1000004317 (Rev. A - 08/2017)

ECH8_2NWR

PAGE 3

1. Temperature Control: Factory set for 50ºF ± 5º (10ºC ± 2.8º) water under normal conditions. To adjust water temperature, turn off electrical supply,

remove front panel (Item 10) using a 5/16" (7.9mm) socket wrench or at head screwdriver, and turn screw on cold control (Item 9) clockwise for

colder, counter clockwise for warmer.

Service: Adjustments

Service: Inspection/Cleaning

• Inspect Water Chiller twice each year for proper operation and performance.

• Inspection of the unit will require disconnecting electrical supply, removal of panels, etc. and reassembly and return to service practices.

1. Condenser Fan Motor: Conrm condenser fan turns freely. If the condenser fan does not spin freely, have an authorized service personnel replace.

2. Ventilation: Cabinet louvers and condenser ns should be periodically cleaned with a brush, air hose or vacuum cleaner. Cleaning should be done

twice each year or more frequently if needed due to environment. Excess dirt or poor ventilation can cause no cold water and compressor cycling

on the compressor overload protector.

3. Water Flow: Conrm proper water ow. If water ow is slow, inspect lter or inline strainer for restriction. Replace lter cartridge if required. Disassemble

inline strainer and clean if required. See Figure 3.

4. Lubrication: Motors are lifetime lubricated.

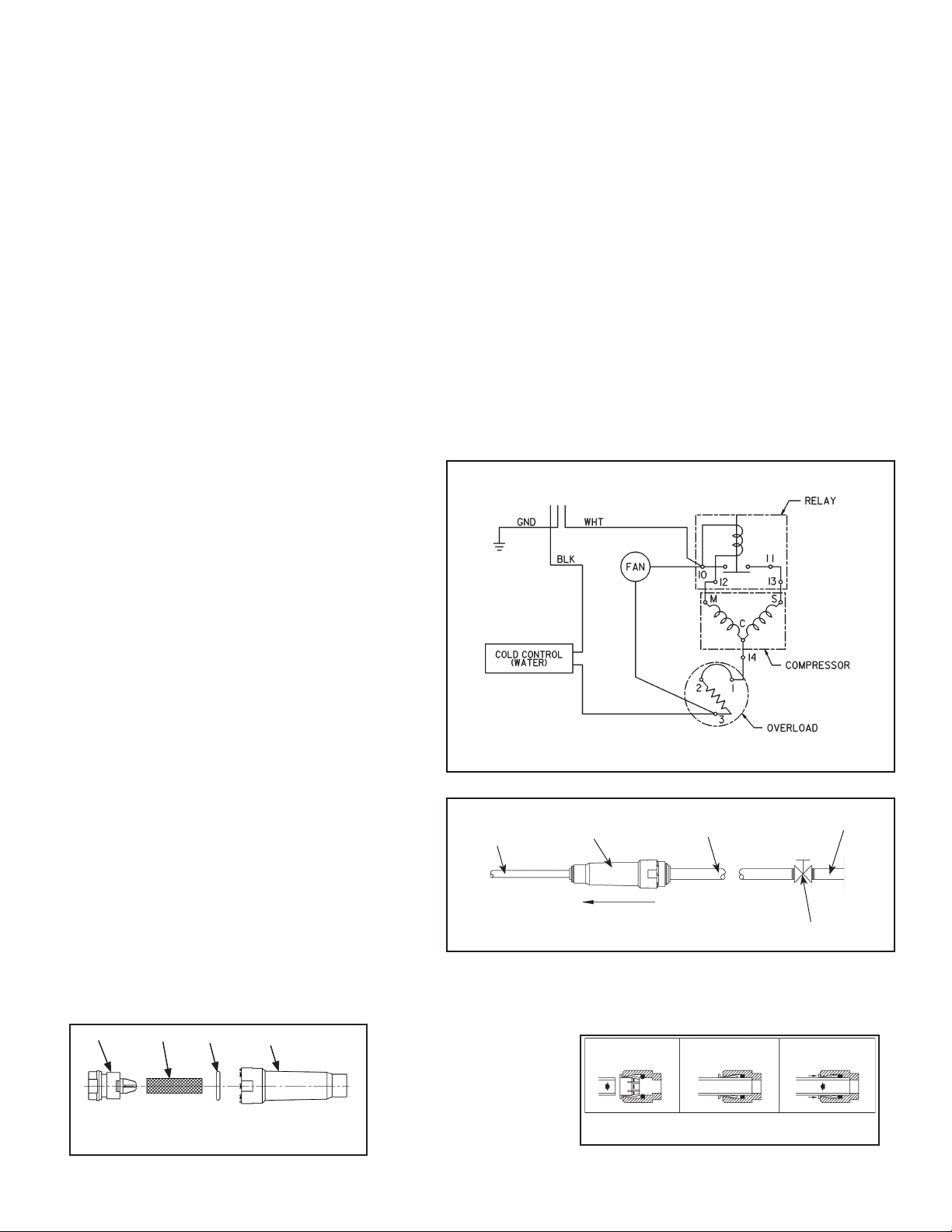

5. Actuation of Quick Connect Water Fittings: Cooler is provided with lead-free connectors which utilize an o-ring seal. To remove tubing from the

ttings, relieve water pressure and push in on gray collar while pulling on the tubing. To insert tubing, push tube straight into tting until it reaches a

positive stop, approximately 3/4" (19mm). See Figure 4.

*INCLUDES RELAY & OVERLOAD. IF UNDER WARRANTY, REPLACE

WITH SAME COMPRESSOR USED IN ORIGINAL ASSEMBLY.

NOTE: All correspondence pertaining to any of the above water cooler or

orders for repair parts MUST include model number and serial number of

cooler, name and part number of replacement part.

For Replacement Parts, contact your local distributor or call 1.800.834.4816

Elkay Manufacturing Co. 2222 Camden Court – Oak Brook, IL 60523 U.S.A – 630.574.8484

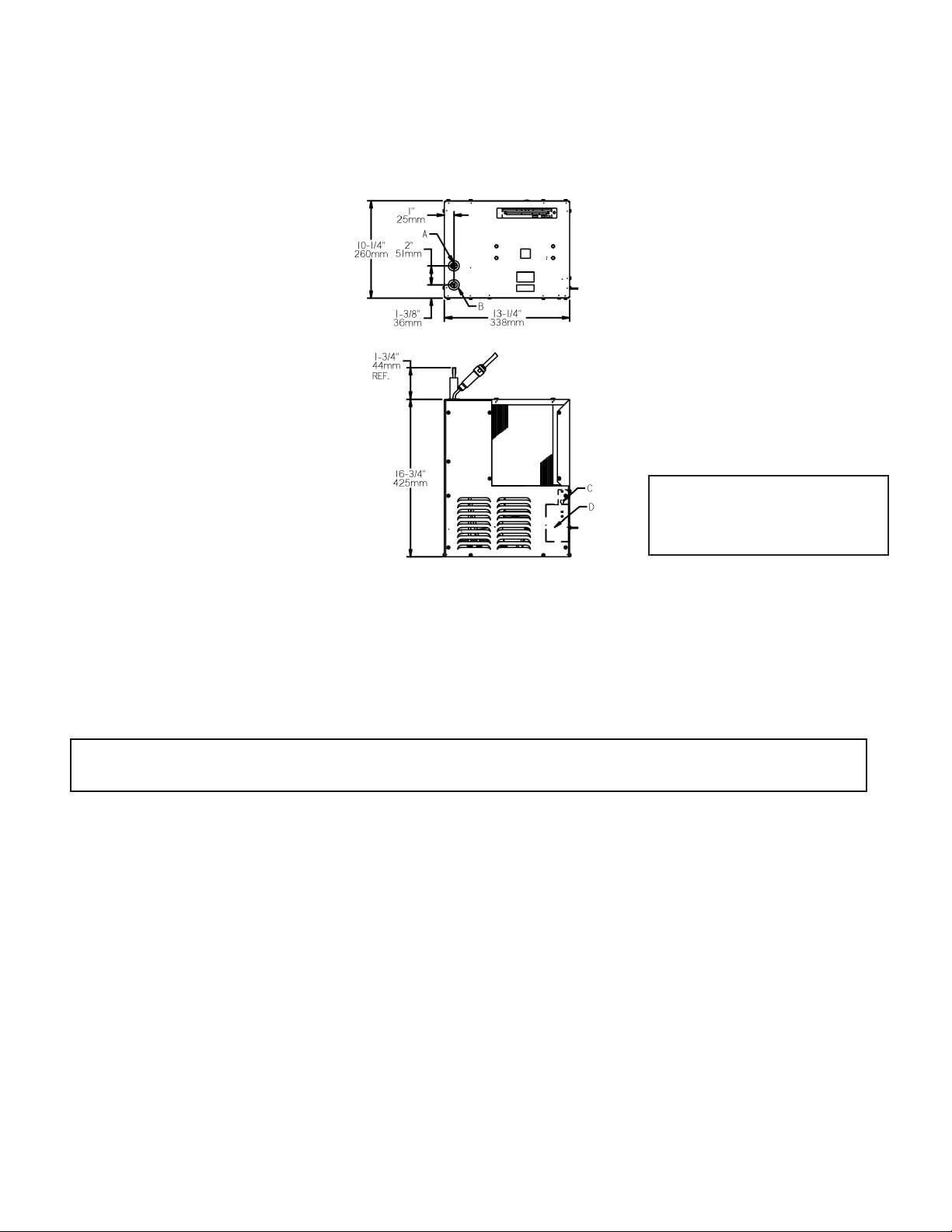

15

16

4

14

7

6

8,11

13

3

2

10

5

17

12

Service

• Safety Glasses

• Protective gloves

• 5/16” (8mm) Hex Socket or Flathead Screwdriver

For proper and safe servicing, please read these instructions completely.

DANGER

• All Service and Maintenance must be performed by an authorized service personnel.

• Disconnect electrical supply to the unit before any service work to reduce risk of electrocution.

• Shut off water supply serving the unit before any service work to reduce risk of water damage.

CAUTION

• Tools/Items required but not provided, for Servicing:

Replacement Parts: Parts List

ITEM NO. PART NO. DESCRIPTION

1 1000004316 KIT - EVAP REPLACE ASSY

2 28478C CABINET

3 98776C KIT - CONDENSER/DRIER

4 0000000244 KIT - FAN MTR/BLADE/NUT/SHROUD (50Hz)

5 20282C BRACKET - FAN MOUNTING

6 98778C KIT - HEAT EXCHANGER/DRIER

7 66703C DRIER

8 1000002147 COMPRESSOR SERVICE PAK (50Hz)

9 98773C KIT - COLD CONTROL/SCREWS

10 28477C PANEL - FRONT

11 98751C KIT - ELECT/RELAY/COVER/OL (50Hz)

12 98777C KIT - COMPRESSOR MTG HDWE

13 50930C BUMPER

14 27303C BASEPLATE

15 22300C PANEL - REAR

16 1000004069 IN-LINE STRAINER

17 56237C SHROUD

*

16

15

3

5

4

17

9

7

8, 11

12

14

10

6

2

1

13