Elite access systems SL-3000-UL Series User manual

V 1102

Click on the desired topic in the “Bookmarks” column or “Table of Contents” to select page.

1

© 1988 – 2002 BY ELITE ACCESS SYSTEMS, INC.

All rights reserved. No part of this manual may be

reproduced in any means: graphic, electronic or

mechanical, including photocopying without the

expressed written permission of the publisher.

Materials, components and specifications are sub-

ject to change without notice.

Do not touch

me unless you are

an authorized

service technician!

UL Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Role of Specifiers and Designers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Role of Dealers, Installers and Trained Gate System Technicians . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Role of End Users / Home Owners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Horizontal Slide Gate Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Gate Post Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Warning Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Warnings and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

ELITE Recommended Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Type of Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

How to Connect the Chain for Different Types of Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Concrete Pad and Gate Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Gate and Operator Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Choosing Movement Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

How to Connect Power (120V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Adjusting Gate Traveling Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Adjustable Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Two-Way Adjustable Reversing Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Master and Slave with Timer On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Master and Slave with Timer Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Solenoid / Maglock J3 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Instructions for Optional Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

QCC (Quick Close Circuit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Solenoid / Maglock Connections with Omni Option Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Master and Slave with Omni Option Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

House Alarm / Proximity Switch Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Optional Plug-In Loop Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Three Push-Button System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Terminal Input Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Safety Loop System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Exit Loop System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

EMERGENCY RELEASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

How to Replace the Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Audio Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Stop Button Alarm Shut-Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Secondary Entrapment Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Secondary Entrapment Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Troubleshooting LED Information / Resetting motor / Gate will not Open /Gate will not Close . . . .34

Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

SL-3000 Parts Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

List of SL-3000 Parts and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Available Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

TABLE OF CONTENTS

11-02

In the United States, Canada and Puerto Rico,

call toll free for technical support: 1-888-ELITE-10

Release 5

UL LISTINGS AND INSTRUCTIONS

2

INSTALLATION INSTRUCTIONS REGARDING THE GATE OPERATOR

A) Install the gate operator only when:

1) The operator is appropriate for the construction and the usage

Class of the gate.

2) All openings of a horizontal slide gate are guarded or

screened from the bottom of the gate to a minimum of 4 feet

(1.2 m) above the ground to prevent a 2 1/4inch (57.15 mm)

diameter sphere from passing through the openings

anywhere in the gate, and in that portion of the adjacent

fence that the gate covers in the open position.

3) All exposed pinch points are eliminated or guarded, and

4) Guarding is supplied for exposed rollers.

B) The operator is intended for installation only on gates used for vehicles.

Pedestrians must be supplied with a separate access opening.

C) The gate must be installed in a location so that enough clearance is

supplied between the gate and adjacent structures when opening and

closing to reduce the risk of entrapment. Swinging gates shall not

open into public access areas.

D) The gate must be properly installed and work freely in both directions

prior to the installation of the gate operator.

E) Controls must be far enough from the gate so that the user is

prevented from coming in contact with the gate while operating the

controls. Controls intended to be used to reset an operator after 2

sequential activations of the entrapment protection device or devices

must be located in the line of sight of the outdoor gate or easily

accessible controls shall have a security feature to prevent unauthorized use.

F) All warning signs and placards must be installed where visible in the area of

the gate. A minimum of two placards installed. A placard is to be installed in

the area of each side of the gate and be visible to persons located on the side

of the gate on which the placard is installed.

UL LISTINGS AND INSTRUCTIONS

3

G) For a gate operator utilizing a non-contact sensor such as a photo beam:

1) See instructions on the placement of non-contact sensor for

each Type of application.

2) Care shall be exercised to reduce the risk of nuisance tripping,

such as when a vehicle trips the sensor while the gate still

moving.

3) One or more non-contact sensors shall be located where the

risk of entrapment or obstruction exists, such as the perimeter

reachable by a moving gate or barrier.

H) For a gate operator utilizing a contact sensor such as an edge sensor:

1) One or more contact sensors shall be located at the leading

edge, trailing edge and post mounted both inside and outside

of a vehicular horizontal slide gate.

2) One or more contact sensors shall be located at the bottom

edge of a vehicular vertical lift gate.

3) One or more contact sensors shall be located at the pinch point

of a vehicular vertical pivot gate.

4) A hard wired contact sensor shall be located and its wiring arranged

so that the communication between the sensor and the gate operator

is not subjected to mechanical damage.

5) A wireless contact sensor such as the one that transmits radio

frequency (RF) signals to the gate operator for entrapment

protection functions shall be located where the transmission of

the signals are not obstructed or impeded by building structures,

natural landscaping or similar obstruction. A wireless contact sensor

shall function under the intended end-use conditions.

6) One or more contact sensors shall be located on the inside and

outside leading edge of a swing gate. Additionally, if the bottom edge

of a swing gate is greater than 6 inches (152 mm) above the ground at

any point in its arc of travel, one or more contact sensors shall be

located on the bottom edge.

UL LISTINGS AND INSTRUCTIONS

4

IMPORTANT SAFETY INSTRUCTIONS

WARNING - To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the

remote control away from children.

3. Always keep people and objects away from the gate.

NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

4. Test the gate operator monthly. The gate MUST reverse on

contact with a rigid object or stop when an object activates

the non-contact sensors. After adjusting the force or the limit of

travel, retest the gate operator, Failure to adjust and retest the gate

operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving. Make

sure the power for the gate operator is off.

6. KEEP GATES PROPERLY MAINTAINED. Read the manual. Have a

qualified service person make repairs to the gate or gate hardware.

7. The entrance is for vehicles only. Pedestrians must use separate

entrance.

8. SAVE THESE INSTRUCTIONS.

UL LISTINGS AND INSTRUCTIONS

5

Gate – A moving barrier such as a swinging, sliding, raising

lowering, rolling, or like, barrier, that is a stand-alone passage

barrier or is that portion of a wall or fence system that controls entrance

and/or egress by persons or vehicles and completes the perimeter of a

defined area.

Vehicular horizontal slide-gate operator (or system) – A

vehicular gate operator (or system) that controls a gate which slides in a

horizontal direction that is intended for use for vehicular entrance or exit

to a drive, parking lot, or the like.

Residential vehicular gate operator – Class I – A

vehicular gate operator (or system) intended for use in

a home of one-to four single family dwelling, or a

garage or parking area associated therewith.

Commercial/General access vehicular gate

operator – Class II – A vehicular gate opera-

tor (or system) intended for use in a commer-

cial location or building such as a multi-family

housing unit (five or more single family units)

hotel, garages, retail store or other building

servicing the general public.

Commercial/General access vehicular

gate operator – Class III – A vehicular gate

operator (or system) intended for use in a

industrial location or building such

as a factory or loading dock area or other

locations not intended to service the

general public.

Restricted access vehicular gate operator –

Class IV – A vehicular gate operator (or sys-

tem) intended for use in a guarded industrial

location or building such as an airport security

area or other restricted access locations not

servicing the general public, in which unautho-

rized access is prevented via supervision by

security personnel.

6

Specifiers and designers should design an automatic vehicular gate system to:

•Incorporate UL 325 compliant equipment.

•Utilize an operator suited for gate system type, size, frequency of use, location and user population

(Refer to UL 325 for usage class definitions)

•Separate pedestrian access from vehicle access.

•Reduce or eliminate pinch points.

•Reduce risk of entrapment injuries by minimizing all gaps in the gate and enclosing the area of the

travel of the gate.

•Secure controls from unauthorized use..

•Locate all controls out of reach from the gate.

•Allow the user full view of the gate when operating.

•Consider special populations, such as children or the elderly.

•Conspicuously display all warnings and instructions.

•Be consistent with DASMA’s Automatic Gate Opener System Safety Guide.

ROLE OF SPECIFIERS AND DESIGNERS

Installers, during the course of the installation proceedings for each job, should:

•Confirm that the gate operator being installed is appropriate for the application.

•Confirm that the gate is designed and built according to current published industry standards.

•Confirm that all appropriate features and accessory devices are being incorporated, including both

primary and secondary entrapment protection devices.

•Make sure that the gate works freely before installing the operator.

•Repair or service worn or damaged gate hardware before installing the operator.

•Eliminate all gaps in the sliding gate below a 4 foot height that permit a 2 1/4 inch sphere to pass

through any location, including the area of the adjacent fence covered when the gate is in the open

position.

•Install the gate operator according to the manufacturer’s installation instructions.

•Adjust the operator clutch or load-sensing device to the minimum force setting that allows reliable gate

operation.

•Install operator inside fence line (DO NOT install operator on public side of fence line)

•Install a proper electrical ground to a gate operator.

•Install keypad controls where users cannot touch, or reach through gate while operating controls.

•Install controls where user has full view of gate operation.

•Install all warning signs (In accordance with UL 325) on both sides of the gate to warn persons in the

area of potential hazards associated with automatic vehicular gate operation.

•test all features for proper functions before placing the automatic vehicular gate into service.

•Demonstrate the basic functions and safety features of the gate system to owners/end users/general

contractors, including how to turn off power and how to operate the manual disconnect feature.

•Leave safety instructions, product literature, installation manual and maintenance manual with end

user.

•Explain to the owners the importance of a service contract that includes a routine re-testing of the

entire system including the entrapment protection devices, and explain the need for the owners to

insure that this testing is performed routinely.

•Offer the owner/end user a maintenance contract, or contact them regularly to offer maintenance.

ROLE OF DEALERS, INSTALLERS AND

TRAINED GATE SYSTEM TECHNICIANS

7

End users should be made aware that they must:

•Contact a trained gate systems technician to maintain and repair the gate system (End users should

never attempt to repair the gate)

•Retain and utilize the installation and maintenance manual and safety instructions.

•Routinely check of all gate operator functions and gate movement.

•Discontinue use if safety systems operate improperly, the gate is damaged, or the gate is difficult to

move.

•Never overtighten the operator clutch of load sensing device to compensate for a damaged or stiff

operating gate.

•Prominently display and maintain warning signs on both sides of the gate.

•Keep all obstructions clear of the vicinity of the path of the gate system.

•Actively discourage pedestrian use of the vehicular gate operating system.

•Prevent anyone from playing near any part of the gate system.

•Never allow anyone to climb under, over or through a gate or the adjacent fence area.

•Never allow children to operate gate

•Keep portable controls out of reach of children.

•Never allow anyone to install an operating control within reach of the gate.

•Never allow anyone to install a horizontal slide gate with exposed rollers or openings large enough to

allow a sphere of 2 1/4 inches to pass through any portion of the gate below a 4 foot height, including

the area of the adjacent fence covered when the gate is in the open position.

•Always be certain that the gate area is clear of pedestrians before operating the gate.

ROLE OF END USERS/HOME OWNER

•Entrapment Zone Hazard - Body parts may become entrapped between a gate and a stationary object

when the gate begins to move, which can result in serious injury or death. Pedestrians must stay clear

of the gate path, and any area where gate motion is close to stationary objects.

•Pinch Points Hazard - In open rollers gates, hands can get caught between the top of the gate and top

rollers, which can result in serious injury. Feet can be injured in the same manner between the bottom

of the gate and bottom rollers. Covers to guard these pinch points should be installed.

•Crush Hazard - In picket gates, body parts positioned between the bars can become seriously

mutilated when the gate begins to move, which can result in serious injury or death. If any openings

are greater than 2 1/4 inches, a screen should be installed over the gate (in accordance with the

provisions of UL 325) to prevent persons from reaching through and/or passing through the gate. In l

ike manner, screening should also be applied to the adjacent fence area covered by the gate when in

the fully open position.

Be sure that warning signs are prominently displayed on both sides of the gate and any other place where

danger exists.

HORIZONTAL SLIDE GATE SYSTEMS

Elite only recommends installation of catch rollers on the side of a catch post or wall with a minimal distance

of half an inch between the rollers and gate. Also when fully open the end of the sliding gate must stop at least

five inches from a wall.

Closing

Closing

Incorrect Correct

Non-Pinch

Rollers

Wall

Wall

Non-Pinch

Rollers

Gate

1/2" Clearance

Between Gate

and Rollers

Minimum of 5" Clearance Between

Gate and Wall or Other Object

Gate in Fully

Opened Position

1/4" Clearance from Top of Gate

5"

8

GATE POST WARNING

For safety reasons, a physical stop must be installed on the gate prior to installa-

tion of the gate operator. This will assure that the gate does not exceed movement

limits and derail while opening or closing fully.

IMPORTANT NOTICE!

Because the coasting distance may vary due to changes in temperature, Elite does NOT recommend the

installation of a stop or catch post in front of the gates path. To do so will cause the gate to hit the post in

certain instances.

CAUTION!

Warning Signs Attached on Both Sides of Gate

Warning Sign Clearly Visible on Operator

WARNING SIGNS

9

IMPORTANT!

Installers are required to adhere to this

procedure: The UL required Warning

Signs must be installed in plain view

and on both sides of each gate

installed. Each sign is made with fas-

tening holes in each corner and should

be permanently secured in a suitable

manner. Also the warning sticker

should be placed on the operator so it

is clearly visible. Installers should keep

photos of signs on gate in their

records.

WARNINGS AND PRECAUTIONS

10

Property owners must never let pedestrians cross the path of a moving gate!

Property owners must never allow anyone to hang or ride on the gate!

Property owners must never mount any gate operating device near the gate's path!

The SL-3000 Series is for Vehicular Gate Use Only!

NOT for Use on Any Pedestrian: Passageways, Doorways or Gateways.

ELITE RECOMMENDED SETUP

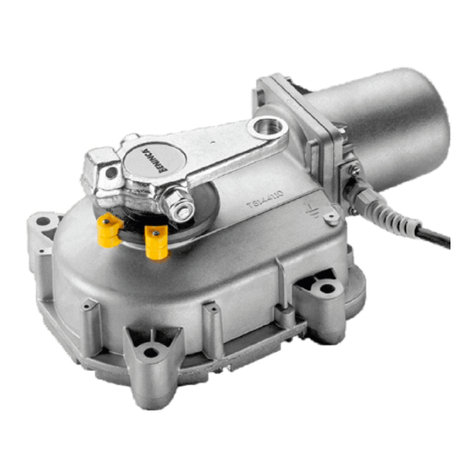

SL-3000-UL-DM

Two-1/2 hp Motors, 120 VAC, 4.7 Amp.

Maximum Gate Travel – 37 ft.

Maximum Gate Weight – 800 lbs.

Maximum Pull – 100 lbs.

SL-3000-UL

1/2 hp Motor, 120 VAC, 4 Amp.

Maximum Gate Travel – 37 ft.

Maximum Gate Weight – 1000 lbs.

Maximum Pull – 105 lbs.

SL-3000-UL-1HP

Two-1/2 hp Motors, 120 VAC, 8.4 Amps.

Maximum Gate Travel – 37 ft.

Maximum Gate Weight – 2000 lbs.

Maximum Pull – 180 lbs.

Recommended Gate Setup Configuration

Warning Signs

Attached

on Both Sides

of Gate

Non-Pinch

Rollers

Sensor Edges

Sensor

Edges

Non-Pinch

Rollers

Warning Sign Clearly

Visible on Operator

3" Max. Width

(2"x 2" Screen)

Weld Physical Stops on

Both Ends of Gate Rail

Be sure to read and follow all Elite and UL instructions before installing and

operating any Elite products. Elite Access Systems, Inc. is not responsible for

improper installations or failure to comply with local building codes.

Pedestrians Must have a Separate Walkway!

11

Physical Stop

Physical Stop

Physical Stop

Physical Stop

Idler Wheel must have Safety Cover

CAUTION!

TYPE OF INSTALLATIONS

12

It is highly recommended installing over-travel stops at both ends

of the gate rail in any type of installation, to prevent derailing.

REAR INSTALLATIONS

REASON: CHAIN IS NOT VISIBLE

FRONT INSTALLATIONS

REASON: COST EFFICIENT

CEILING MOUNT UNDERGROUND

REASON: SPACE EFFICIENT - CHAIN IS NOT VISIBLE

CONNECTING THE CHAIN

13

FRONT INSTALLATION

Weld front bracket with gate in open position. Weld rear bracket with gate in closed position.

17.5"

2"

Cut the chain access slot on the one side

of the cover to the exact specifications.

Important: For safe operation of the gate

opener do not cut the slots any wider or

longer than shown. DO NOT modify the

housing in any way other than specified.

REAR INSTALLATION – COVER MODIFICATION

Make sure the idler wheel has a safety cover.

Cut the cover 17 1/2 inches high. (See below)

CONCRETE PAD AND GATE ATTACHMENT

6"

Concrete (Reinforced Recommended)

Above

Ground

Below

Ground 24"

24" 24"

Rear Installation

Top Inside View

Front Installation

Physical

Stops on Both

Ends of Rail

Cover over

Wheel

Physical

Stops on

Both Ends

of Rail

10"

8"

12"

12"

Red Head Fastener

1/2" x 3 1/2"

Conduit Area Without

Battery Back-Up

Follow gate

manufacturers

specifications

and local

building codes

for setting post.

Suggested installation for dirt

ground. The measurements

depend on the type of ground

(ie., asphalt, cement, dirt)

13"

8.25"

14

GATE AND OPERATOR DISTANCE

15

CHOOSING MOVEMENT DIRECTION

15

4"

Minimum

Distance

Between Gate

and Sprocket

Correct Installation Incorrect Installation

OUT

IN

OUT

IN

Open to the Left

Open to the Right

Omni Control Board

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN RADIO

RECEIVER

TIMER

SYSTEMON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP CENTER

LOOP

GATE

LOCKED

60 POWER

OVERLOAD

OFF

W4

OPENLEFT

DC-BACKUP

ALARMSENSOR

OPENRIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MSLINK

A

MADEIN USA

RADIO

MER 60

OFF 13

ON

OPEN LEFT OPEN RIGHT

Omni Control Board

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN RADIO

RECEIVER

TIMER

SYSTEMON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP CENTER

LOOP

GATE

LOCKED

60 POWER

OVERLOAD

OFF

W4

OPENLEFT

DC-BACKUP

ALARMSENSOR

OPENRIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MSLINK

A

MADEIN USA

RADIO

MER 60

OFF 13

ON

OPEN LEFT OPEN RIGHT

HOW TO CONNECT POWER (120V)

16

Use U.L. Listed Conduit for

Supplying Power to the Unit

Suggestion:

Seal all open holes of

electronic box with

sealant when finished

wiring.

Do Not Use This Outlet Unless You Are

An Authorized Service Technician

Minimum:

15-amp

breaker

switch per

operator

needed

Gate Operator MUST be Properly Grounded

Caution: ELITE ACCESS SYSTEMS, INC. is not responsible for conflicts between the information listed in the above chart and the requirements

of your local building codes. The information is for suggested use only. Check your local codes before installation.

White Wires (Neutral)

Black Wires (120 VAC)

Green Wires (Ground)

16 Gauge

150 Feet

14 Gauge

250 Feet

12 Gauge

400 Feet

10 Gauge

650 Feet

8 Gauge

1000 Feet

4 Gauge

2200 Feet

WIRE GAUGE REQUIREMENT FOR 120 VAC POWER SUPPLY: 1/2 HP AND DUAL MOTOR ONLY

W4

OFF

ON

OFF

ON

Earth Ground Rod Installation

12 gauge wire

Elite Access Systems is not responsible for improper

installation or failure to comply with all necessary local

building codes.

8 ft

The earth ground rod must be located within 3 feet of the Elite gate

operator. Use the proper type earth ground rod for your local area.

The ground wire must be a single, whole piece of wire. Never splice two

wires for the ground wire. If you should cut the ground wire too short,

break it, or destroy its integrity, replace it with a single wire length.

Proper grounding gives an electrical charge, such as from an electrical static

discharge or a near lightning strike, a path from which to dissipate its energy safely

into the earth.

Without this path, the intense energy generated by lightning could be directed

towards the Elite gate operator. Although nothing can absorb the tremendous power

of a direct lightning strike, proper grounding can protect the gate operator in most

cases.

Before digging more than 18" deep, contact local underground utility companies.

Avoid damaging gas, power, or other underground utility lines.

ADJUSTING GATE TRAVELING DISTANCE

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP CENTER

LOOP

GATE

LOCKED

60 POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

TIMER

NSOR

60

OFF

OPEN LEFT OPEN RIGHT

3

13

ON

Timer ON

TIMER

NSOR

60

OFF

OPEN LEFT OPEN RIGHT

3

13

ON

Timer OFF

Set Timer

1 to 60 seconds

Timer can be set from 1 to 60 seconds (Timer ON),

or for push open/push close type operation (Timer OFF).

Note: When using master/slave gates, the gate that takes the longest to open should be set as the master.

ADJUSTABLE TIMER

17

Limit Nut

Lock Plate

Each notch indicates an

estimated 1 inch of gate travel

Nut

Push Plate

1.Turn the Power OFF!

2. Push the limit nut lock plate inward.

Roll the nut to the direction desired.

3. Place the plate back in the notch

4. Turn the machine off.

5. If you need more adjusting,

repeat the process.

Before Adjusting, Do the Following:

TWO-WAY ADJUSTABLE REVERSING SENSOR

18

DO NOT Touch Alarm Sensor

Adjusted by Qualified Service Personnel

The level of sensitivity has to do with the weight of

the gate and the condition of installation. To make a

better gate system, use any of Elite's power wheels.

Too sensitive = If the gate stops or reverses by

itself.

Not sensitive enough = If the gate hits a car and

does not stop or reverse.

CAUTION: If the power supply to the gate operator is less than 99 volts, adjust the alarm by turning

the alarm adjustment counter-clockwise enough to actuate the alarm when obstructed but not

sensitive enough for false triggering to occur.

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP CENTER

LOOP

GATE

LOCKED

60 POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

REVERSE

SENSOR

13

Maximum

Sensitivity

Minimum

Sensitivity

19

StrikeOpen

PushButton

StrikeOpen

PushButton

24VoltsDC

24VoltsDC

FireDept

KeySwitch

FireDept

KeySwitch

M/SLink

M/SLink

Class2

Supply

Class2

Supply

Center

Loop

Center

Loop

Safety

Loop

Safety

Loop

Radio

Receiver

Radio

Receiver

Exit

Loop

Exit

Loop

GG BB AA

–– ++

OmniControl SurgeSuppressor

P/NQ410

PatentPending

P/NQ410

PatentPending

®

StrikeOpen

PushButton

StrikeOpen

PushButton

24VoltsDC

24VoltsDC

FireDept

KeySwitch

FireDept

KeySwitch

M/SLink

M/SLink

Class2

Supply

Class2

Supply

Center

Loop

Center

Loop

Safety

Loop

Safety

Loop

Radio

Receiver

Radio

Receiver

Exit

Loop

Exit

Loop

GG BB AA

–– ++

OmniControl SurgeSuppressor

P/NQ410

PatentPending

P/NQ410

PatentPending

®

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP CENTER

LOOP

GATE

LOCKED

60 POWER

OVERL OAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADEIN USA

CENTER SAFETY EXIT

CENTER SAFETY EXIT

FIRE

DEPT.

13

STRIKE

OPEN RADIO

RECEIVER

TIMER

SYSTEM ON

EXIT

LOOP

ALARM

SENSOR

REVERSE

SENSOR

OPEN

STOPCLOSE

SAFETY

LOOP CENTER

LOOP

GATE

LOCKED

60 POWER

OVERLOAD

OFF

W4

OPEN LEFT

DC-BACKUP

ALARMSENSOR

OPEN RIGHT

3

SENSORS

RESET

MOTOR

13

13

COMMAND

PROCESSED

ON

GB

MS LINK

A

MADE IN USA

TIMER

TIMER

NSOR

60

OFF

OPEN LEFT OPEN RIGHT

3

13

ON

ON

MAXIMUM

Counterclockwise

Setting

TIMER

TIMER

NSOR

60

OFF

OPEN LEFT OPEN RIGHT

3

13

ON

ON

Master Omni Board

Slave Omni Board

Adjust Time Desired

0 to 60 seconds

Slave Timer “ON”

Master Timer “ON”

1. Connect Gfrom the master surge suppressor to Gof the slave surge

suppressor.

2. Connect Bfrom the master surge suppressor to Bof the slave surge

suppressor.

3. Connect Afrom the master surge suppressor to Aof the slave surge

suppressor.

4. Turn timers on BOTH Omni boards to the “ON” position

5. Turn the SLAVE Timer adjustment all the way Counterclockwise

6. Use MASTER timer ONLY to select the desired time

Master and Slave Boards are Interchangeable Master Omni Board Primary Control for System

CHASSIS

GROUND

M/SLink

M/SLink

P/N Q410

PatentPending

P/N Q410

PatentPending

Center

Loop

Center

Loop

GG BB AA

CHASSIS

GROUND

M/SLink

M/SLink

P/N Q410

PatentPending

P/N Q410

PatentPending

Center

Loop

Center

Loop

GG BB AA

Use Shielded Twisted Wires

to Connect the Surge

Suppressor of each

Gate Operator Together

Use low voltage wires in separate conduit to connect gate operators together

Caution: Never run high voltage and low voltage wires in same conduit

MASTER AND SLAVE WITH TIMER ON

This manual suits for next models

3

Table of contents

Other Elite access systems Gate Opener manuals

Popular Gate Opener manuals by other brands

Centurion

Centurion D10 installation manual

Chamberlain

Chamberlain MEGA ARM / MEGA ARM TOWER Installation and service manual

Motorline professional

Motorline professional Gateway Control SLIDE 500 Operating and installation instructions

RIB

RIB K500 manual

Beninca

Beninca DU.IT14NE Operating instructions and spare parts catalogue

FAAC

FAAC 746 ER CAT manual