elobau eloProg User manual

eloProg - Vers. 1.0

eloProg

Configurable safety system

Manual

Product description

Doc.-No. 350HB002en

Last updated: 05/20111 (Vers. 1.0)

(

(C

Co

op

py

y

o

of

f

t

th

he

e

o

or

riig

giin

na

all

iin

ns

st

tr

ru

uc

ct

tiio

on

ns

s)

)

2

eloProg - Vers. 1.0

CONTENTS

INTRODUCTION................................................................................................................................................5

Contents of this handbook............................................................................................................................. 5

Important safety instructions ......................................................................................................................... 5

Abbreviations and symbols ........................................................................................................................... 6

Applicable standards..................................................................................................................................... 6

OVERVIEW ........................................................................................................................................................7

PRODUCT COMPOSITION ...............................................................................................................................8

INSTALLATION .................................................................................................................................................9

Mechanical fastening..................................................................................................................................... 9

Calculation of safety distance of an ESPE connected to eloProg............................................................... 10

Electrical connections.................................................................................................................................. 10

Instructions concerning connection cables............................................................................................. 11

USB input................................................................................................................................................ 12

eloProg memory stick (350EPS )............................................................................................................ 13

MULTIPLE LOAD function.................................................................................................................. 13

RESTORE function............................................................................................................................. 13

EXAMPLE OF CONNECTION OF eloProg TO THE MACHINE CONTROL SYSTEM.......................... 18

CHECKLIST AFTER INSTALLATION......................................................................................................... 18

OPERATING DIAGRAM..................................................................................................................................19

SIGNALS..........................................................................................................................................................20

INPUTS ....................................................................................................................................................... 20

MASTER ENABLE.................................................................................................................................. 20

NODE SEL.............................................................................................................................................. 20

RESTART_FBK ...................................................................................................................................... 21

OUTPUTS ................................................................................................................................................... 22

OUT STATUS ......................................................................................................................................... 22

OUT TEST .............................................................................................................................................. 22

OSSD (485EPB, 485EPE08A02, 485EPA02, 485EPA04)..................................................................... 22

SAFETY RELAYS (485EPR02, 485EPR04) .......................................................................................... 23

Characteristics of the output circuit......................................................................................................... 23

485EPR02/485EPR04 internal contacts................................................................................................. 23

Wiring example 485EPR02 / 485EPB .................................................................................................... 24

Switching operation timing diagram........................................................................................................ 24

TECHNICAL FEATURES.................................................................................................................................25

GENERAL SYSTEM CHARACTERISTICS............................................................................................ 25

Safety level parameters...................................................................................................................... 25

General data....................................................................................................................................... 25

Enclosure............................................................................................................................................ 26

485EPB module.................................................................................................................................. 26

485EPE08A02 module....................................................................................................................... 26

485EPE08 - 485EPE16 modules ....................................................................................................... 27

485EPA02 - 485EPA04 modules ....................................................................................................... 27

485EPR02 - 485EPR04 modules....................................................................................................... 27

MECHANICAL DIMENSIONS..................................................................................................................... 28

SIGNALS..................................................................................................................................................... 29

485EPB................................................................................................................................................... 29

485EPE08A02 ........................................................................................................................................ 30

485EPE08............................................................................................................................................... 31

485EPE16............................................................................................................................................... 32

485EPA02............................................................................................................................................... 33

485EPA04............................................................................................................................................... 34

485EPR02 / 485EPR04.......................................................................................................................... 35

TROUBLESHOOTING................................................................................................................................ 36

485EPB................................................................................................................................................... 36

485EPE08A02 ........................................................................................................................................ 37

485EPE08............................................................................................................................................... 38

485EPE16............................................................................................................................................... 39

485EPA02 / 485EPA04........................................................................................................................... 40

eloProg - Vers. 1.0

3

eloProg safety designer SOFTWARE...........................................................................................................41

Installing the software.................................................................................................................................. 41

PC HARDWARE requirements............................................................................................................... 41

PC SOFTWARE requirements................................................................................................................ 41

How to install the configuration software ................................................................................................ 41

Fundamentals ......................................................................................................................................... 42

Standard tool bar .................................................................................................................................... 43

Create a new project (configure the eloProg system)............................................................................. 44

EDIT CONFIGURATION (composition of the various modules) ............................................................ 45

Change user parameters........................................................................................................................ 45

OBJECTS - OPERATOR - CONFIGURATION tool bars ....................................................................... 46

Creating the diagram (Figure 29)............................................................................................................ 47

Example of a project............................................................................................................................... 48

Project validation ................................................................................................................................ 48

Project report...................................................................................................................................... 48

Connect to eloProg............................................................................................................................. 49

Sending the configuration to the eloProg ........................................................................................... 49

Configuration LOG.............................................................................................................................. 49

Upload system configuration.............................................................................................................. 50

Disconnecting System........................................................................................................................ 50

MONITOR (I/O status in real time - table).......................................................................................... 50

MONITOR (I/O status in real time - graphic)...................................................................................... 51

Password protection ............................................................................................................................... 52

Level 1 password................................................................................................................................ 52

Level 2 password................................................................................................................................ 52

Password Change .............................................................................................................................. 52

TESTING the system.............................................................................................................................. 53

OBJECT FUNCTION BLOCKS................................................................................................................... 54

OUTPUT OBJECTS................................................................................................................................ 54

OSSD (safety outputs)........................................................................................................................ 54

STATUS (signal output)...................................................................................................................... 54

INPUT OBJECTS.................................................................................................................................... 55

E-STOP (emergency stop)................................................................................................................. 55

E-GATE (safety gate device).............................................................................................................. 56

ENABLE (enable key)......................................................................................................................... 58

ESPE (optoelectronic safety light curtain / laser scanner) ................................................................. 59

FOOTSWITCH (safety pedal)............................................................................................................. 60

MOD-SEL (safety selector)................................................................................................................. 62

PHOTOCELL (safety photocell) ......................................................................................................... 62

TWO-HAND safety control ................................................................................................................. 64

SENSOR............................................................................................................................................. 65

S-MAT (safety mat)............................................................................................................................. 66

SWITCH.............................................................................................................................................. 67

COMMENTS....................................................................................................................................... 68

OPERATOR FUNCTION BLOCKS............................................................................................................. 68

LOGICAL OPERATORS......................................................................................................................... 68

AND.................................................................................................................................................... 68

NAND.................................................................................................................................................. 69

NOT.................................................................................................................................................... 69

OR ...................................................................................................................................................... 69

NOR.................................................................................................................................................... 70

XOR.................................................................................................................................................... 70

XNOR ................................................................................................................................................. 70

MULTIPLEXER................................................................................................................................... 71

MEMORY OPERATORS........................................................................................................................ 71

D FLIP FLOP (max number = 8) ........................................................................................................ 71

SR FLIP FLOP.................................................................................................................................... 72

USER RESTART MANUAL (max number = 8 with RESTART MONITORED).................................. 72

USER RESTART MONITORED (max number = 8 with RESTART MANUAL)................................. 72

COUNTER OPERATORS....................................................................................................................... 73

COUNTER (max number = 8)............................................................................................................ 73

4

eloProg - Vers. 1.0

TIMER OPERATORS (max number = 8)................................................................................................ 73

CLOCKING......................................................................................................................................... 73

MONOSTABLE................................................................................................................................... 74

PASSING MAKE CONTACT.............................................................................................................. 75

DELAY................................................................................................................................................ 76

MUTING OPERATORS (max number = 4)............................................................................................. 77

"Concurrent" MUTING........................................................................................................................ 77

MUTING “L”........................................................................................................................................ 78

"Sequential" MUTING......................................................................................................................... 79

MUTING “T”........................................................................................................................................ 80

SPECIAL APPLICATIONS...................................................................................................................... 81

Output delay with manual................................................................................................................... 81

ACCESSORIES AND SPARE PARTS............................................................................................................82

EC DEclaration of conformity........................................................................................................................83

eloProg - Vers. 1.0

5

INTRODUCTION

Contents of this handbook

This handbook describes how to use the eloProg programmable safety module and its expansion

units ("SLAVES");

it includes:

• a description of the system

• method of installation

• connections

• signals

• troubleshooting

• use of the configuration SW

Important safety instructions

This safety alert symbol indicates a potential personal safety hazard. Failure to comply with

instructions bearing this symbol could pose a very serious risk to personnel.

ÎThis symbol indicates an important instruction.

The eloProg is built to the following safety levels: SIL 3, SILCL 3, PL e, Cat. 4, Type 4 in

accordance with the applicable standards.

However, the definitive SIL and PL of the application will depend on the number of safety

components, their parameters and the connections that are made, as per the risk analysis.

Read the "Applicable Standards" section carefully.

Perform an in-depth risk analysis to determine the appropriate safety level for your specific

application, on the basis of all the applicable standards.

Always test the complete system whenever new safety components are added (see the

"TESTING the system" section).

The ambient temperature in the place where the system is installed must be compatible with

the operating temperature parameters stated on the product label and in the specifications.

For all matters concerning safety, if necessary, contact your country's competent safety

authorities or the competent trade association.

6

eloProg - Vers. 1.0

Abbreviations and symbols

350EPS = eloProg memory stick: for basic module 485EPB (accessory)

350EPT = eloProg t-fitting

350EPKS = eloProg configuration software

OSSD = Output Signal Switching Device: solid state safety output

MTTFd= Mean Time to Dangerous Failure

PL = Performance Level

PFHd= Probability of a dangerous failure per Hour

SIL = Safety Integrity Level

SILCL = Safety Integrity Level Claim Limit

SW = Software

Applicable standards

eloProg complies with the following European Directives:

• 2006/42/EC "Machinery Directive"

• 2004/108/EC "Electromagnetic Compatibility Directive"

• 2006/95/EC "Low Voltage Directive"

and is built to the following standards:

CEI EN 61131-2 Programmable controllers, part 2:

Equipment requirements and tests

ISO 13489-1 Safety of machinery:

Safety related parts of control systems. General principles for design

EN 61496-1 Safety of machinery: Electro-sensitive protective equipment. Part 1: General

requirements and tests.

IEC 61508-1 Functional safety of electrical/electronic/programmable electronic safety-related

systems: General requirements.

IEC 61508-2 Functional safety of electrical/electronic/programmable electronic safety-related

systems: Requirements for electrical/electronic/programmable electronic safety-

related systems.

IEC 61508-3 Functional safety of electrical/electronic/programmable electronic safety-related

systems: Software requirements.

IEC 61784-3 Digital data communication for measurement and control: Functional safety field

buses.

IEC 62061 Safety of machinery. Functional safety of safety-related electrical, electronic and

programmable electronic control systems

Table 1

eloProg - Vers. 1.0

7

OVERVIEW

eloProg is a modular safety controller. It consists of a master unit (485EPB), which can be

configured using the configuration software graphic interface, and a number of expansion

units connected via the proprietary bus.

The master unit can also be used as a stand-alone device. It has 8 safety inputs and 2

independent programmable dual channel outputs.

ÎThe following expansions are available:

ÎI/O expansion (485EPE08A02)

Îinput expansions (485EPE08 and 485EPE16)

Îoutput expansions (485EPA02 and 485EPA04)

Îguided contact safety relay output modules (485EPR02 and 485EPR04)

Îdiagnostic connections to the main field buses:

485EPFPD (PROFIBUS), 485EPFCO (CanOpen), 485EPFDN (DeviceNet).

eloProg is capable of monitoring the following safety sensors and commands:

optoelectronic sensors (safety light curtains, scanners, safety photocells), mechanical

switches, safety mats, emergency stops, two-hand controls,all managed by a single

flexible and expandable device.

The system must consist of just one Master 485EPB and a number of electronic

expansions that can range from 0 to a maximum of 7, not more than 4 of the same type.

There is no limit to the number of relay modules that can be installed.

With 7 expansions, the system can have up to 72 inputs and 8 dual channel safety

outputs. The MASTER and its SLAVE units communicate via the 5-way bus sensor,

physically arranged on the rear panel of each unit.

The configuration software is capable of creating complex logics, using logical operators

and safety functions such as muting, timer, counters, etc.

All this is performed through an easy and intuitive graphic interface.

The configuration performed on the PC is sent to the basic module via USB connection;

the file resides in the basic module and can also be saved on the memory chip 350EPS

(accessory). The configuration can therefore quickly be copied to another basic module.

ÎThe eloProg system is certified to the maximum safety level envisaged by the applicable

industrial safety standards (SIL 3, SILCL 3, PL e, Cat. 4).

8

eloProg - Vers. 1.0

PRODUCT COMPOSITION

The basic module 485EPB is supplied with:

• CD-ROM containing the free configuration software SW and PDF handbook.

ÎNB: the rear panel connector (t-fitting350EPT) and memory stick (350EPS) can be ordered

separately as accessories.

The expansion units are supplied with:

• Multilingual Installation sheet.

• Rear panel connector 350EPT (t-fitting),

(not present in the 485EPR02 and 485EPR04 which are connected via terminal blocks

only).

ÎNB: to install an expansion unit (excluding relays) you will need the t-fitting supplied with the

unit plus another t-fitting for the connection to the basic module. This can be ordered

separately as an accessory.

INSTA

L

Mecha

n

Fix the m

o

1. C

o

2. Fi

x

(h

o

3. Fa

s

re

s

4. To

th

e

L

LATI

O

n

ical fast

o

dules to

a

o

nnect the

s

x

the train

o

oking the

m

s

ten the

u

s

pective c

o

remove

a

e

unit; the

n

2b

O

N

ening

a

35mm D

I

s

ame nu

m

of conne

c

m

at the t

o

u

nits to th

e

o

nnector.

P

a

unit, use

n

lift the un

i

1

I

N rail as f

o

m

ber of t-fit

t

c

tors thus

o

p first).

e

rail, arra

n

P

ress the

u

a screwd

r

i

t upwards

Fi

g

o

llows:

t

ings as th

obtained

t

n

ging the

u

nit gently

r

iver to pu

and pull.

3

g

ure 1

e number

t

o the Om

contacts

o

until you f

e

ll down th

eloProg

of units to

ega DIN

3

o

n the ba

s

e

el it snap

e locking

2a

- Vers. 1.0

be install

e

3

5mm (EN

s

e of the

u

into place

latch on t

h

4

9

e

d.

5022) rai

l

u

nit on th

e

.

h

e back o

f

9

l

e

f

10

eloProg - Vers. 1.0

Calculation of safety distance of an ESPE connected to eloProg

Any Electro-sensitive Protective Equipment device connected to eloProg, must be positioned at a

distance equal to or greater than the minimum safety distance Sso that the dangerous point can

be reached only after stopping the dangerous movement of the machine.

The european standard:

- ISO 13855:2010- (EN 999:2008) Safety of machinery - Positioning of safeguards with respect to

the approach speeds of parts of the human body.1

provides the elements to calculate the proper safety distance.

Carefully read the installation manual of each device for specific information on the correct

positioning.

Remember that the total response time depends on:

eloProg response time + ESPE response time + response time of the machine (i.e. the time

taken by the machine to stop the dangerous movement from the moment in which the stop

signal is transmitted).

Electrical connections

The modules are provided with terminal blocks for the

electrical connections. Each unit can have 8, 16 or 24

terminals.

Each module also has a rear panel plug-in connector

(for communication with the master and with the other

expansion units).

The 485EPR02 and 485EPR04 are connected via

terminal blocks only.

Install safety units in an enclosure with a protection class of at least IP54.

The supply voltage to the units must be 24Vdc ±20% (PELV, in compliance with the

standard EN 60204-1 (Chapter 6.4)).

Do not use the eloProg to supply external devices.

The same ground connection (0VDC) must be used for all system components.

1"Describe the methods that designers can use to calculate the minimum safety distance from a specific dangerous point

for the safety devices, particularly Electro-sensitive devices (eg. light curtains), safety-mats or pressure sensitive floors and

bimanual control. It contains a rule to determine the placement of safety devices based on approach speed and the

stopping time of the machine, which can reasonably be extrapolated so that it also includes the interlocking guards without

guard locking."

eloProg - Vers. 1.0

11

Instructions concerning connection cables

ÎCables used for connections must be AWG26 - AWG14. Cables used for connections of

longer than 50m must have a cross-section of at least 1mm2 (AWG16).

ÎWe recommend the use of separate power supplies for the safety module and for other

electrical power equipment (electric motors, inverters, frequency converters) or other sources

of disturbance.

Connections of each unit are listed in the table below:

Master 485EPB

TERMINAL SIGNAL TYPE DESCRIPTION OPERATION

1 24VDC

- 24VDC power supply -

2 MASTER_ENABLE1

Input Master Enable 1 Input ("type B" according to EN 61131-2 )

3 MASTER_ENABLE2

Input Master Enable 2 Input ("type B" according to EN 61131-2 )

4 GND

- 0VDC power supply -

5 OSSD1_

A

Output safety output 1 PNP active high

6 OSSD1_B Output PNP active high

7 RESTART_FBK1

Input Feedback/Restart 1 Input according to EN 61131-2

8 OUT_STATUS1

Output Programmable digital output PNP active high

9 OSSD2_

A

Output safety output 2 PNP active high

10 OSSD2_B Output PNP active high

11 RESTART_FBK2

Input Feedback/Restart 2 Input according to EN 61131-2

12 OUT_STATUS2

Output Programmable digital output PNP active high

13 OUT_TEST1 Output Short circuit detected output PNP active high

14 OUT_TEST2 Output Short circuit detected output PNP active high

15 OUT_TEST3 Output Short circuit detected output PNP active high

16 OUT_TEST4 Output Short circuit detected output PNP active high

17 INPUT1

Input Digital input 1 Input according to EN 61131-2

18 INPUT2

Input Digital input 2 Input according to EN 61131-2

19 INPUT3

Input Digital input 3 Input according to EN 61131-2

20 INPUT4

Input Digital input 4 Input according to EN 61131-2

21 INPUT5

Input Digital input 5 Input according to EN 61131-2

22 INPUT6

Input Digital input 6 Input according to EN 61131-2

23 INPUT7

Input Digital input 7 Input according to EN 61131-2

24 INPUT8

Input Digital input 8 Input according to EN 61131-2

Table 2

12

eloProg - Vers. 1.0

USB input

The basic module 485EPB includes a

USB 2.0 connector for connection to a

Personal Computer where

the configuration software resides.

The USB-cable 350EPU (3m) is

available as an accessory.

Figure 2 - USB 2.0 front panel connector

If the

f

over

w

modu

l

WAR

N

RESTOR

E

If the basi

c

the config

u

basic mo

d

configurati

Î

The

kon

n

35

0

Figu

r

f

ile contain

e

w

rite operati

l

e will be pe

N

ING: ALL

E

function

c

module u

u

rations on

d

ule and

s

on. In this

w

LOAD and

n

te nicht

g

0

EPS LABEL

r

e 3 - 350EP

S

e

d in the m

e

on that wi

rformed.

DATA PR

E

nit is dam

a

the memo

s

witch on

w

ay, the w

o

RESTOR

E

g

efunden

S

e

mory stic

k

ll perman

e

E

VIOUSLY

C

a

ged, you

c

ry stick, all

the eloPr

o

o

rk interrup

t

E

functions

c

werden.)

el

o

A

ca

an

pa

Th

pr

o

m

o

Î

In

s

p

a

sh

o

M

U

T

o

m

o

co

co

th

e

m

o

is not iden

t

e

ntly delete

C

ONTAINE

c

an replace

you need

o

g system,

t

ions will be

c

an be dis

a

o

Prog me

m

backup m

e

n be instal

l

d used t

o

rameters.

e 350EP

S

o

ject is s

e

o

dule.

Î

A

lways

before

l

memor

y

s

ert the me

a

nel of the

o

wn in - 3

5

U

LTIPLE L

O

o

perform t

h

o

dules wit

h

nnector,

y

nfiguration

e

n use it

t

o

dules to b

e

t

ical to the

o

the confi

g

D IN THE

B

it with a n

e

to do is in

s

which wil

minimized

.

a

bled via S

W

eloProg

m

ory stick

(

e

mory, call

e

l

ed in the

b

o

save t

h

S

is writte

n

e

nt from t

h

switch t

h

l

ogging on

y

stick.

mory stick

basic m

o

5

0EPS ).

O

AD funct

h

e configu

r

h

out using

y

ou can

on a sin

g

t

o downlo

a

e

configure

d

o

ne contain

e

g

uration da

t

B

ASIC MO

D

e

w one; ha

s

ert the m

e

l immedia

t

.

W

. (see Fe

- Vers. 1.0

(

350EPS

)

e

d 350EP

S

b

asic mod

u

h

e SW c

o

n

each ti

m

h

e PC to

h

e basic

m

/logging o

in the slot

o

dule (in t

h

ion

r

ation of s

e

a PC an

d

save th

e

g

le memor

y

a

d data on

d

.

e

d in basic

t

a contain

e

D

ULE WILL

ving alrea

d

e

mory stick

t

ely load t

hler! Ver

w

1

3

S

(optional

)

u

le 485EP

B

o

nfiguratio

n

m

ea ne

w

the basi

c

m

odule of

f

ff from th

e

in the rea

r

h

e directio

n

e

veral basi

c

d

the US

B

e

desire

d

y

stick an

d

the basi

c

module, a

n

e

d in basi

c

BE LOST.

d

y saved al

l

in the ne

w

he backu

p

w

eisquell

e

3

)

B

n

w

c

f

e

r

n

c

B

d

d

c

n

c

l

w

p

e

14

eloProg - Vers. 1.0

ÎIn order to be used, the expansion units must be addressed at the time of installation (see

the NODE SEL section).

Each time memory stick is used, carefully check that the chosen configuration is the one that

was planned for that particular system. Try again a fully functional test of the system

composed of eloProg plus all devices connected to it (see the TESTING the system section).

eloProg - Vers. 1.0

15

485EPE08A02

TERMINAL SIGNAL TYPE DESCRIPTION OPERATION

1 24VDC

- 24VDC power supply -

2 NODE_SEL1

Input Node selection Input ("type B" according to EN 61131-2 )

3 NODE_SEL2

Input Input ("type B" according to EN 61131-2 )

4 GND

- 0VDC power supply -

5 OSSD1_A

Output safety output 1 PNP active high

6 OSSD1_B

Output PNP active high

7 RESTART_FBK1

Input Feedback/Restart 1 Input according to EN 61131-2

8 OUT_STATUS1

Output Programmable digital output PNP active high

9 OSSD2_A

Output safety output 2 PNP active high

10 OSSD2_B

Output PNP active high

11 RESTART_FBK2

Input Feedback/Restart 2 Input according to EN 61131-2

12 OUT_STATUS2

Output Programmable digital output PNP active high

13 OUT_TEST1

Output Short circuit detected output PNP active high

14 OUT_TEST2

Output Short circuit detected output PNP active high

15 OUT_TEST3

Output Short circuit detected output PNP active high

16 OUT_TEST4

Output Short circuit detected output PNP active high

17 INPUT1

Input Digital input 1 Input according to EN 61131-2

18 INPUT2

Input Digital input 2 Input according to EN 61131-2

19 INPUT3

Input Digital input 3 Input according to EN 61131-2

20 INPUT4

Input Digital input 4 Input according to EN 61131-2

21 INPUT5

Input Digital input 5 Input according to EN 61131-2

22 INPUT6

Input Digital input 6 Input according to EN 61131-2

23 INPUT7

Input Digital input 7 Input according to EN 61131-2

24 INPUT8

Input Digital input 8 Input according to EN 61131-2

Table 3

485EPE16

TERMINAL SIGNAL TYPE DESCRIPTION OPERATION

1 24VDC

- 24VDC power supply -

2 NODE_SEL1

Input Node selection Input ("type B" according to EN 61131-2 )

3 NODE_SEL2

Input Input ("type B" according to EN 61131-2 )

4 GND

- 0VDC power supply -

5 INPUT1

Input Digital input 1 Input according to EN 61131-2

6 INPUT2

Input Digital input 2 Input according to EN 61131-2

7 INPUT3

Input Digital input 3 Input according to EN 61131-2

8 INPUT4

Input Digital input 4 Input according to EN 61131-2

9 OUT_TEST1

Output Short circuit detected output PNP active high

10 OUT_TEST2

Output Short circuit detected output PNP active high

11 OUT_TEST3

Output Short circuit detected output PNP active high

12 OUT_TEST4

Output Short circuit detected output PNP active high

13 INPUT5

Input Digital input 5 Input according to EN 61131-2

14 INPUT6

Input Digital input 6 Input according to EN 61131-2

15 INPUT7

Input Digital input 7 Input according to EN 61131-2

16 INPUT8

Input Digital input 8 Input according to EN 61131-2

17 INPUT9

Input Digital input 9 Input according to EN 61131-2

18 INPUT10

Input Digital input 10 Input according to EN 61131-2

19 INPUT11

Input Digital input 11 Input according to EN 61131-2

20 INPUT12

Input Digital input 12 Input according to EN 61131-2

21 INPUT13

Input Digital input 13 Input according to EN 61131-2

22 INPUT14

Input Digital input 14 Input according to EN 61131-2

23 INPUT15

Input Digital input 15 Input according to EN 61131-2

24 INPUT16

Input Digital input 16 Input according to EN 61131-2

Table 4

16

eloProg - Vers. 1.0

485EPE08

TERMINAL SIGNAL TYPE DESCRIPTION OPERATION

1 24VDC

- 24VDC power supply -

2 NODE_SEL1

Input Node selection Input ("type B" according to EN 61131-2 )

3 NODE_SEL2

Input Input ("type B" according to EN 61131-2 )

4 GND

- 0VDC power supply -

5 INPUT1

Input Digital input 1 Input according to EN 61131-2

6 INPUT2

Input Digital input 2 Input according to EN 61131-2

7 INPUT3

Input Digital input 3 Input according to EN 61131-2

8 INPUT4

Input Digital input 4 Input according to EN 61131-2

9 OUT_TEST1

Output Short circuit detected output PNP active high

10 OUT_TEST2

Output Short circuit detected output PNP active high

11 OUT_TEST3

Output Short circuit detected output PNP active high

12 OUT_TEST4

Output Short circuit detected output PNP active high

13 INPUT5

Input Digital input 5 Input according to EN 61131-2

14 INPUT6

Input Digital input 6 Input according to EN 61131-2

15 INPUT7

Input Digital input 7 Input according to EN 61131-2

16 INPUT8

Input Digital input 8 Input according to EN 61131-2

Table 5

485EPA04

TERMINAL SIGNAL TYPE DESCRIPTION OPERATION

1 24VDC

- 24VDC power supply -

2 NODE_SEL1

Input Node selection Input ("type B" according to EN 61131-2 )

3 NODE_SEL2

Input Input ("type B" according to EN 61131-2 )

4 GND

- 0VDC power supply -

5 OSSD1_A

Output safety output 1 PNP active high

6 OSSD1_B

Output PNP active high

7 RESTART_FBK1

Input Feedback/Restart 1 Input according to EN 61131-2

8 OUT_STATUS1

Output Programmable digital output PNP active high

9 OSSD2_A

Output safety output 2 PNP active high

10 OSSD2_B

Output PNP active high

11 RESTART_FBK2

Input Feedback/Restart 2 Input according to EN 61131-2

12 OUT_STATUS2

Output Programmable digital output PNP active high

13 24VDC

- 24VDC power supply OSSD1/2 power supply

14 24VDC

- 24VDC power supply OSSD3/4 power supply

15 GND

- 0VDC power supply -

16 GND

- 0VDC power supply -

17 OSSD4_A

Output safety output 4 PNP active high

18 OSSD4_B

Output PNP active high

19 RESTART_FBK4

Input Feedback/Restart 4 Input according to EN 61131-2

20 OUT_STATUS4

Output Programmable digital output PNP active high

21 OSSD3_A

Output safety output 3 PNP active high

22 OSSD3_B

Output PNP active high

23 RESTART_FBK3

Input Feedback/Restart 3 Input according to EN 61131-2

24 OUT_STATUS3

Output Programmable digital output PNP active high

Table 6

eloProg - Vers. 1.0

17

485EPA02

TERMINAL SIGNAL TYPE DESCRIPTION OPERATION

1 24VDC

- 24VDC power supply -

2 NODE_SEL1

Input Node selection Input ("type B" according to EN 61131-2 )

3 NODE_SEL2

Input Input ("type B" according to EN 61131-2 )

4 GND

- 0VDC power supply -

5 OSSD1_A

Output safety output 1 PNP active high

6 OSSD1_B

Output PNP active high

7 RESTART_FBK1

Input Feedback/Restart 1 Input according to EN 61131-2

8 OUT_STATUS1

Output Condition of outputs 1A/1B PNP active high

9 OSSD2_A

Output safety output 2 PNP active high

10 OSSD2_B

Output PNP active high

11 RESTART_FBK2

Input Feedback/Restart 2 Input according to EN 61131-2

12 OUT_STATUS2

Output Condition of outputs 2A/2B PNP active high

13 24VDC

- 24VDC power supply OSSD1/2 power supply

14 n.c.

- - -

15 GND

- 0VDC power supply -

16 n.c.

- - -

Table 7

485EPR04

TERMINAL SIGNAL TYPE DESCRIPTION OPERATION

1 24VDC - 24VDC power supply -

4 GND - 0VDC power supply -

5 OSSD1_A

Input Control ZONE 1 PNP active high

6 OSSD1_B

Input

7 FBK_K1_K2_1

Output Feedback K1K2 ZONE 1 N.C.

9 A_NC1

Output NC contact ZONE 1

10 B_NC1

Output

13 A_NO11

Output NO1 contact ZONE 1

14 B_NO11

Output

15 A_NO12

Output NO2 contact ZONE 1

16 B_NO12

Output

11 A_NC2

Output NC contact ZONE 2

12 B_NC2

Output

17 OSSD2_A Input Control ZONE 2 PNP active high

18 OSSD2_B Input

19 FBK_K1_K2_2

Output Feedback K1K2 ZONE 2 N.C.

21 A_NO21

Output NO1 contact ZONE 2

22 B_NO21

Output

23 A_NO22

Output NO2 contact ZONE 2

24 B_NO22

Output

Table 8

18

eloProg - Vers. 1.0

485EPR02

TERMINAL SIGNAL TYPE DESCRIPTION OPERATION

1 24VDC - 24VDC power supply -

4 GND - 0VDC power supply -

5 OSSD1_A

Input Control ZONE 1 PNP active high

6 OSSD1_B

Input

7 FBK_K1_K2_1

Output Feedback K1K2 ZONE 1 N.C.

9 A_NC1

Output NC contact ZONE 1

10 B_NC1

Output

13 A_NO11

Output NO1 contact ZONE 1

14 B_NO11

Output

15 A_NO12

Output NO2 contact ZONE 1

16 B_NO12

Output

Table 9

EXAMPLE OF CONNECTION OF eloProg TO THE MACHINE CONTROL SYSTEM

Figure 4

CHECKLIST AFTER INSTALLATION

The eloProg system is able to detect the faults that occur in each own module.

Anyway to have the system perfect perform the following checks at start up and at least every one

year:

1. Operate a complete system TEST (see "TESTING the system")

2. Verify that all the cables are correctly inserted and the terminal blocks well screwed.

3. Verify that all the leds (indicators) light on correctly.

4. Verify the positioning of all the sensors connected to eloProg.

5. Verify the correct fixing of eloProg to the Omega rail.

6. Verify that all the external indicators (lamps) work properly.

After installation, maintenance and after any eventual configuration change perform a System

TEST as described in the paragraph "TESTING the system" at page 53.

eloProg - Vers. 1.0

19

OPERATING DIAGRAM

Mechanical fastening

Electrical connections

between the eloProg

modules and with the

external sensors

Designing the diagram

Validation

sw OK ?

NO

YES

Downloading the

diagram to master module

Configuration

control on master

module OK?

NO

YES

End of connection

via USB

System

startup

Connection

via USB

20

eloProg - Vers. 1.0

SIGNALS

INPUTS

MASTER ENABLE

The eloProg 485EPB master has two inputs: MASTER_ENABLE1 and MASTER_ENABLE2.

ÎThese signals must both be permanently set to logic level 1 (24VDC) for the eloProg to

operate. If the user needs to disable the eloProg simply lower these inputs to logic level 0

(0VDC).

NODE SEL

The NODE_SEL1 and NODE_SEL2 inputs (on the SLAVE units) are used to attribute a physical

address to the slave units with the connections shown in Table 10:

NODE_SEL1 NODE_SEL2

SLAVE 0 0 (or not connected) 0 (or not connected)

SLAVE 1 0 (or not connected) 24VDC

SLAVE 2 24VDC 0 (or not connected)

SLAVE 3 24VDC 24VDC

Table 10

ÎIt is not allowed to use the same physical address on two units of the same type.

Other manuals for eloProg

1

Table of contents

Other elobau Controllers manuals

Popular Controllers manuals by other brands

Linear Technology

Linear Technology LT3790 Demo Manual

Trimteck

Trimteck OPTIMUX OpTK Product instruction manual

Ametek

Ametek DPA1 Series Installation, operation and troubleshooting instructions

CALEFFI

CALEFFI Z-one ZSR10X Series manual

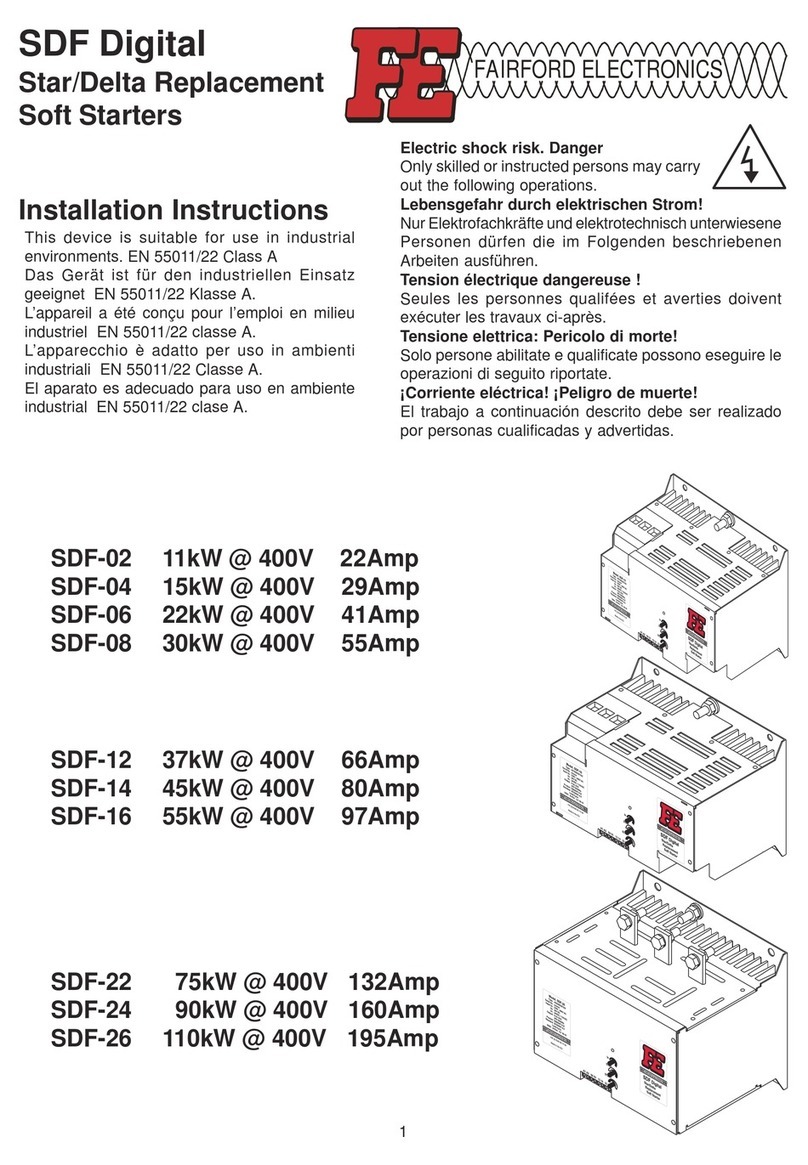

Fairford

Fairford SDF-02 installation instructions

Graco

Graco ProControl 1KS Operation