Eliwell EWTQ 905 User manual

GENERAL DESCRIPTION

EWTQ 905 is a “single loop” digital microproces-

sor-based controller, with ON/OFF, Neutral Zone

ON/OFF, PID single action, PID dual action

(direct and reverse) control and with AUTO-

TUNING FAST function and SELF-TUNING

function for PID control.

The process value is visualized on 4 red displays,

while the output status is indicated by 2 LED

displays.

The instrument is equipped with a 3 LED pro-

grammable shift indexes.

The instrument can have up to 2 outputs: relay

type or can drive solid state relays type (SSR).

Depending on the model required the input

accept:

• C: Thermocouples temperature probes (J,K),

mV signals (0..50/60 mV, 12..60 mV),

Thermoresistances PT100.

• E : Thermocouples temperature probes (J,K),

mV signals (0..50/60 mV, 12..60 mV),

Thermistors PTC and NTC.

• I : normalized analogue signals 0/4..20 mA

• V : normalized analogue signals

0..1 V, 0/1..5V, 0/2..10 V

PROGRAMMING

FAST PROGRAMMING OF THE SET POINT

This procedure permits rapid programming of

the Set Point (SP1) and possibly the alarm

thresholds (AL1).

• Push key set, then release it and the display

will visualise “SP1” alternatively to the pro-

grammed value.

To modify the value, press “UP” key to increase

it or the “DOWN” key to decrease it.

PLEASE NOTE: These keys change the value one

digit at a time but if they are pressed for more

than one second, the value increases or

decreases rapidly and, after two seconds in the

same condition, the changing speed increases in

order to allow the desired value to be reached

rapidly.

• Once the desired value has been reached, by

pushing key set it is possible to exit by the fast

programming mode or it is possible to visualise

the alarm thresholds.

• To exit the fast Set programming it is neces-

sary to push key set, after the visualisation of

the last Set Point, or alternatively, if no key is

pressed for approx. 15 seconds, the display will

return to normal functioning automatically.

PARAMETER PROGRAMMING

By pushing key set and holding it down for

approx. 2 sec. it is possible to enter into the

main selection menu.

Using the "UP" or DOWN” keys, it is then possi-

ble to roll over the selections:

• "OPEr" to enter into the operating parame-

ters menu;

• "ConF" to enter into the configuration para-

meters menu;

Once the desired item has been selected, push

key set to confirm.

Selecting "OPEr" and "ConF" gives the possibili-

ty of accessing other menus containing addi-

tional parameters and more precisely :

• "OPEr" - Operating parameters Menu: this

normally contains the Set Point parameters but

it can contain all the desired parameters.

• "ConF" - Configuration parameters Menu: this

contains all the operating parameters and the

functioning configuration parameters.

To enter the menu “OPEr”, select the option

“OPEr” and press the key set and the display

will now show “0”.

By pressing the “UP” and “DOWN” keys please

set number (password) 381 (see last page) and

press “set” key.

If the password is not correct the instrument

will return in previous regulation status.

If the password is correct the display will show

the parameter’s code (“ ]SP “) (first parameters’

group). Again using the “UP” and “DOWN” keys,

it is possible to select the desired group of

parameters.

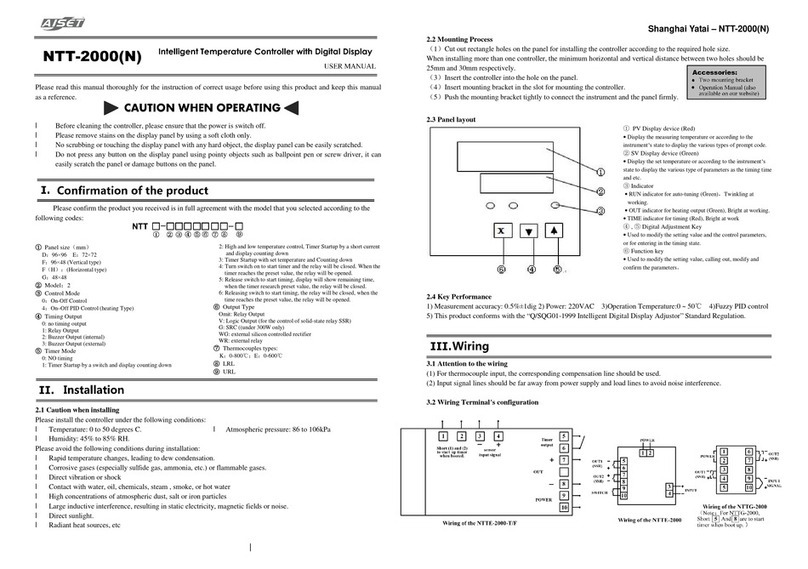

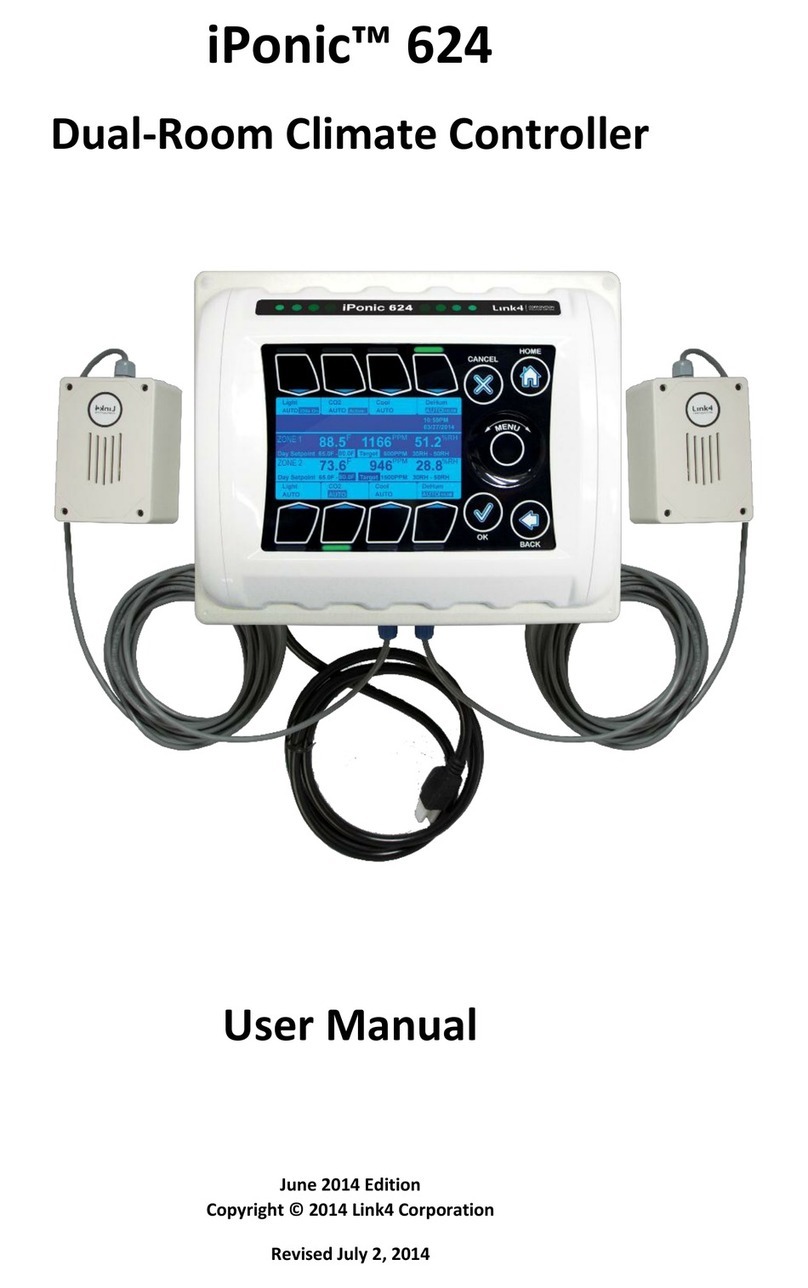

USER INTERFACE

1 - Key set : This is used to access the pro-

gramming parameters and to confirm selec-

tion.

2 - Key DOWN : This is used to decrease the

values to be set and to select the parameters.

If the key is held down, the user returns to

the previous programming level until he exits

the programming mode.

3 - Key UP : This is used to increase the val-

ues to be set and to select the parameters. If

the key is held down, the user returns to the

previous programming level until he exits the

programming mode.

Outside the programming mode it permits

visualisation of the output control power.

4 - Key F : This is a key that can be set to :

Activate Auto-tuning and Self-tuning func-

tions;In “ConF” mode can be used to change

parameters’ visibility

5 - Led OUT1 : indicates the state of output

OUT1

6 - Led OUT2 : indicates the state of output

OUT2

7 - Led SET : when flashing, it indicates

access to the programming mode.

8 - Led AT/ST : indicates that the Self-tuning

function is activated (light on) or that Auto-

tuning (flashing ) is in progress.

9 - Led – Shift index: indicates that the

process value is lower than the one pro-

grammed on par. “AdE”.

10 - Led = Shift index: indicates that the

process value is within the range [SP+AdE ...

SP-AdE]

11 - Led + Shift index: indicates that the

process value is higher than the one set on

par. “AdE”.

EWTQ 905

digital temperature regulator 48x48

cod. 9IS23045

rel. 1/04

I

10

3

4

AT

9

5

ST

8

2

1

EWTQ 905

OUT2OUT1 -=+

6

SET

7

11

Fset

Once the desired value has been programmed,

push key set once more: the new value will be

memorised and the display will show only the

code of the selected parameter.

By using the “UP” or “DOWN” keys, it is then

possible to select a new parameter (if present)

and modify it as described above.

To select another group of parameters, keep the

“UP” or “DOWN” key setressed for approx. 2

sec., afterwards the display will return to visu-

alise the code of the group of parameters.

Release the key and by using the “UP” and

“DOWN” keys, it will be possible to select a new

group (if present).

To exit the programming mode, no key should

be pressed for approx. 20 seconds, or keep the

“UP” or “DOWN” pressed until exit from the

programming mode is obtained.

To enter the menu "ConF" a PASSWORD is

required.

At this request, enter, using keys “UP” and

“DOWN”, the number reported on the last page

of this manual and push key set.

If an incorrect password is entered, the instru-

ment returns to the previous control state.

If the password is correct, the display will visu-

alise the code identifying the first group of

parameters (“ ]SP “) and with keys “UP” and

“DOWN” it will be possible to select the desired

group of parameters

The programming and exit modes for the

“ConF” menu are the same as those described

for menu “OPEr”.

PARAMETERS PROGRAMMING LEVELS

The menu “OPEr” normally contains the para-

meters used to program the Set Point; however

it is possible to make all desired parameters

appear or disappear on this level, by following

this procedure:

Enter the menu “ConF” and select the parame-

ter to be made programmable or not program-

mable in the menu “OPEr”.

Once the parameter has been selected, if the

LED SET is switched off, this means that the

parameter is programmable only in the menu

“ConF”, if instead the LED is on, this means that

the parameter is also programmable in the

menu “OPEr”.

FUNCTIONS

MEASURING AND VISUALIZATION

All the parameters referring measurements are

contained in the group “]InP”.

Depending on the model required the input

accept:

• C: Thermocouples temperature probes (J,K),

mV signals (0..50/60 mV, 12..60 mV),

Thermoresistances PT100.

• E : Thermocouples temperature probes (J,K),

mV signals (0..50/60 mV, 12..60 mV),

Thermistors PTC and NTC.

• I : normalized analogue signals 0/4..20 mA

• V : normalized analogue signals

0..1 V, 0/1..5 V, 0/2..10 V

Depending on the model, using par. “SEnS”, it’s

possible to select the type of input probe,

which can be :

• for thermocouples J (J), K (CrAL)

• for thermoresistances Pt100 IEC (Pt1)

• for thermistors PTC KTY81-121 (Ptc) or NTC

103AT-2 (ntc)

• for normalised signals in current 0..20 mA

(0.20) or 4..20 mA (4.20)

• for normalised signals in tension 0..1 V (0.1),

0..5 V (0.5), 1..5 V (1.5), 0..10 V (0.10) or 2..10 V

(2.10).

- for normalised signals in tension 0..50 mV

(0.50), 0..60 mV (0.60), 12..60 mV (12.60).

We recommend to switch on and off the instru-

ment when these parameters are modified, in

order to obtain a correct measuring.

For the instruments with input for temperature

probes (tc, rtd) it’s possible to select, through

par. “Unit”, the unit of measurement (°C, °F)

and, through par. “dP” (Pt100, PTC and NTC

only) the desired resolution (0=1°; 1=0,1°).

Instead, with regards to the instruments with

normalised analogue input signals, it is first nec-

essary to program the desired resolution on par.

“dP” (0=1; 1=0,1; 2=0,01; 3=0,001) and then,

on par. "SSC", the value that the instrument

must visualise at the beginning of the scale (0/4

mA, 0/12 mV, 0/1 V o 0/2 V) and, on par. "FSC",

the value that the instrument must visualise at

the end of the scale (20 mA, 50 mV, 60 mV, 5 V

or 10 V).

The instrument allows for measuring calibration,

which may be used to recalibrate the instru-

ment according to application needs, by using

par. “OFSt” and “rot”.

Programming par. “rot”=1,000, in par. “OFSt” it

is possible to set a positive or negative offset

that is simply added to the value read by the

probe before visualisation, which remains con-

stant for all the measurements.

If instead, it is desired that the offset set should

not be constant for all the measurements, it is

possible to operate the calibration on any two

points.

In this case, in order to decide which values to

program on par. “OFSt” and “rot”, the following

formulae must be applied :

“rot” = (D2-D1) / (M2-M1)

“OFSt” = D2 - (“rot” x M2)

where:

M1 =measured value 1

D1 = visualisation value when the instrument

measures M1

M2 =measured value 2

D2 = visualisation value when the instrument

measures M2

It then follows that the instrument will visualise

: DV = MV x “rot” + “OFSt”

where: DV = visualised value MV= measured

value

Example 1: It is desired that the instrument visu-

alises the value effectively measured at 20° but

that, at 200°, it visualises a value lower than 10°

(190°).

Therefore : M1=20 ; D1=20 ; M2=200 ;

D2=190

“rot” = (190 - 20) / (200 - 20) = 0,944

“OFSt” = 190 - (0,944 x 200) = 1,2

Example 2: It is desired that the instrument visu-

alises 10° whilst the value actually measured is

0°, but, at 500° it visualises a 50° higher value

(550°).

Therefore : M1=0 ; D1=10 ; M2=500 ;

D2=550

“rot” = (550 - 10) / (500 - 0) = 1,08

“OFSt” = 550 - (1,08 x 500) = 10

By using par. “FiL” it is possible to program time

constant of the software filter for the input

value measured, in order to reduce noise sensi-

tivity (increasing the time of reading).

In case of measurement error, the instrument

supplies the power as programmed on par.

“OPE”.

This power will be calculated according to cycle

time programmed for the PID controller, while

for the ON/OFF controllers the cycle time is

automatically considered to be equal to 20 sec.

(e.g. In the event of probe error with ON/OFF

control and “OPE”=50, the control output will

be activated for 10 sec., then it will be deacti-

vated for 10 sec. and so on until the measure-

ment error remains.).

Again in the group “]PAn” the par. “AdE” is pre-

sent that defines the 3 led shift index function-

ing.

The lighting up of the green led = indicates that

the process value is within the range [SP+AdE

... SP-AdE], the lighting up of the led – indicates

that the process value is lower than [SP-AdE]

and the lighting up of the led + indicates that

the process value is higher than [SP+AdE].

EWTQ 905 2/8

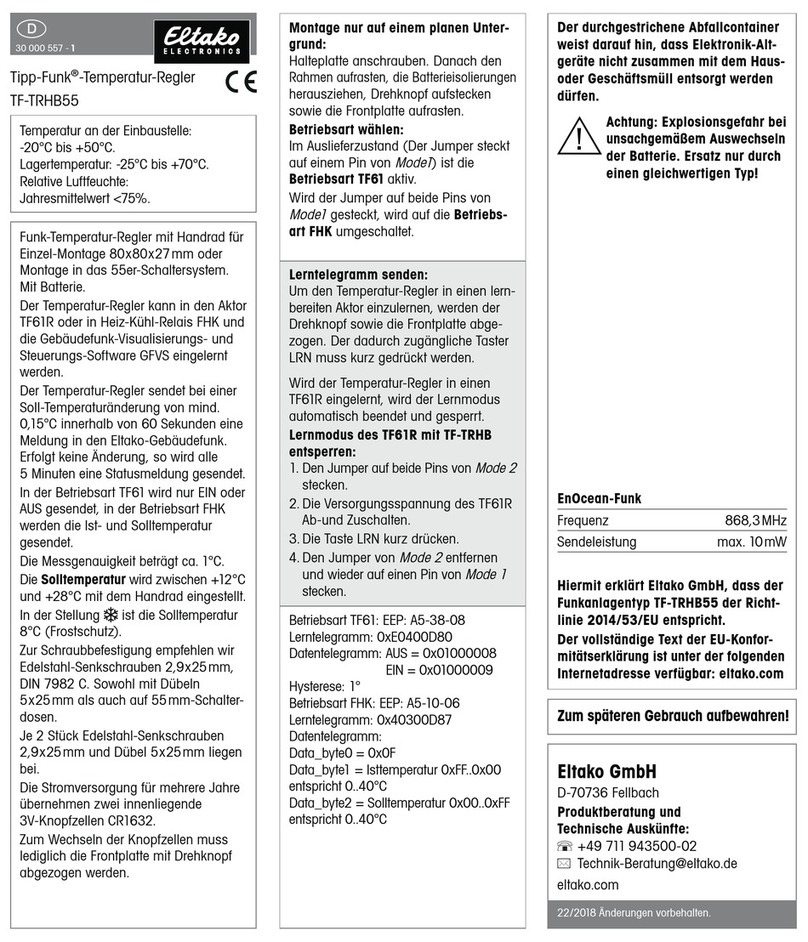

PASSWORD

2 sec.

Hold for

SET/imposta

menu

" OPEr "

" ConF "

menu

Tenere premuto

per 2 sec.

EXIT /

USCITA

men˘

"ConF"

"OPEr"

or/oppure

Longer

Hold

2 sec.

Hold for

O

2 sec.

Hold for Next

Group

Previous

Group

PARAMETER GROUPS

Next

Parameter

Previous

Parameter

PARAMETERS

Value

Decrease

Value

Increase

SET PARAMETER

RO

R

GRUPPI PARAMETRI PARAMETRI IMPOSTA PARAMETRO

gruppo precedente

parametro

precedente

incrementa

valore

parametro

seguente

decrementa

valore

gruppo seguente

premere per 2sec

+ a lungo

premere

OUTPUTS CONFIGURATION

The instrument’s outputs can be programmed

by entering the group of parameters “]Out,

where the relative parameters “O1F” and “O2F”

(depending on the number of outputs available

on the instrument) are located.

The outputs can be set for the following func-

tions :

• Main control output (1.rEG)

• Secondary control output (2.rEG)

• Alarm output normally open (ALno)

• Alarm output normally closed (ALnc)

• Alarm output normally closed with led reverse

indication (ALni)

• Output deactivated (OFF)

The coupling outputs number outputs – number

alarms can be made in the group referring to

the alarm to the alarm (“]AL1”).

ON/OFF CONTROL (1REG)

All the parameters referring to the ON/OFF

control are contained in the group “]rEG”.

This type of control can be obtained by pro-

gramming par."Cont" = On.FS or = On.FA and

works on the output programmed as 1.rEG,

depending on the measure, on the active Set

Point “SP”, on the functioning mode "Func” and

on the hysteresis "HSEt".

The instrument carries out an ON/OFF control

with symmetric hysteresis if “Cont" = On.FS or

with asymmetrical hysteresis if “Cont” = On.Fa.

The control works in the following way : in the

case of reverse action, or heating

(“FunC”=HEAt), it deactivates the output, when

the process value reaches [SP + HSEt] in case of

symmetrical hysteresis, or [SP] in case of asym-

metrical hysteresis and is then activated again

when the process value goes below value [SP -

HSEt].

Vice versa, in case of direct action or cooling

("Func”=CooL), it deactivates the output, when

the process value reaches [SP - HSEt] in case of

symmetrical hysteresis, or [SP] in case of asym-

metrical hysteresis and is activated again when

the process value goes above value [SP + HSEt].

NEUTRAL ZONE ON/OFF CONTROL (1REG -

2REG)

All the parameters referring to Neutral Zone

ON/OFF control are contained in the group

“]rEG”.

This type of control can be obtained when 2

outputs are programmed respectively as 1rEG

and 2rEG and the par. “Cont” = nr .

The Neutral Zone control is used to control

plants in which there is an element which caus-

es a positive increase (ex. Heater, humidifier,

etc.) and an element which causes a negative

increase (ex. Cooler, de-humidifier, etc).

The control functions works on the pro-

grammed outputs depending on the measure-

ment, on the active Set Point “SP” and on the

hysteresis "HSEt".

The control works in the following way : it deac-

tivates the outputs when the process value

reaches the Set Point and it activates the output

1rEG when the process value goes below value

[SP - HSEt], or it activates the output 2rEG when

the process value goes above [SP + HSEt].

Consequently, the element causing a positive

increase has to be connected to the output pro-

grammed as 1rEG while the element causing a

negative increase has to be connected to the

output programmed as 2rEG.

If 2rEG output is used to control compressor is

possible to use the “Compressor Protection”

function that has the meaning to avoid com-

pressor “short cycles”.

This function allows a control by time on the

output 2rEG activation, independently by the

temperature control request.

The protection is a “delayed after deactivation”

type.

This protection permits to avoid the output

activation for a time programmable on par.

“CPdt” (expressed in sec.); the output activation

will occurs only after the elapsing of time

“CPdt”.

The time programmed on parameter “CPdt” is

counted starting from the last output deactiva-

tion.

Obviously, whether during the time delay

caused by the compressor protection function,

the regulator request should stop, the output

activation foreseen after time “CPdt” would be

erased.

The function is not active programming “CPdt”

=OFF.

The led relative to 2rEG output blinks during

the phases of output activation delay, caused by

“Compressor Protection” function.

SINGLE ACTION PID CONTROL (1REG)

All the parameters referring to PID control are

contained in the group “]rEG”.

The Single Action PID control can be obtained

by programming par."Cont" = Pid and works on

the output 1rEG depending on the active Set

Point “SP”, on the functioning mode "Func” and

on the instrument’s PID algorithm with two

degree of freedom.

In order to obtain good stability of the process

variable, in the event of fast processes, the cycle

time “tcr1” has to have a low value with a very

frequent intervention of the control output.

In this case use of a solid state relay (SSR) is

recommended for driving the actuator.

EWTQ 905 3/8

OUT

SP1

PV

off

ON

HEAt - On.FA

OUT

time

HSEt

SP1

PV

HSEt

time

CooL - On.FA

ON ON ON ON ON

off off off

CooL - On.FSHEAt - On.FS

ONON

OUT

SP1

off

PV

off

ON

HSEt

time

OUT ON

SP1

PV

ON

off off

ON

time

HSEt

HSEt HSEt

1.rEG 1.rEG

1.rEG1.rEG

0N

OUT 2.rEG

(cooling)

OUT 1.rEG

(heating)

SP1

PV

off

0N

off

off

off

0N time

HSEt

HSEt

,,

,,,,

,,,,,

,,,,,

,,,,

,,,

,

,,,

,,

,

,

,,

,

,,

,,

,

,,

,,,,

,,

,,

,,,,

,,

,

,,

,,

,

,,

,,

,

,,

,,,,

,,

The Single Action PID control algorithm fore-

sees the setting of the following parameters :

"Pb" – Proportional Band

"tcr1" – Cycle time of the output 1rEG

"Int" – Integral Time

"rS" – Manual Reset (if “Int =0 only)

"dEr" – Derivative Time

“FuOC” - Fuzzy Overshoot Control

This last parameter allows the variable over-

shoots at the start up of the process or at the

changing of the Set Point to be avoided.

Please remember that a low value on this para-

meter reduces the overshoot while a high value

increase it.

1: Value “FuOC” OK

2: Value “FuOC” too high

3: Value “FuOC” too low

DOUBLE ACTION PID CONTROL (1REG -

2REG)

All the parameters referring to PID control are

contained in the group “]rEG”.

The Double Action PID control is used to con-

trol plants where there is an element which

causes a positive increase (ex. Heating) and an

element which causes a negative increase (ex.

Cooling).

This type of control can be obtained when 2

outputs are programmed respectively as 1rEG

and 2rEG and the par. “Cont” = Pid.

The element causing a positive increase has to

be connected to the output programmed as

1rEG while the element causing a negative

increase has to be connected to the output pro-

grammed as 2rEG.

The Double Action PID control works on the

outputs 1rEG and 2rEG depending on the active

Set Point “SP” and on the instrument’s PID algo-

rithm with two degrees of freedom.

In order to obtain good stability of the process

variable, in case of fast processes, the cycle

times “tcr1” and “tcr2” have to have a low value

with a very frequent intervention of the control

outputs.

In this case use of solid state relays (SSR) to

drive the actuators is recommended.

The Double Action PID control algorithm needs

the programming of the following parameters :

• "Pb" – Proportional Band

• "tcr1" – Cycle time of the output 1rEG

• “tcr 2” – Cycle time of the output 2rEG

• "Int" – Integral Time

• "rS" – Manual Reset (if “Int =0 only)

• "dEr" – Derivative Time

• “FuOC” - Fuzzy Overshoot Control

• "Prat" - Power Ratio or relation between

power of the element controlled by output

2rEG and power of the element controlled by

output 1rEG.

AUTOTUNING AND SELFTUNING FUNCTIONS

All the parameters referring to the AUTO-TUN-

ING and SELF-TUNING functions are contained

in the group “]rEG”.

The AUTO-TUNING and SELF-TUNING functions

permit the automatic tuning of the PID con-

troller.

The AUTO-TUNING function permits the calcula-

tion of thePID parameters by means of a FAST

type tuning cycle and, at the end of this opera-

tion, the parameters are stored into the instru-

ment’s memory and remain constant during

control.

The SELF-TUNING function (rule based "TUNE-

IN") instead allows control monitoring and the

continuous calculation of the parameters during

control.

Both functions automatically calculate the fol-

lowing parameters :

"Pb" – Proportional Band

"tcr1" – Cycle time of the output 1rEG

"Int" – Integral Time

"dEr" – Derivative Time

“FuOC” - Fuzzy Overshoot Control

and, for the Double Action PID control, also :

“tcr 2” – Cycle time of the output 2rEG

"Prat" - Ratio P 2rEG/ P 1rEG

To activate the AUTO-TUNING function proceed

as follows :

1) Program and activate the desired Set Point.

2) Program par. "Cont" =Pid.

3) Program par. "Func" according to the process

to be controlled through output 1rEG.

4) Program an output as 2rEG if the instrument

controls a plant with double action

5) Program par. "Auto" as:

- "1” – if auto-tuning is desired automatically,

each time the instrument is switched on, on the

condition that the process value is lower (with

“Func” =HEAt) than [SP- |SP/2|] or higher (with

“Func” =CooL) than [SP+ |SP/2|].

- "2" – if auto-tuning is desired automatically,

the next time the instrument is switched on, on

the condition that the process value is lower

(with “Func” =HEAt) than [SP- |SP/2|] or higher

(with “Func” =CooL) than [SP+ |SP/2|], and

once the tuning is finished, the par. “Auto” is

automatically swapped to the OFF state

- "3" - if manual auto-tuning is desired, by

selecting par. “tunE” in the main menu or by

correctly programming key F as “USrb” = tunE.

In this case the auto-tuning starts without any

control on the process value condition. It is rec-

ommended to use this option, starting the auto-

tuning when the process value is as far as possi-

ble from the Set Point because, in order to fea-

ture the Auto-tuning FAST with its best perfor-

mances , it is preferable to respect this condi-

tion.

- "4" - if it’s desired to activate the autotuning

automatically at the end of programmed Soft-

Start cycle. The Autotuning will start at the con-

dition that the process value is lower (with

“Func” =HEAt) than [SP- |SP/2|] or higher (with

“Func” =CooL) than [SP+ |SP/2|].

6) Exit from the parameter programming.

7) Connect the instrument to the controlled

plant.

8) Activate the Auto-tuning by selecting par.

“tunE” in the main menu (or by correctly pro-

gramming key F ).

At this point the Auto-tuning function is activat-

ed and is indicated by the flashing led AT/ST.

The regulator carries out several operations on

the connected plant in order to calculate the

most suitable PID parameters.

If “Auto” = 1 or “Auto” = 2, and if, at the Auto-

tuning start, the condition for the lower process

value is not found (with “Func” =HEAt) than

[SP- |SP/2|] or higher (with “Func” =CooL) than

[SP+ |SP/2|], the display will show “ErAt” and

the instrument will be swapped to normal con-

trol conditions according to the previously pro-

grammed parameters.

The Auto-tuning cycle duration has been limited

to 12 hours maximum.

If Auto-tuning is not completed within 12 hours,

the instrument will show "noAt" on the display.

In case of probe error, the instrument automati-

EWTQ 905 4/8

0N

tcr1

1.rEG

(HEat)

SP1

PV

tcr1

off

tcr1tcr1tcr1 tcr1

0N

off off

0N

offoff

0N 0N

tcr1

off

0N 0N

time

OUT

2

1

3

SP1

PV

time

cally stops the cycle in progress.

The values calculated by Auto-tuning are auto-

matically stored in the instrument’s memory at

the end of the correct PID parameters tuning.

To activate the SELF-TUNING function proceed

as follows

1) Program and activate the desired Set Point.

2) Program par. "Cont" =Pid.

3) Program par. "Func" according to the process

to be controlled through output 1rEG.

4) Program an output as 2rEG if the instrument

controls a dual-action plant

5) Program par. "SELF" = yES

6) Exit from the parameter programming.

7) Connect the instrument to the controlled

plant.

8) Activate Self-tuning selecting par. “tunE” in

the main menu (or by correctly programming

key F).

When the Self-tuning function is active, the led

AT/ST is permanently lit up and all the PID para-

meters ("Pb", "Int", "dEr", etc.) are no longer

visualized.

To stop the Auto-tuning cycle or deactivate the

Self-tuning function select one of the control

types : "rEG", "OPLO" or "OFF" from the menu

“SEL”. If the instrument is switched off during

Auto-tuning or with the Self-tuning function

activated, these functions will remain activated

the next time it is switched on.

DYNAMIC SET POINT (RISE RAMP)

All the parameters referring to the ramps func-

tioning are contained in the group “]rEG”.

It is possible to reach the set point in a prede-

termined time (in any case longer than the time

the plant would naturally need). This could be

useful in those processes (heating or chemical

treatments, etc.) where the set point has to be

reached gradually, in a predetermined time.

Once the instrument has reached the first Set

Point (SP1) it is possible to have automatic

switching to the second Set Point (SP2) after a

set time, thus obtaining a simple automatic

thermic cycle.

These functions are available for all the pro-

grammable controls (PID single and double

action, ON/OFF and Neutral Zone ON/OFF).

The function is determined by the following

parameter:

"SLor" - Gradient of rise ramp (Process value <

Set point) expressed in unit/minute.

Note: In case of PID control, if Auto-tuning is

desired whilst the ramp function is active, this

will not be carried out until the tuning cycle has

been completed.

It is therefore recommended that Auto-tuning

be started avoiding activating the ramp function

and, once the tuning is finished, deactivate

Auto-tuning (“Auto” = OFF), program the

desired ramps and, if it automatic tuning is

desired, enable the Self-tuning function.

Examples with starts from values lower than

SP and with decreasing of SP.

EWTQ 905 5/8

LoAb

off

ON

AL1

AL1

PV

HiAb

HAL1

time

off

ON

AL1

PV

time

HAL1

off off

ON

OUT

off off

ON

OUT

AL1

SP1

[Unit]

PV

SP1 Value

change

SP1

time [min.]

SLor SLor

LoAb = ABSOLUTE LOW ALARM: The alarm is

activated when the process value goes below

the alarm threshold set on parameter "AL1”.

With this mode is possible to program the mini-

mum and the maximum set of “AL1” by “AL1L”

and “AL1H” parameters.

HiAb = ABSOLUTE HIGH ALARM: The alarm is

activated when the process value goes higher

than the alarm threshold set on parameter

"AL1". With this mode is possible to program

the minimum and the maximum set of “AL1”

by “AL1L” and “AL1H” parameters.

LodE

ON

off

PV

SP1

-AL1

HAL1

time

off

ON

SP1

AL1

PV

HidE

time

HAL1

ON

off off off off

ON

OUT

AL1 OUT

AL1

LHAb = ABSOLUTE BAND ALARM: The alarm

is activated when the process value goes under

the alarm threshold set on parameter "AL1L" or

goes higher than the alarm threshold set on

parameter "AL1H".

LodE = DEVIATION LOW ALARM: The alarm is

activated when the process value goes below

the value [SP + AL1]. With this mode is possible

to program the minimum and the maximum set

of “AL1” by “AL1L” and “AL1H” parameters.

LHAb

ON

off

AL1H

AL1L

PV

ON

time

off

HAL1

HAL1

SP1

AL1L

AL1H

PV

time

LHdE

HAL1

HAL1

off off

ON ON

off off

OUT

AL1 OUT

AL1

HidE = DEVIATION HIGH ALARM: The alarm is

activated when the process value goes above

the value [SP + AL1]. With this mode is possible

to program the minimum and the maximum set

of “AL1” by “AL1L” and “AL1H” parameters.

LHdE = DEVIATION BAND ALARM: The alarm

is activated when the process value goes below

the value [SP + AL1L] or goes above than the

value [SP + AL1H]

ALARM FUNCTIONING (AL1)

The alarm is depending on the process value

(AL1) and before to set his functioning it’s nec-

essary to establish to which output the alarm

has to correspond to.

First of all it’s necessary to configure, in the

parameters group “]Out”, the parameters rela-

tive to the outputs required as alarm (“O1F” ,

“O2F”) programming the parameter relative to

the desired output as follows :

= ALno if the alarm output has to be ON when

the alarm is active, while it’s OFF when the

alarm is not active

= ALnc if the alarm output has to be ON when

the alarm is not active, while it’s OFF when the

alarm is active

= ALni if the alarm output has to be ON when

the alarm is not active, while it is OFF when the

alarm is active but with reverse led indication

(led ON= alarm OFF).

Have now access at the group “]AL1”, and pro-

gram on par. “OAL1” , to which output the

alarm signal has to be sent.

The alarm functioning is instead defined by

parameters (see Group “]AL1” (parameters

relative to alarm AL1):

"AL1t" – ALARM TYPE : the alarm output can behave in six different ways.

USE CONDITIONS

The instrument CANNOT be used in dangerous

environments (flammable or explosive) without

adequate protection.

The installer must ensure that EMC rules are

respected, also after the instrument installation,

if necessary using proper filters.

Whenever a failure or a malfunction of the

device may cause dangerous situations for per-

sons, thing or animals, please remember that

the plant has to be equipped with additional

devices which will guarantee safety.

MECHANICAL MOUNTING

The instrument, in DIN case 48 x 48 mm, is

designed for flush-in panel mounting.

Make a hole 45 x 45 mm and insert the instru-

ment, fixing it with the provided special bracket.

We recommend that the gasket is mounted in

order to obtain the front protection degree as

declared. Avoid placing the instrument in envi-

ronments with very high humidity levels or dirt

that may create condensation or introduction of

conductive substances into the instrument.

Ensure adequate ventilation to the instrument

and avoid installation in containers that house

devices which may overheat or which may cause

the instrument to function at a higher tempera-

ture than the one permitted and declared.

Connect the instrument as far away as possible

from sources of electromagnetic disturbances

such as motors, power relays, relays, solenoid

valves, etc.

The instrument can be removed from its hous-

ing from the front side : it is recommended that

the instrument be disconnected from the

power supply when it is necessary to carry out

this operation.

ELECTRICAL CONNECTIONS

Warning! Never work on electrical connections

when the machine is switched on.

The instrument is equipped with screw terminal

boards for connection of electrical cables (one

conductor only per terminal for power connec-

tions): for the capacity of the terminals, see the

label on the instrument. The relay contacts are

voltage free.

Do not exceed the maximum current allowed;

in case of higher loads, use an appropriate con-

tactor. Make sure that power supply voltage

meets the instrument voltage.

It is also recommended that all the electrical

circuits connected to the instrument must be

protect properly, using devices (ex. fuses) pro-

portionate to the circulating currents.

It is strongly recommended that cables with

proper insulation, according to the working

voltages and temperatures, be used.

Furthermore, the input cable of the probe has

to be kept separate from line voltage wiring. If

the input cable of the probe is screened, it has

to be connected to the ground with only one

side.

TECHNICAL DATA - ELECTRICAL DATA

Power supply: 24, 115, 230 VAC, 24 VAC/VDC,

100... 240 VAC +/- 10%

Frequency AC: 50/60 Hz

Power consumption: 5 VA approx.

Input/s: 1 input for temperature probes: tc J,K;

RTD Pt 100 IEC; PTC KTY 81-121 (990 W @ 25

°C); NTC 103AT-2 (10KW @ 25 °C) or mV sig-

nals 0...50 mV, 0...60 mV, 12 ...60 mV or normal-

ized signals 0/4...20 mA, 0..1 V, 0/1...5 V ,

0/2...10 V.

Normalized signals input impedance: 0/4..20

mA: 51 W; mV and V: 1 MW

Output/s: Up to 2 outputs. Relay SPST-NO (8 A-

AC1, 3 A-AC3 / 250 VAC) ; or in tension to drive

SSR (8mA/ 8VDC).

Auxiliary supply output: 10 VDC / 20 mA Max.

Electrical life for relay outputs: 100000 operat.

Installation category: II

Measurement category: I

Protection class against electric shock: Class II

for Front panel

Insulation: Reinforced insulation between the

low voltage section (supply and relay outputs)

and the front panel; Reinforced insulation

between the low voltage section (supply and

relay outputs) and the extra low voltage section

(inputs, SSR outputs); No insulation between

input and SSR outputs.

MECHANICAL DATA

Housing: Self-extinguishing plastic, UL 94 V0

Dimensions: 48 x 48 mm DIN, depth 98 mm

Weight: 225 g approx.

Mounting: Flush in panel in 45 x 45 mm hole

Connections: 2 x 1 mm2 screw terminals block

Degree of front panel protection : IP 54 mount-

ed in panel with gasket

Pollution situation: 2

Operating temperature: 0 ... 50 °C

Operating humidity: 30 ... 95 RH% without con-

densation

Storage temperature: -10 ... +60 °C

FUNCTIONAL FEATURES

Control: ON/OFF, single and double action PID

Measurement range: according to the used

probe (see range table)

Display resolution: according to the probe used

1/0,1/0,01/0,001

Overall accuracy: +/- 0,5 % fs

Sampling rate: 130 ms.

Display: 4 Digit Red h 12 mm

PANEL CUT-OUT

EWTQ 905 6/8

PLEASE NOTE: The technical data included in this

document, related to measurement (range, accu-

racy, resolution, etc.) refer to the instrument

itself, and not to its equipment such as, for exam-

ple, sensors.

This means, for example, that sensor(s) error(s)

shall be added to the instrument’s one.

LIABILITY AND RESIDUAL RISKS

Eliwell & Controlli srl shall not be liable for

any damages deriving from:

- installation/use other than that prescribed

and, in particular, that which does not com-

ply with safety standards anticipated by regu-

lations and/or those given herein;

- use on boards which do not guarantee ade-

quate protection against electric shock, water

or dust under the conditions of assembly

applied;

- use on boards which allow access to dan-

gerous parts without the use of tools;

- tampering with and/or alteration of the

products;

DISCLAIMER

This manual and its contents remain the sole

property of Eliwell & Controlli s.r.l., and shall

not be reproduced or distributed without

authorization. Although great care has been

exercised in the preparation of this docu-

ment, Eliwell & Controlli s.r.l., its employees

or its vendors, cannot accept any liability

whatsoever connected with its use. Eliwell &

Controlli s.r.l. reserves the right to make any

changes or improvements without prior

notice.

45

min. 15 mm

PANEL CUTOUTS

RECOMMENDED

45

min. 15 mm

EWTQ 905 7/8

PARAMETERS TABLE

Par. Description Range Def.

Group “]SP” (parameters relative to the Set Point)

1 SP1 Set Point SPLL ÷ SPHL 0

2 SPLL Low Set Point -1999 ÷ SPHL -1999

3 SPHL High Set Point SPLL ÷ 9999 9999

Group “]InP” (parameters relative to the measure input)

4 SEnS Probe type input C :

J / CrAL / S / Ir.J / Ir.CA / Pt1 / 0.50 / 0.60 / 12.60 J

input E :

J / CrAL / S /Ir.J / Ir.CA / Ptc/ ntc / 0.50 / 0.60 / 12.60 Ptc

input I :

0.20 / 4.20 4.20

input V :

0.1 /0.5 / 1.5 / 0.10 / 2.10 0.10

5 SSC Low scale limit in case of input with V / I signals -1999 ÷ FSC 0

6 FSC High scale limit in case of input with V / I signals SSC ÷ 9999 0

7 dP Number of decimal figures Pt1 / Ptc / ntc: 0 / 1

norm sig.: 0 ÷ 3 0

8 Unit Temperature unit of measurement °C / °F °C

9 FiL Input digital filter 0FF÷ 20.0 sec. 0.1

10 OFSt Measuring Offset -1999 ÷ 9999 0

11 rot Rotation of the measuring straight line 0.000 ÷ 2.000 1.000

12 OPE Output power in case of measuring error -100 ÷ 100% 0

Group “]Out” (parameters relative to the outputs)

13 O1F Functioning of output 1

1.rEG / 2.rEG ALno / ALnc ALni / OFF 1.rEG

14 O2F Functioning of output 2 1.rEG / 2.rEG ALno / ALnc ALni / OFF ALno

Group “]AL1” (parameters relative to alarm AL1)

15 OAL1 Output where alarm AL1 is addressed Out1 / Out2 /OFF Out2

16 AL1t Alarm AL1 type LoAb / HiAb LHAb / LodE HidE / LHdE LoAb

17 AL1 Alarm AL1 threshold AL1L÷ AL1H 0

18 AL1L Low threshold band alarm AL1 or

Minimum set alarm AL1 for high or low alarm -1999 ÷ AL1H -1999

19 AL1H High threshold band alarm AL1 or

Maximum set alarm AL1 for high or low alarm AL1L ÷ 9999 9999

20 HAL1 Alarm AL1 hysteresis OFF ÷ 9999 1

21 AL1d Activation delay of alarm AL1 OFF ÷ 9999 sec. OFF

22 AL1i Alarm AL1 activation in case of measuring error no / yES no

Group “]rEG” (parameters relative to the control)

23 Cont Control type Pid / On.FA On.FS / nr Pid

24 Func Functioning mode output 1rEg HEAt / CooL HEAt

25 HSEt Hysteresis of ON/OFF control 0 ÷ 9999 1

26 CPdt Compressor Protection time for 2.rEG OFF÷ 9999sec. 0

27 Auto Autotuning Fast enable OFF / 1 / 2 / 3 / 4 1

28 SELF Selftuning enable no / yES no

29 Pb Proportional band 0 ÷ 9999 50

30 Int Integral time OFF ÷ 9999 sec. 200

31 dEr Derivative time OFF÷ 9999 sec. 50

32 FuOc Fuzzy overshoot control 0.00 ÷ 2.00 0,5

33 tcr1 Cycle time of output 1rEg 0.1 ÷ 130.0 sec. 20,0

34 Prat Power ratio 2rEg / 1rEg 0.01 ÷ 99.99 1.00

35 tcr2 Cycle time of 2rEg 0.1 ÷ 130.0 sec. 10.0

36 rS Manual reset -100.0÷100.0 % 0.0

37 SLor Gradient of rise ramp 0.00 ÷ 99.99 / InFunit/min. InF

Group “]PAn” (parameters relative to the user interface)

38 AdE Shift value for the shift index functioning OFF...9999 2

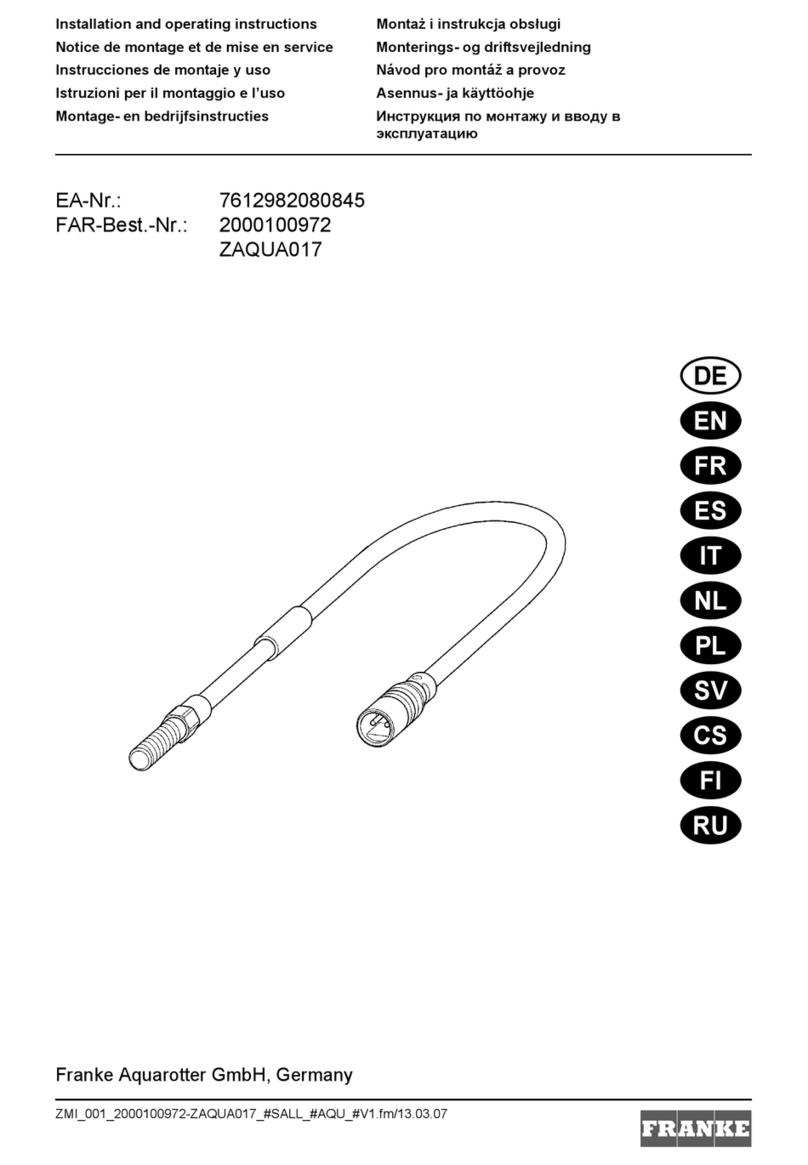

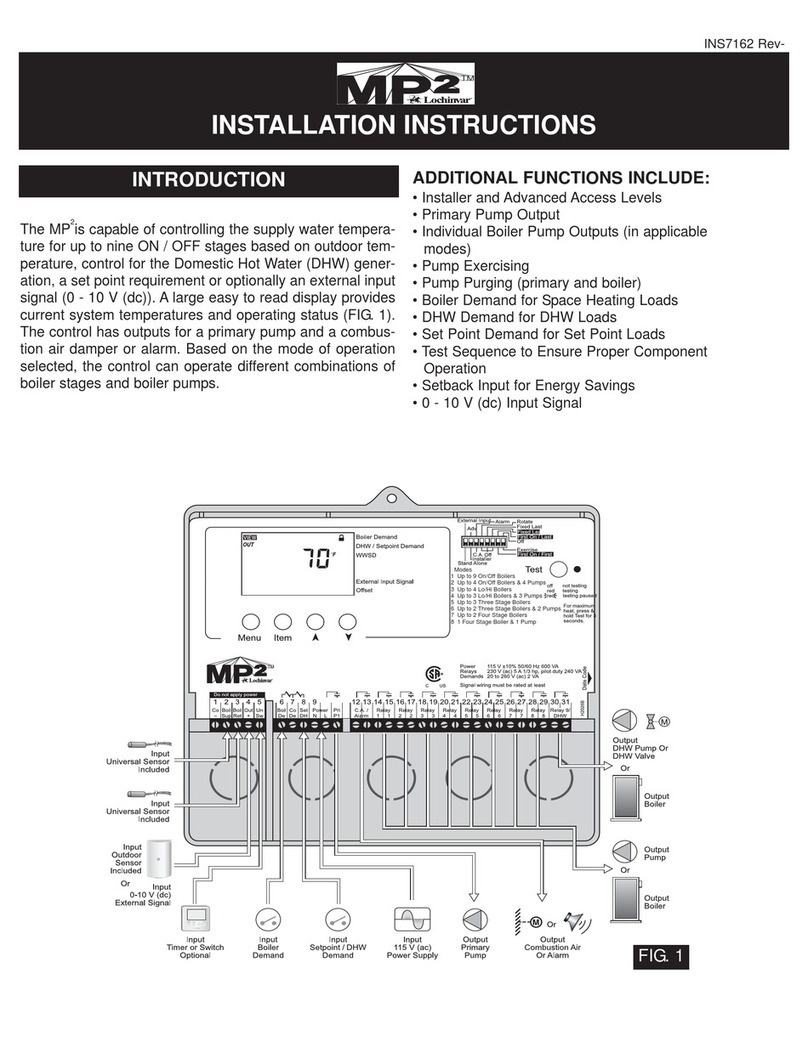

EWTQ 905 WIRING DIAGRAM

EWTQ 905

6

5

4

3

2

PtC/NtC

Pt100 / Ni100

TcJ / TcK

+–

1 2 3

12

11

10

9

81 2 3 12

17

1 2 3 4

V

+

I

0...1V

0/2...10V

0/1...5V

4…20 mA

SUPPLY

OUT1

OUT2

TcJ / TcK

+–

12

active

1 2 3 4

V

-

I

+10V

0...1V

0/2...10V

0/1...5V

4…20 mA passive

with ext gen.

TERMINALS

INPUTS

1 - 2 TCJ/TCK 1 +; 2 -

2 - 3 Pt100/Ni100

1 - 2 TCJ/TCK 1 +; 2 -

1 - 2 - 3 PtC/NtC

1 - 2 0…1V; 0/1…5V; 0/2…10V 1 +;

1 - 2 0/4…20mA active 1 +;

1 - 4 4…20mA passive 4+ (+10Vdc)

OUTPUTS

7 - 8 SUPPLY

9 - 10 OUT2 9 COMMON; 10 N.O.

11 - 12 OUT1 11 COMMON; 12 N.O.

EWTQ 905 8/8

Error

- - - -

uuuu

oooo

ErAt

noAt

ErEP

Reason

Probe interrupted

The measured variable is under the probe’s limits (under-range)

The measured variable is over the probe’s limits (over-range)

Auto-tuning not possible because the process value is higher (with “Func” =HEAt)

than [SP- |SP/2|] or lower (with “Func” =CooL) than [SP+ |SP/2|].

Auto-tuning not finished within 12 hours

Possible anomaly of the EEPROM memory

ERROR SIGNALLING

Action

Verify the correct connection

between probe and instrument

and then verify the correct func-

tioning of the probe

Restart Auto-tuning when the

process value conditions allow it

Check the working of probe and

actuator and try again to start

Auto-tuning

Push key set

ALARMS

Eliwell & Controlli s.r.l.

via dell'Industria, 15 Zona Industriale Paludi

32010 Pieve d'Alpago (BL) ITALY

Telephone +39 0437 986111

Facsimile +39 0437 989066

Internet http:/www.eliwell.it

1/2004 eng

cod. 9IS23045

In error conditions, the instrument provides an output power as

programmed on par “OPE” and activates the desired alarms, if

the relative parameters “ALni” have been programmed = yES.

44.5

98

48

OUT2

48

ST

AT

OUT1 -+

=

9.5

SET

EWTQ 905

Fset

MAX 9 mm

PANEL + GASKET BRACKET TYPE 1 BRACKET TYPE 2

,,,

,,,,

,,,,,

,,,,

,,,

MECHANICAL DIMENSIONS,

PANEL CUT-OUT AND

MOUNTING [MM]

INPUT

tc J

tc K

Pt100 (IEC)

PTC (KTY81-121)

NTC (103-AT2)

0..20 mA

4..20 mA

0 ... 50 mV

0 ... 60 mV

12 ... 60 mV

0 ... 1 V

0 ... 5 V

1 ... 5 V

0 ... 10 V

2 ... 10 V

available on

models:

C,E

C,E

C,E

E

E

I

I

C,E

C,E

C,E

V

V

V

V

V

MEASURING RANGE TABLE

input

“dP”= 1, 2, 3

- - - -

- - - -

-199.9 ... 850.0 °C

-199.9 ... 999.9 °F

-55.0 ... 150.0 °C

-67.0 ...302.0 °F

-50.0 ... 110.0 °C

-58.0 ... 230.0 °F

-199.9 ... 999.9

-19.99 ... 99.99

-1.999 ... 9.999

-199.9 ... 999.9

-19.99 ... 99.99

-1.999 ... 9.999

-199.9 ... 999.9

-19.99 ... 99.99

-1.999 ... 9.999

-199.9 ... 999.9

-19.99 ... 99.99

-1.999 ... 9.999

-199.9 ... 999.9

-19.99 ... 99.99

-1.999 ... 9.999

-199.9 ... 999.9

-19.99 ... 99.99

-1.999 ... 9.999

-199.9 ... 999.9

-19.99 ... 99.99

-1.999 ... 9.999

-199.9 ... 999.9

-19.99 ... 99.99

-1.999 ... 9.999

-199.9 ... 999.9

-19.99 ... 99.99

-1.999 ... 9.999

-199.9 ... 999.9

-19.99 ... 99.99

-1.999 ... 9.999

MEASURING RANGE

input

“dP” = 0

0 ... 1000 °C

32 ... 1832 °F

0 ... 1370 °C

32 ... 2498 °F

-200 ... 850 °C

-328 ... 1562 °F

-55 ... 150 °C

-67 ... 302 °F

-50 ... 110 °C

-58 ... 230 °F

-1999 ... 9999

-1999 ... 9999

-1999 ... 9999

-1999 ... 9999

-1999 ... 9999

-1999 ... 9999

-1999 ... 9999

-1999 ... 9999

-1999 ... 9999

-1999 ... 9999

parameter

SenS=

J

CrAl

Pt1

Ptc

ntc

0.20

4.20

0.50

0.60

12.60

0.1

0.5

1.5

0.10

2.10

EWTQ 905 PASSWORD = 381

Table of contents

Other Eliwell Temperature Controllers manuals