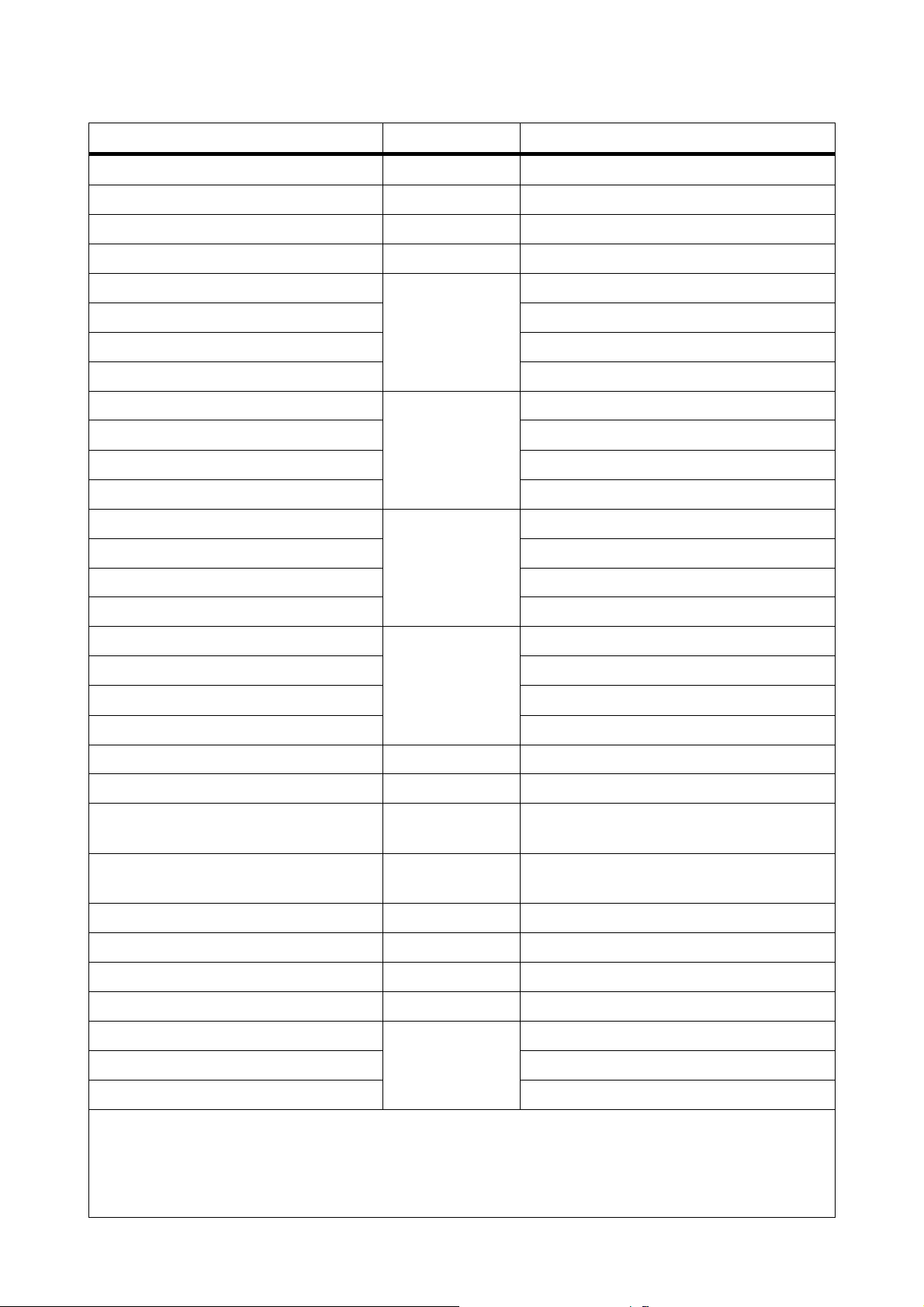

6 X 6 8 X 6 10 X 6 12 X 6

1 50’Glazing beading 1 1 0 0

2 100’Glazing beading 2 2 3 3

3 Eave gusset plate 2 2 2 2

4 Black draught excluder 2 2 2 2

5 Top door panel Taped together and

marked door 1 1 1 1

6 Bottom door panel 1 1 1 1

7 Door infill panels 3 3 3 3

8 Door track support 1 1 1 1

9 Ridge Taped together in

extension box 1 1 1 1

10 Gutter / Eave 1 1 1 1

11 Front Cill 1 1 1 1

12 Heavy angle brace 1 1 1 1

13 Rear end cill Taped together and

marked end 1 1 1 1

14 Rear end glazing bar 2 2 2 2

15 Rear end horizontal bracing angle 1 1 1 1

16 Rear end wall bar 1 1 1 1

17 Door end cill Taped together and

marked en 1 1 1 1

18 Door end glazing bar 2 2 2 2

19 Door end horizontal bracing angle 1 1 1 1

20 Door end wall bar 1 1 1 1

21 Door glazing bars—marked door 2 2 2 2

22 Front glazing bars—marked front 2 3 4 5

23 Corner bars—taped in two packs

1 = left end, 1 = right end 4 4 4 4

24 Short bracing angles marked door end 3 3 3 3

25 6’shelf 1 1 1 1

26 Vent (in packs) 1 1 1 1

27 Louvre (in packs) 1 1 1 1

28 Door track 1 1 1 1

29 Roof glazing bars Taped

together and marked

roof

2 3 4 5

30 Roof strengthening bars 2 3 4 5

31 Roof flat bars 3 4 5 6

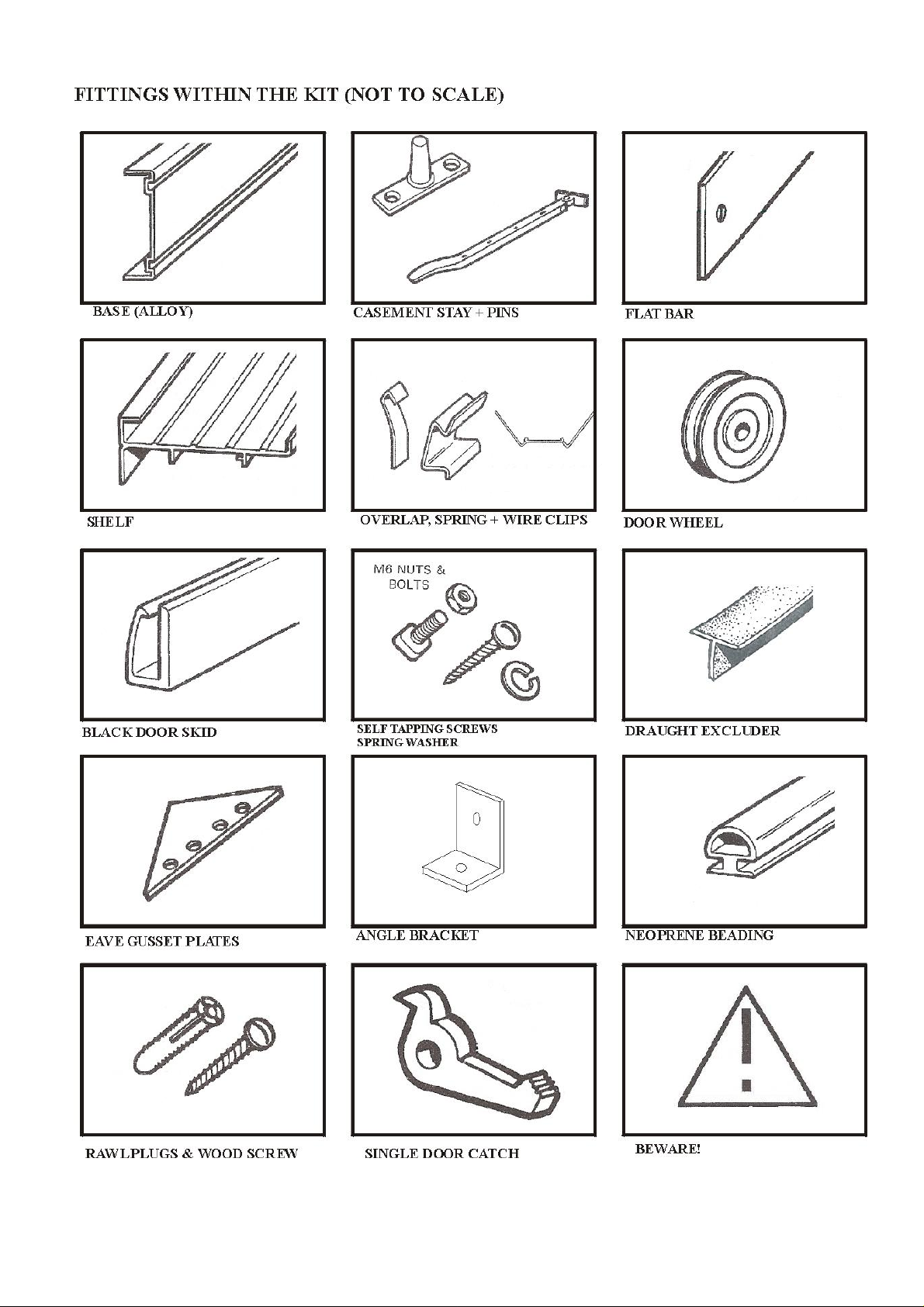

32 The following items can be found in the bag of fittings or additional packages.

Skeleton gun, tube of silicon, rolls of foam seal, anchor brackets, stainless steel screws, plastic plugs, M10

nuts and bolts, stainless steel clips, wire clips, overlap clips, casement stays, stay pins, M4 pins, nuts and

bolts, door catch, short and long self tapping screws, spring washers, door skids, door wheels and fittings.

PARTS LIST