available braking power when full brake

is applied. Large amount will shorten the braking time but it may damage your pinion and spur.

3C. Initial Brake Force

Itisalsoknownas“minimumbrakeforce”.Itistheforcewhenpushingthrottletriggerfromneutralzonetotheinitialbrakeposition.Togetasmootherbrakingeffect,thedefaultisequal to the drag brake.

3D. Brake Rate Control

It’s adjustable from 1 to 20 (step: 1), the lower the brake rate, the more limit on the brake response. A suitable rate can aid the driver to brake his vehicle correctly. Generally, you can

set it to a high value to have a quick brake response.

3E. Brake Curve

This item is used for regulating the relation between the throttle range in brake zone and the brake force. The default setting is linear. You can change it to non-linear via a LCD

programboxandaPC(HOBBYWINGUSBLINKsoftwareneedstobeinstalledonthePC.)fordifferentbrakingeffect.3F. Brake Frequency

The brake force will be larger if the frequency is low; you will get a smoother brake force when the value is higher.

3G. Brake Control

Option 1: Linear

Hobbywing has recommended using this mode under all circumstances. The braking effect is a bit weaker in this mode than in Traditional brake mode, but it’s easy to control and

brings great control feel.

Option 2: Traditional

ThisbrakemodeisthesameastotheXERUNseriesofESCs,thebrakeforceisstronger.Option 3: Hybrid

The ESC switches the brake mode between Linear and Traditional as per the vehicle speed to prevent the slide (between tires and track) from affecting the braking effect.

Note 7: Please select the right mode for your vehicle as per the track condition, motor performance, and etc.

4A. Boost Timing

It is effective within the whole throttle range; it directly affects the car speed on straightaway and winding course. The ESC adjusts the timing dynamically as per the RPM

(when“BoostTimingActivation”setto“RPM”)orthrottleamount(when“BoostTimingActivation”setto“Auto”)intheoperation.TheBoostTimingisnotconstantbutvariable.4B. Boost Timing Activation

Option 1: RPM

In RPM mode, the ESC adjusts the Boost Timing dynamically as per the motor speed (RPM). The actual Boost Timing is 0 when the RPM is lower than the Boost Start RPM. The Boost

Timing changes as per the RPM when the RPM change is between the Boost Start RPM and the Boost End RPM. For example, if the Boost Timing is set to 5 degrees and the Boost

Start RPM is 10000, the Boost End RPM is 15000. The Boost Timing corresponds to different RPM is shown below. When the RPM is higher than the Boost End RPM, the actual Boost

Timing is the value you had previously set.

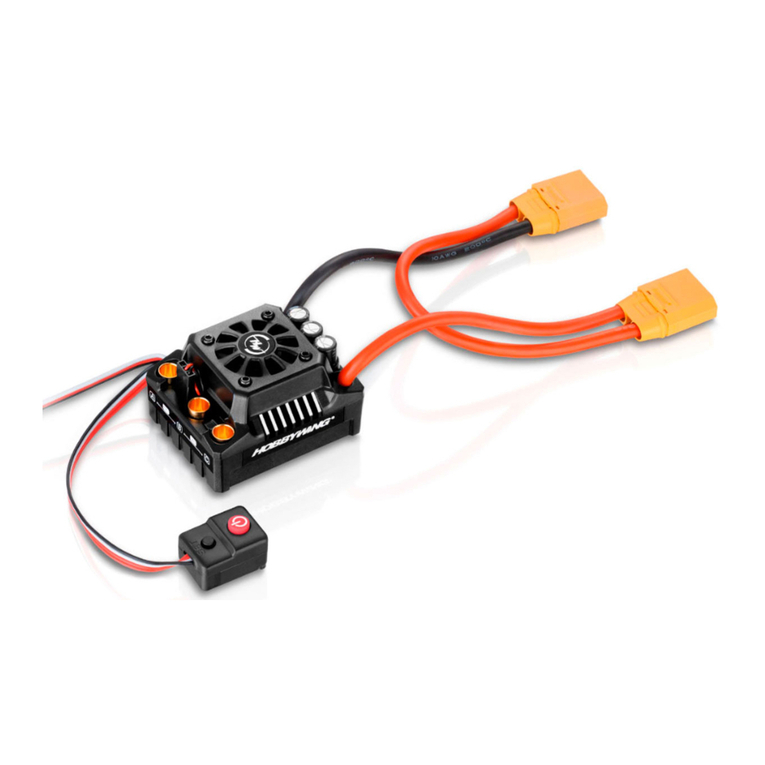

External Programming

Port for Connecting

Program Card or WIFI

module.

1A

1B

1C

1D

1E

1F

1G

1H

2A

2B

2C

2D

2E

2F

2G

3A

3B

3C

3D

3E

3F

3G

4A

4B

4C

4D

5A

5B

5C

5D

For/Brake

25%

Auto

105℃/221℉105℃/221℉6.0V

Enabled

Full

Sensored

30

Linear

6%

0%

2K

0 Deg

0%

0%

100%

=Drag Brake

20

Linear

1K

Traditional

0 Deg

RPM

6000

22500

0 Deg

0.3

12

24

For/Brake

25%

Auto

105℃/221℉105℃/221℉6.0V

Enabled

Full

Sensored

30

Linear

6%

0%

4K

0 Deg

0%

5%

87.5%

=Drag Brake

20

Linear

1K

Linear

30 Degs

Auto

4000

12000

25 Degs

0.2

24

18

For/Brake

25%

Auto

105℃/221℉105℃/221℉6.0V

Enabled

Full

Sensored

30

Linear

6%

0%

4K

0 Deg

0%

5%

87.5%

=Drag Brake

20

Linear

1K

Linear

30 Degs

Auto

2000

8000

35 Degs

0.1

24

18

For/Rev

100%

Auto

105℃/221℉105℃/221℉6.0V

Disabled

Full

Sensored

20

Linear

6%

0%

4K

0 Deg

0%

100%

100%

=Drag Brake

20

Linear

1K

Traditional

0 Deg

RPM

6000

22500

0 Deg

0.3

12

24

For/Brake

25%

Auto

105℃/221℉105℃/221℉6.0V

Enabled

Full

Sensored

20

Linear

6%

0%

4K

0 Deg

0%

0%

75%

=Drag Brake

10

Linear

1K

Traditional

0 Deg

RPM

6000

22500

0 Deg

0.3

12

24

Running Mode

Max. Reverse Force

Cutoff Voltage

ESC Thermal Protection

Motor Thermal Protection

BEC Voltage

Remote Off

Sensor Mode

Throttle Rate Control

Throttle Curve

Neutral Range

Coast

PWM Drive Frequency

Softening Value

Softening Range

Drag Brake

Max. Brake Force

Initial Brake

Brake Rate Control

Brake Curve

Brake Frequency

Brake Control

Boost Timing

Boost Timing Activation

Boost Start RPM

Boost End RPM

Turbo Timing

Turbo Delay (sec)

Turbo Increase Rate (deg/0.1sec)

Turbo Decrease Rate (deg/0.1sec)

Section Item Programmable Item Zero Timing Open-BL 13.5T Open-BL 17.5T Crawler Drift

General SettingThrottle ControlBrake ControlTiming

Inordertomakeonefirmwareapplicabletoalldifferentracingconditions,therearefive“easy-to-select”presetmodes(asshownbelow).Usersareabletochangethesettingsofthemodes provided (and rename those modes) as per the control feel, track, and etc. For example, the name can be changed from "Open-BL 13.5T" to "TITC2016_STOCK 13.5T" to indicate

the race was ran with a 13.5T motor at 2016 TITC. This can be saved for future reference as well.

Mode #

1

2

3

4

5

Modes/Profiles

Zero Timing

Stock-13.5T

Stock-17.5T

Crawler

Drift

Applications

All Stock racing requiring users to use Zero timing (/blinky) program on their ESCs.

13.5T Open Stock class of 1/10th touring car racing

17.5T Open Stock class of 1/10th touring car racing

1/10th rock crawler

1/10th drift car

Preset Modes for Different Racing:Default Settings of Different Preset Modes:

Preset Modes

4