Eliwell EWPC 961 User manual

The EWPC 961 is a temperature

controller specifically designed for

refrigeration applications and pro-

vides time control for off-cycle de-

frost management.

GENERAL DESCRIPTION

The EWPC 961 is a temperature controller

specifically designed for refrigeration appli-

cations and provides time control for off-

cycle defrost management.

It incorporates an output relay for com-

pressor control and a PTC sensor input.

A number of parameters are displayed al-

phanumerically to set up the instrument for

each specific application.

The EWPC 961 is supplied in the popular

“32x74” ELIWELL.

OPERATION

The EWPC 961 is designed to operate

strictly as a cooling control, which means

that the switching differential is positive:

the compressor cuts off at setpoint and is

started at a temperature of set plus differ-

ential. The on-board microprocessor pro-

vides several timing functions for the

defrost; the defrost cycle as well the de-

frost cycle duration are user selectable.

At the start of each defrost cycle, the com-

pressor is simply stopped, regardless of

the temperature control circuit.

In addition, the EWPC 961 offers several

system protection features, all easy to un-

derstand and easy to program.

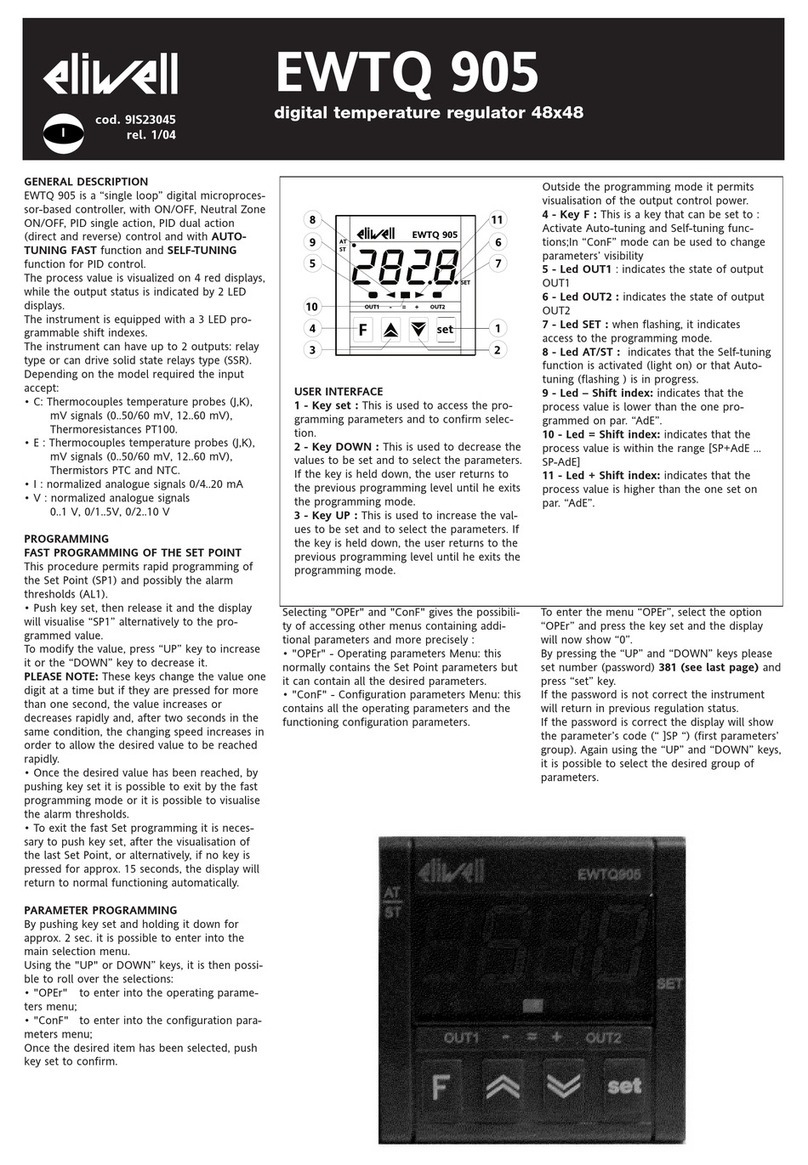

FRONT KEYPAD

SET: push to display the setpoint temper-

ature; the “DEF/SET” status light will blink.

The setpoint can be changed within 5 sec-

onds with the “UP” or “DOWN” button.

The control will automatically switch back

to normal operating mode within 5 sec-

onds; the last entered setpoint will stay in

memory.

UP: used to increase the setpoint value, as

well as the parameter when in program-

ming. When held down for a few seconds,

the change rate accelerates.

DOWN: same functions, except to de-

crease a value.

DEFROST: push to initiate a manual de-

frost cycle (override of programmed de-

frost start; programmed time resets to

zero). Manual defrost can not be started

while in setpoint or in parameter program-

ming mode. This button must be activated

for 3 seconds to start a defrost; the

“DEF/SET” status light will come on and

the compressor is stopped.

Led “COMP”: status light of the compres-

sor output.

Led “DEF/SET”: blinks during setpoint

display/change. When Led is on the de-

frost is in progress.

PARAMETER PROGRAMMING

Programming is easily accessed by hold-

ing the “SET” button down for more than

4 seconds; the first parameter is displayed

while the status light “DEF/SET” remains

blinking during the programming period.

Other parameters are accessed with the

“UP” and “DOWN” button.

With the “SET” button, the actual setting of

each parameter is displayed. To change a

parameter setting, push the “SET” plus the

“UP” (or “DOWN”).

The system will automatically return to its

normal operating mode a few seconds af-

ter the programming procedure is com-

pleted or interrupted.

DESCRIPTION OF PARAMETERS

d: differential.

LS: Lower Set.

Setting of the lower user-access setpoint

limit.

HS: Higher Set.

Setting of the upper user-access setpoint

limit.

CA: CAlibration.

Temperature read-out offset to allow for

possible error due to probe location.

rP: relay Protection.

Select relay status in case of probe defect.

on = compressor ON in case of probe de-

fect;

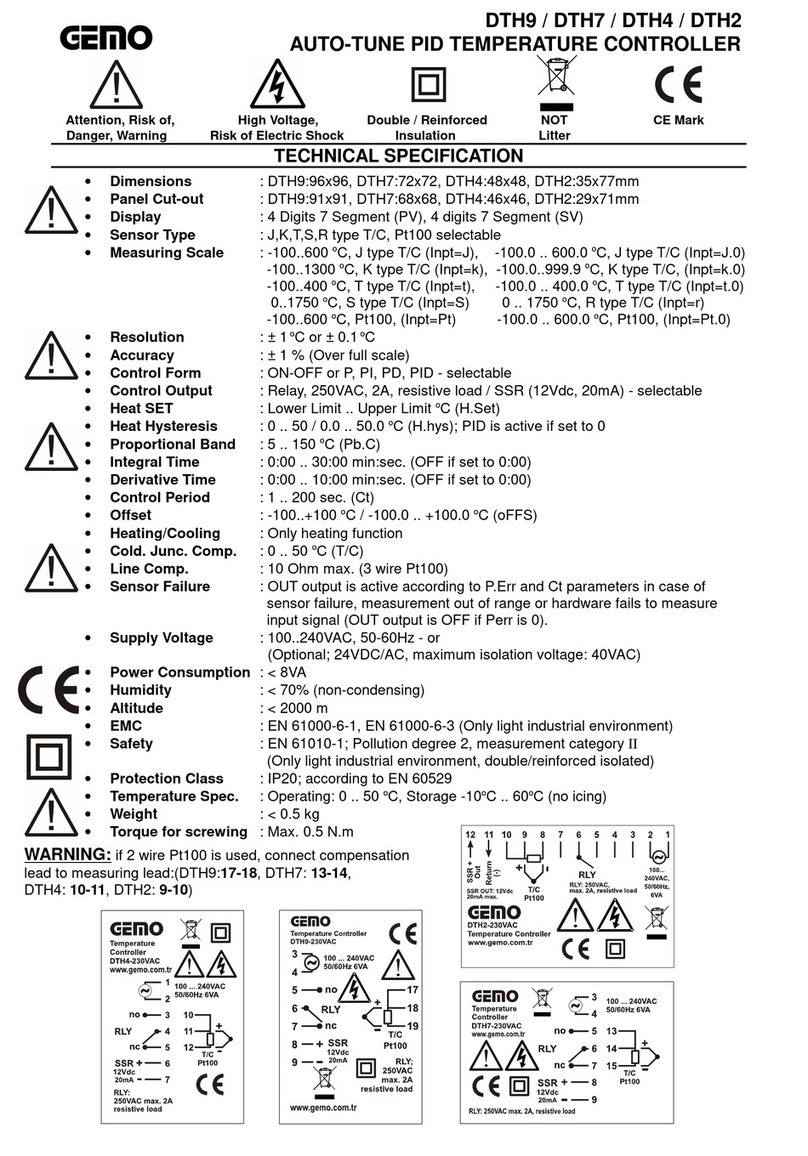

HOW IT IS MADE

• Housing: black ABS plastic, self-

estinguishing

• Dimensions: front 74x32 mm

(2.913x1.260"), depth 67 mm

(2.637")

• Protection: the instrument front-

panel is waterproof IP65; an op-

tional snap-on cover can be

supplied to provide additional pro-

tection of the rear terminal block

• Connections: screw terminal

block (2.5 mm2; one wire each ter-

minal onl)

• Display: 12.5 mm LED (0.50")

• Push buttons: located on front

panel

• Output: one (1) SPDT relay 8(3)A

250Va

• Input: PTC probe

• Resolution: 1 °C (°F)

• Accuracy: better than 0.5% of full

scale

• Power supply (depending on mod-

el): 12 Va/cor 24 Va/c

WHAT IT IS

EWPC 961

freezer controls

2EWPC 961 1/2001 eng

oF = compressor OFF in case of probe de-

fect.

PS: Protection System-short cycle.

Select type of compressor protection de-

sired (the actual time delay is set with the

next parameter):

0 = delay before start - in seconds;

1 = delay before start - in minutes;

2 = delay after stop - in minutes;

3 = delay between starts - in minutes.

Pt: Protection time.

Time delay setting for compressor short-

cycle protection; expressed in seconds (0

to 31) if PS = 0 or in minutes (0 to 31) if PS

> 0 (see parameter PS ).

dS: defrost System (computation).

dF = digifrost®Feature; defrost start time is

based on total compressor running time.

rt = real time; defrost initiation frequency is

based on real time.

Time between defrost starts is always the

same.

dI: defrost Interval.

Defrost start frequency in hours; the time is

calculated based on the selection of para-

meter “dS”.

dE: defrost Endurance.

Total (maximum) length of a defrost cycle,

expressed in minutes.

dL: display Lock.

Temperature display is locked in during a

defrost cycle.

n = no (read-out will continue to display the

actual temperature, even during defrost);

y = yes (read-out is locked in).

dr: display read-out.

Select the type of visualization in case of

temperature display lock during defrost

(see parameter “dL”).

C = the temperature displayed at the start

of a defrost is locked in and does not

change during this cycle.

dF = during the defrost the label “dF”

(deFrost) is displayed to indicate a defrost

is in progress.

do: defrost at (power) on.

Selects whether the system should go

through a defrost cycle at start-up (or after

a power failure).

n = no;

y = yes.

dd: defrost delay at (power) on.

Time delay of defrost at (power) on; ex-

pressed in minutes.

INSTALLATION

The instrument is designed for flush panel

mounting. Insert the unit through a

71x29 mm panel cut-out and affix with the

U-bracket supplied. The ambient tempera-

ture around the instrument should be kept

between –5 and 65 °C (23…149 °F).

Select a location which will not be subject

to high humidity or condensation and allow

some ventilation to provide cooling to the

instrument.

ELECTRICAL WIRING

The instrument is equipped with an internal

screw terminal block suitable for max

2.5 mm2wiring (one wire each terminal

only).

Make sure that the power supply corre-

sponds with the rating shown on the in-

strument, i.e. 12 Va/c±15% (VDE/UL

version) or 24 Va/c±15%.

The 2-wire PTC type probe does not re-

quire polarity and can easily be extended

by using common 2-lead wire.

It is strongly recommended to run the

probe cable separate from line voltage

wiring. Also, it is good practice to install the

tip of the probe in upright position, to avoid

moist from entering into the stainless steel

sensor housing.

The output relay contacts are voltage-free

and are suitable for in-line switching of

compressors up to 0.5 HP at 220 Va(or

0.25 HP to 110 Va). For larger loads, an

external contactor must be used.

ERROR ANNOUNCIATION

The instrument is provided with only one

error message “E1”, both in case of short-

ed sensor and in case of sensor break, or

sensor absence. The “E1” error message

also appears in the event of underrange of

the system temperature (–55).

In the event of overrange of the system

temperature (99), the “99” value will blink

first, then the “E1” error message will be

displayed in case the probe will exceed the

value of 150

TECHNICAL DATA

Housing: black ABS plastic, self-estin-

guishing.

Dimensions: front 74x32 mm

(2.913x1.260"), depth 67 mm (2.637").

Mounting: flush panel mount with mount-

ing bracket.

Protection: the instrument frontpanel is

waterproof IP65; an optional snap-on cov-

er can be supplied to provide additional

protection of the rear terminal block.

Connections: screw terminal block

EWPC 961

16 7 8 9

thermostat

PTC probe

compressor

POWER SUPPLY

53

DEFAULT SETTINGS - STANDARD MODELS

Parameter

d

LS

HS

CA

rP

PS

Pt

dS

dI

dE

dL

dr

do

dd

Description

differential

Lower set

Higher set

CAlibration

relay Protection

Protection System

Protection time

defrost System

defrost Interval

defrost Endurance

display Lock

defrost read-out

defrost at (power) on

defrost delay at (power) on

Range

1…15

–55…99

–55…99

–15…15

on / oF

0…3

0…31

dF / rt

0…31

1…99

n / y

C / dF

n / y

0…99

Default

2

–55

99

0

oF

0

0

rt

8

15

y

C

n

0

Unit

°C / °F

°C / °F

°C / °F

°C / °F

flag

number

seconds

flag

hours

minutes

flag

flag

flag

minutes

CONNECTIONS

3EWPC 961 1/2001 eng

(2.5 mm2; one wire each terminal only).

Display: 12.5 mm LED (0.50").

Push buttons: located on front panel.

Data storage: non-volatile EEPROM

memory.

Operating temperature: –5…65 °C

(23…149 °F).

Storage temperature: –30…75 °C

(–22…167 °F).

Output: one (1) SPDT relay 8(3)A 250V a.

Input: PTC probe.

Resolution: 1 °C (°F).

Accuracy: better than 0.5% of full scale.

Power supply (depending on model):

12 Va/c±15% or 24 Va/c±15%.

DISCLAIMER

This manual and its contents remain the

sole property of Invensys Controls Italy

s.r.l., and shall not be reproduced or dis-

tributed without authorization. Although

great care has been exercised in the

preparation of this document, Invensys

Controls Italy s.r.l., its employees or its

vendors, cannot accept any liability what-

soever connected with its use. Invensys

Controls Italy s.r.l. reserves the right to

make any changes or improvements with-

out prior notice.

Invensys Controls Italy s.r.l

via dell'Industria, 15 Zona Industriale Paludi

32010 Pieve d'Alpago (BL) ITALY

Telephone +39 0437 986111

Facsimile +39 0437 986066

Email [email protected]

Internet http:/www.climate-eu.invensys.com

1/2001 eng

cod. 9IS40120

Other Eliwell Temperature Controllers manuals