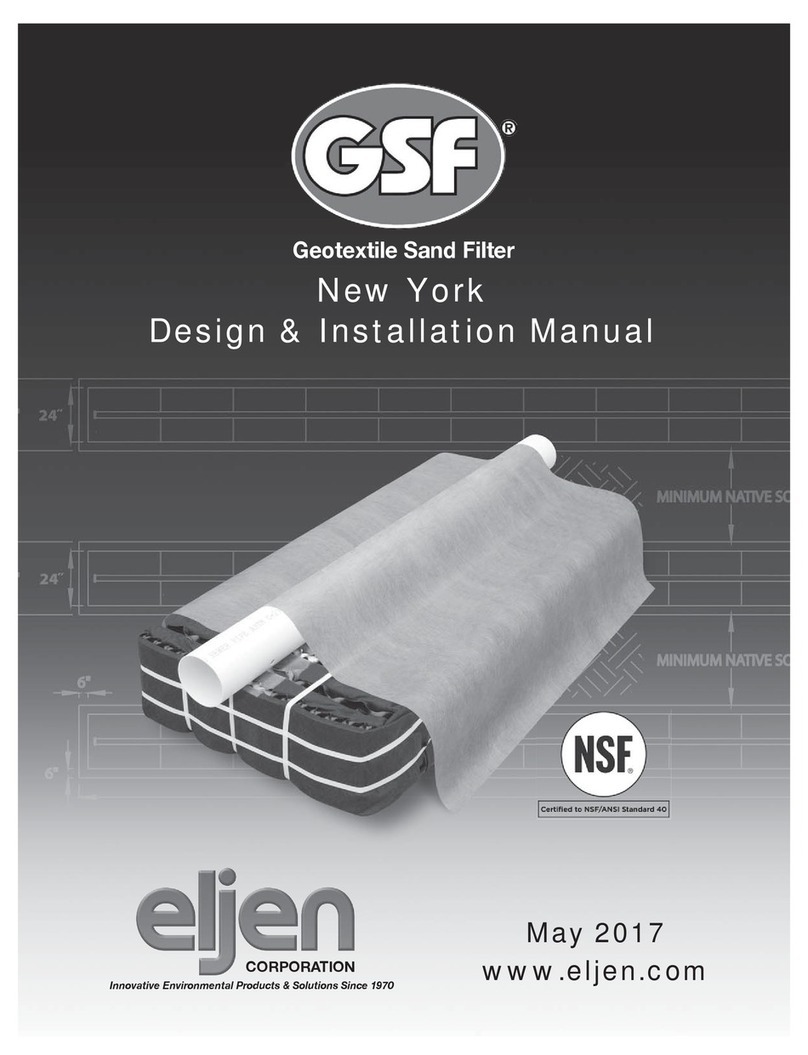

2013 Virginia Design & Installation Manual 10 www.eljen.com

1.0 Basic System Design

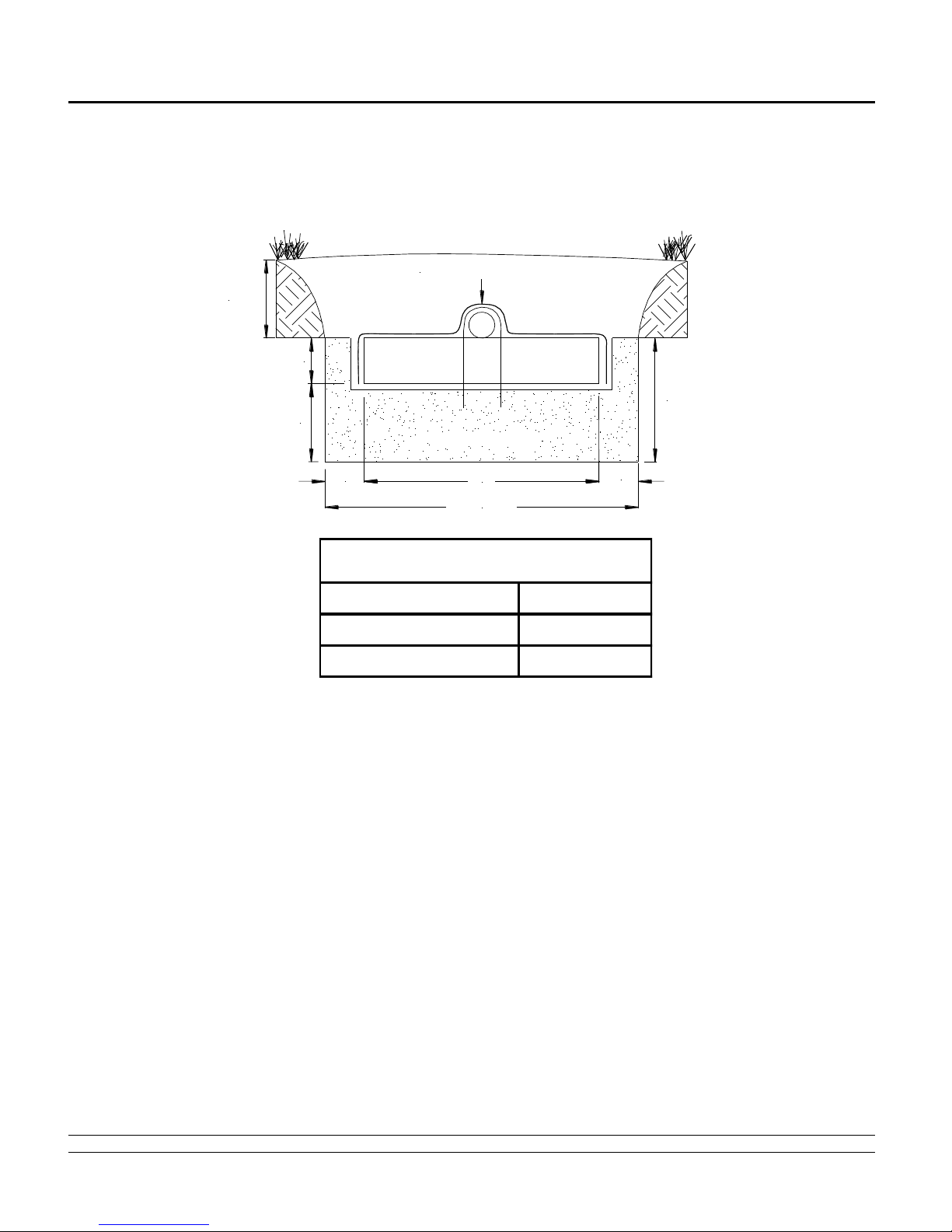

1.20 Separation Distances to Water Table: The separation distances between the infiltrative surface of a soil

absorption system and a water table is shown Figure 1 of this manual. *Note: The minimum vertical separation

distance to a limiting feature must be maintained across the entire modified trench/pad area.

1.21 Separation Distance to Impervious Strata for Shallow Placed Systems: The separation distance to an

impervious strata may be reduced from 18 inches to a distance not less than 12 inches below the Modified Trench or

PAD bottom when a professional engineer certifies in writing that they have evaluated the hydraulic capacity of the

site to disperse wastewater and that in their professional opinion, water mounding will not encroach on the

separation distance required as outlined in Figure 1 of this manual. *Note: The minimum vertical separation distance

to a limiting feature must be maintained across the entire modified trench/pad area.

1.22 Plans and Specifications: When plans conform to requirements of GMP #125, the requirements for formal

plans and specification required in 12 VAC 5-610-250.C is waived. Typical treatment system drawings and

specifications are shown at the end of this manual. When used in conjunction with a permit sketch, site specific

specifications, and manufacturer installation criteria, these documents will normally be sufficient to assure a system

can be properly installed. In some instances where a complex system is encountered, formal plans and

specifications may be required. This determination is left to the discretion of the District Health Department.

2.0 Systems for Level Sites

2.1 SYSTEM CONFIGURATIONS: Design level in-ground or raised PAD systems with 12-inch minimum spacing

between module rows. For Modified Trenches, center-to-center spacing must be no less than three times the width

of the trench for slopes up to 10%. For slopes over 10%, add one extra foot of separation for every 10% increase in

slope. The Specified Sand, Modified Trench, PAD, GSF modules, and distribution pipes are installed level at their

design elevations.

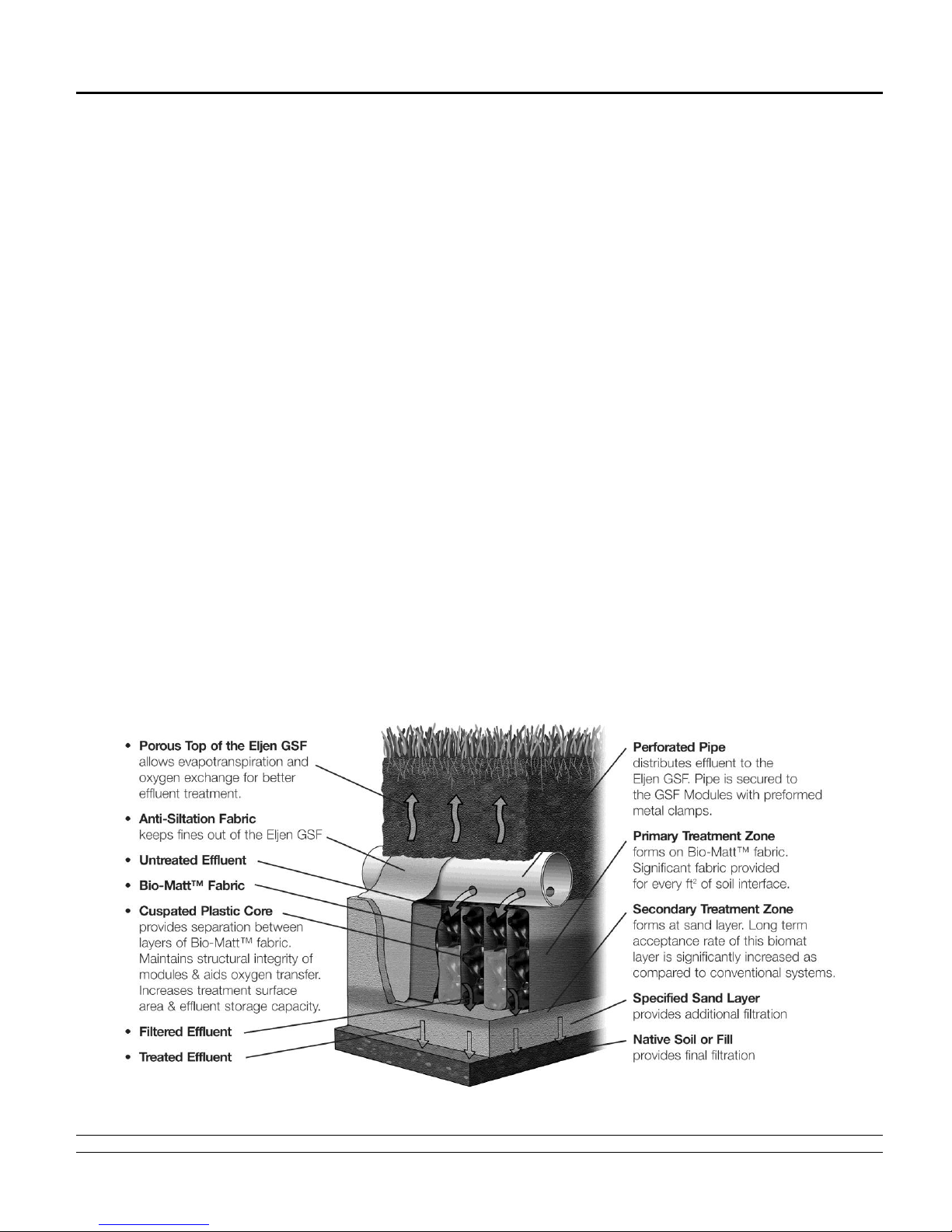

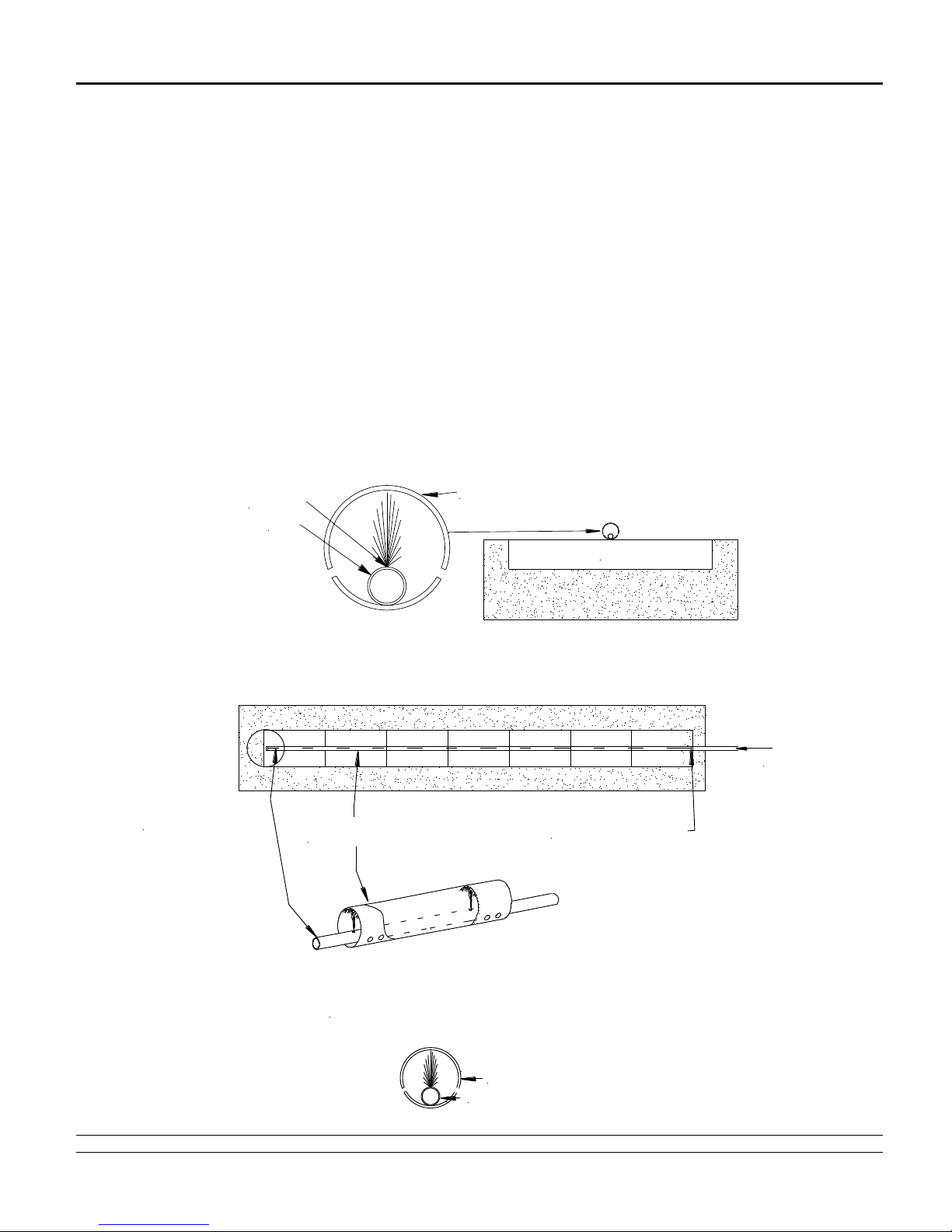

2.2 DISTRIBUTION PIPE LAYOUT: Perforated SDR-35 pipe or equivalent runs along the center of the modules for

both Modified Trench and PAD configurations. Ends for PAD systems should be connected with non-perforated pipe

at the distal end of the system as shown in Figure 5. For PAD systems over 40 feet in length, a non-perforated

“cross-over” connection should be installed perpendicular to the length of the STA connecting all distribution pipes at

the midway point of the system.

3.0 Systems for Sloped Sites

3.1 ROW SPACING: For PAD Systems, center-to-center and center-to-edge spacing will vary per design. For

slopes up to 15% a minimum of 1 foot edge to edge module spacing is required. For slopes over 15% a minimum 2

foot edge to edge module spacing is required. The edge of module to toe of downhill slope spacing is based on the

Regulations or a minimum 3:1 slope requirement.

For Modified Trenches, center-to-center spacing must be no less than three times the width of the trench for slopes

up to 10%. For slopes over 10%, add one extra foot of separation for every 10% increase in slope.

Note: For proposed PAD sites with slopes greater than 25% - Professional Engineer consultation is recommended.

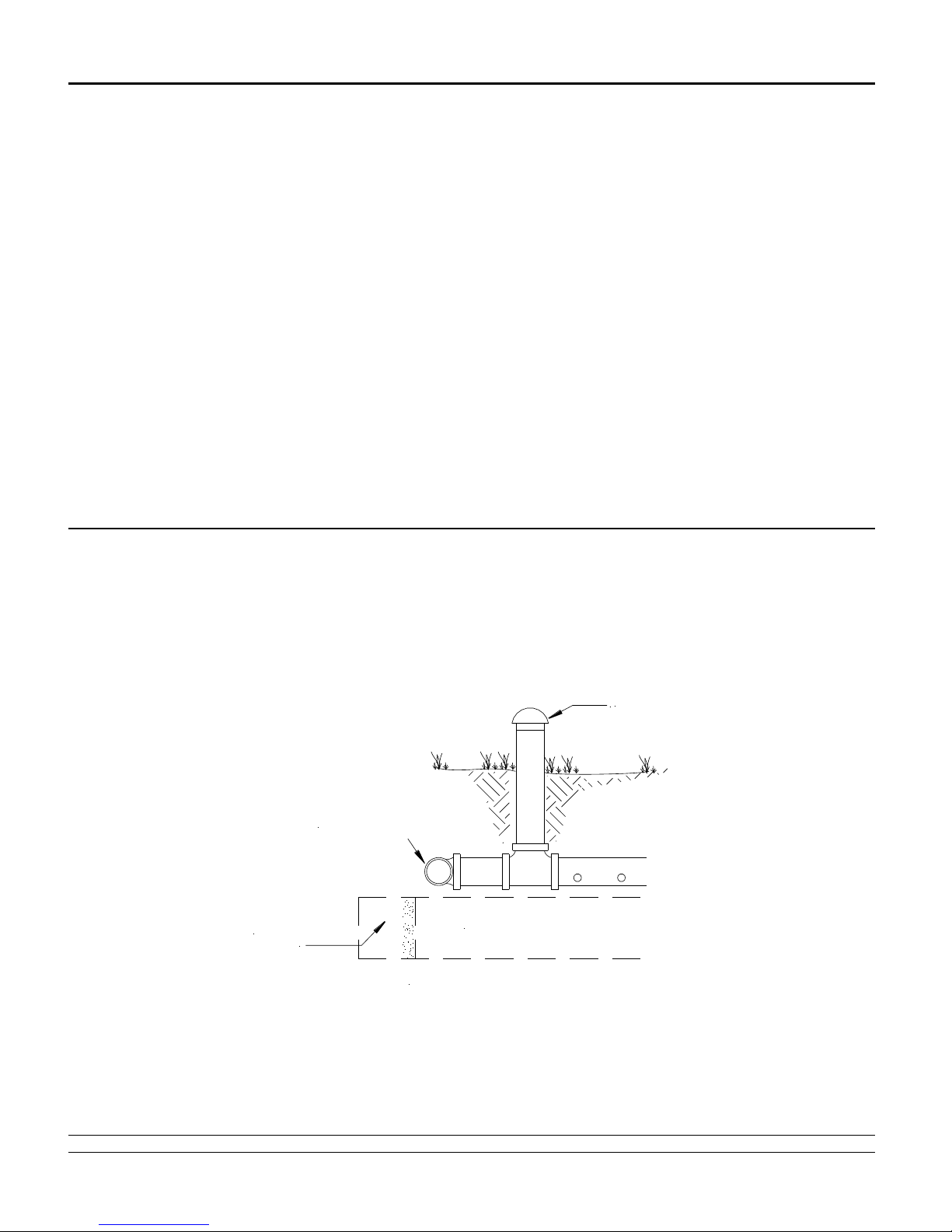

3.2 DISTRIBUTION BOX: Provide a D-box at the beginning of the first row of modules for effluent distribution and

velocity reduction and as a system inspection port. All rows must be fed evenly.

4.0 Pumped & Pressure Systems

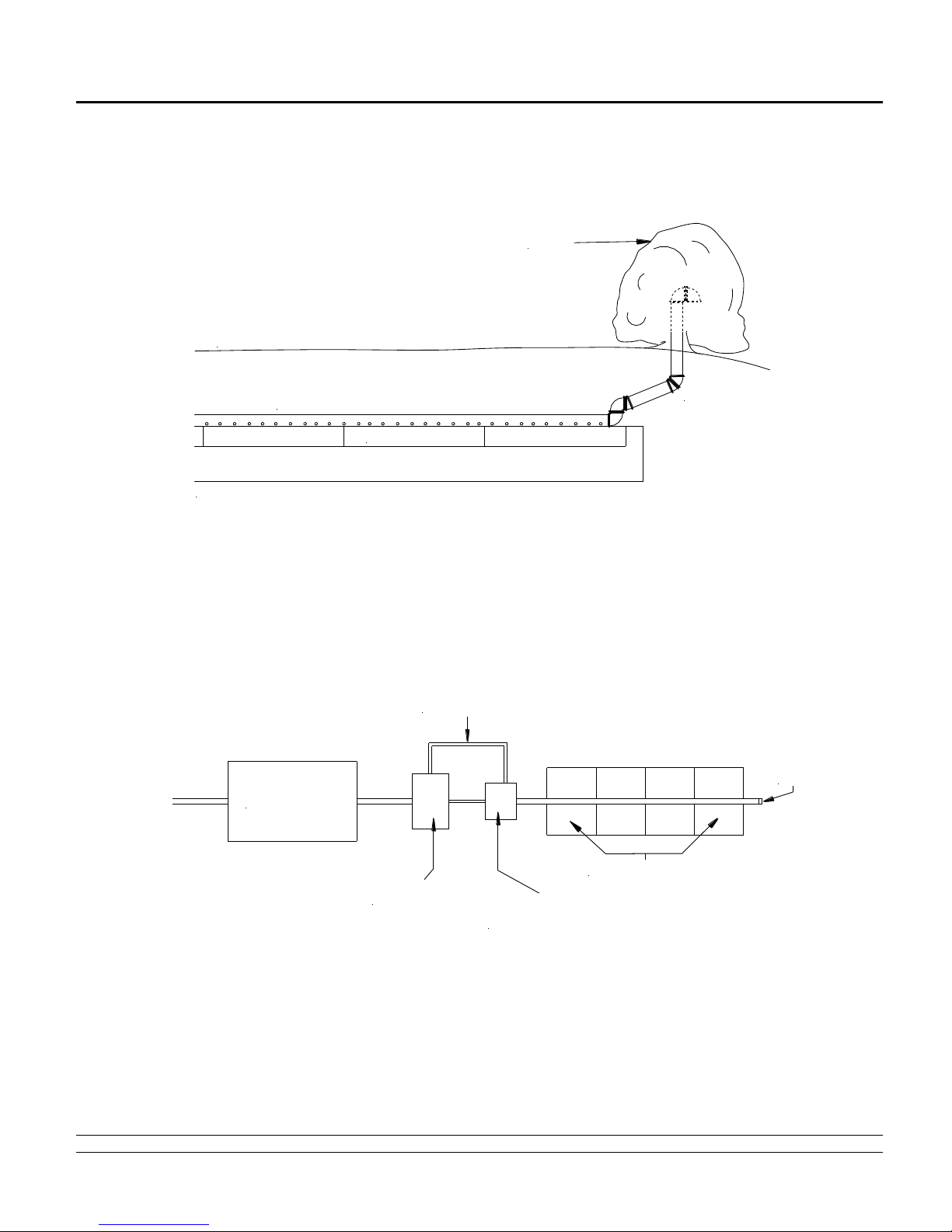

4.1 PUMP DISTRIBUTION BOX: Specify an oversized distribution box for pumped systems. Provide velocity

reduction in the D-box with a tee or baffle. Set D-box invert 2 inches higher than invert of perforated pipe over GSF

modules. If the absorption area is installed deeper than 18 inches, the system must be vented. See section 5.0 of

this manual for detailed information on venting of systems.