2016 British Columbia Design & Installation Manual 14 www.eljen.com

2.6 Commercial Systems – Cont.

2.6.4 SITE DRAINAGE AND STORMWATER: Larger flow onsite absorption systems can be impacted by

site drainage from above the systems area. The additional effluent can also increase the groundwater

mound down slope. Recharge systems such as the GSF must be designed and located so that they can

accept precipitation and the specified wastewater volume. Control and diversion of up-slope storm water

is normally included in the design. Understanding the storm water flows onto and out of the system is

essential to successful management of these systems.

Landscape position and slope impact the drainage because the gradient frequently changes with the

slope of the land, especially if placed above a restrictive layer. The depth and permeability of each soil

layer above the restrictive horizon impacts the groundwater mound. For example, upper horizons may be

fairly permeable and accept precipitation easily. If these layers are above a more restrictive horizon, a

perched water table will develop whenever it rains. Movement of this perched groundwater can influence

the disposal system and if not recognized will result in surfacing effluent. Interception and diversion of the

groundwater is therefore necessary with larger systems especially over restrictive soils to insure

acceptance of the treated effluent under wet conditions.

Down slope hydraulic capacity is also an important consideration with larger systems. For example, a

system may be located on a free draining slope but down slope conditions show a perched water table

due to a reduced hydraulic gradient. Design limits and linear loading must be considered and these limits

should be based on the limitations of these down slope soils and gradient. Ideally systems are located

with diverging topography that reduces the linear loading and results in the effluent moving down slope.

2.6.5 MULTI-FAMILY DWELLINGS: Condominiums, apartments, trailer parks, RV campgrounds and other

systems with domestic type wastewater, designers must have reference to 2.6.2 above and the maximum

loading specified in Section 2.1.10. Make sure that garbage disposals are not being installed or specified.

Appropriate sized septic tank effluent filters are required for all commercial systems.

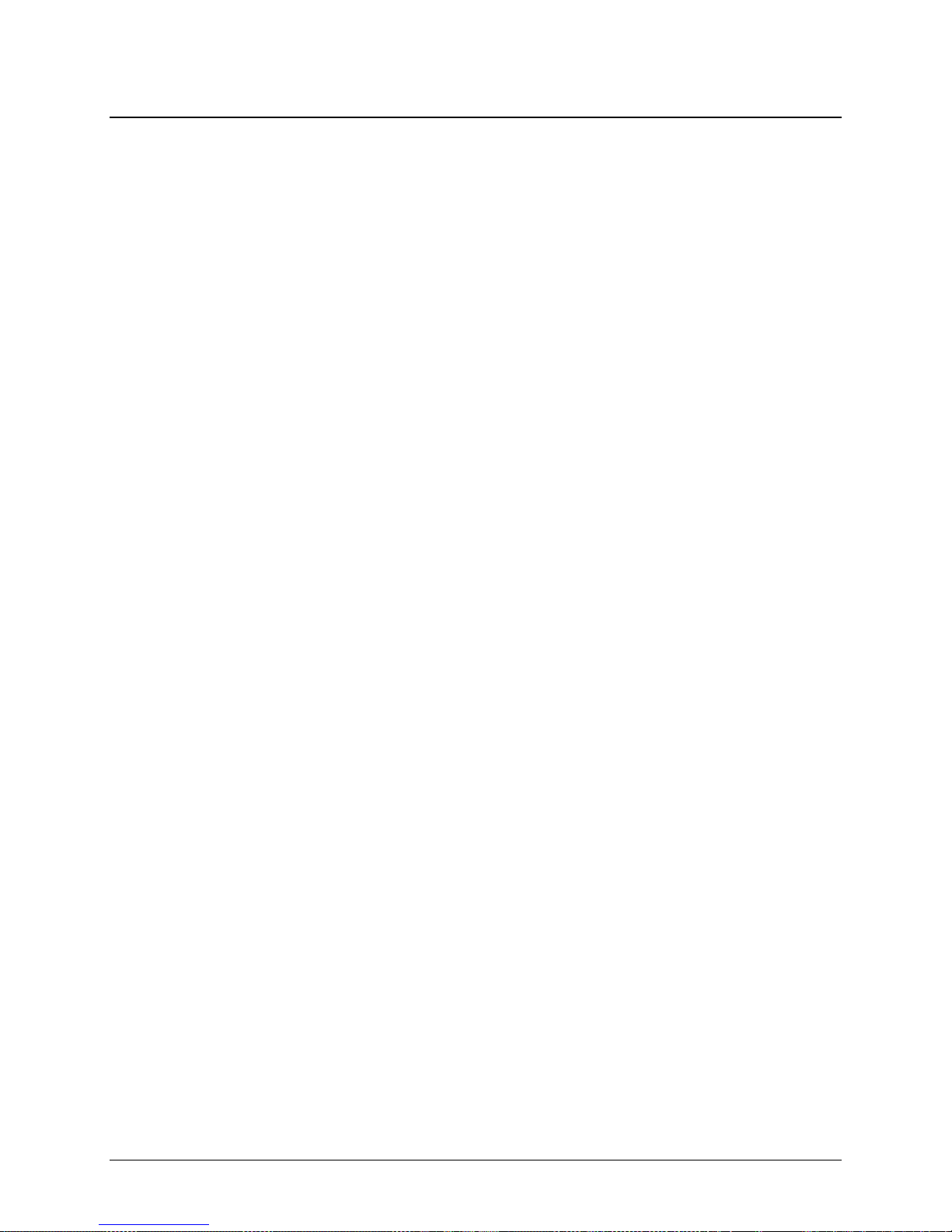

2.6.6 RESTAURANTS: Restaurant systems, designers must have reference to 2.6.2 above for system

sizing Designs shall use 1 more appropriately sized grease filters at the outlet of the grease trap as required

by BC Regulation. Specify grease traps whose outlets are compatible with the filter designed or allow for

external filter between grease trap and septic tank. Combine kitchen flow with black water flow in 1 or more

septic tanks. Multiple tanks are preferred. Install 1 or more appropriately sized septic tank effluent filter(s) at

the outlet of the final septic tank.

2.6.7 LAUNDROMATS: Laundromat systems, designers must have reference to 2.6.2 above for system

sizing. Designs shall use 1 or more appropriately sized filter(s) to help remove suspended lint.

2.6.8 OTHER COMMERCIAL SYSTEMS: Other non-residential systems, e.g. schools, butcher shops, milk

or ice cream facilities etc. may require more conservative sizing. The designer is advised to contact BWD

Engineering Inc. (604-789-2204) for recommendations on sizing prior to design and submission of plans to

the local authority.

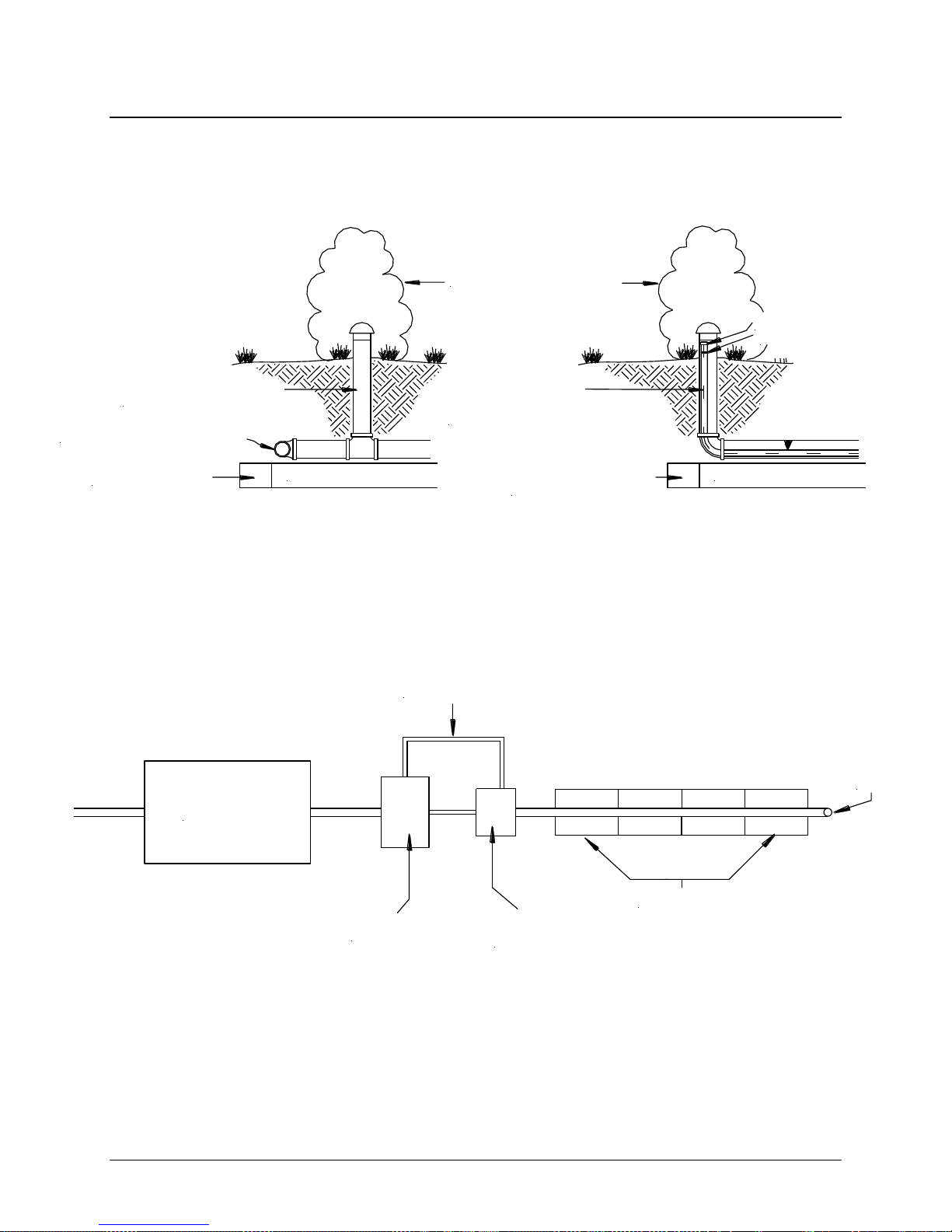

2.6.9 SYSTEM VENTING: It is recommended that all commercial systems be designed with vents.

Systems with high waste strength and systems with more than 46 cm of cover material as measured from

the top of the GSF modules to finished grade require venting. Designers that include vents in their

designs often specify the use of Granular Activated Carbon or Charcoal (GAC) filters to ensure that septic

odors do not become a nuisance. Designers should verify with the GAC filter manufacturer or supplier to

ensure that the filter will allow airflow from both directions of the filter. Otherwise the filter will block airflow

and the vent will not be effective in supplying enough oxygen that the system demands for long term

performance.

2.6.10 COMMERICAL SYSTEM PLANS REVIEW: BWD Engineering Inc. (604-789-2204), Eljen

Corporation’s Canadian Technical Representative, is available for a no cost review of any commercial

GSF plan prior to submission for approval from the local approving authority. Overall responsibility for

system design remains with the licensed designer and/or professional.