GEZE hold-open device FA GC 160

2

Table of contents

1 Key to symbols .......................................................................................................................................................4

2 Notes .........................................................................................................................................................................4

2.1 Assembly and electrical connection of the hold-open device ....................................................................................................4

2.2 Installation of lintel smoke switch ...........................................................................................................................................................5

2.3 Protection of a lintel smoke switch against dirt accumulation ....................................................................................................5

2.4 Waste disposal ................................................................................................................................................................................................5

3 Hold-open device FA GC 160 ............................................................................................................................6

3.1 Operation .........................................................................................................................................................................................................6

3.2 Hold-open device with separate smoke switch control unit RSZ6 .............................................................................................7

3.3 Integrated hold-open device ....................................................................................................................................................................8

3.4 Classication according to EN 14637 ......................................................................................................................................................8

3.5 Fire alarm and manual release button design ....................................................................................................................................9

3.5.1 Smoke detector or temperature sensor ................................................................................................................................................................. 9

3.5.2 Number and installation of the re alarm ............................................................................................................................................................. 9

3.5.3 Manual release button ....................................................................................................................................................................................................10

4 Technical data .......................................................................................................................................................11

4.1 Hold-open device FA GC 160 ..................................................................................................................................................................11

4.2 Guidelines.......................................................................................................................................................................................................11

4.3 Power pack .....................................................................................................................................................................................................11

4.4 Lintel smoke switch GC 161 ....................................................................................................................................................................12

4.6 Ceiling smoke detector GC 162 .............................................................................................................................................................14

4.7 Ceiling temperature sensor GC 163 .....................................................................................................................................................15

4.8 Manual release button UTA .................................................................................................................................................................... 16

5 Wiring diagram ....................................................................................................................................................17

5.1 Mains connection ........................................................................................................................................................................................17

5.1.1 Mains connection for protection class I ..............................................................................................................................17

5.1.2 Mains connection for protection class II ............................................................................................................................18

5.2 Ceiling detector ...........................................................................................................................................................................................18

5.2.1 Ceiling detectors GC 162 and GC 163 ....................................................................................................................................................................18

5.3 Manual release button UTA .................................................................................................................................................................... 20

5.3.1 Manual release button UTA with line monitoring ..........................................................................................................................................20

5.3.2 Manual release button UTA without line monitoring ..................................................................................................................................21

5.4 Alarm output ................................................................................................................................................................................................ 22

5.5 Hold-open device ....................................................................................................................................................................................... 22

5.5.1 Hold-open device RSZ6 ................................................................................................................................................................................................ 22

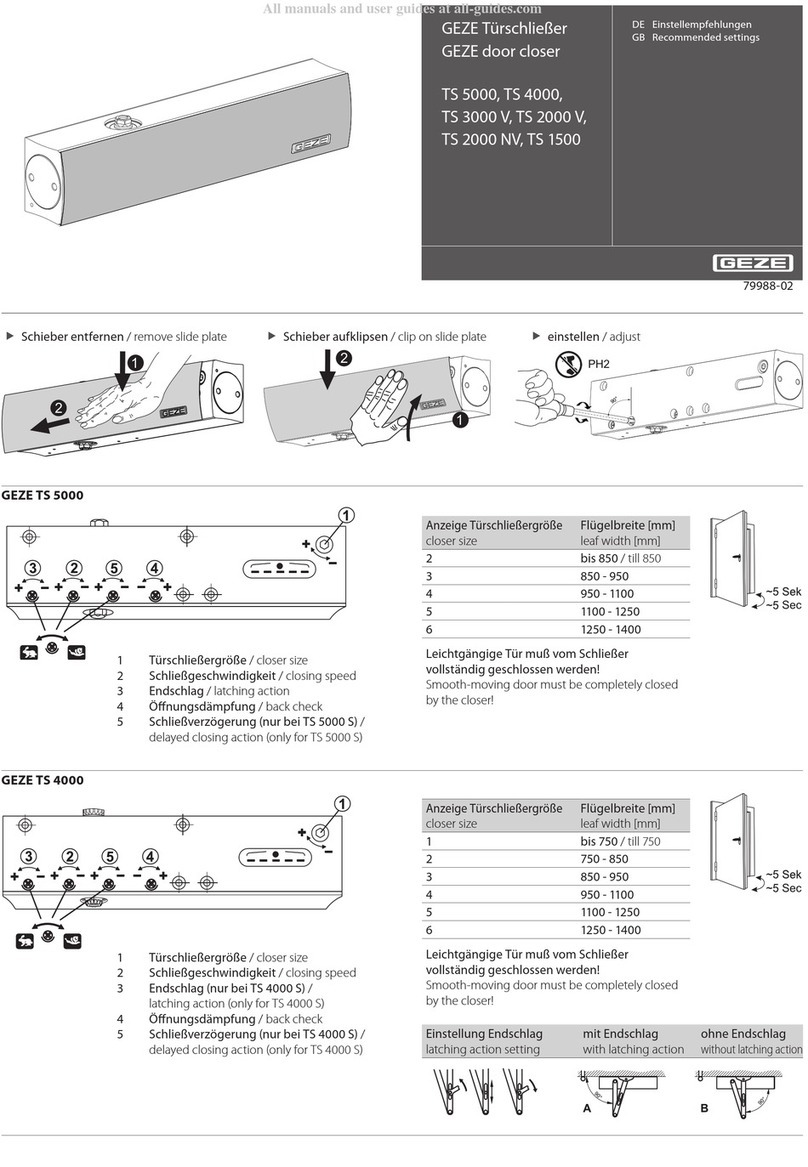

5.5.2 Hold-open systems TS 4000 R, TS 4000 RFS ......................................................................................................................................................26

5.5.3 Hold-open system TS 4000 R-IS ................................................................................................................................................................................26

5.5.4 Hold-open system TS 5000 R ......................................................................................................................................................................................26

5.5.5 Hold-open system TS 5000 R-ISM ............................................................................................................................................................................27

5.5.6 Hold-open system TS 5000 R-ISM-EFS ..................................................................................................................................................................27

5.5.7 Hold-open system TS 5000 RFS .................................................................................................................................................................................27

5.5.8 Hold-open system TS 5000 RFS-KB .........................................................................................................................................................................27

6 Commissioning ................................................................................................................................................... 28

6.1 Examination of the self-closing feature of the door ...................................................................................................................... 28

6.1.1 1-leaf door ...............................................................................................................................................................................................................................28

6.1.2 2-leaf door ...............................................................................................................................................................................................................................28

6.2 Testing the smoke detector ................................................................................................................................................................... 28

6.2.1 GC 161 ........................................................................................................................................................................................................................................28

6.2.2 GC 162 ........................................................................................................................................................................................................................................28

6.3 Testing the temperature sensor ............................................................................................................................................................ 29

6.3.1 GC 163 ........................................................................................................................................................................................................................................29