2

IMPORTANT SAFETY INSTRUCTIONS FOR THE

INSTALLATION

G

B

ATTENTION - FOR THE SAFETY OF PEOPLE IT IS IMPORTANT TO FOLLOW ALL THE

INSTRUCTIONS

KEEP THESE INSTRUCTIONS WITH CARE

1° - If it is not forecast in the electric gearcase, install a switch of magneto thermic type

upstream, (omni polar with minimum opening of the contacts of 3 mm) with a check of

conformity to the international standards. Such device must be protected against the

accidental lockup (for example by installing inside a locked board).

2° - For the section and the type of the cables RIB advices to use a cable of H05RN-F type

with 1,5 sqmm minimum section and, however, to keep to the IEC 364 and installation

standards in force in your country.

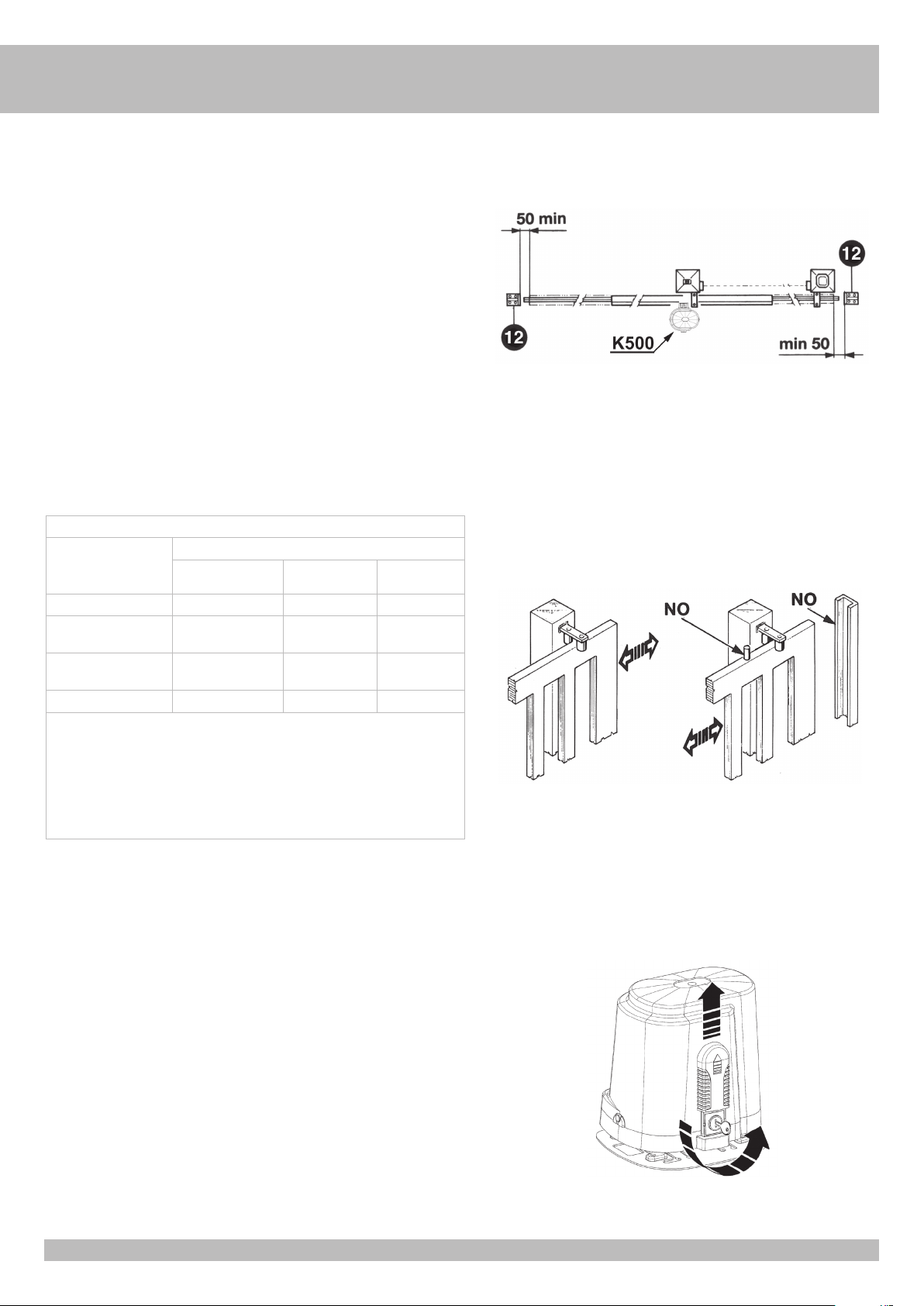

3° - Positioning of a possible couple of photoelectric cells: the radius of the photoelectric

cells must be at a height of no more than 70 cm from the ground and at a distance

not superior to 20 cm from the motion plane of the door. Their correct working must be

verified at the end of the installation in accordance with the point D.3.2 of the EN 12453

4° - To fulfill the limits set by EN 12453, and in case the peak force exceeds the normative

limit of 400 N it is necessary to have recourse to the active presence survey on the

whole height of the door (up to max 2,5 m) - The photoelectric cells, in this case, must

be applied in accordance with the point D.4.1 of the EN 12453.

N.B.: The earthing of the system is obligatory.

The data described in this handbook are purely a guide.

RIB reserves the right to change them in any moment.

Carry out the system in the respect of the standards and laws in force.

IMPORTANT SAFETY INSTRUCTIONS FOR THE INSTALLATION

ATTENTION - THE INCORRECT INSTALLATION CAN CAUSE SERIOUS DAMAGES

FOLLOW ALL INSTALLATION INSTRUCTIONS

1° - This handbook is exclusively addressed to the specialized personnel who knows

the constructive criteria and the protection devices against accidents for motorized

gates, doors and main doors (follow the standards and the laws in force).

2° - The installer will have to issue a handbook to the final user in accordance with the

EN 12635.

3° - Before proceeding with the installation, the installer must forecast the risks analysis

of the final automatized closing and the safety of the identified dangerous points

(Following the standards EN 12453).

4° - Before installing the motion motor, the installer must verify that the gate is in good

mechanical conditions and that it adequately opens and closes.

5° - The installer must install the member for the manual release at a height inferior to

1,8 m.

6° - The installer will have to remove possible impediments to the motorized motion of the

gate (eg. door bolts, sliding bolts, door locks etc.)

7° - The installer will permanently have to put the tags warning against the deflection on a

very visible point or near possible fixed controls.

8° - The wiring harness of the different electric components external to the operator (for

example photoelectric cells, flashlights etc.) must be carried out according to the EN

60204-1.

9° - The possible assembly of a keyboard for the manual control of the movement must be

done by positioning the keyboard so that the person operating it does not find himself

in a dangerous position; moreover, the risk of accidental activation of the buttons must

be reduced.

10° - Keep the automatism controls (push-button panel, remote control etc.) out of the

children way. Command device for operating the motor (a switch manually closed)

should be placed in area visible from the guided site and far from moving parts. It

should be placed at least at 1,5 m height.

11° - this appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge

if they have been given supervision or instruction concerning use of the appliance in

a safe way and understand the hazards involved

12° - children shall not play with the appliance

13° - cleaning and user maintenance shall not be made by children without supervision

14° - do not allow children to play with fixed controls. Keep remote controls away from

children

15° - Fixed command devices should be installed in a well visible way.

16° - Before carrying out any installation, regulation or maintenance operation of the

system, take off the voltage by operating on the special magneto thermic switch

connected upstream.

17° - At the end of the installation, the installer will have to make sure that the parts of the

door do not encumber streets or public sidewalks.

THE RIB COMPANY DOES NOT ACCEPT ANY RESPONSIBILITY for possible damages

caused by the non observance during the installation of the safety standards and of

the laws in force at present.