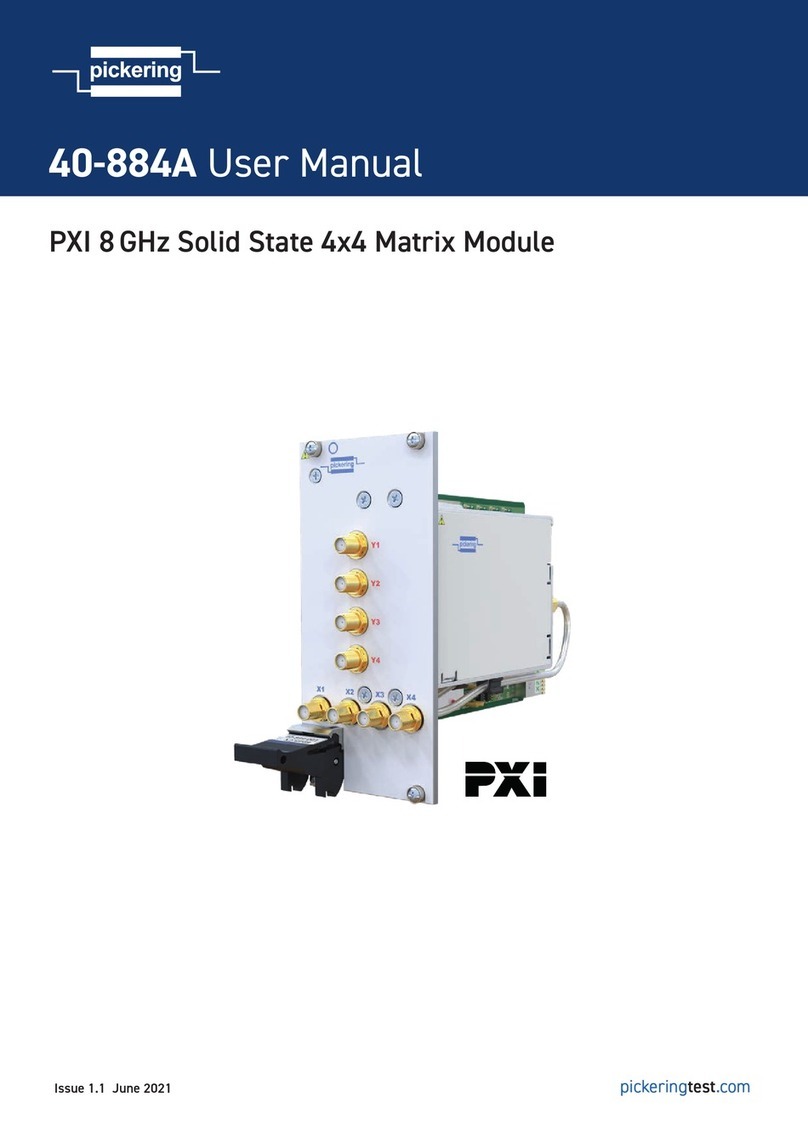

Elitex WGT 5 User manual

1

Shut Version

WGT 5/7/10/12/14/16/20

Water Gas Termination

I N S T A L L A T I O N I N S T R U C T I O N

Application

The WGT fits independent from pipe manufacturer as a sealing

element for all listed sizes. The WGT seal off water and gas in

microducts with various cable diameters and works also like a

blind plug. Beside excellent sealing performance the WGT also has

good strain relief for cable and microduct. With the optional PowerClip

the strain relief improve by clamping the strength members like

aramid yarn. At the cable side the WGT has an integrated shape for bend

protection. Please also refer to the technical data sheets for the products.

Scope of delivery

Every WGT housing comes with a sealing gasket

according to the selected cable size. The sealing

gasket has two functions. It works as a blind plug for

empty microducts and as a seal for the cable.

Sealing gaskets

Various sealing gaskets for different microducts and applicable cable diameters

are available. Please refer to the table with available sizes on last page.

Customer specific gaskets are available on request.

PowerClip

If fixation of strain relief elements

of the cable is required, the PowerClip

is the right choice.

Tools

For every size of WGT a disassembly clip is available.

For most sizes also a professional installation tool is

available. The tool simplifies assembly and disassembly

of the WGT especially if the cable is already in place.

The WGT can be installed without using the tool but

for disassembly, at least for WGT size 5mm, 7mm and

thin cables, the use of the PullClip

is strongly recommended.

PullClip

Order No.

Assembly Pliers

Order No.

PowerClip

Order No.

WGT 5mm

01-044-01 A

-

-

WGT 7mm

01-045-01 A

WGT 7mm

01-038-01 A

WGT 7mm-

01-011-01-A

WGT 10mm

01-046-01 A

WGT 10mm

01-039-01 A

WGT 10mm

01-008-01 A

WGT 12mm

01-047-01 A

WGT 12mm

01-040-01 A

WGT 12mm

01-009-01 A

WGT 14mm

01-048-01 A

-

-

-

-

WGT 16mm

01-049-01 A

-

-

-

-

2

1. Important instructions

The manual is for the full version of WGT, separated into

the parts assembly with and without tools.

- Before starting installation, check if the end of the

microduct is clean from any kind of dirt pollution and

lubricants. Also check carefully inside of microduct on

such contamination, to avoid application problems later.

- The end of a microduct need a straight, vertical, clean

cut with a tool recommended by duct manufacture.

- Due to tolerances of the outside diameter of the

microduct, different force may appear for installing the

WGT body onto the duct.

1.1 Mounting the WGT without tools on an empty

microduct

The WGT with sealing gasket can be used as sealing blind

plug for empty microducts.

1.2 Select the appropriate size of WGT according to

the diameter of microduct and size of sealing gasket to

fit the cable diameter which will be installed later

1.3 Insert sealing gasket with cone side into the

microduct, blind plug pointing towards the WGT.

1.4 Slide WGT over the blind plug and push it onto

the microduct

1.5 Push WGT on the microduct until the edge of

the duct is at least flush with the ring marking on WGT

body (arrows). This ensures tightness of WGT.

Note: To improve tightness and tensile strength on

microduct, rotate WGT ¼ turn clockwise.

3

2. Disassembly of WGT without tools for an

empty microduct

2.1 Release WGT by turning it counterclockwise.

Remove seal and keep it for later use.

3. Installation of WGT without tools for

microduct with cable

3.1 Before installation remove blind plug from

sealing gasket. Hold blind plug with one hand and seal

cone with other hand, turn against each other and rip off

blind plug. The blind plug is no longer required.

3.2 Slide sealing gasket with cone side towards microduct

onto the cable till it stops in the microduct. Slide WGT

body on cable afterwards.

Note: To facilitate seal installation, cut sealing gasket in

longitudinal direction. Place seal around cable and slide

it till stop into the microduct.

3.3 Push WGT on the microduct.

3.4 Push WGT on the microduct until the edge of

the duct is at least flush with the ring marking on WGT

body (arrows). This ensures the tightness.

4

Note: To improve tightness and tensile strength on

microduct, rotate WGT ¼ turn clockwise.

3.5 Disassembly of WGT without tools for a

microduct with cable

3.6 Release WGT by turning counterclockwise but hold

cable during procedure.

If sealing gasket is clean and in good condition it may be

used again.

Note: If WGT 5/7mm and thin cables are used, usage of

dismounting tool is strongly recommended.

4. Installation of WGT with assembly pliers for

microduct with cable

Installation and mainly disassembly is much faster and

gentle for the cable.

Note: Always press release lever during installation or

disassembly.

4.1 Install WGT and sealing gasket till chapter 3.2.

but don’t push WGT body onto microduct!

4.2 Open assembly pliers by pushing opening lever.

4.3 Put WGT into assembly pliers and close it. Cable

has to point out top side of tool microduct to bottom

side. If it doesn’t close perfect, WGT was inserted faulty.

4.4 Press release lever and push WGT onto

microduct.

WGT must be in position like described in point 3.4

5

5. Disassembly of WGT with tools for a microduct

with cable

5.1 Put WGT into assembly pliers and close it. Cable

has to point out top side of tool, microduct has to point

out to bottom side. If it doesn’t close perfect, WGT was

inserted faulty.

5.2 Press release lever and remove the WGT from

the micro tube. Open the assembly tool and remove the

WGT. If sealing gasket is clean and in good condition it

may be used again.

5.3 Disassembly of WGT with PullClip for a

microduct with cable

5.4 Slide PullClip on the microduct behind WGT. The

cone-shaped notch must point towards WGT.

5.5 Place one finger left and another finger on right

side under the PullClip, fix top side of WGT with your

thumb and pull off WGT from micro tube.

Note: If sealing gasket is clean and in good condition it

may be used again.

7. . Installation of WGT with PowerClip to clamp strain

relief (aramid) of cable

If fixation of strain relief elements of the cable is

required, PowerClip has to be installed.

6

7.1 Install sealing gasket like in capture 3 to 3.3. To

facilitate mounting of WGT, untie strength members

(aramid yarn) after installation of WGT.

7.2 Strip cable jacket according to specification of

cable manufacturer. After installing of WGT, edge of

cable jacket must be flush with edge of WGT body. Lines

in picture shows length of cable jacket to be cut. Leave at

least 25 cm of aramid yarn for PowerClip installation.

7.3 Install WGT with or without tool like described

in the previous chapters.

Push WGT on the microduct until the edge of the duct is

at least flush with the ring marking on WGT body

(arrows). This ensures the tightness.

Note: To improve tightness and tensile strength on

microduct, rotate WGT ¼ turn clockwise.

Pull aramid yarn tight and slightly twist or twirl it.

Note: To improve tightness and tensile strength on

microduct, rotate WGT ¼ turn clockwise.

Pull aramid yarn tight and slightly twist or twirl it.

7.4 Mount PowerClip onto the WGT in a way all 3

tabs inside of the clip fit into the holes of the WGT body.

7.5 Wrap aramid yarn in a figure 8 shape under the

flaps of the PowerClip. Pull aramid yarn tight, twist and

pull into direction towards microduct and beneath flap

of PowerClip.

7

7.6 Pull aramid yarn diagonally, up to the side of the

cable. Then slide it beneath flap of PowerClip back into

direction of the micro tube.

7.7 Again pull aramid yarn diagonally, upwards

beneath PowerClip like described before.

7.8 Repeat this figure 8 shape wrap up to 6 times.

If possible, remain enough length of aramid yarn to

enable a retry of installation.

8. Installation LabelClip

The LabelClip is available for microducts with outer

diameters of 7/10/12/14/16/20mm (https://www.elitex-

gmbh.de/werkzeuge-zubehör-en/beschriftungsclip-en/)

Item

Order No

LabelClip for WGT 7mm

01-061-01 A

LabelClip for WGT 10mm

01-062-01 A

LabelClip for WGT 12mm

01-063-01 A

LabelClip for WGT 14mm

01-064-01 A

LabelClip for WGT 16mm

01-065-01 A

LabelClip for WGT 20mm

01-066-01 A

8.1 Position the LabelClip right below WGT and clip

it onto microduct. The LabelClip is rewriteable multiple

times with permanent marker. Labels from common

label printers stick well to the LabelClip and still can be

removed.

8

Table sealing gaskets

Elitex GmbH

Justus-von-Liebig-Straße 13

D-85247 Schwabhausen

Mail: office@elitex-gmbh.de

www.elitex-gmbh.de WGT shut Version

The information contained herein, including the illustrations and graphical representations, correspond to the current

state of our knowledge and are correct and reliable to the best of our knowledge. However, they do not represent any

binding assurance of properties. Such an assurance is only given by our product standards. The user of this product must

decide on his own responsibility about its suitability for the intended use. Our liability for this product is governed

exclusively by our General Terms and Conditions. Elitex specifications are subject to change without notice. In addition,

Elitex reserves the right, without notice to the purchaser, to make changes in materials or workmanship that do not

affect compliance with applicable specifications

Product and System patented for Elitex GmbH. ©Copyright Elitex GmbH 2023 Version 1.6

sealing gasket

min

cable

max

gasket no.

min

cable

max

gasket no.

min

cable

max

gasket no.

min

cable

max

gasket no.

min

cable

max

gasket no.

min

cable

max

gasket no.

min

cable

max

gasket no.

min

cable

max

gasket no.

micro duct dia.

5mm

5x1= inner 3.0 0.9 - 1.5 11.4 - 2 21.9 - 2.5 3- - - -

5x0.75= inner 3.5 0.9 - 1.5 11.4 - 2 21.9 - 2.5 32.4 - 3 4- - - -

7mm

7x1.50= inner 3.0 1 - 1.6 51.5 - 2.1 62 - 2.6 72.5 - 3.1 8- - - -

7x0.75= inner 5.5 1 - 1.6 51.5 - 2.1 62 - 2.6 72.5 - 3.1 83 - 3.6 93.5 - 4.1 10 -

10mm

10x2.0= inner 6.0 1 - 2 11 2 - 3 12 2.9 - 3.9 13 3.8 - 4.8 14 4.7 - 5.7 15 - - -

10x1.0= inner 8.0 1 - 2 11 2 - 3 12 2.9 - 3.9 13 3.8 - 4.8 14 4.7 - 5.7 15 5.6 - 6.6 16 - -

12mm

12x2.0= inner 8.0 2 - 3 12 2.9 - 3.9 13 3.8 - 4.8 14 4.7 - 5.7 15 5.6 - 6.6 16 - - -

12x1.1= inner 9.8 2 - 3 17 2.9 - 3.9 18 3.8 - 4.8 19 4.7 - 5.7 20 5.6 - 6.6 21 6.5 - 7.5 22 - -

14mm

14x2.0= inner 10.0 2.5 - 3.5 35 4 - 5 36 5 - 6 23 6 - 7 24 6.9 - 7.9 25 7.8 - 8.8 26 - -

14x1.3= inner 11.4 2.5 - 3.5 35 4 - 5 36 5 - 6 23 6 - 7 24 6.9 - 7.9 25 7.8 - 8.8 26 8.7 - 9.7 27 -

16mm

16x2.0= inner 12.0 2.5 - 3.5 35 4 - 5 36 5 - 6 23 6 - 7 24 8 - 9 28 8.9 - 9.9 29 9.8 - 11 30 -

20mm

20x2.5= inner 15.0 4.5 - 5.5 39 7.5 - 8.5 40 8 - 9 31 8.9 - 9.9 32 9.8 - 10.8 33 11 -12 34 - -

20x2.0= inner 16.0 4.5 - 5.5 39 7.5 - 8.5 40 8 - 9 31 8.9 - 9.9 32 9.8 - 10.8 33 11 -12 34 - -

This manual suits for next models

6

Table of contents