BA_Cyclomotion_EN_Vers.09.2019

Contents

1General....................................................................... 3

2Safety warnings.......................................................... 3

2.1 Instructions for the use of the present manual.......... 3

2.2 Instructions for the use of the unit............................ 4

3Product description..................................................... 5

3.1 Cyclomotion product features .................................. 5

3.2 CE conformity.......................................................... 5

3.3 Delivered equipment................................................ 6

3.4 Optional accessories................................................ 6

3.5 Technical details...................................................... 7

3.6 Functioning of the Cyclomotion................................ 8

3.7 Front view................................................................ 9

3.8 Rear view................................................................10

3.9 Operating panel......................................................11

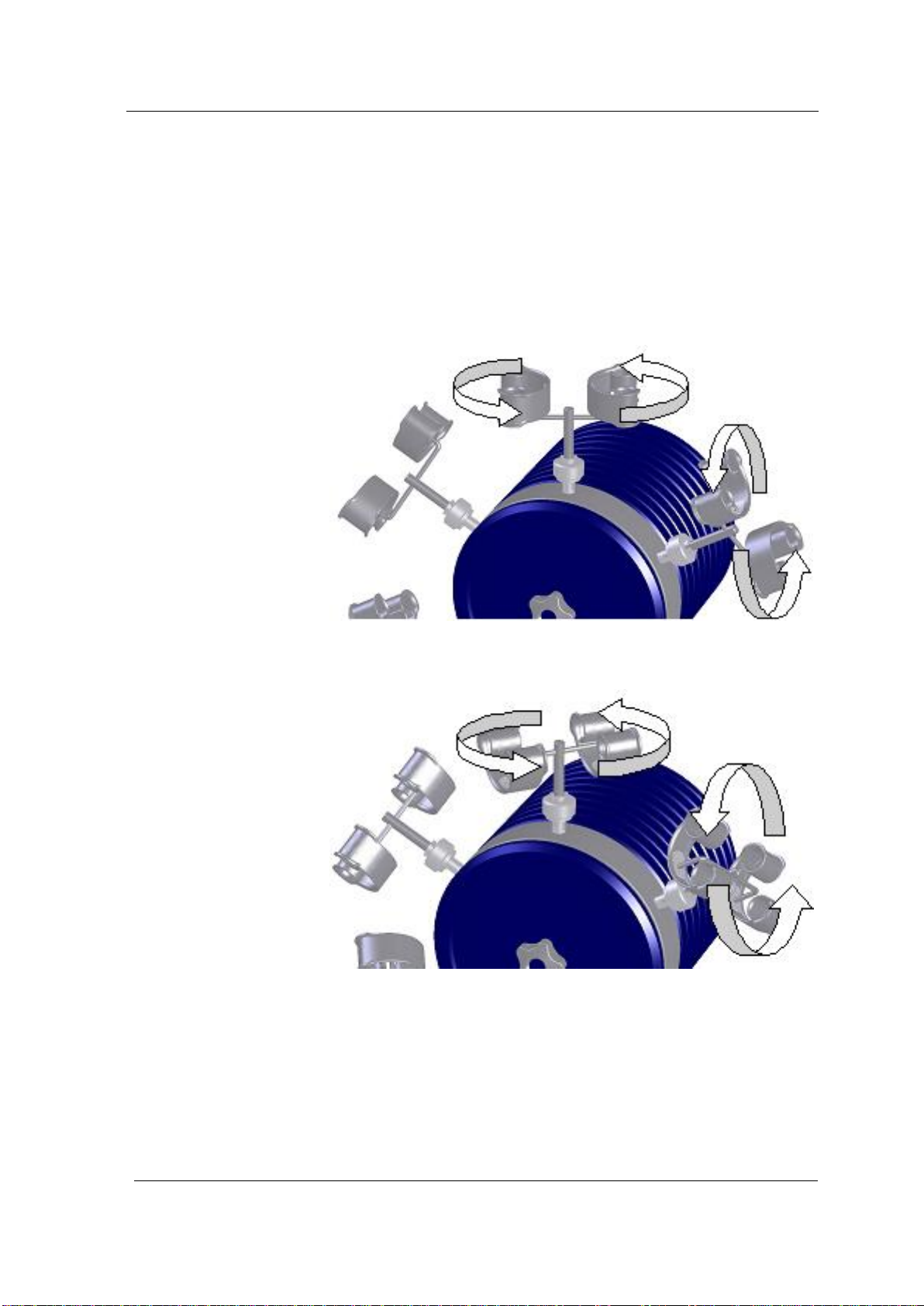

3.10 Individual combination of clips ................................11

3.10.1 Description of the clips .....................................12

3.10.2 Combination examples.....................................13

4Before initial operation.............................................. 14

4.1 Unpacking and placement.......................................14

4.2 Connection to the mains .........................................14

5Initial operation......................................................... 15

6Setting of the wind-up mode..................................... 17

7Maintenance............................................................. 18

7.1 Maintenance of the unit...........................................18

7.2 Cleaning of the protecting hood (Optional)* ............19

8Putting out of action and waste disposal .................. 21

9Manufacturer’s contact address ............................... 21