Prophi®15T-III

4

Section 1: GENERAL

The power factor controller Prophi-15T-III is the consequent follow-up development of

the well proven series Prophi.

The main distinctive feature is the new 3-phases measuring system. Due to the 3-phases

recording of voltage and current the device allows a convenient usage as grid measuring

device and as power factor controller.

All measuring values can be edited and may be displayed in big letters for easier

readability.

2 interfaces are standard. By means of the comfortable windows-software that is included

in the delivery and by using one interface for a connection to a PC the execution and

evaluation of grid measurements is possible. The second interface can be used for

customer specific purposes.

Used as PF-controller various control modes are available. They allow not only to control

according to the phase with the highest load or the average demand of the phases, but

also to realize a real single-phase control (balancing) or a mix of balancing and

conventional three-phases-control.

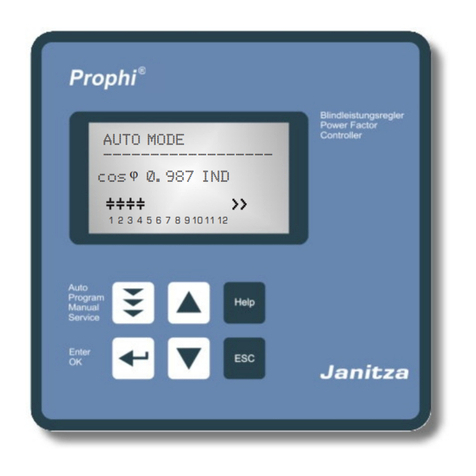

For an easy usage the concept of graphic menu navigation has mainly been adapted.

New are amongst others an integrated help (HELP-button) and the possibility to jump

back in the programming menu by an additional ESCape-button.

The usage of a fully graphic support display allows an additional Oscilloscope-Mode where

the phases (half waves) of voltage and current can graphically be displayed.

R3 x 5 free programmable switching outputs

R1 alarm relay, 1 programmable message relay, 1 relay for the cabinet fan

ROperating voltage: 110 ... 230VAC (+/-15%)

RMeasuring voltage: 3 x 30 ... 440 VAC (L-N) / 50...760 V (L-L)

RMeasuring current: 3 x 5A / 1A

RPre-programmed control series and control series editor

RIlluminated graphic display 128 x 64 dot, graphical menu navigation

R4-quadrant-operation

RMeasuring of capacitor current possible

RThree-phase display of various grid parameters ( U, I, F, Q, P, S Delta Q ... )

RSwitch over to large display possible

RDisplay up to 31st harmonic of voltage and current

RSimultaneous graphical display 1 period of voltage and current in Osci-mode

RMonitoring of temperature

RStorage of maximum grid parameters with time stamp

RManual/automatic operation

RProgramming of fixed steps or mascing of particular outputs possible

RControl possible as 3-phase, 1-phase or mixed-mode

RDisplay of different error messages

RError storage

RComplete 2nd parameter set programmable

R2 integrated separate interfaces

RIntegrated clock, several timers possible

RIntegrated help-function/plain text

RPanel-mounted instrument 144 x 144 x 60 mm