elliot 5224XL Manual

www.elliott-tool.com

Tube & Pipe Cleaners Tube Testers Tube Plugs Tube Removal Tube Installation

5224XL & 5224XLBMC (Air Purge)

Heat Exchanger Cleaner

Tube ID 3/8” to 1” (9.5mm to 25.4mm)

Operating and Maintenance Instructions

TABLE OF CONTENTS

Introduction .......................................................................................................... 4

Safety Guidelines ................................................................................................. 5

General Information.............................................................................................. 7

Operation Instructions.......................................................................................... 8

Technical Information ........................................................................................... 9

Parts List & Diagrams......................................................................................... 10

Shafting & Couplings.......................................................................................... 12

Maintenance Instructions ................................................................................... 13

Troubleshooting.................................................................................................. 14

Warranty ............................................................................................................. 15

4 5224XL & 5224XLBMC

INTRODUCTION

Thank you for purchasing this Elliott product. More than 100 years of experience have been employed

in the design and manufacture of this control, representing the highest standard of quality, value and

durability. Elliott tools have proven themselves in thousands of hours of trouble-free eld operation.

If this is your rst Elliott purchase, welcome to our company; our products are our ambassadors.

If this is a repeat purchase, you can rest assured that the same value you have received in the past

will continue with all of your purchases, now and in the future.

The 5224XL & 5224XLBMC Heat Exchanger Cleaners are designed to provide high-torque for cleaning

hard scale, coke, gummy, oily, or rubbery deposits from straight tubes. Ideal tools for sugar, pulp,

paper mills, chemical plants, and oil reneries.

Model 5224XL is water-ush operation- convenient for ushing away heat transfer deposits.

Model 5224XLBMC is an air purge unit, for use where water-ush cannot be used.

If you have any questions regarding this product, manual or operating instructions, please call Elliott

at +1 800 332 0447 toll free (USA only) or +1 937 253 6133, or fax us at +1 937 253 9189

for immediate service.

5224XL & 5224XLBMC 5

WARNING

!

SAFETY GUIDELINES

Read and save all instructions. Before use, be sure everyone using this machine reads and

understands this manual, as well as any labels packaged with or attached to the machine.

• Know Your Elliott Tool. Read this manual carefully to learn your tool’s application and

limitations as well as the potential hazards specic to this tool.

• Keep Work Area Clean and Well Lit. Cluttered, dark work areas invite accidents.

• Dress Properly. Do not wear loose clothing or jewelry. Wear a protective hair covering

to contain long hair. It is recommended that the operator wear safety glasses with

side shields or a full face shield eye protection. Gloves and water repellent, nonskid

footwear are also recommended. Keep hands and gloves away from moving parts.

• Use Safety Equipment. Everyone in the work area should wear safety goggles or

glasses with side shields complying with current safety standards. Wear hearing

protection during extended use, respirator for a conned space and a dust mask for

dusty operations. Hard hats, face shields, safety shoes, respirators, etc. should be

used when specied or necessary. Keep a re extinguisher nearby.

• Keep Bystanders Away. Bystanders should be kept at a safe distance from the work

area to avoid distracting the operator and contacting the blade.

• Use The Right Tools. Do not force a tool or attachment to do a job or operate at a

speed it was not designed for.

• Use Proper Accessories. Use Elliott accessories only. Be sure accessories are properly

installed and maintained.

• Check for Damaged Parts. Inspect guards and other parts before use. Check for

misalignment, binding of moving parts, improper mounting, broken parts or any other

conditions that may affect operation. If abnormal noise or vibration occurs, turn the

When using electric tools, certain safety precautions

are required to reduce the risk of electrical shock

and personal injury.

WARNING

!

To reduce the risk of injury, always unplug your

machine before performing any maintenance. Never

disassemble the machine or try to do any wiring on

the electrical system. Contact Elliott for all repairs.

Continued On The Next Page

6 5224XL & 5224XLBMC

tool off immediately and have the problem corrected before further use. Do not use a

damaged tool. Tag damaged tools “Do Not Use” until repaired. A damaged part should

be properly repaired or replaced by an Elliott service facility. For all repairs, insist on

only identical replacement parts.

• Keep Hands Away from All Moving Parts.

• Do Not Overreach. Maintain Control. Keep proper footing and balance at all times.

• Stay Alert. Watch what you are doing, and use common sense. DO NOT use a

tool when you are tired, distracted or under the inuence of drugs, alcohol or any

medication causing decreased control.

• Unplug Tool. Unplug tool when it is not in use, before changing accessories or

performing recommended maintenance.

• Maintain Tool Carefully. Keep tools sharp and clean for best and safest performance.

Follow instructions for lubrication, maintenance and changing accessories. For

more information see “Maintenance” section. Periodically inspect the tool cord and

extension cords for damage. Have damaged parts repaired or replaced by an Elliott

service facility.

• Store Idle Tools. When not is use, store your tool in a dry, heated, secured place. For

more information see “Maintenance” section.

• Maintain Labels and Nameplates. These carry important information and will assist you

in ordering spare and replacement parts. If unreadable or missing, contact an Elliott

service facility for a replacement.

SAFETY GUIDELINES

5224XL & 5224XLBMC 7

GENERAL INFORMATION

A clean lubricated air supply must be available at 90 to 125 psi (6.2 to 8.6 Bar), and not less than 45

cfm (1.3 M3/min.), at the point of connection to the motor. A shut-off valve should be provided at

the air supply connection source. If there is any doubt about the cleanliness of the air supply, a lter

should be installed at the supply connection.

Proper lubrication of the unit is a must for peak performance; therefore, a lubricator (preferably a lter/

lubricator) should be installed in the airline immediately downstream of the shut-off valve. A lter-

lubricator (PN 901717P) is available from Elliott Tool Technologies. For best results, use 10W/NR Lube

Oil (PN 900082P), also available from Elliott Tool Technologies in 16 oz. (0.5 L) cans.

A clean water supply must be provided (preferably city water). Water pressure should not exceed 125

psi (8.6 Bar). A ow rate of at least 30 gpm (114 L/min.) should be available. A shut-off valve should

be at the point of connection of the hose whip to the water source. (IMPORTANT: Never operate

Model 522400XL tube cleaner without water supply. Running this tool without water will damage the

shaft seal assembly and cause immediate tool failure.)

Swivel connections are provided on both of the hose whips to provide for easy hookup and eliminate

kinks in the hoses. Connect each hose whip to its corresponding connection on the motor and to its

supply source. Service ends of the hose whips are furnished with female thread connections; 1/2”

NPT (Air) and 1/4” NPT (Water). (Note: Only one hose whip connection is required for the 5224XLBMC

air-purge motor.)

8 5224XL & 5224XLBMC

OPERATION INSTRUCTIONS

Set-Up

1. Open the air & water supply valves (air only if air-purge). Holding the motor with the

threaded shaft end away from you, slowly depress the trigger. The threaded shaft (31)

should rotate & water (or air if air-purge) should exit the opening in the threaded shaft.

The ow of the water (or air) should increase as the motor RPM increases. If this does not

occur, recheck hose connections, or refer to “Troubleshooting” on page 14.

2. After attaching the motor coupling, the motor shafting, the extension shafting (if req’d.),

and the cleaning attachment (drill or brush), insert the shaft into the tube I.D.. (NOTE: DO

NOT activate the motor while the shaft end is outside the tube. Doing so could result

in serious injury.) Maximum length of shafting outside of the tube during the cleaning

process is 5 ft. (1.5M).

(NOTE: If tubes are completely blocked by deposit close to the tube sheet, it is recommended that

only a 5 ft. (1.5M) motor shaft be used to clean all of the blocked tubes. Additional 5 ft. (1.5M) shaft

extensions can be added for deeper cleaning requirements. Operating the cleaner in completely

blocked tubes with a shaft length extending outside of the tube greater than 5 ft. (1.5M) from the tube

sheet can result in excessive whipping of the shaft, which could cause serious injury to the operator

and/or bystanders.) If a length of shafting exceeding 5 ft. (1.5M) must be used then support must be

provided for the shafting.

(NOTE: DO NOT support shafting with your hands. Keep hands & clothing clear of rotating shaft &

components to avoid serious injury.) An acceptable means of support for the shafting would be a tube

guide that is supported by a height-adjustable stand.

5224XL & 5224XLBMC 9

TECHNICAL INFORMATION

Motor Specications

Operating Pressure 90 to 125 PSI (6.2 to 8.6 bar)

Air Consumption 45 cfm (1.3M3 /min) @ 90 PSI (6.2 bar)

Water Pressure (5224XL ONLY) Max: 125 PSI (8.6 bar)

Water Flow Rate 30 gpm (114 L/min)

Operating Speed 1500 RPM

Maximum HP 1HP @ 700 RPM

Maximum Torque 7 ft. lbs. (9.5Nm) @ 700 RPM

Approximate Weight 8lbs (3.6 Kg)

Overall Length 9” (228.6mm)

10 5224XL & 5224XLBMC

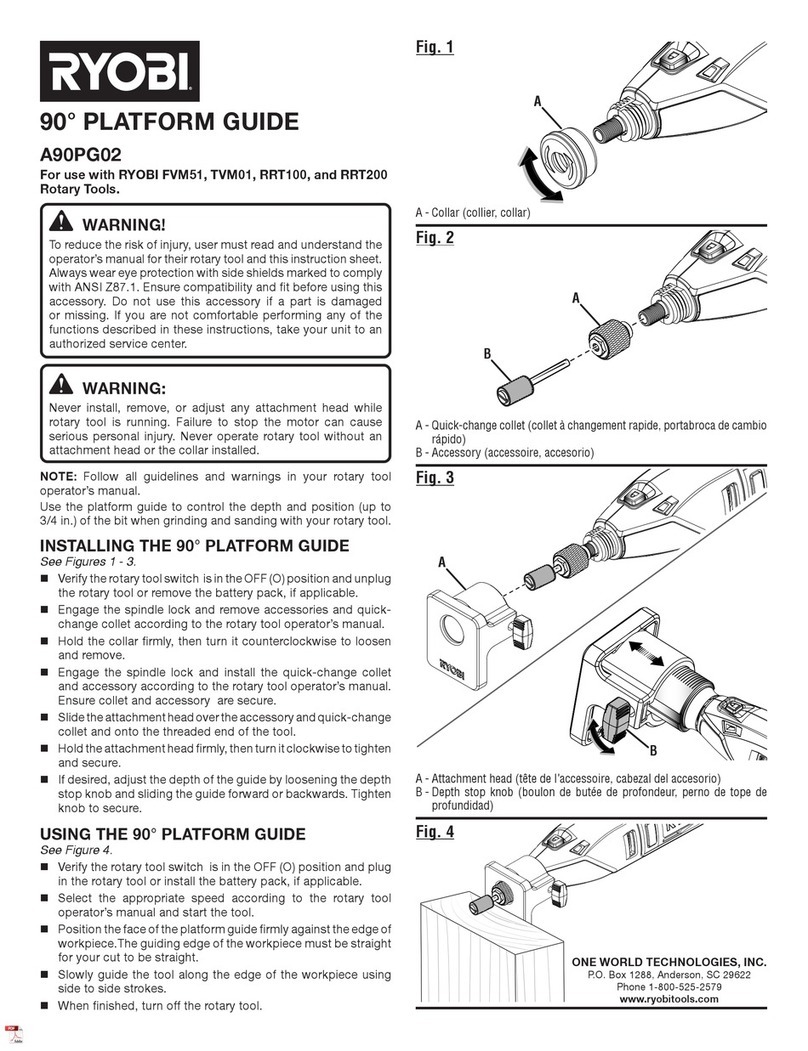

PARTS LISTS & DIAGRAMS

5224XL Heat Exchanger Cleaner

Item # Item Name Qty Part Number

1Motor with water feed

attachment 1 522400XL

2Motor Case 1 5224XLA

3Seal Case 1 5224XLC

4Gear Case 1 5224XLE

5Motor Cap 1 5224XLB

6Plunger 1 5224XLG

7Rear Bushing 1 5224XLH

8Gear Case 1 5224XLK

9Rear Seal 1 5224XLR

10 Drive Pin 1 5224-7

11 Trigger 1 5224D

12 Spacer 1 5224H

13 Shaft 1 5224R

14 Shaft Seal Assembly 1 P5224-5

15 Rotor 1 901005

16 Paddle Set 1 901008P-5

17 End Plate 2 901009

18 Pin 2 901017P

19 Planet Gear & Bearing 2 901020

20 Adapter 1 901178-P

21 Spring 1 P512521

22 Adapter 1 P5370M

23 Bearing 1 P8305B

Item # Item Name Qty Part Number

24 Bearing 1 P8559-12

25 Bearing 1 P8588E

26 Socket Head Cap 4 P8302-72

27 “O” Ring 2 P8309-3

28 “O” Ring 1 P8309-6

29 “O” Ring 2 P8309-8A

30 “O” Ring 1 P8309-13

31 “O” Ring 1 P8309-15

32 Retaining Ring 1 P8368-165

33 Button Head Socket

Screw 4 P8597-11

34 Retaining Ring 1 P8286-78

35 Dowel Pin 2 P8383-6

36 Retaining Ring 2 P8587-106

37 Bearing 2 901011P

38 Rotor Spacer 2 901007

39 Dowel Pin 1 P8381-8

40 Side Handle

(not shown) 1 5224F

5224XL & 5224XLBMC 11

PARTS LISTS & DIAGRAMS

5224XLBMC Heat Exchanger Cleaner

Item # Item Name Qty Part Number

1Motor

2Motor Case 1 5224-XLA

3Seal Case 1 5224XLC

4Gear Case 1 5224-XLE

5Motor Cap 1 5224-XLB

6Plunger 1 5224-XLG

7Rear Bushing 1 5224-XLH

8Gear Case 1 5224-XLK

9Rear Seal 1 5224-XLR

10 Drive Pin 1 5224-7

11 Trigger 1 5224-D

12 Spacer 1 5224-H

13 Shaft 1 5224-R

14 Packaging Box 2 5224-16

15 Rotor 1 901005

16 Paddle Set 1 901008P-5

17 End Plate 2 901010

18 Pin 2 901017-P

19 Planet Gear & Bearing 2 901020

20 Adapter 1 901178-P

21 Spring 1 P-512521

22 Adapter 1 P-5370-H

23 Bearing 1 P-8305-8

Item # Item Name Qty Part Number

24 Bearing 1 P-8559-12

25 Bearing 1 P-8588-E

26 Socket Head Cap 4 P-8302-72

27 “O” Ring 2 P-8309-3

28 “O” Ring 1 P-8309-6

29 “O” Ring 2 P-8309-8A

30 “O” Ring 1 P-8309-13

31 “O” Ring 1 P-8309-15

32 Retaining Ring 1 P-8309-165

33 Button Head Socket

Screw 4 P-8597-11

34 Retaining Ring 1 P-8286-78

35 Dowel Pin 2 P-8383-6

36 Retaining Ring 2 P-8587-106

37 Bearing 2 901011-P

38 Rotor Spacer 2 901007

39 Dowel Pin 1 P-8381-6

40 Packing 2 522415

41 Follower 2 512517

42 Spring 1 P-512518

43 Air Purge Hose 1 P-5370-NP

44 Air Purge Adapter 1 5224-APA

45 “O” Ring 2 P8309-21

46 Side Handle

(not shown) 1 5224F

12 5224XL & 5224XLBMC

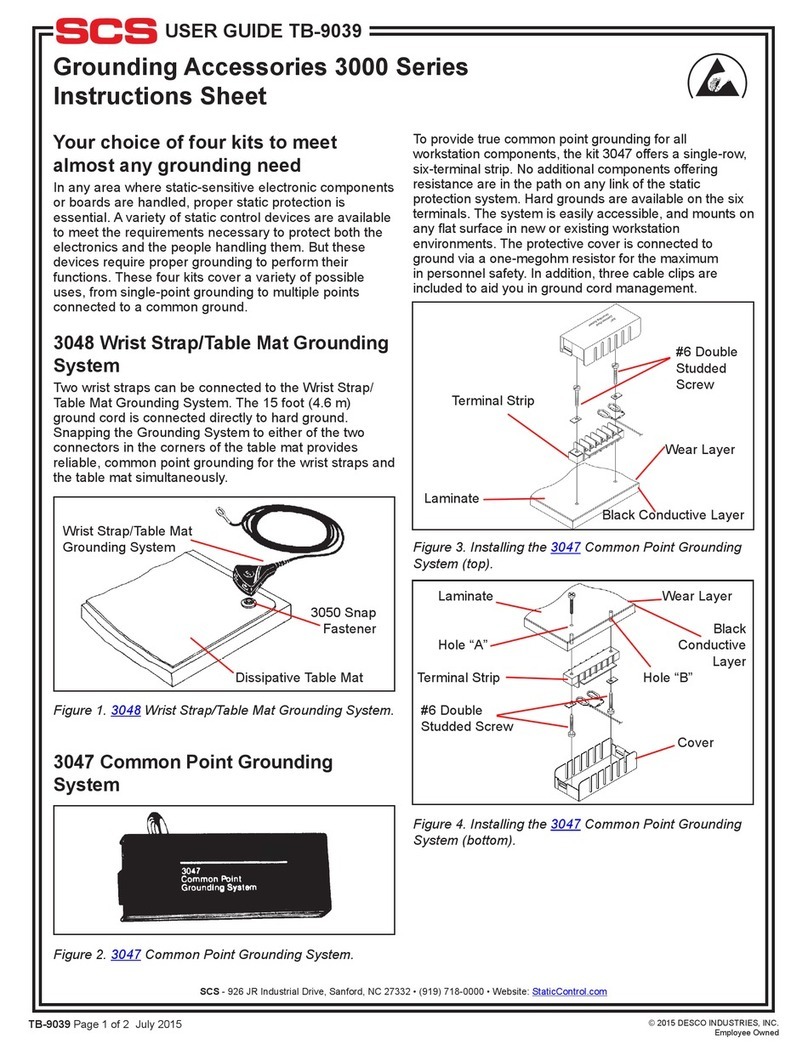

SHAFTING & COUPLINGS

Motor Shaft

Connects Motor Coupling

to the Extension Coupling.

Extension Coupling

Connects Motor Shaft to

the Extension Shaft.

Extension Shaft

Extends the Reach of the

Cleaning Tool by 5’ (1.5M)

Motor Coupling- Connects 5224XL and 5215 Motor to Motor Shaft

Tube ID Range Cleaning

Shaft OD

*Motor

Shaft

Part #

Motor

Shaft

Thread

Size

Motor

Coupling

Part #

**Extension

Coupling

Gasket

Part #

Extension

Coupling

Part #

Extension

Shaft

Part #

0.370” - 0.407”

(9.40 - 10.32 mm)

5/16”

(7.9mm) 5213-(FT) #10-32 F 5213C

0.435” - 0.459”

(11.05 - 11.66 mm)

3/8”

(9.5mm) 5214-(FT) 1/4-20 F 5214C 501406 5014-(FT)

0.481” - 0.560”

(12.22 - 14.22 mm)

7/16”

(11.1mm) 5215-(FT) 5/16-18 F 5215C P5034A CS113106 5015-(FT)

0.584” - 0.685”

(14.83 - 16.56 mm)

1/2”

(12.7mm) 5216-(FT)

3/8-16 F

5216C P5034B CS113206 5016-(FT)

0.709” - 0.810”

(18.01 - 20.57 mm)

5/8”

(15.9mm) 5218-(FT) 5218C P5034C CS113406 5018-(FT)

0.834” - 0.902”

(21.18 - 22.91 mm)

3/4”

(19.1mm) 5219-(FT) 1/2-13 F 5219C P5034D CS113506 5059-(FT)

Note: * Specify shaft length in feet (i.e. 5213-5). ** Included with each Extension Coupling, except where noted.

For Additional Lengths and Sizes Contact Customer Service.

Elliott Tool offers a number of shafts and couplings to be used with the 5224XL and 5125 Heat Exchanger

Tube Cleaners to accommodate different tube sizes and tube lengths.

How To Order Tube Cleaner Shafting, Accessories, Drills, And Brushes:

1. Measure the tube ID behind the tube sheet in the unrolled area

2. Measure the length of the tube(s) to be cleaned

3. Identify the type of deposit to be removed. (Hard, Soft, Gummy or Powder)

4. Select proper type and size drill and/or brush for the deposit being removed.

5. To select proper size Motor Coupling, Motor Shaft, Gaskets, Extension Couplings, and

Extension Shafts refer to the cleaning shaft OD for the drills and/or brushes selected in the right

hand column on the following page. Then refer to the shaft OD in the chart above to select the

proper components.

6. It is recommended to brush the tubes after they are cleaned with a drill to remove any residual

debris and to polish the tube’s ID.

NOTE: Although Motor Shafts are available in lengths of up to 18 feet (5.5M) they are not readily available.

Motor and Extension shafting are readily available in 5’ (1.5M) and 10’ (3M) lengths for handling, storage and

shipping purposes. (Maximum length to ship UPS is 5’ (1.5M)).

5224XL & 5224XLBMC 13

MAINTENANCE INSTRUCTIONS

Care & Maintenance

This cleaning motor should give good performance for many hours under extreme load

provided that it is supplied with proper lubrication as described in the Operating Instructions on

page 4. All rotating parts are mounted on ball bearings, which are either pre-lubricated or get their

lubrication from the air stream. The paddles (16) are considered a standard replacement item as they

receive the most wear. A loss of power is a strong indication of paddle wear. To replace the paddles,

remove the button head screws (33), then carefully remove the Motor Cap (5), and follow with the

removal of the Rotor (15) and Rear End Plate (17). Remove the worn blades & replace with the new

set (4 req’d per set). Reassemble the removed items being careful not to over tighten the four button

head screws. Should this not restore the power to its original state, check “Troubleshooting” on page

6. If solution still cannot be found, motor may have to be returned to the factory for evaluation.

Repairs recommended to be done at factory

1. Excessive leakage of air behind the trigger (11) or the unit not shutting off indicates worn

O-Rings (28 or 29) or worn Plunger (6).

2. Water leakage around the Plunger (6), or water not shutting off completely, indicates worn

O-Rings (27).

3. Excessive gear noise with attendant loss of power, due to damaged or worn gears.

4. Water draining out of the small weep holes in the Seal Case (3) indicates a defective Shaft

Seal Assembly (14). Replacement of this seal should not be done in the eld. This is a

rugged seal, but it can easily be damaged if installed improperly.

5. Motor running rough and causing vibration indicates worn bearings in any one of four

locations (23, 24, 25, and 37).

Please note that the above repairs can be made by the customer, but should be done at a clean work

area by someone experienced with repairs of pneumatic motors. Elliott Tool Technologies cannot be

responsible for damage to the motor, or its components, when repairs are made by the customer.

Prior to returning the motor to the factory for repairs, contact our Customer Service Group for

a Returned Goods (RG) Authorization number. Upon receipt of the motor, an evaluation will be

performed, and a cost estimate will be returned to you for approval prior to any actual repairs.

14 5224XL & 5224XLBMC

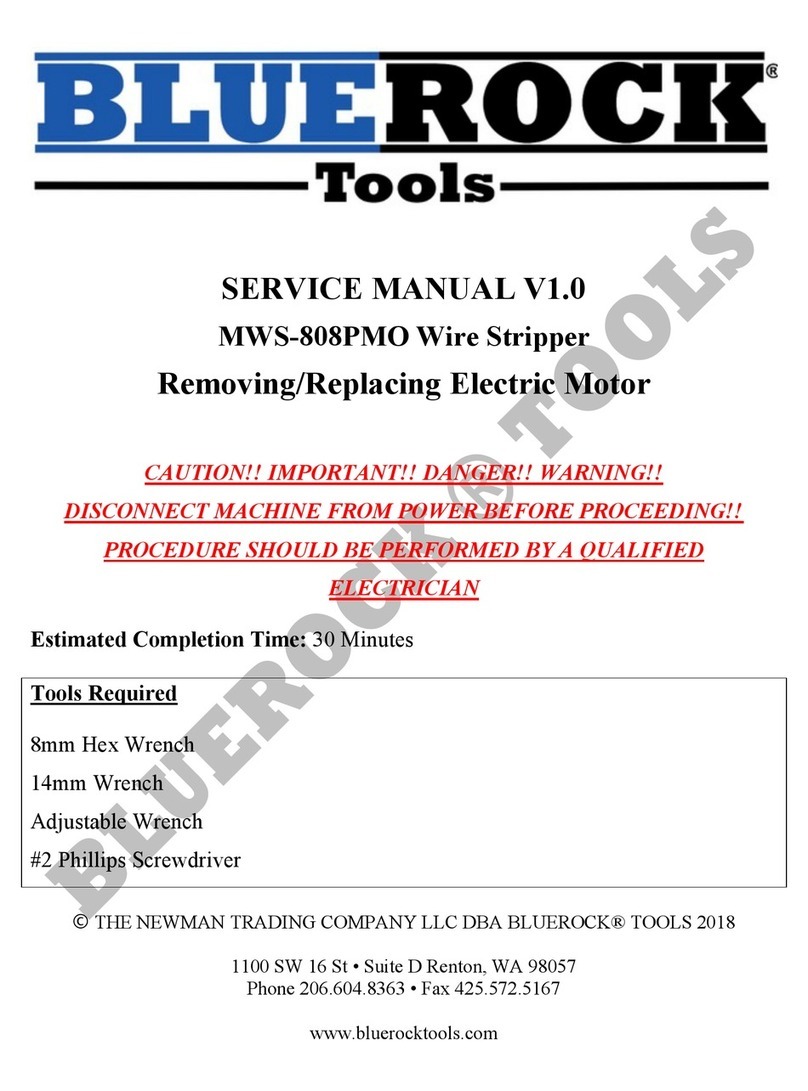

TROUBLESHOOTING

AIR MOTOR TROUBLESHOOTING

AirLeakage

AirStrainersClogged

AirPressureTooLow

DirtyAir

WaterInAir

IncorrectLubrication

InsufficientLubrication

HoseTooSmall

LongPaddles*

WornPaddles

RotorRubbing

WornBearingPlates

WornValveSeat

ThrottlePinSticking

Motor Will Not Run

X

X

X

X

X

LackOfPower

X

X

X

X

X

X

X

X

SpeedTooLow

X

X

X

X

HighAirConsumption

X

X

X

ExcessivePaddleWear

X

X

X

ExcessiveBearingWear

X

X

X

RustingOfParts

X

X

X

DelaminationOfPaddles

X

X

X

PaddlesChipping

X

X

X

MotorContinuesToRun,

ThrottleOff

X

X

MOTORS:

Pneumaticmotorshaveassembliesbuilttoveryclosetolerances.Underconstantuseandwiththepossibility

offoreignpartsmovingthroughtheairline,thesetoleranceshaveatendencytoincreaseduetovanewear.Air

motormaintenanceiscritical.Dirtshouldnotbeallowedtocollectaroundexhaustportsorfittingconnections.

*NOTE:

Ifmotorisstoredinanareaofhighhumidity,vanesmayexpandinlength.

5224XL & 5224XLBMC 15

WARRANTY

Should any part, of Seller’s own manufacture, prove to have been defective in material or workmanship

when shipped (as determined by Seller), Seller warrants that it will, at its sole option, repair or replace

said part f.o.b., point of manufacture, provided that Buyer noties, in writing, of such defect within

twelve (12) months from date of shipment from the manufacturing plant.

On request of Seller, the part claimed to be defective will be returned, transportation, insurance, taxes

and duties prepaid, to the factory where made, for inspection. Any item, which has been purchased by

Seller, is warranted only to the extent of the original manufacturer’s warranty to Seller.

Seller shall not be liable for any damages or delays caused by defective material or workmanship.

No allowance will be made for repairs or alterations made by others without Seller’s written consent or

approval. If repairs or alterations are attempted without Seller’s consent, Seller’s warranty is void.

THE WARRANTIES PROVIDED IN THE OBLIGATIONS AND LIABILITIES OF SELLER HEREUNDER,

AND THE RIGHTS AND REMEDIES OF BUYER HEREUNDER ARE EXCLUSIVE AND IN

SUBSTITUTION FOR, AND BUYER HEREBY WAIVES ALL OTHER WARRANTIES, GUARANTEES,

OBLIGATIONS, CLAIMS FOR LIABILITIES, RIGHTS AND REMEDIES, EXPRESS OR IMPLIED,

ARISING BY LAW OR OTHERWISE, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTY

FOR MERCHANTABILITY AND FITNESS FOR PURPOSE.

Seller’s total liability is limited to the lower of the cost of repair or replacement.

This page intentionally left blank.

This page intentionally left blank.

Elliott Tool Technologies, Ltd.

1760 Tuttle Avenue

Dayton, Ohio 45403-3428

Phone: +1 937 253 6133 • +1 800 332 0447

Fax: +1 937 253 9189

www.elliott-tool.com

Printed in the USA

©10/2017 Elliott Tool Technologies, Ltd.

TM-80

PL-42

Elliott Tool offers a complete line of

precision tube tools to meet your needs.

Contact us or your local support.

Contact Us

www.elliott-tool.com/support

Locally Supported By:

This manual suits for next models

1

Table of contents