Elsner Cala Touch KNX CH Series User manual

Room Controller Cala Touch KNX CH 1

Room Controller Cala Touch KNX CH • Version: 28.04.2020 • Technical changes and errors excepted. • Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany • www.elsner-elektronik.de • Technical Service: +49 (0) 7033 / 30945-250

EN

Technical specifications and installation instructions

This document describes the functions for ALL device models.

Please check the information at the beginning of the chapter and in the

text which describes the functions available for the respective

individual models.

1. Description

The Room Controller Cala Touch KNX CH for the KNX bus system measures va-

rious ambient climate. Via the bus, the indoor sensor can receive external values

and process them further with its own data to a total value (mixed value, e.g. room

average).

All measured values can be used for the control of threshold value-dependent swit-

ching outputs. States can be linked via AND logic gates and OR logic gates. Multi-

functional modules change input data as required by means of calculations, query-

ing a condition, or converting the data point type. In addition, an integrated mani-

pulated variable comparator can compare and output variables that were received

via communication objects.

Integrated PI-controllers control ventilation (according to humidity or CO2-concen-

tration) and/or heating/cooling (according to temperature), depending on the re-

spective model.

Cala Touch KNX CH features a touch display that shows various display and con-

trol pages depending on the individual configuration. There is one page available

that shows the current measured values, a menu area to adjust device settings and

pages with touch control elements for internal temperature control, for light (manu-

al switching or dimming), for shades or windows (manual operation).

Cala Touch KNX CH is supplemented with a frame of the switch series used in

buildings, and thus fits seamlessly into the interior fittings.

Common features in all models:

•Colour touch display with display and operating pages for

- 1× display of current measured values

- 1× display of bus data (4 universal spaces)

- 1× temperature control (incl. mode change, indication whether heating/

cooling active); can also be used as an extension unit for operating another

controller

- 3× drive operation (shading, window) with buttons, slider, position display

(incl. slat position)

- 3× switching or dimming of light (with percentage display)

- 1× RGB light control

- 1× light color temperature setting

- 1× HCL control (adaption of light color temperature over adjustable periods

of time)

- 1× scenes (4 scenes with recall, storage, status indication)

- weekly timer switch with 8 periods

- 2× info page (each displays 2 text objects)

- device settings

•Screen saver (clock, clock/indoor/outdoor temperature alternately, off) may

be switched on or off

• Key tone may be switched on or off

•4 inputs for binary contacts or T-NTC temperature sensor.

•8 AND and 8 OR logic gates each with 4 inputs. All switching events as

well as 16 logic inputs (in the form of communications objects) can be used

as inputs for the logic gates. The output from each gate can be configured

optionally as 1-bit or 2 x 8-bit

•8 multi-function modules (computers) for changing the input data by

calculations, by querying a condition or by converting the data point type

•4 manipulated variable comparators to output minimum, maximum or

average values. 5 inputs each for values received via communication objects

•Summer compensation for cooling systems. A characteristic curve

matches the target temperature in the room to the external temperature and

sets the minimum and maximum target temperature values

Cala Touch KNX AQS/TH functions (no. 70821, 70823):

• Measuring the CO2-concentration of the air, the temperature and air

humidity (relative, absolute), each with mixed value calculation. The

share of internal measurement value and external value can be set as a

percentage

• Bus message, whether the values for temperature and air humidity are within

the comfort field (DIN 1946). Dew point calculation

•Threshold values can be adjusted per parameter or via communication

objects

•PI-controller for heating (one or two-level) and cooling (one or two-level)

according to temperature. Regulation according to separate set points or

basic set point temperature. Fan coil control

•PI controller for ventilation according to humidity and CO2-concentration:

Ventilate/Air (one-level) or Ventilate (one or two-levels)

Cala Touch KNX TH functions (no. 70811, 70813):

•Temperature and air humidity measurement (relative, absolute), in each

case with mixed value calculation. The share of internal measurement

value and external value can be set as a percentage

• Bus message, whether the values for temperature and air humidity are within

the comfort field (DIN 1946). Dew point calculation

•Threshold values can be adjusted per parameter or via communication

objects

•PI-controller for heating (one or two-level) and cooling (one or two-level)

according to temperature. Regulation according to separate setpoints or

basic set point temperature. Fan coil control

•PI controller for ventilation according to humidity: Ventilate/Air (one-

level) or Ventilate (one or two-level)

Cala Touch KNX T functions (no. 70801, 70803):

• Measuring the Temperature with a mixed value calculation. The share of

internal measurement value and external value can be set as a percentage

•Threshold values can be adjusted per parameter or via communication

objects

•PI-controller for heating (one or two-level) and cooling (one or two-level)

according to temperature. Regulation according to separate set points or

basic set point temperature. Fan coil control

Configuration is made using the KNX software ETS. The product file can be dow-

nloaded from the Elsner Elektronik website on www.elsner-elektronik.de in the

“Service” menu.

1.0.1. Deliverables

• Housing with display

• Mounting adapter with screws

• Analogue/digital supply line

You will need in addition (not supplied):

•Inletbox

• Cover frame (for insert 60 x 60 mm) and mounting plate (77 mm) for swiss

installation standard

1.1. Technical specifications

Cala Touch KNX CH

Room Controller

Item numbers

Cala Touch KNX T CH:

70801 (pure white RAL 9010),

70803 (jet black RAL 9005)

Cala Touch KNX TH CH:

70811 (pure white RAL 9010),

70813 (jet black RAL 9005)

Cala Touch KNX AQS/TH CH:

70821 (pure white RAL 9010),

70823 (jet black RAL 9005)

Material Real glass, plastic

Display Visible diagonal: 2.3 inch (59 mm)

Resolution: 320 × 240 pixel

Colours • white glass, white housing (pure white RAL

9010)

• black glass, black housing (jet black RAL

9005)

Assembly Installation in inlet box

Protection category IP 20

Dimensions approx. 60 × 60 (W × H × D, mm), mounting

depth approx. 8 mm

Total weight approx. 70 g (including mounting adapter)

Ambient temperature Operation -20…+70°C, storage -30…+70°C

Ambient humidity max. 95% RH, avoid condensation

Operating voltage KNX bus voltage

Bus current max. 18 mA

Data output KNX +/- bus connector terminal

BCU type Integrated microcontroller

PEI type 0

Group addresses max. 2000

Assignments max. 2000

Communication objects Cala Touch KNX AQS/TH: 471

Cala Touch KNX TH: 433

Cala Touch KNX T: 379

Inputs 4× analogue/ digital, max. cable length 10 m.

measuring range T-NTC

temperature sensor on

Cala input

-40°C...+80°C

CO2-sensor (for Cala Touch KNX AQS/TH):

CO2-measuring range 300...5000 ppm

CO2resolution 1 ppm

Temperature sensor (for Cala Touch KNX AQS/TH, Cala Touch KNX TH,

Cala Touch KNX T):

Temperature measu-

ring range

-20…+70°C

Temperature resolution 0.1°C

Humidity sensor (for Cala Touch KNX AQS/TH, Cala Touch KNX TH):

Humidity measuring

range

0% HR … 100% HR

Humidity resolution 0.1%

Humidity drift ± 0.5% RH per year in normal atmosphere

Room Controller Cala Touch KNX CH 2

Room Controller Cala Touch KNX CH • Version: 28.04.2020 • Technical changes and errors excepted. • Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany • www.elsner-elektronik.de • Technical Service: +49 (0) 7033 / 30945-250

The product is compliant with the provisions of EC guidelines.

1.1.1. Measuring accuracy

Measurement deviations due to sources of interference (see chapter Installation lo-

cation) must be corrected in the ETS in order to ensure the specified accuracy of the

sensor (offset).

For a correct CO2measurement it is necessary to install the device in a windproof

socket. After applying the operating voltage, it can take up to 15 minutes until the

CO2measured value is output correctly.

During temperature measurement, the self-heating of the device is taken into

consideration by the electronics. It is compensated for by the software, therefore the

displayed/output inside temperature measuring value is correct.

2. Installation and commissioning

2.1. Installation notes

Installation, testing, operational start-up and troubleshooting should

only be performed by an electrician.

CAUTION!

Live voltage!

There are unprotected live components inside the device.

• National legal regulations are to be followed.

• Ensure that all lines to be assembled are free of voltage and take

precautions against accidental switching on.

• Do not use the device if it is damaged.

• Take the device or system out of service and secure it against

unintentional use, if it can be assumed, that risk-free operation is

no longer guaranteed.

The device is only to be used for its intended purpose. Any improper modification

or failure to follow the operating instructions voids any and all warranty and gua-

rantee claims.

After unpacking the device, check it immediately for possible mechanical damage.

If it has been damaged in transport, inform the supplier immediately.

The device may only be used as a fixed-site installation; that means only when as-

sembled and after conclusion of all installation and operational start-up tasks and

only in the surroundings designated for it.

Elsner Elektronik is not liable for any changes in norms and standards which may

occur after publication of these operating instructions.

2.2. Installation location

The sensor is made for wall mounting in an inlet box. The device is supplemented

with a frame of the 60 mm swiss installation standard..

The sensor may only be installed and used in dry interior

spaces. Avoid condensation.

When selecting an installation location, please ensure that the measurement results

are affected as little as possible by external influences. Possible sources of interfe-

rence include:

• Direct sunlight

• Draughts from windows and doors

• Draughts from ducts which lead to the junction box in which the sensor is

mounted from other rooms.

• Warming or cooling of the building structure on which the sensor is mounted,

e.g. due to sunlight, heating or cold water pipes

• Connection lines, which lead from warmer or colder areas to the sensor

Temperature variations from such sources of interference must be corrected in the

ETS in order to ensure the specified accuracy of the sensor (temperature offset).

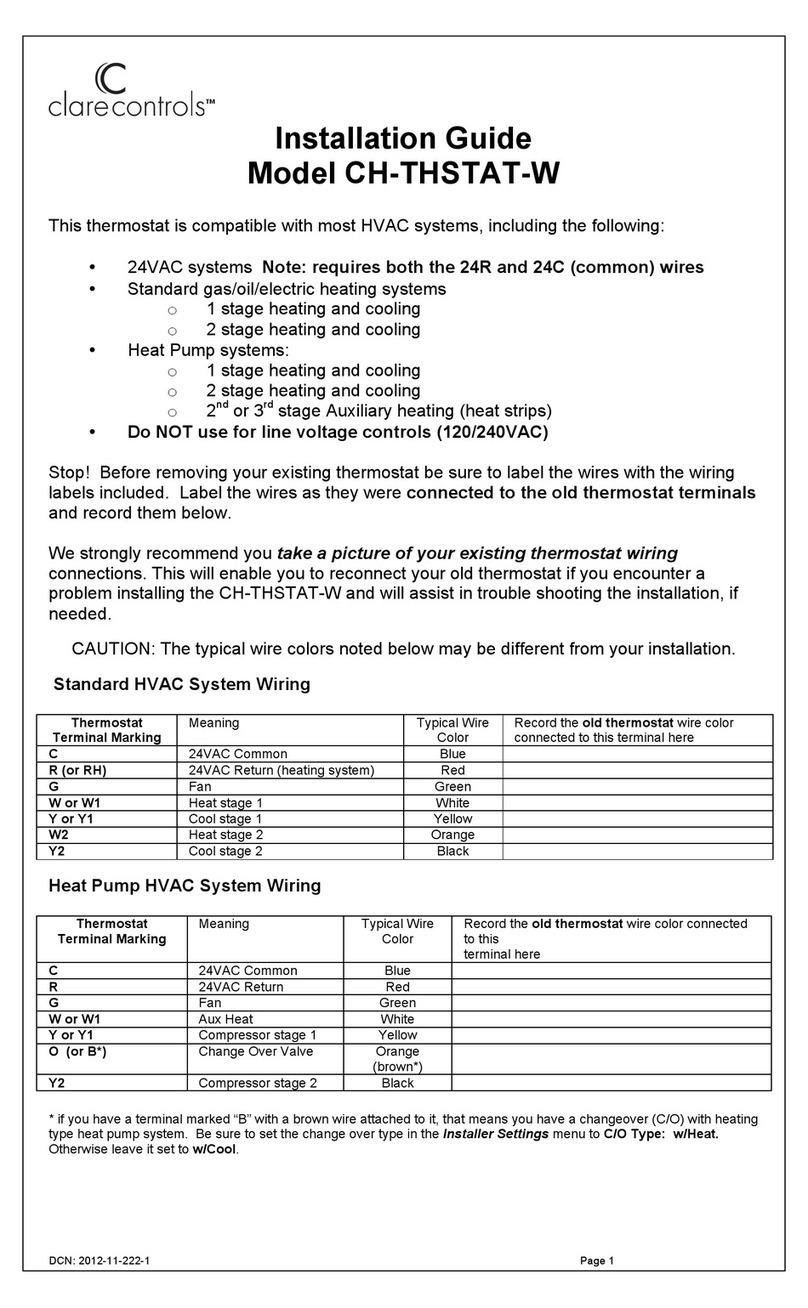

2.3. Device design

Analogue/digital supply line inputs:

2.4. Sensor assembly

First of all fit the windproof inlet box with connection. Also seal inlet pipes to avoid

infiltration.

Turn the screws little way into the mounting adapter.

Position the frame of the switching programme. Connect the bus line +/- to the

black-red plug.

Pin the housing with the notches on to the mounting adapter, so that device and

frame are fixed.

2.5. Notes on mounting and commissioning

Never expose the device to water (e.g. rain) or dust. This can damage the electro-

nics. You must not exceed a relative humidity of 95%. Avoid condensation.

After the bus voltage has been applied, the device will enter an initialisation phase

lasting a few seconds. During this phase no information can be received or sent via

the bus.After the bus voltage has been applied, the device will enter an initialisation

phase lasting a few seconds. During this phase no information can be received or

sent via the bus.

3. Addressing the equipment

The equipment is delivered with the bus address 15.15.255. You can program a dif-

ferent address in the ETS by overwriting the address 15.15.255 or by teaching the

device via the programming button.

The programming button can be reached through the opening on the rear of the

housing; it is recessed. Use a thin object to reach the button, e.g. a 1.5 mm² wire.

4. Maintenance and care

Fingerprints on the display and the housing are best removed with a cloth moiste-

ned with water or a microfibre cloth. Do not use an abrasive cleaning agent or ag-

gressive cleansing agents.

1yellow (GND) –– Input 1

2yellow ––

3white (GND) –– Input 2

4white ––

1

2

4

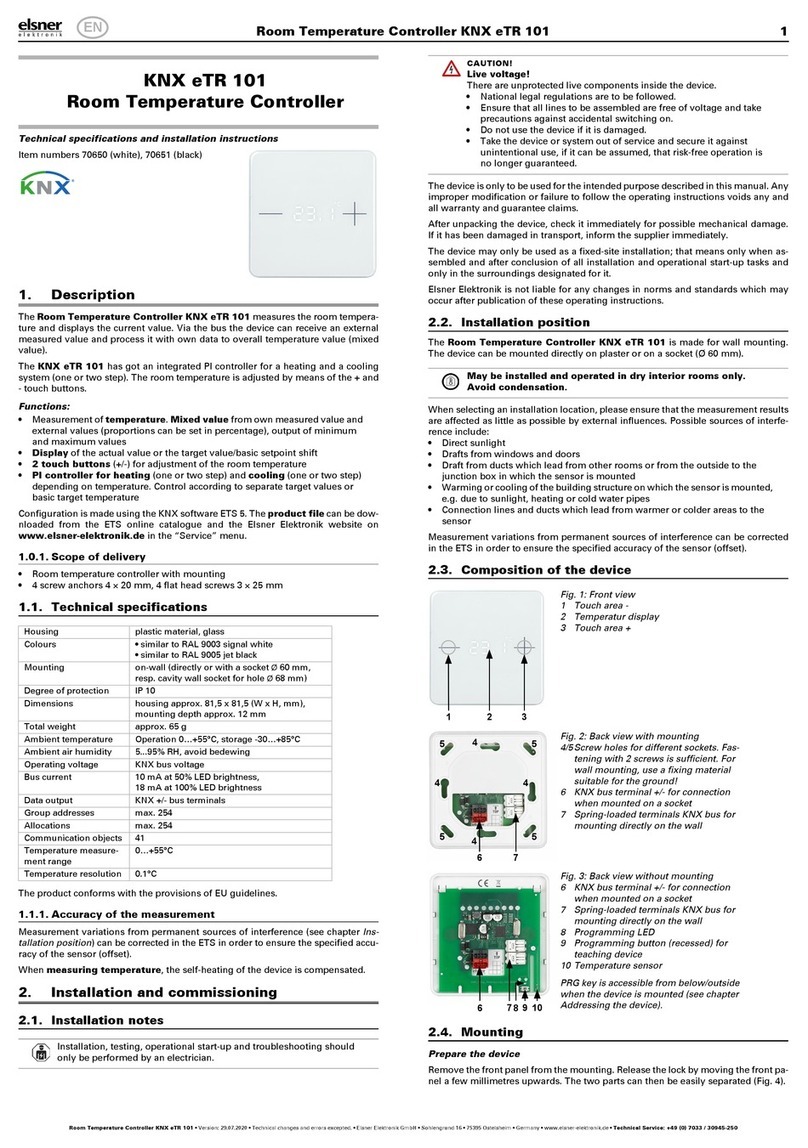

Fig. 1

1 Mounting adapter with screws

2 Openings for air circulation

3 Catches

4 Touch Display

5KNX-terminalBUS+/-

6 Slot for connecting cable

7 Programming-LED (recessed)

8 Programming-Button (reces-

sed) for teaching device

7

3

5

8

6

3

5orange (GND) –– Input 3

6brown ––

7purple (GND) –– Input 4

8blue ––

Fig. 2

Hook the mounting adapter into

the mounting plate of the

switch system and tighten the

screws.

Fig. 3

Screw the mounting plate onto

the inlet box

This manual suits for next models

9

Other Elsner Thermostat manuals