Elk M1XSP Instruction Manual

Table of Contents

M1XSP Installation and Setup.....................................................................................................................................2

ELK-M1 Data Bus E.O.L. Termination..........................................................................................................................3

INSTEON ** Lighting Control ONLY **.......................................................................................................................4

Updating/Replacing Firmware in the ELK-M1XSP.....................................................................................................8

Firmware Release Notes..............................................................................................................................................8

Version 50.1.4 released Jan 20, 2009 ....................................................................................................................8

Version 50.1.2 released Jan 5, 2008......................................................................................................................8

Version 50.0.28 released June 2, 2008..................................................................................................................8

Version 50.0.26 released Mar 9, 2007....................................................................................................................9

Version 50.0.22 released June 23, 2006 ................................................................................................................9

PO Box 100 • Hwy. 70W • Hildebran, NC 28637 • USA • 828-397-4200 • http://www.elkproducts.com

Firmware and/or bootware releases contain enhancements and/or resolutions for issues found in previous releases.

For the latest Updates refer to the Elk Website. http://www.elkproducts.com

Copyright 2012, Elk Products, Inc. No portion of this document shall be copied or distributed without the express written permission of Elk.

8/11/2014

ELK-M1XSP Serial Port Expander

Supplementary Instructions & Release Notes

for

Firmware Version 50.X.X

This version provides M1 Integration to:

INSTEON ** Lighting Control ONLY **

Page2 M1XSP Supplementary Instructions and Release Notes

M1XSP Diagnostic LED indicator

Slow blink (1/2 sec.) = Normal communication with M1.

Fast flicker = Communicating with other equipment (Thermostat, Lighting Controller, PC, etc.)

No blink = No communication with M1. Unit might be unplugged or powered off.

M1XSP Installation and Setup

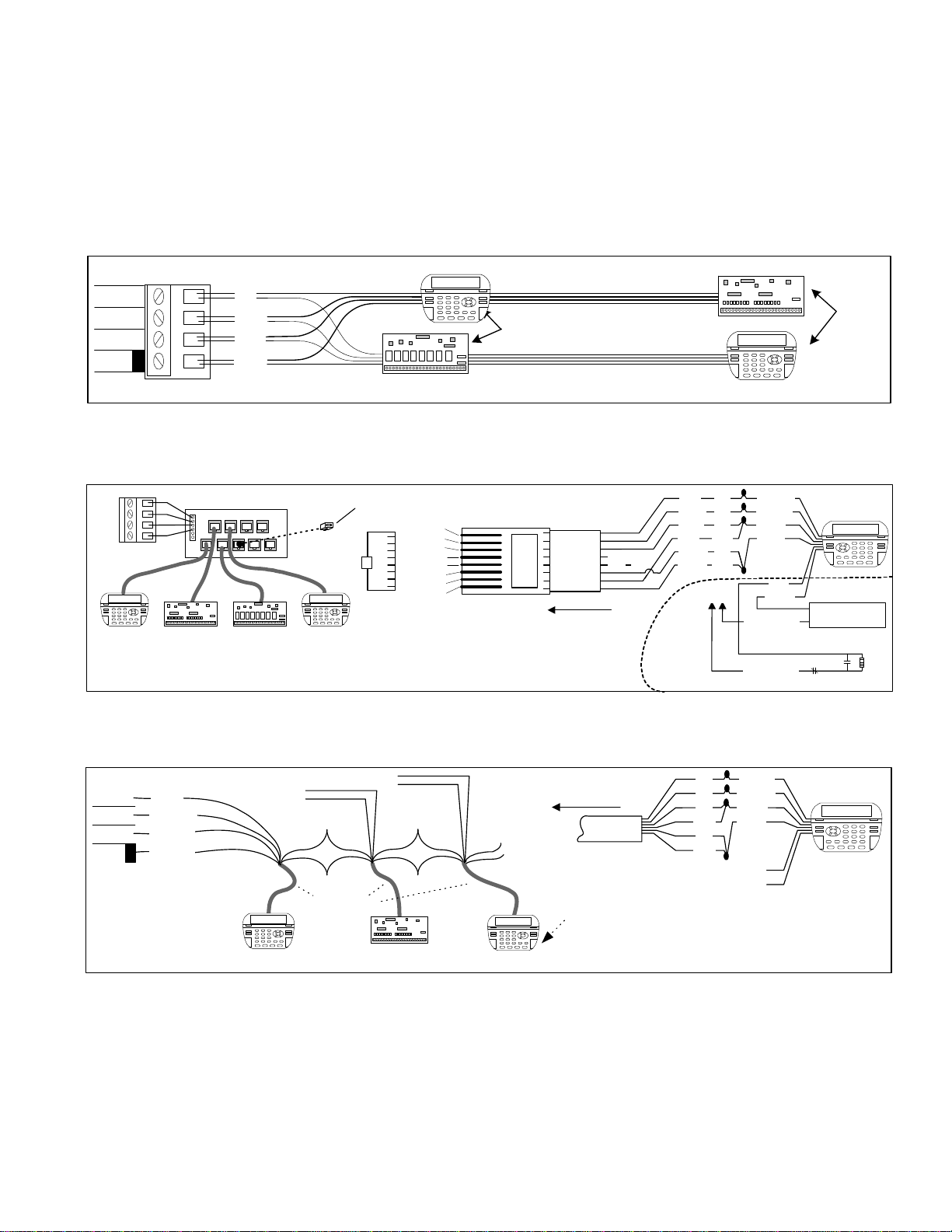

1. The M1XSP operates on the M1 Keypad data bus and may therefore be remoted near the equipment being interfaced.

2. Before making any wiring connections, turn Off the M1 Master Power Switch.

3. Connect terminals +12V, A, B, and Neg from the M1XSP to the M1's Keypad Data Bus (terminals +VKP, Data A, Data B, &

Neg). NOTE: Refer to the M1 Installation Manual and the M1DBH information in this manual about proper

connections of data bus devices with multiple homerun cables.

4. There are 4 address switches, each with a position of OFF or ON (binary value 0 or 1) and a decimal equivalent value of

(1, 2, 4, or 8). The total decimal value of the "ON" switches equates to the data bus address. As a rule, the first M1XSP

should be set to address 1. If more than 1 M1XSP is installed, set each one to a unique (sequential) address (2, 3, etc).

5. Set the "Mode", "Baud", and other necessary jumpers according to the Installation diagrams on previous pages.

6. After all connections are complete, turn On the M1 Master Power Switch.

7. Enroll the M1XSP into the M1 Control. From the Keypad access the Installer level programming and select Menu 01-Bus

Module Enrollment. Press the right arrow key to start the enrollment. Onceenrollment has completed, press the right

arrow key to view results. Enrolled M1XSPs will show up as type 5 (T5) followed by the specific address number.

RS-232 (DB9) 9 Pin

Partner Port

INSTALLUNIT * SETADDRESSAND OPTION JUMPERS * ACTIVATE M1 BUS ENROLLMENT PROCESS

RS-485

M1 Data Bus

RS-485

Partner Port

Data Bus

Address

Switches

Jumpers

S1,S2,S3 select

BAUD rate

Jumpers

S4,S5,S6,S7,S8

select Interface

MODE

J1 -Factory

Use ONLY! JP3 - Jumper selects

between RS-232 or

RS-485

JP5 - Jumper Selects

+12VDC to DB9 Pin 4

(MUST be in-place for

HAI Thermostats)

JP1 - Jumper selects

termination of M1

RS-485 Data Bus

JP2 - Jumper selects

termination of

other Mfg. RS-485

Table 1: Data Bus Address Switch Settings

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

Address 1

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

Address 2 Address 3 Address 4

Address 5 Address 6 Address 7

LEGEND

ON

OFF

M1XSP Data Bus Terminating Jumper

JP1 Used to engage a 120 Ohm resistor for

terminating the M1 RS-485 Data Bus. See

Data bus wiring instructions before use.

For an M1XSP the only valid Data Bus

Addresses are 1 thru 7 since the max.

number of M1XSPs is 7.

Page3 M1XSP Supplementary Instructions and Release Notes

VERY IMPORTANT!

The control uses a RS-485 “differential” data bus operating at 38,400 bits per second. This is relatively high speed by industry standards

and ensures fast, accurate communications. EOL data bus terminating resistors are strongly suggested to eliminate the possibility of

reflection errors due to varying cable lengths. Every device; keypad, expander, etc. and the control has a built-in bus terminating resistor

(120 Ohm) which can be activated via a 2 pin jumper (2 Gold Pins). Two black shorting caps are included in the hardware pack. When one

of the shorting caps is placed on the two gold pins, it activates the 120 Ohm terminating resistor across Data Lines A & B. Terminating

resistors are marked JP2 on the keypads and JP1 on the expanders. From the factory, no terminating resistors are installed (activated).

WARNING! The RS-485 Data Bus must NEVER have more than 2 terminating resistors header/jumpers installed.

The M1 should have no more than 2 home run cables but devices can be daisy chained along each. The last device on each home run

SHOULD be terminated via the gold 2 pin terminating header/jumper. Placing a shorting cap on the pins will engage a 120 Ohm resistor across

data lines A & B. If there is only 1 data bus home run cable then place shorting cap on JP3 of Main Board. See other hookups below.

The optional ELK-M1DBH † Data Bus Hub is suggested if the job must have more than 2 home runs. The M1DBH accepts CAT5 or CAT6 cable

with RJ45 plugs. It keeps wires more organized while also providing easy bus termination. Essentially, the M1DBH circuit board daisy chains

the devices by series connecting the DATA lines A & B. An plug-in RJ45 terminator is supplied for use in the first unused jack.

Another option for wiring multiple home runs is with 6 conductor cable. This allows devices to daisy chained by making an in and out

connection, basically a 3 way splice of the data A (Green)wire to 2 wires of the 6 conductor cable (designated A and A1). Do the same for the

data B (White) wire. At the control splice the A1 and B1 wires to the A and B wires going to the next device. Terminate the last wired device

and the control JP3 ONLY! The data wires will be in series, but the POS (+) and Neg (-) power wires should be parallel wired to the +VKP and

Neg terminals or to an auxiliary Power Supply if the combined current draw exceeds the rated current available from the Control.

BLACK

WHITE

GREEN

RS-485 Data Bus (Max. length is 4000 ft.

Max. bus devices vary by control.)

RED

Jumper

Terminate

these two

devices.

DO NOT Jumper

Terminate these devices.

Keypad 1 Data Bus Devices e.g. Keypads, Expanders

Keypad 3

Daisy Chain Connection of Data Bus Devices Using Two (2) Home Run Cables

+VKP

DATA B

DATA A

NEG

RS-485 DATA BUS

Install Teminating

Jumper on this last

device AND on the

control JP3.

6 conductor cable

DATA

A1 A

B1 B

DATA

A1 A

B1 B

Optional Output and Zone Input - See Keypad Instructions

Connect each device to the 6 conductor cable as shown above

Daisy Chain Connection of Data Bus Devices Using 6 Conductor Cables

Keypad

RS-485 DATA BUS

+VKP

DATA B

DATA A

NEG

Keypad

RED

GREEN

BLACK

WHITE

To 12VDC

To 12VDC

BLUE

BROWN

6 Wire

Cable

Keypad

RED +12

+BLACK (-)

-

GREEN

WHITE

A

A1

B

B1

TO CONTROL

Keypad

ELK-M1DBH Data Bus Hub †

MountM1DBHinsidecontrol. Connect it to the M1

DataBusterminals usinga4conductorcable.

J2 J4 J6 J8

J1 J3 J5 J7 J9

RJ45 Terminating Plug Insert in first unused jack and terminate the

control at JP3. DO NOT TERMINATE AT ANY OF THE DEVICES!

CAT5 Cables

Daisy Chain Connection using the ELK-M1DBH and CAT5 Cables.

RS-485 DATA BUS

Keypad

Refer to

Keypad

Instructions

for more info

about Output

and Zone Input

+

-

A

A1

B

B1

TO CONTROL

8 - Brown

7 - Wht/Brn

6 - Orange

5 - Wht/Blue

4 - Blue

3 - Wht/Org

2 - Green

1 - Wht/Grn Pin1

RJ45 Plug Blue pair

is unused

COLOR CODE for CAT5 or CAT6 Data Bus Cable

to RJ45 Plugs for ELK-M1DBH Data Bus Hub.

Pin1

Front

view

Optional programmable Zone Input

Optional programmable Output

-

+

N.C. N.O. 2200

Ohm

EOL

To BLACK (Neg)

To BLACK (Neg)

Wht/Blue

Brown

Wht/Brn

Orange

Wht/Org

Green

Blue Wht/Grn

RED +12V

BLACK (-)

GREEN

WHITE

BROWN

BLUE

Keypad

CAT5

or

CAT6

Cable To

+ 12V Load (50mA max)

I.E. LED, Relay

+ VKP

DATA A

DATA B

NEG

ELK-M1 Data Bus E.O.L. Termination

Page4 M1XSP Supplementary Instructions and Release Notes

INSTEON ** Lighting Control ONLY **

INSTEON - INSTEON utilizes Powerline Communications (PLC) technology. Numerous device types are available; such as:

Light Switches, Lamp Modules, Applicance Modules, Keypad Controllers, etc. A unique feature of INSTEON is the availability of

RF signal enhancers or "Bridges" that can extend signal range as well as provide power line signal coupling.

IMPORTANT! There are 2 methods for interfacing INSTEON with an M1 Control.

Carefully read and understand the following before proceeding.

Method 1 is to use an ISY Controller from Universal Devices Inc. to connect with a INSTEON Powerlinc Modem.

This is a popular and often recommended method as it does not require an ELK-M1XSP AT ALL!!

The ISY connects via IP (LAN) to the M1Control using the Elk M1XEP Ethernet Adapter. Again, no ELK-M1XSP required! The

reason this method is so popular is that it provides a more powerful interface with INSTEON, including Computer setup and

management of the devices in an easy to use Graphical User environment

Method 2 is to use an ELK-M1XSP Serial Interface to connect with an INSTEON Powerlinc Modem. See below.

Integration with INSTEON using an M1XSP:

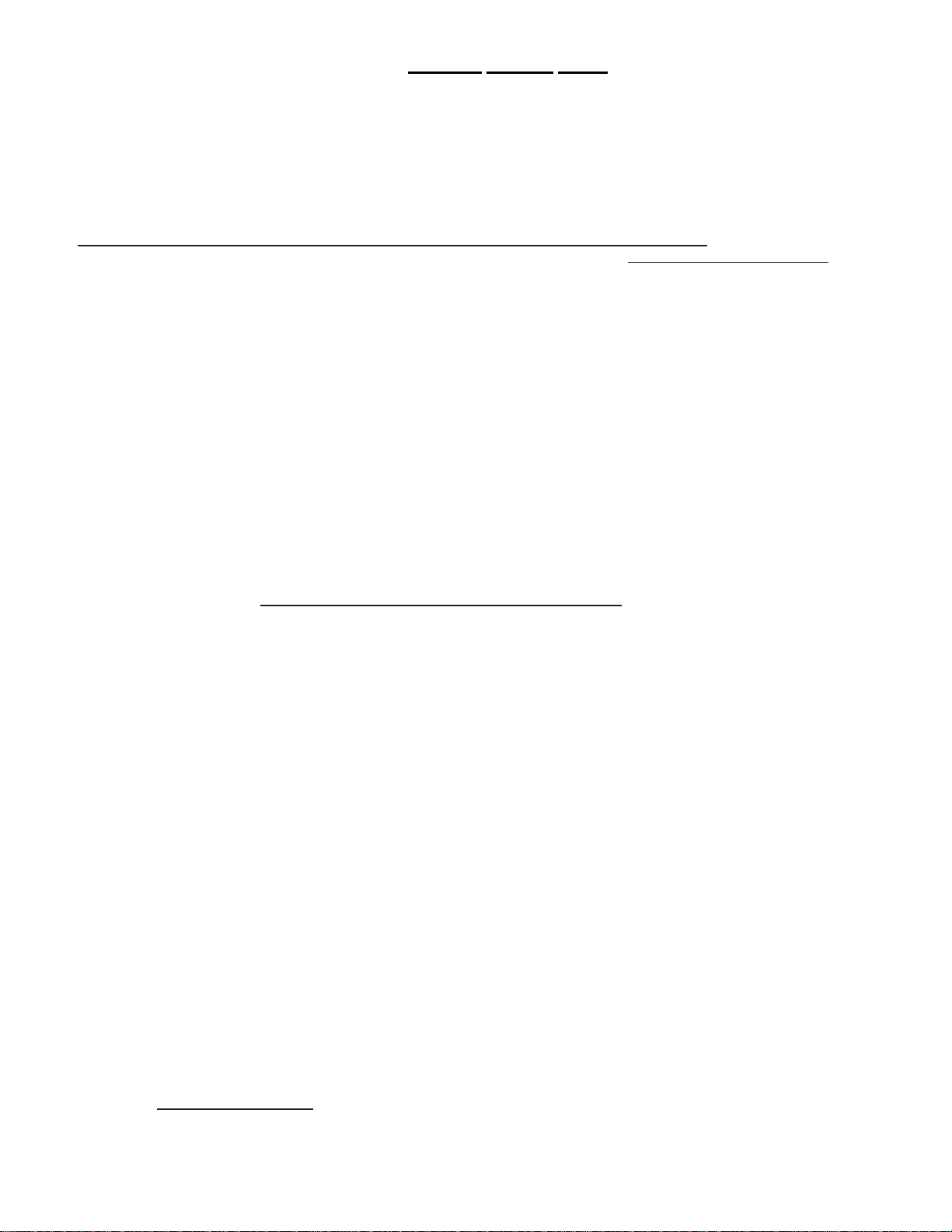

Using the M1XSP an M1 can support up to 192 individually addressable INSTEON Devices and up to 63 Scenes or Groups.

Individual addresses 1-192 are mapped into the M1 architecture as lighting devices 1 to 192. Groups 1-63 are mapped in as

lighting devices 193-255. For example, to turn on INSTEON Group 1 it would be necessary to turn on M1 Lighting device 193.

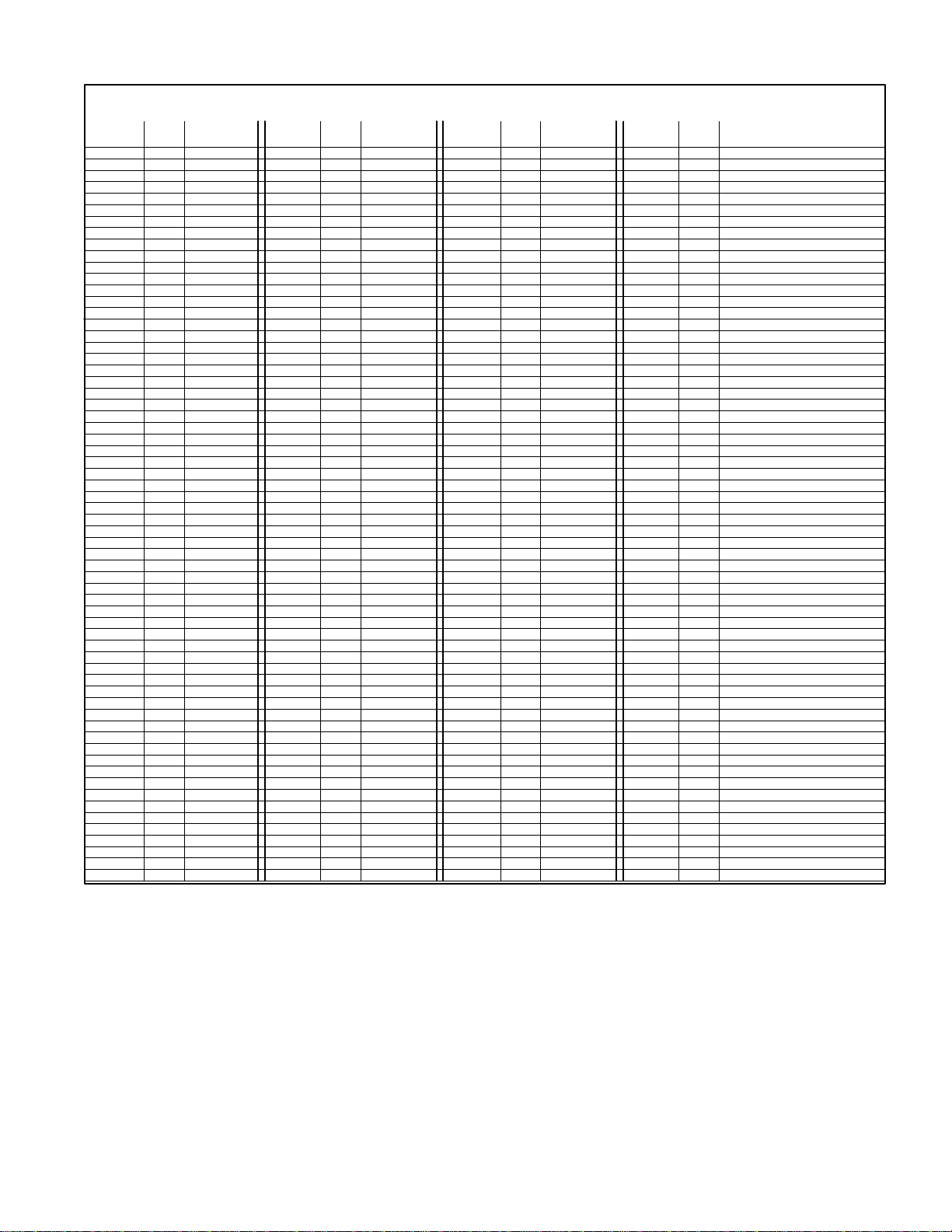

An attached chart outlines the M1 Lighting devices and their corresponding INSTEON devices.

Limitations with the M1XSP: (With no "third party" hardware/software the following limitations apply)

- INSTEON devices can only be "linked" (learned) into the M1XSP starting at M1 Lighting device 001 (A1). In other words,

there is no way to have devices start at a specific location.

- INSTEON devices cannot be removed or re-arranged individually. If it becomes necessary to remove or re-arrange any

linked devices the entire memory must be cleared and all devices re-linked (learned) again.

- Once an M1XSP has been linked with INSTEON devices, any updating to the firmware in that M1XSP will cause all memory

of linked addresses to be erased, requiring all devices to be re-linked (learned) again.

- INSTEON devices do not initiate a report of their dim level status to the M1. However, they can initiate reports of their full ON

or full OFF status changes. Refer to the section titled "Load Status Communications".

- The M1XSP is capable of sending commands to Groups 1 thru 62, but only if you have a way to setup the groups.

A third party hardware/software interface like the Universal Devices Ins. (ISY99) does not have the above limitations.

Setting up the M1XSP and the M1 to communicate with INSTEON

Componentsrequired:

- ELK-M1 or ELK-M1EZ8 Controller.

- ELK-M1XSP Serial Port Expander. The M1XSP must be flashed with firmware version 50.x.x to support INSTEON

- INSTEON Powerlinc Modem

- One or more INSTEON lighting devices and/or switches.

1. Install the ELK-M1XSP and set its data bus address per instructions on page 2.

2. Set the M1XSP MODE and BAUD jumpers as follows:

S1=1 Is the recommended position. Setting this jumper temporarily to “0” is useful for erasing the INSTEON IDs from

the M1XSP memory. See ERASING INSTEON IDs.

S2=1 Is the recommended position. Do NOT set this jumper to a “0”.

S3=1 Is the recommended position. Setting this jumper to “0” enables polling of the INSTEON network for device

status. Unfortunately this places a heavy burden on the network and is not generally recommended.

S4=1 Is the recommended position. NOTE: Some M1XSPs don’t have this jumper at all.

S5=0 Is the recommended position. This reserves M1 Lighting devices 193-254 for use with INSTEON Groups 1-63.

Setting this jumper to “1” allows M1 Lighting device 193-254 for use with X-10 device codes M01 to P14.

S6=1 Normal position for this jumper. Do NOT set this jumper to a “0”.

S7=0 Normal position for this jumper is “0” which selects compatibilty with the INSTEON Powerlinc Modem. An older

and now discontinued Powerlinc Modem required this jumper to be set to a 1.

S8=1 Normal position for this jumper.

3. Set Jumper JP3 to the “232” position. If there is a shorting Jumper plug on JP5 then remove it and discard.

4. Connect a 9-pin serial cable between the M1XSP and serial connector on the Powerlinc Modem.

5. Power up all the devices and enroll the M1XSP into the M1. VERY IMPORTANT!

Page5 M1XSP Supplementary Instructions and Release Notes

6. Update the firmware in the M1XSP to version 50.1.4 (or the latest 50.x.x version). Download from the Elk website.

7. Use the ELK-RP Software to program the M1 Lighting device attributes for devices 1 through 192 as:

Format = Serial Expander, Type = Dimmer (Type may alternately be On/Off Switch if device does not support dimming).

The first 192 M1 lighting devices may now be "linked" to INSTEON individual addresses.

8. Program the attributes for Lighting devices 193 through 254 as:

Format = Serial Expander, Type = On/Off Switch These 62 lighting devices can be used to control INSTEON Groups.

9. Program the attributes for Lighting devices 255 and 256 as:

Format = Serial Expander, Type = On/Off Switch. Device 255 is reserved for future use. Device 256 is useful for remotely

starting and ending the INSTEON "linking" mode. Program the name for device 256 as: INSTEON LinkMode. Manually

turning device 256 to ON begins the linking mode. Manually turning device 256 to OFF ends then linking mode.

Programming and Linking INSTEON Modules into the M1XSP:

Each INSTEON device has an unique Address ID hardcoded into it. E.G. 00.42.12 Before the M1XSP can send commands to

INSTEON devices it must acquire their IDs. This is done by putting both the M1XSP and INSTEON PLM Interface into “linking"

mode. During the linking mode each device ID will become mapped to an M1 Lighting Device location in the exact order in

which it was linked. I.E. The first linked device will be mapped as M1 Lighting device 1 (A1), the second is 2 (A2), etc. NOTE:

It is not possible to start INSTEON devices at a chose location. This is only possible with 3rd party, separetely puchases

hardware/software from such companies as ISY and Powerhome.

1. To start the linking mode:

a. From the M1 Keypad press the ELK key followed by the Right arrow key. 1-View/Control Automation Fncts.

b. Press the 2 key followed by the right arrow key. 2-Lighting

c. Advance to M1 Light number 256 by entering 2 - 5 - 6. Light 256 should be labeled INSTEON LinkMode.

d. Turn ON Light 256 by pressing the pound (#) key. The M1XSP will then send a serial command to the M1XSP and

PLM Interface and instruct it to begin a 4 minute linking period.

The first device must be linked during this 4 minute time period.

2. Press & hold the link mechanism (LampLinc "SET" button / SwitchLinc "PADDLE") on the INSTEON device to be linked.

NOTE: The 4 minute time period will automatically restart each time a device is linked. At this point it is important to

work quickly so that the 4 minute timer does not expire. If the timer does expire it will be necessary to repeat step

1d and restart the timer before proceeding with any additional linking.

3. The light "LOAD" being controlled should flash once or twice as indication that it has become linked.

NOTE: The M1XSP status LED should flash ON 3 times and then OFF for 2 seconds at it receives the linking from each

INSTEON device. This blink cadence continues until the linking process is manually ended by step 8. **

4. Release the link mechanism. The LED on the device will return to flashing as an indication it is still in the link mode.

5. This step is very important! With the LED on the device still flashing, momentarily tap the the link mechanism once and

verify that the LED stops flashing. This stops the link mode for this device. Be sure the LED has stopped flashing or else

the device will remain in the link mode causing it to be cross linked with future linked devices.

6. Repeat steps 2 thru 5 for each INSTEON device to be learned. Each time this is done, the device will be linked to the next

incremental M1 Lighting device number (002, 003, 004, etc.). A written record should be kept for future recall.

7. Also important! To end the linking process... From the M1 Keypad access the lighting menu just as you did in Step 1,

only this time Turn OFF Light device 256 by pressing the pound (#) key. (Pound toggles between On and Off) Ending the

linking mode will result in the LED on the M1XSP returning to its normal status blink.

8. Test the operation of each light from the ELK-M1 Keypad utilizing the lighting control menu.

** Optional: You may elect to end the linking process after each new device (using step 5) just so the next linked device

will be visually confirmed by the start of the special blink process of the M1XSP. Keep in mind if you elect to do this, the

linking process must then be restarted (using step 2) prior to proceeding to the next device.

Page6 M1XSP Supplementary Instructions and Release Notes

Factory Defaulting INSTEON Devices

During installation or troubleshooting it may be necessary to factory default one or more devices. For example; multiple

devices may inadvertently become cross-linked together, making them turn on together when they should be separate. This

is caused by accidentally linking one device while another device is still in the link mode. Consult the instructions that came

with the device for steps on factory defaulting, including possibly the INSTEON PLM Interface.

Adding (linking) new or additional INSTEON devices at a later date:

Additional devices can be added "linked" at any time by performing the previous steps. The newly linked device(s) will be

associated to the M1 starting with the first empty lighting device locations. The maximum number of devices is 192.

Erasing (unlinking) INSTEON IDs from the M1XSP

Should it ever be necessary to erase the linked INSTEON IDs from the M1XSP memory do the following:

1. Power down the M1XSP

2. Set Jumper S1 = "0" (down)

3. Power up the M1XSP and wait 5 seconds.

4. Power down the M1XSP.

5. Set Jumper S1 = "1" (up) and reapply power to the M1XSP.

NOTE: ALL linked devices are now permanently erased. It is not possible to erase (unlink) individual devices.

Grouping:

Lighting devices 193 to 254 are mapped to control INSTEON “Groups” 1 to 62. Unfortunately, while the M1XSP is capable of

sending INSTEON group commands, only special “third party” hardware/software products are capable of setting up

INSTEON devices into groups. Without this the M1 can only utilize group #1. To setup Group 1 you have to manually place the

INSTEON PLM or PLC Interface into the linking mode and then press the Link mode on the INSTEON device, repeating the

whole process for each device to be included into Group 1. M1 can then controll Group 1 by turning lighting device 193 On/Off.

Operating BOTH INSTEON and X-10 devices:

It is possible for the M1XSP to communicate with both INSTEON and regular X-10 devices via the PLM Interface. Essentially,

on activation of a M1Lighting command the M1XSP (with 50.x.x INSTEON Firmware) will send INSTEON commands for the

lighting device numbers that have an INSTEON linked address, and it will send X-10 commands for the lighting devices that

do not have an INSTEON "linked" address. This helps eliminate the need for a separate X-10 PSC05 or TW523 Interface.

The limitations are this: No X-10 devices should have a House/Unit code that conflicts with any present or future linked

INSTEON device locations. INSTEON device linking ALWAYS begins at M1 Lighting device 1 (A01) and ENDS at 192 (L16).

When setting the House and Unit codes for X-10 devices we recommend NOT using any of the low range numbers.

Special Option - Jumper S5

With the INSTEON version of the M1XSP in default settings no X-10 House or Unit codes can be programmed in the M1

Lighting device locations 193 (M1) to 256 (P16). This is because these locations are reserved for INSTEON Groups and

special commands. But there is a special option (selected by Jumper S5) that will convert this range of device numbers

from INSTEON Groups to X-10. See notes below.

Reminder: M1 Lighting devices start at 1 (A01) and go up to 256 (P16). See the chart on the next page.

N1. M1XSP Jumper S5 = 0 (factory setting) - The M1XSP supports 62 INSTEON Groups mapped as M1 Lighting device

locations 192 to 254 . It cannot support any X-10 devices using a House/Unit code of M01 or above.

N2. M1XSP Jumper S5 = 1 This will disable INSTEON groups and permit X-10 House/Unit codes to occupy M1 Lighting

device locatons 192 (M01) to 254 (P14). INSTEON Groups are disabled when S5 = 1.

N3. Please note that INSTEON RF Signal Enhancers DO NOT provide phase bridging for X-10 transmissions, nor do they

improve or extend the range of X-10 transmissions. A X-10 bridge/coupler is still required for this purpose.

N4. When controlling INSTEON together with X-10 through the PLM Interface and the ELK-M1XSP it is important to

understand that all M1 Lighting Devices should be set as ”Serial Expander" regardless of whether they are INSTEON

or X-10. Do not set the Option box, but be sure to set the Format, Type, Show, and to program an applicable Name.

N5. Transmitted X-10 commands are limited to On, Off, and Preset Dim (provided the X-10 devices support preset).

Received X-10 commands passed from the INSTEON Interface to the M1XSP are limited to On and Off states ONLY.

Load Status Communications:

INSTEON devices can send their On or OFF status to the M1 when a User turns the load On or Off. However, In order for Load

Status "On or Off" tracking to be enabled, the LampLinc or SwitchLinc devices must have the Interface's address linked into

their database. To do this, activate linking mode at the LampLinc or SwitchLinc by pressing and holding the set button or

paddle for 10 seconds. The LED will blink on the LampLinc or SwitchLinc. Now press and hold the set button on the

INSTEON Interface for 10 seconds. The LED on the LampLinc or SwitchLinc should go solid to indicate they have been

successfully linked to the Interface.

NOTE: INSTEON devices DO NOT initiate a report of their dim level status to the M1 when a device is changed by the User

to a new level (eg:100% to 50%), only On or Off. However, the latest M1XSP firmware does send a command to request

the level of a switch whenever it hears a switch has been pressed.

Page7 M1XSP Supplementary Instructions and Release Notes

INSTEON

Device 1

Device 2

Device 3

Device 4

Device 5

Device 6

Device 7

Device 8

Device 9

Device 10

Device 11

Device 12

Device 13

Device 14

Device 15

Device 16

Device 17

Device 18

Device 19

Device 20

Device 21

Device 22

Device 23

Device 24

Device 25

Device 26

Device 27

Device 28

Device 29

Device 30

Device 31

Device 32

Device 33

Device 34

Device 35

Device 36

Device 37

Device 38

Device 39

Device 40

Device 41

Device 42

Device 43

Device 44

Device 45

Device 46

Device 47

Device 48

Device 49

Device 50

Device 51

Device 52

Device 53

Device 54

Device 55

Device 56

Device 57

Device 58

Device 59

Device 60

Device 61

Device 62

Device 63

Device 64

ELK

Light

Device #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

PLC

(X-10)

Ref.

A01

A02

A03

A04

A05

A06

A07

A08

A09

A10

A11

A12

A13

A14

A15

A16

B01

B02

B03

B04

B05

B06

B07

B08

B09

B10

B11

B12

B13

B14

B15

B16

C01

C02

C03

C04

C05

C06

C07

C08

C09

C10

C11

C12

C13

C14

C15

C16

D01

D02

D03

D04

D05

D06

D07

D08

D09

D10

D11

D12

D13

D14

D15

D16

INSTEON

Device 65

Device 66

Device 67

Device 68

Device 69

Device 70

Device 71

Device 72

Device 73

Device 74

Device 75

Device 76

Device 77

Device 78

Device 79

Device 80

Device 81

Device 82

Device 83

Device 84

Device 85

Device 86

Device 87

Device 88

Device 89

Device 90

Device 91

Device 92

Device 93

Device 94

Device 95

Device 96

Device 97

Device 98

Device 99

Device 100

Device 101

Device 102

Device 103

Device 104

Device 105

Device 106

Device 107

Device 108

Device 109

Device 110

Device 111

Device 112

Device 113

Device 114

Device 115

Device 116

Device 117

Device 118

Device 119

Device 120

Device 121

Device 122

Device 123

Device 124

Device 125

Device 126

Device 127

Device 128

ELK

Light

Device #

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

PLC

(X-10)

Ref.

E01

E02

E03

E04

E05

E06

E07

E08

E09

E10

E11

E12

E13

E14

E15

E16

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

F11

F12

F13

F14

F15

F16

G01

G02

G03

G04

G05

G06

G07

G08

G09

G10

G11

G12

G13

G14

G15

G16

H01

H02

H03

H04

H05

H06

H07

H08

H09

H10

H11

H12

H13

H14

H15

H16

ELK

Light

Device #

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

PLC

(X-10)

Ref.

I01

I02

I03

I04

I05

I06

I07

I08

I09

I10

I11

I12

I13

I14

I15

I16

J01

J02

J03

J04

J05

J06

J07

J08

J09

J10

J11

J12

J13

J14

J15

J16

K01

K02

K03

K04

K05

K06

K07

K08

K09

K10

K11

K12

K13

K14

K15

K16

L01

L02

L03

L04

L05

L06

L07

L08

L09

L10

L11

L12

L13

L14

L15

L16

ELK

Light

Device #

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

INSTEON

Device 129

Device 130

Device 131

Device 132

Device 133

Device 134

Device 135

Device 136

Device 137

Device 138

Device 139

Device 140

Device 141

Device 142

Device 143

Device 144

Device 145

Device 146

Device 147

Device 148

Device 149

Device 150

Device 151

Device 152

Device 153

Device 154

Device 155

Device 156

Device 157

Device 158

Device 159

Device 160

Device 161

Device 162

Device 163

Device 164

Device 165

Device 166

Device 167

Device 168

Device 169

Device 170

Device 171

Device 172

Device 173

Device 174

Device 175

Device 176

Device 177

Device 178

Device 179

Device 180

Device 181

Device 182

Device 183

Device 184

Device 185

Device 186

Device 187

Device 188

Device 189

Device 190

Device 191

Device 192

INSTEON

Group 01

Group 02

Group 03

Group 04

Group 05

Group 06

Group 07

Group 08

Group 09

Group 10

Group 11

Group 12

Group 13

Group 14

Group 15

Group 16

Group 17

Group 18

Group 19

Group 20

Group 21

Group 22

Group 23

Group 24

Group 25

Group 26

Group 27

Group 28

Group 29

Group 30

Group 31

Group 32

Group 33

Group 34

Group 35

Group 36

Group 37

Group 38

Group 39

Group 40

Group 41

Group 42

Group 43

Group 44

Group 45

Group 46

Group 47

Group 48

Group 49

Group 50

Group 51

Group 52

Group 53

Group 54

Group 55

Group 56

Group 57

Group 58

Group 59

Group 60

Group 61

Group 62

Reserved for future use

Linking Mode (On/Off)

PLC

(X-10)

Ref.

M01

M02

M03

M04

M05

M06

M07

M08

M09

M10

M11

M12

M13

M14

M15

M16

N01

N02

N03

N04

N05

N06

N07

N08

N09

N10

N11

N12

N13

N14

N15

N16

O01

O02

O03

O04

O05

O06

O07

O08

O09

O10

O11

O12

O13

O14

O15

016

P01

P02

P03

P04

P05

P06

P07

P08

P09

P10

P11

P12

P13

P14

P15

P16

The PLC column is for reference only.

M1 Lighting Devices Mapped to INSTEON

INSTEON-(continued)

Page8 M1XSP Supplementary Instructions and Release Notes

Changes effective with this new application firmware:

NOTE: Updating will ERASE ALL linked Insteon devices!

1. Found a reported problem of the M1XSP occasionally defaulting itself (erasing all enrolled devices) upon power up.

Added a 1 second debounce timer upon power-up before reading the state of Jumper S1.

2. New feature - It is now possible to tell the M1XSP to totally ignore X-10 type commands heard from the M1 or from the

Insteon PLC by setting Jumper S8 to “0”. I.E. X-10 can still travel on the X-10 connector located on the M1G board while

Insteon commands travel on the M1XSP without clashing or inteferring with one another.

Version 50.0.28 released June 2, 2008

The M1XSP stores it’s operating firmware in “Flash” memory. This state-of-the-art memory allows electronic field updates

and eliminates the old fashion method of changing IC chips or shipping boards back to the factory. As new firmware updates

become available, they will be posted on ELK’s website found at www.elkproducts.com. NOTE: Firmware updating can only

be done through the M1 Control using a Direct to PC Com port connection or an optional Ethernet Network connection.

Dial-up connections cannot be used to perform firmware updates.

How to Update:

1. Physically connect the Computer and Control using either the RS-232 Serial Port 0 or the M1XEP Ethernet Interface.

2. Open ElkRP and the account belonging to the control. Click on the Connection menu icon and establish a connection.

Use either the Direct using Com_ OR Network options.

3. On the Send/Rcv menu icon there is a selection that allows the firmware to be updated.

4. Select the device to be updated. In this case it is a Serial Expander. Select the update firmware option.

5. Display will show: Device name, current Firmware, Hardware, and Bootware version, and a pull down window for selecting

the update firmware. NOTE: All update (.bin) files downloaded or received should be stored in a directory on your

computer. Refer to the Options tab under the Setup menu in RP. It will indicate what directory is used for the update files.

6. Click on the check box for “Update”. If “Reprogram” or “Rollback” is displayed the firmware file is the same as OR older

that what is in the control. Reprogramming with the same firmware is a waste of time but was included for factory testing

purposes. Rollback is not recommended except under the guidance of Elk Technical Support.

Updating/Replacing Firmware in the ELK-M1XSP

Firmware Release Notes

Version 50.1.4 released Jan 20, 2009

Changes effective with this new application firmware:

NOTE: Updating will ERASE ALL linked Insteon devices!

1. Found and resolved an issue when using a rule to turn on a light for a timed period using the Insteon PowerLinc MODEM.

The timer associated with the light would be erased, resulting in the light never turning off.

IMPORTANT REMINDERABOUTTHE POWERLINC MODEM:

For persons using PowerHome’s “Elk Insteon Device Loader” there is a new version required

for use with this firmware and the Powerlinc Modem (PLM). Refer to Elk’s website

under Partner Manufacturers page for a link to the PowerHome software.

Version 50.1.2 released Jan 5, 2008

Changes effective with this new application firmware:

NOTE: Updating will ERASE ALL linked Insteon devices!

1. Added support for the new INSTEON PowerLinc Modem which replaced the now obsolete older PLC interface.

For at least the time being this version continues to provide support for the obsolete PLC interface.

Page9 M1XSP Supplementary Instructions and Release Notes

Changes effective with this new application firmware:

NOTE: Updating will ERASE ALL linked Insteon devices!

1. Polling for status after a manual switch press - Added a new routine to make the M1XSP poll a device if it detects release of

the on or off switch. This should improve the ability for the M1 to get the level (instead of just on and off) of the light after a

local switch press.

2. Polling for status after a group command - Added a new routine to make the M1XSP poll devices that were controlled by the

group command AS LONG AS the controller sends the group cleanup messages. CAUTION! Not all controllers send the

cleanup messages. Also, if another command needs to be sent the cleanup messages are generally discarded.

3. Reports of the M1XSP losing the programmed Insteon ID numbers after a power reset - A modification has been made to

the flash memory write routine to provide additional protection against this possibility.

4. Reports of lights changing levels a short period after the light is manually changed - It was found that this could be caused

after the PLC receives a group command. A modification has been made to the way the data is parsed which should

resolve this possibility.

Version 50.0.26 released Mar 9, 2007

Changes effective with this new application firmware:

NOTE: Updating will ERASE ALL linked Insteon devices!

1. Added support for “Powerhome” software (available from: http://www.myx10.com). Powerhome can now be used for

programming and managing Insteon address IDs in the M1XSP. This includes: reading Insteon address IDs from the

M1XSP into the PC software, and reading (discovery) of the M1 Lighting device names (text) which are stored inside the

M1 by way of the M1XSP. This process requires a direct serial port connection directly from the PC to the M1XSP,

temporarily disconnecting the M1XSP from the Insteon Powerlinc interface.

2. Added a text string “LINK^M” to be transmitted from the M1XSP to the M1 whenever the link mode is activated (lighting

device 256 ON) and a valid link is received from the Insteon Powerlinc interface. This is helpful during the manual linking

mode. An M1 rule can be written to blink an output, make an announcement, etc. whenever a new device is linked into the

Insteon Powerlinc interface. Be certain to program this exact text into the ElkRP Automation/Text string locations in order

for it to be available in the rules engine.

3. Improved the receiving of certain commands from the Powerlinc interface during the manual link mode.

Version 50.0.22 released June 23, 2006

Other manuals for M1XSP

1

Table of contents