elock KC1005-4 BW User manual

Popular Door Opening System manuals by other brands

Kesseböhmer

Kesseböhmer eTouch DISPENSA operating instructions

hager

hager 4500 Series installation instructions

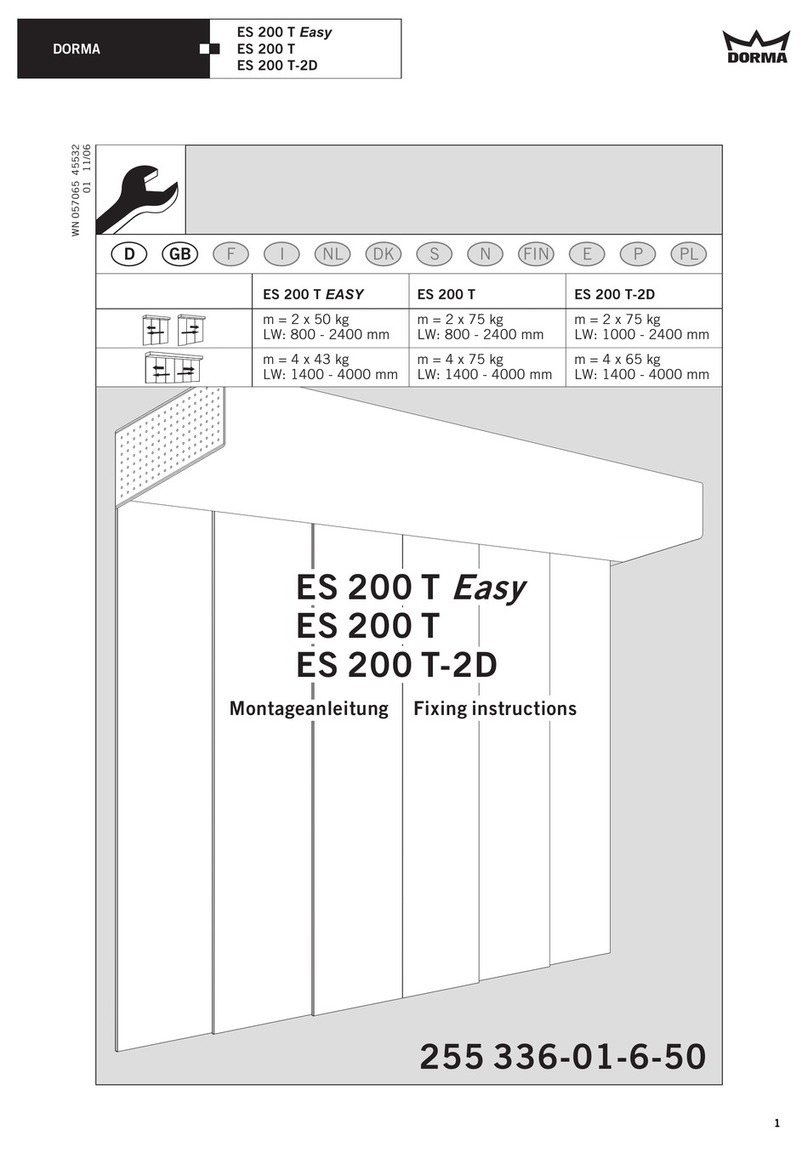

GEZE

GEZE RSZ6 Wiring diagram

WSS

WSS SPRINT Slide Line Original Assembly and Maintenance Instructions

Record

Record FlipFlow TWIN user manual

Roger Technology

Roger Technology R41 Series Instructions and Recommendations

Daihatsu

Daihatsu EDM18ZII instruction manual

Mantion

Mantion SLID'UP 2500 Instructions for assembly

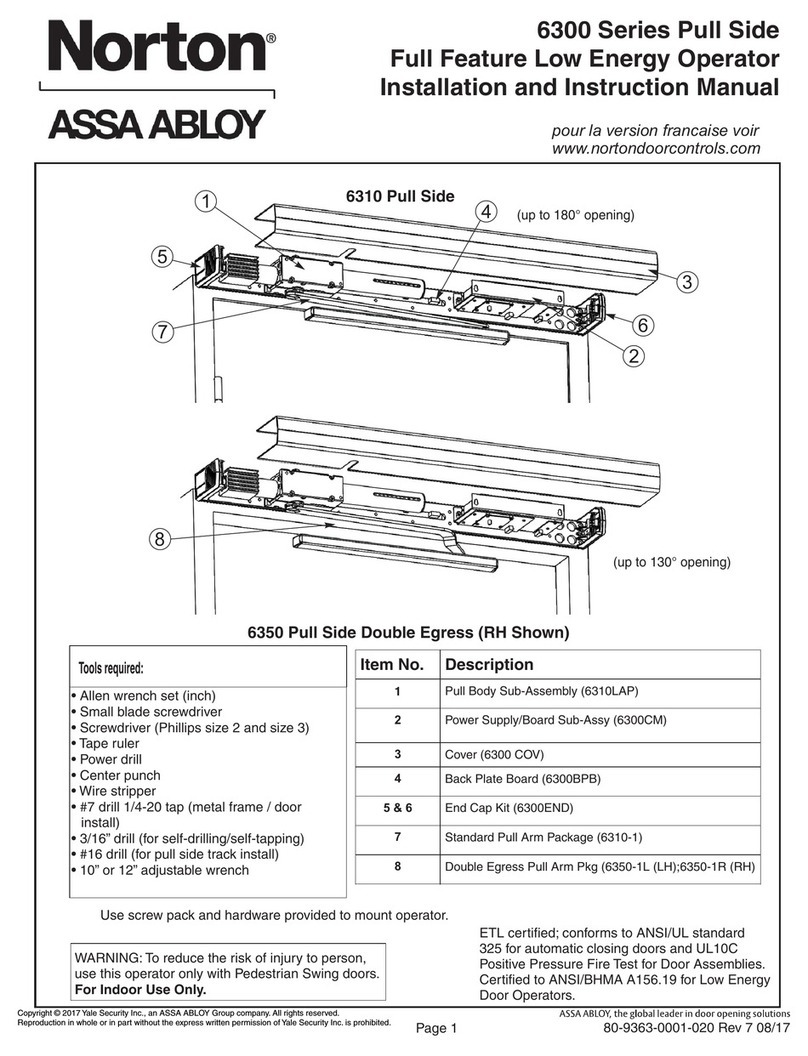

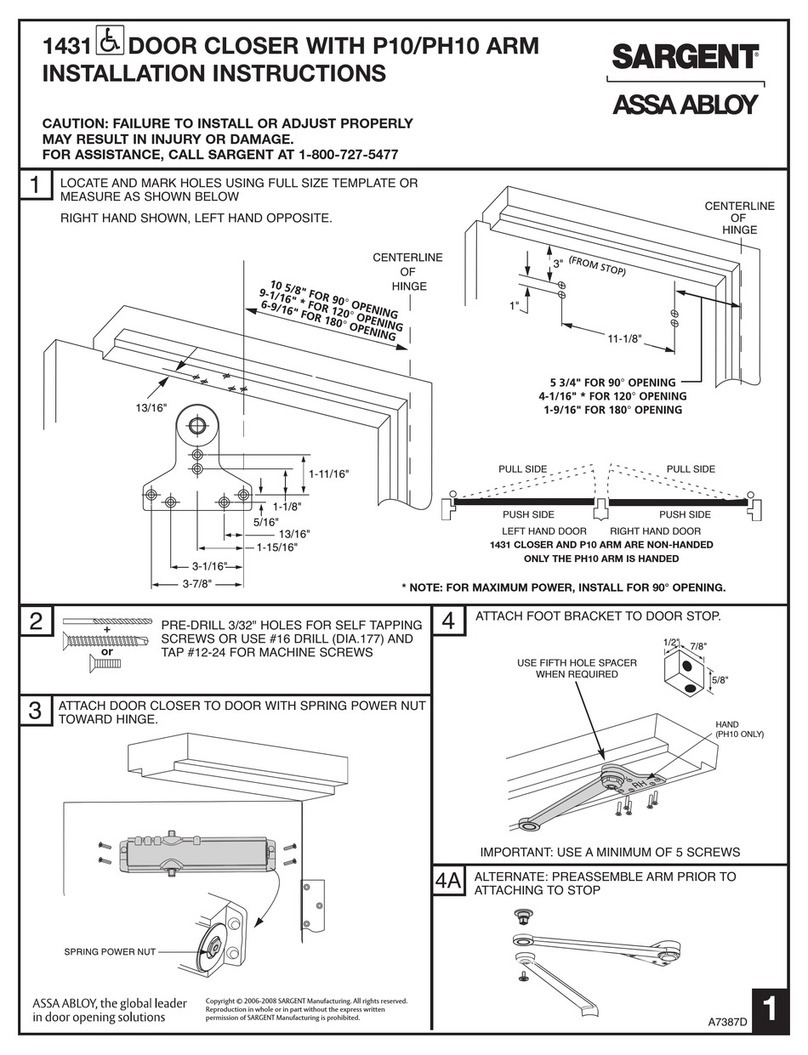

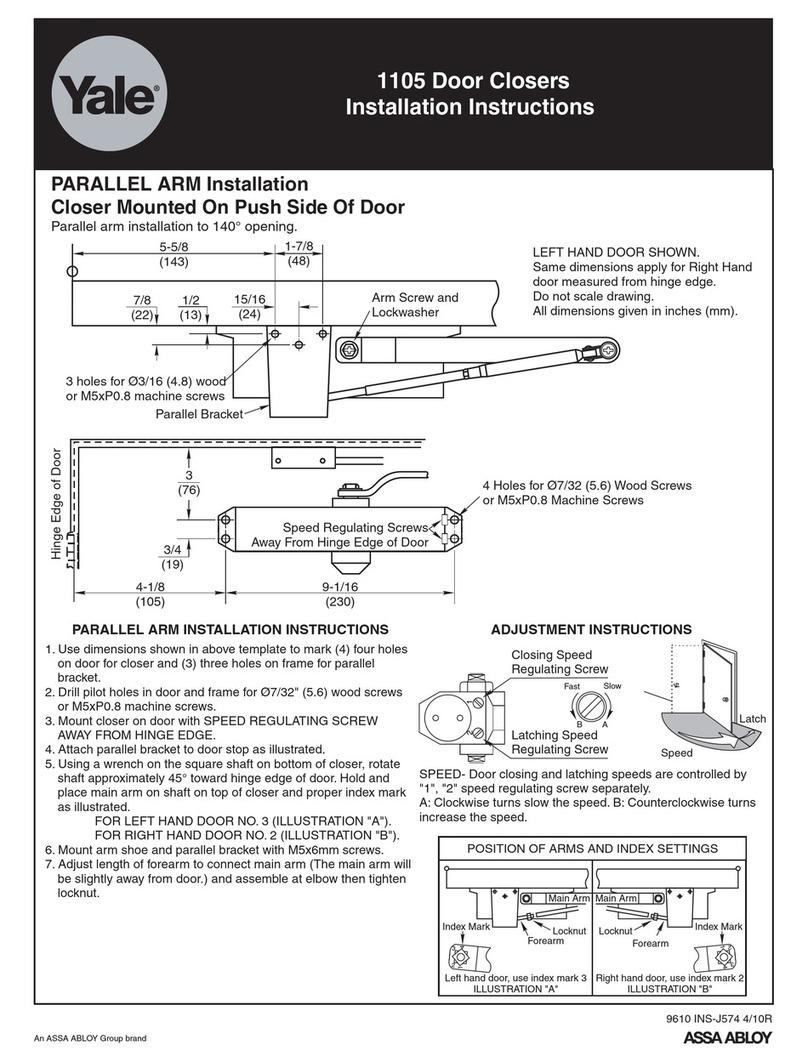

Assa Abloy

Assa Abloy Yale 1105 installation instructions

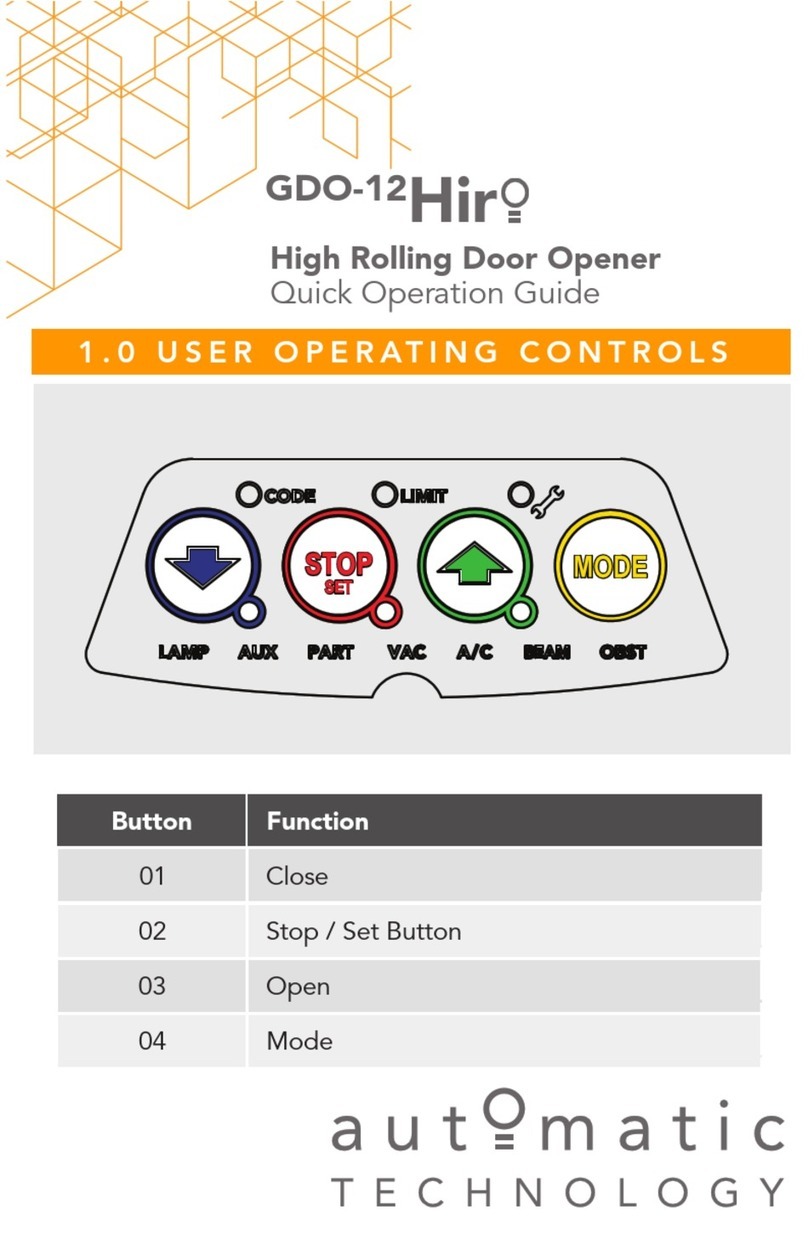

Automatic Technology

Automatic Technology GDO-12Hir Quick operation guide

Beninca

Beninca VN.S20E Operating instructions and spare parts catalogue

Assa Abloy

Assa Abloy Adams Rite EX88 Preparation Guide and Installation Instructions