Technical Manual MiniMEP Data Loggers page 3

02.07.96 12:27

Sensor 1 -23.5°C

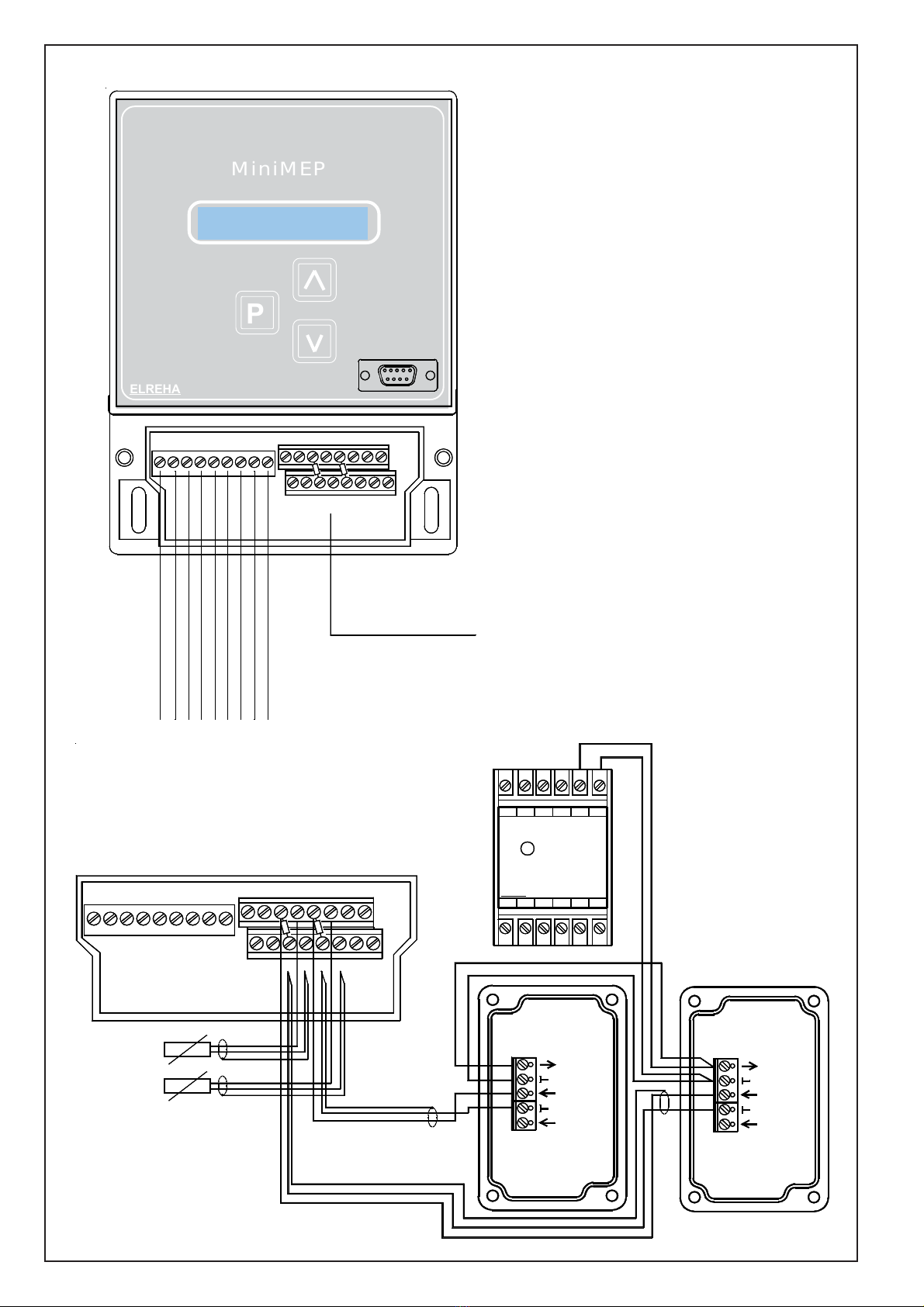

After power-up, the

display shows date,

Current time and value

of sensor 1.

Operating

By pushing the 'up/down' keys you

can select the desired values.

Every keypress brings you to the

next recorded value. Holding an

'up' or 'down' key effects an

automatic, accelerating scrolling.

02.07.96 12:00

sensor 1 -23.5°C

02.07.96 11:45

sensor 1 -23.5°C

02.07.96 12:15

sensor 1 -23.5°C

02.07.96 12:15

sensor 1 -23.5°C 02.07.96 12:15

sensor 2 -12.0°C 02.07.96 12:15

sensor 4 -5.5°C

02.07.96 12:15

sensor 3 21.5°C

serial no

000000

Holding the button 'P' for more than 1 sec. brings you to the parameter page. Select parameter

by the 'up/down' keys (see parameter descriptions on the next pages). Holding the 'P' button

again brings you back to the sensor 1 page.

Every push on button 'P' brings you to the

page of the next sensor.

zSelect desired parameter by the 'up/down' keys

zPress 'P'-key short

zAn access code is

requested

zEnter access code by

'up/down' keys

The code is related from the time of the day as the sum of the hour (0 to 23) plus ‘10’.

Example: At 9:35 a.m. the code is 9 + 10 = 19.

At 9:35 p.m. the code would be 21 + 10 = 31

zNotation of parameter flashes

zChange value by the 'up/down' keys

zPress 'P'-key short

zSelect new parameter if necessary

If you have pressed the 'P' key longer than 1 second or no key is pressed for about 1 minute

after entering the code, the display will switch back to the actual value of sensor 1.

Programming / Access Authorization

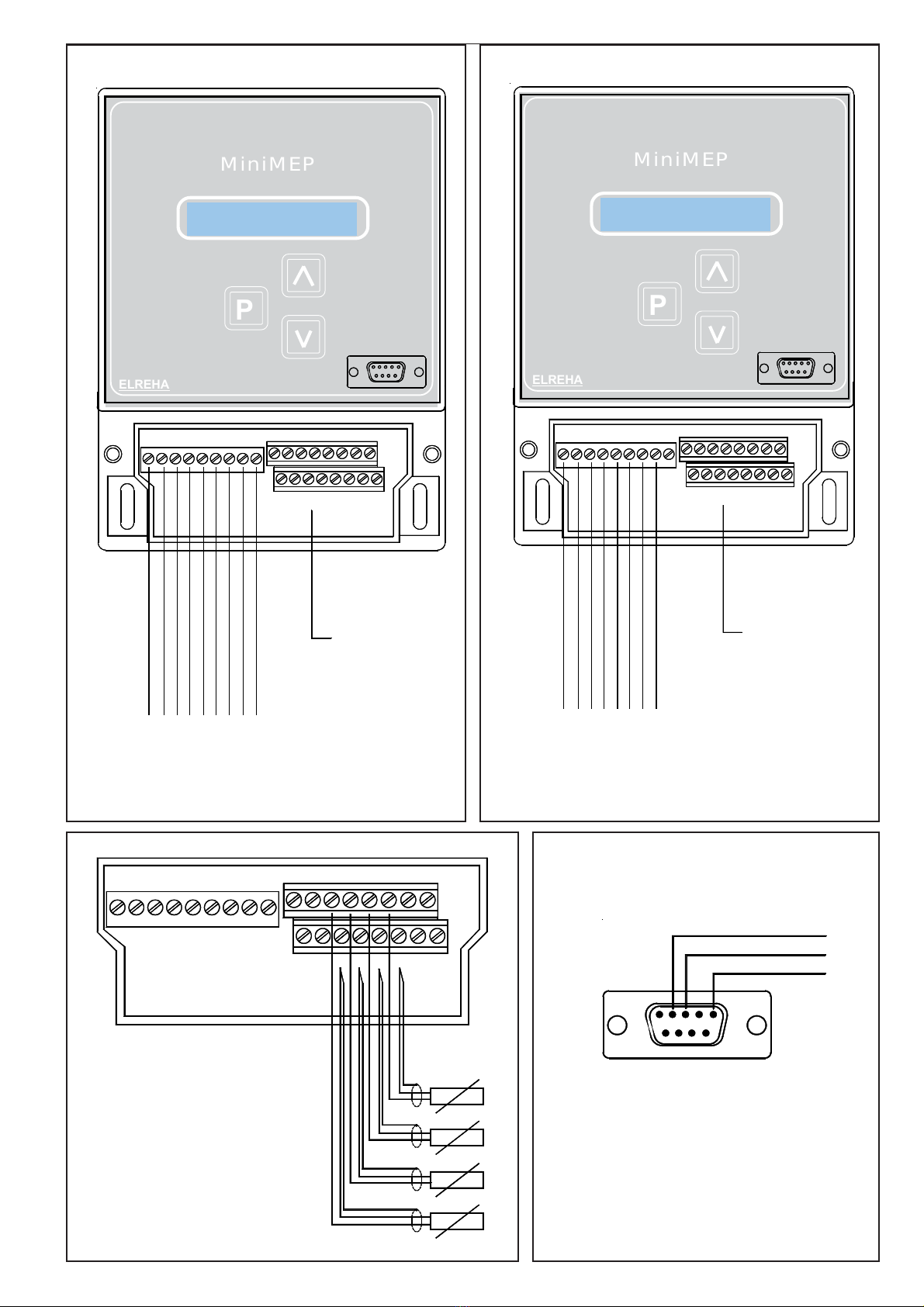

Organisation of the display pages

All parameters and values are partitioned on four

sensor pages and a parameter page. The sensor

pages contain the recorded values. The parameter

page contains setpoints, times, error messages,

etc. Operating the MiniMEP is very easy by three

keys. Key 'P' changes the pages, with the up/down

buttons you are able to scroll the lists or to change

values.

Pages

Overview

Read off recorded values

P P PP

Basic settings / Reading Error messages

02.07.96 12:15

sensor 1 -23.5°C 02.07.96 12:15

sensor 1 -23.5°C

P P

01.07.96 14:15

sensor 4 -17.5°C

01.07.96 14:30

01.07.96 14:45

01.07.96 14:15

sensor 1 -1.0°C

01.07.96 15:00

P

01.07.96 14:15

sensor 3 -24.5°C

01.07.96 14:45

01.07.96 15:00

01.07.96 14:30

01.07.96 14:15

sensor 2 -21.0°C

01.07.96 14:30

01.07.96 14:45

01.07.96 15:00

P P

MINIMEP

serial no

000000

01.07.96 14:30

01.07.96 15:00

01.07.96 14:45

correction

probe selection

push for longer

than 1 second

P P

Identification 1

entry : > 0 <

Reset of Error Messages

If an error message occurs,

push shortly

Buzzer and relay will be reset, but will come

back after the set alarm repetition time. If an

error with a higher priority occurs, it will come

at once.

Buzzer / Relay Test

To test, if the internal buzzer and the alarm

relay works correctly,

push and

at the same time while the actual values are

displayed. The buzzer sounds and the relay

switches off as long as you press the keys.

P

Error codes

If a failure occurs, the MiniMEP generates an

error message by de-activating the alarm relay

and switching ON the internal buzzer.

Additionally, the display starts flashing to get

your attention. Each error message has a

priority level. If several messages occur, the

messages with higher priority are displayed on

top, messages with lower priority are blinded

by the higher ones.

x34-types only: If the current inputs

get > 20mA or if they are not connected:

display shows 100%, no error

message.

'——' ................... no error

'Poff' .................... main power was switched off

prio.1 ........... 'al1' ...................... digital input 1 (Default=al1) was/is not connected

prio.2 ........... 'al2' ...................... digital input 2 (Default=al2) was/is not connected

prio.3 ........... 'door' ................... digital input 3 (Default=door) was/is not connected

prio.4 ........... probe 1, 'p-break' (sensor is broken) or 'p-short' (sensor has short circuit)

prio.5 ........... probe 2, 'p-break' (sensor is broken) or 'p-short' (sensor has short circuit)

prio.6 ........... probe 3, 'p-break' (sensor is broken) or 'p-short' (sensor has short circuit)

prio.7 ........... probe 4, 'p-break' (sensor is broken) or 'p-short' (sensor has short circuit)

prio.8 ........... 'ot 1' .................... sensor 1 has increased the warning limit

prio.9 ........... 'ot 2' .................... sensor 2 has increased the warning limit

prio.10 ......... 'ot 3' .................... sensor 3 has increased the warning limit

prio.11 ......... 'ot 4' .................... sensor 4 has increased the warning limit

prio.12 ......... 'accu' ................... accu operation after mains is lost

prio.13 ......... 'dch.' .................... accu discharged or defect

prio.14 ......... 'ut 1' .................... sensor 1 has decreased the warning limit

prio.15 ......... 'ut 2' .................... sensor 2 has decreased the warning limit

prio.16 ......... 'ut 3' .................... sensor 3 has decreased the warning limit

prio.17 ......... 'ut 4' .................... sensor 4 has decreased the warning limit

'prb1' to 'prb4' ..... an error is occured on sensor x

Reading the Current Error

While the display flashes, you can read the

current error by holding

for > 1 sec.

Then parameter (actual error) will be displayed