Elster Instromet EK205 User manual

Operating manual

Volume conversion device

EK205

Volume Conversion Device EK205

Operating instructions: 73023159

Version: d

Issue date: 16.12.2016

Software version: from 1.02

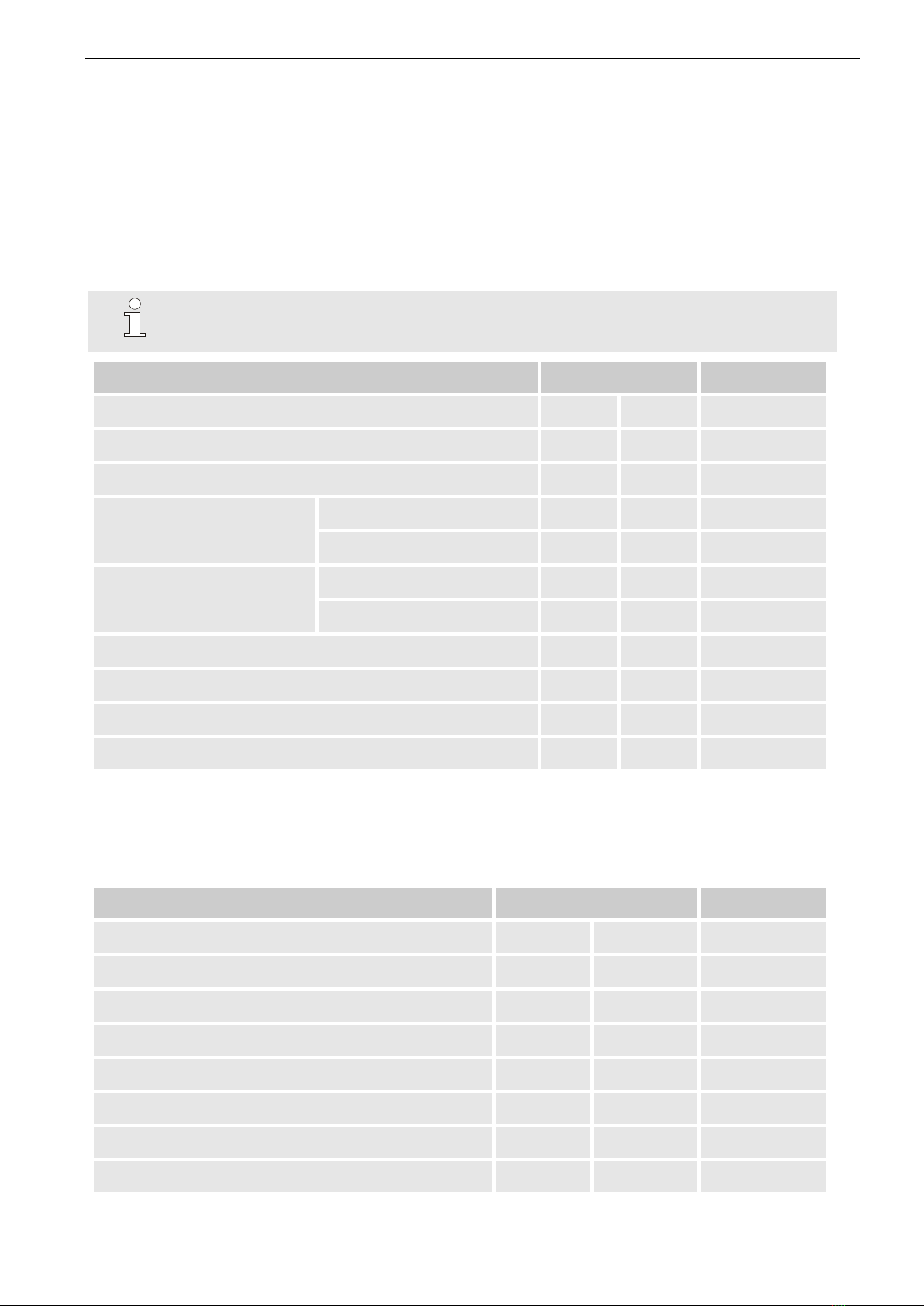

General 3

Contents

1 General .............................................................................................................................. 7

1.1 Information in these instructions...................................................................................... 7

1.2 Warranty provisions......................................................................................................... 7

1.3 Customer service ............................................................................................................ 7

1.3.1 Customer services and repairs................................................................................. 7

1.3.2 Electronics hotline .................................................................................................... 7

1.4 Explanation of symbols ................................................................................................... 8

1.4.1 Safety instructions.................................................................................................... 8

1.4.2 Tips and recommendations...................................................................................... 8

1.5 Limitation of liability ......................................................................................................... 9

1.6 Copyright ......................................................................................................................... 9

1.7 Scope of delivery............................................................................................................. 9

1.8 Replacement and accessory parts ................................................................................ 10

1.9 Storage.......................................................................................................................... 11

2 Safety............................................................................................................................... 12

2.1 General ......................................................................................................................... 12

2.2 Intended use.................................................................................................................. 13

2.3 Staff............................................................................................................................... 14

2.4 Personal protective equipment ...................................................................................... 15

2.5 Special hazards............................................................................................................. 15

2.6 Environmental protection............................................................................................... 16

2.7 Operator liability ............................................................................................................ 16

3 Technical data................................................................................................................. 17

3.1 General data.................................................................................................................. 17

3.2 Power supply for EK205 without integrated mains adapter ........................................... 17

3.2.1 Battery supply ........................................................................................................ 17

3.2.2 External power supply for the basic device ............................................................ 17

3.3 Pressure sensor ............................................................................................................ 18

3.3.1 CT30 Type Pressure Sensor.................................................................................. 18

3.4 Temperature sensor ...................................................................................................... 18

3.5 Digital inputs.................................................................................................................. 19

3.5.1 Pulse and reporting inputs NF................................................................................ 19

3.6 Digital outputs................................................................................................................ 19

3.7 Optical serial interface................................................................................................... 20

3.8 Electrical serial interface ............................................................................................... 20

3.8.1 RS485 type ............................................................................................................ 20

3.9 Operating conditions ..................................................................................................... 20

3.9.1 Environment........................................................................................................... 20

3.10 Identification ................................................................................................................ 21

3.10.1 Type plate and EX identification........................................................................... 21

3.10.2 Device software identification............................................................................... 21

4 Construction and function............................................................................................. 22

4.1 External view ................................................................................................................. 22

4 General

4.2 Internal view...................................................................................................................22

4.3 Brief description .............................................................................................................23

4.4 Connections...................................................................................................................23

5 Installation, connection and commissioning ...............................................................24

5.1 Installation......................................................................................................................24

5.1.1 Installation on a gas meter......................................................................................24

5.1.2 Installation on a pipeline .........................................................................................24

5.1.3 Installation on a wall ...............................................................................................25

5.1.4 Three-way cock ......................................................................................................25

5.2 Connection.....................................................................................................................26

5.2.1 Connecting gas meters...........................................................................................27

5.2.2 Lead-sealing of the input terminals.........................................................................27

5.2.3 Connect temperature sensor ..................................................................................27

5.2.4 Connect pressure line.............................................................................................28

5.2.5 Connect outputs of the EK205................................................................................29

5.3 Commissioning ..............................................................................................................29

5.3.1 Setting the operating parameters ...........................................................................29

5.3.2 Sealing....................................................................................................................36

5.3.3 Close housing.........................................................................................................37

5.3.4 Check installation and connection ..........................................................................37

5.3.5 Data transfer...........................................................................................................37

6 Operation .........................................................................................................................38

6.1 Safety.............................................................................................................................38

6.1.1 Personal protective equipment ...............................................................................38

6.2 Operating staff ...............................................................................................................38

6.2.1 Trained individual....................................................................................................38

6.2.2 Specialist ................................................................................................................38

6.2.3 Calibration officer....................................................................................................38

6.3 Basics ............................................................................................................................39

6.3.1 Display....................................................................................................................39

6.3.2 Functions of the keys..............................................................................................40

6.3.3 Calling up the data, navigation in the display..........................................................41

6.3.4 Meaning of the status symbols ...............................................................................42

6.3.5 Error messages when entering values....................................................................43

6.3.6 Access rights ..........................................................................................................44

6.4 Content of the data register ...........................................................................................46

6.4.1 Access rights ..........................................................................................................46

6.4.2 Main tab (main display)...........................................................................................46

6.4.3 Customer tab ..........................................................................................................47

6.4.4 Admin tab (administrator) .......................................................................................49

6.4.5 Serv. tab (service)...................................................................................................50

6.4.6 Strg. tab (control)....................................................................................................50

7 Maintenance ....................................................................................................................52

7.1 Safety.............................................................................................................................52

General 5

7.1.1 Staff........................................................................................................................ 53

7.1.2 Personal protective equipment............................................................................... 53

7.1.3 Environmental protection ....................................................................................... 53

7.2 Check and replace device batteries .............................................................................. 54

7.2.1 Replace and connect device batteries ................................................................... 54

7.2.2 Enter battery capacity ............................................................................................ 55

7.2.3 Display remaining operating duration of the battery ............................................... 56

8 Faults............................................................................................................................... 57

8.1 Safety ............................................................................................................................ 57

8.1.1 Staff........................................................................................................................ 57

8.1.2 Personal protective equipment............................................................................... 57

8.1.3 Improper fault rectification...................................................................................... 58

8.1.4 Conduct in the event of faults................................................................................. 58

8.2 Fault and other status messages .................................................................................. 58

9 Appendix ......................................................................................................................... 62

9.1 Replacement and accessory parts list........................................................................... 62

9.1.1 Fastening parts ...................................................................................................... 62

9.1.2 Pressure connection .............................................................................................. 62

9.1.3 Temperature sensor bags ...................................................................................... 63

9.1.4 Small parts and other ............................................................................................. 63

9.1.5 Documentation ....................................................................................................... 63

9.2 Conformity declarations................................................................................................. 64

9.3 Design test certifications ............................................................................................... 65

9.3.1 ATEX - EC Type Examination Certificat................................................................. 65

9.3.2 IECEx Certificate of Conformity.............................................................................. 68

General 7

1 General

1.1 Information in these instructions

These instructions make it possible to work with the device in a safe and efficient manner.

Compliance with all of the safety and handling instructions specified in these operating

manual is a prerequisite to working with the device in a safe manner and to use it properly. In

addition, compliance is also necessary with the guidelines, standards, local accident

prevention regulations and general safety regulations that apply for the device's area of

application.

The instructions are a component of the product and must be kept in the immediate vicinity of

the device, so that installation, operational, maintenance, and cleaning personnel may

access them at any time. The graphical illustrations in these instructions serve to depict the

facts that are being explained, and are therefore not necessarily true to scale and may differ

from the actual design of the device.

The data and material properties that are presented below are guidelines. They

must be reviewed for each individual case and corrected if necessary.

For the commissioning of the various communication and device applications,

you can use the application manual of the EK205 at www.elster-

instromet.com/en.

1.2 Warranty provisions

You will find our current warranty conditions in the General Terms and Conditions, e.g. on the

website http://www.elster-instromet.com/en

1.3 Customer service

Our customer service department is available for technical advice as well as repairs.

Furthermore, our employees are always interested in new information and experiences that

arise through use of the device and that may be valuable for improving our products.

1.3.1 Customer services and repairs

Tel. +49 (0) 61 34/605-0

Fax +49 (0) 61 34 605-390

Email: [email protected]

1.3.2 Electronics hotline

You can also contact the electronics hotline in the event of faults.

Tel. +49 (0) 6134/605-123

http://www.elster-instromet.com/en

Email: [email protected]

8 General

1.4 Explanation of symbols

1.4.1 Safety instructions

Safety instructions are indicated in these instructions by symbols. The safety instructions are

introduced by keywords that express the extent of the risk.

Safety instructions must be observed and treated diligently to avoid accidents, personal injury

and material damage.

DANGER!

…indicates an immediately hazardous situation that leads to death or severe

injury if it is not avoided.

WARNING!

…indicates an immediately hazardous situation that may lead to death or severe

injury if it is not avoided.

CAUTION!

…indicates an immediately hazardous situation that may lead to minor or slight

injury if it is not avoided.

… indicates hazards from electric current. In the event of non-observance of the

safety instructions, there is a risk of severe or fatal injuries.

CAUTION!

…indicates an immediately hazardous situation that may lead to material

damage if it is not avoided.

1.4.2 Tips and recommendations

… highlights useful tips and recommendations as well as information for

ensuring efficient and smooth operations.

General 9

1.5 Limitation of liability

All specifications and instructions in these operating instructions were compiled under

consideration of applicable standards and regulations, the current state of the art and the

knowledge and experience we gained over the years. The manufacturer assumes no liability

for loss due to:

Non-compliance with these operating instructions

Use of the device not in accordance with its intended use

Use of the device by non-instructed personnel

Unauthorized device modifications

Technical changes

Use of non-authorized replacement parts

The actual scope of delivery may differ from the explanations and descriptions included here

in case of special device designs, the use of additional order options or because of the latest

technical changes.

The obligations arranged in the delivery contract apply, as do the General Terms and

Conditions, manufacturer delivery conditions and current legal regulations that apply at the

time the contract was concluded.

Read through these operating instructions carefully before beginning any work

to and with the device, especially before commissioning the device!

The manufacturer assumes no liability for loss and malfunctions that result from

non-compliance with these instructions.

We reserve the right to make technical changes within the scope of improving performance

characteristics and continuous development of the device.

1.6 Copyright

These instructions are copyright-protected and intended for internal purposes only. Handover

to third parties, copies of any form, including extracts, as well as utilization and/or notification

of the content without written approval of the manufacturer is not permitted, except for

internal purposes. Violations give rise to compensation. Further claims remain reserved.

1.7 Scope of delivery

The scope of delivery of the EK205 includes:

Electronic Volume Conversion Device EK205

Dispatch breakdown

Interpretation data sheet

Instructions

Accessories bag

10 General

1.8 Replacement and accessory parts

WARNING!

Incorrect replacement parts and accessories are a safety risk!

Incorrect or defective replacement parts and accessories may detract from

safety and lead to damage, malfunction, or total device failure.

Therefore:

–Use only original replacement parts and accessories from the

manufacturer.

–Always contact the manufacturer if you are in doubt.

The replacement parts and accessories list can be found in the appendix. Replacement parts

and accessories can be ordered from a contract dealership or directly from our customer

service.

The accessories of the EK205 also include the free enSuite program, available at

www.elster-instromet.com. With them, you can program the Volume Conversion Device

EK205 via its data interfaces in order to carry out further applications.

The EK205 is available in numerous equipment variants.

Details can be found at www.elster-instromet.com as well as in the chapter Installation,

connection and commissioning.

General 11

1.9 Storage

CAUTION!

Reduced performance after exceeding or falling below the valid

temperature range of the batteries.

Exceeding or falling below the valid temperature range can reduce the

performance of the batteries when storing the device.

Therefore:

–For longer-term storage, ensure that the valid temperature range of the

built-in batteries between -25 °C and +55 °C is not exceeded or fallen

below.

CAUTION!

Material damage from formation of condensation!

Storing the device can lead to the formation of condensation resulting from

variations in temperature. This may result in the device malfunctioning at a

later time.

Therefore:

–After the device has been stored or transported in cold weather or if it has

been subject to extreme variations in temperature, bring it slowly to room

temperature before it is commissioned.

–The device must undergo a waiting period of at least 12 hours before it is

put into operation if condensation formed during storage.

If the power supply of the device is interrupted during storage from clamping

the batteries, the time and date need to be reset.

The following regulations apply for storage:

Relative humidity may not exceed 93%.

Do not store the packaging units outdoors.

The storage temperature may not fall below -25°C and exceed +55°C.

Avoid mechanical vibrations during storage.

12 Safety

2 Safety

This section provides an overview of all key safety aspects for optimal protection of the staff

as well as for safe and fault-free operation.

Non-observance of these operating and safety instructions may result in considerable

hazards.

2.1 General

The EK205 is an intrinsically safe device and is suitable for operation within the zones at risk

of gas explosion 0, 1 or 2 for gases of temperature class T4.

Check for use in zones 0, 1 or 2 in accordance with the currently applicable rules of the art:

see chapter 9.3: EC type examination certificate no. LCIE 16 ATEX 3007 X and no. IECEx

LCIE 16.0003X

1

DANGER!

Risk of explosion by connection to non-intrinsically-safe and associated

equipment.

When operating the EK205 in an area at risk of explosion (zones 0, 1 or 2) and

connecting devices without certification as an "associated piece of equipment",

there is a risk of explosion.

Therefore:

–When used in an area at risk of explosion, connect the EK205 to certified,

associated pieces of equipment only in accordance with the valid rules of the

art stated in the design test certificates.

–Connect the EK205 only to intrinsically safe pieces of equipment whose

electric data correspond to the requirements stated in the design test

certificates of the EK205 (see chapter 9.3).

DANGER!

Risk of explosion from use of wrong batteries.

Use only batteries stated in the design test certificates of the EK205 (see

chapter 9.3). Order number, see section 9.1.4.

During connection and operation of the EK205 in areas at risk of gas explosion,

observe the associated norms:

DIN EN 60079-0

The device may only be used in an area at risk of gas explosion if the

installation is carried out in accordance with the general requirements of DIN EB

60079-0 and the operating conditions (see chapter Technical data) and

connection conditions (see chapter Installation, connection and commissioning)

are observed.

The device can be hazardous if it is used by staff not trained correctly in an improper or

unintended manner.

Anyone appointed to perform work to or with the device must read and understand

these operating instructions before beginning work on the device. This also applies if

1

Not available for all device types.

Safety 13

the individuals concerned have already worked with such a device or a similar one, or

were instructed by the manufacturer.

Knowledge of the content is one of the requirements of protecting staff from hazards

and avoiding faults and therefore operating the device in a safe and fault-free manner.

In order to avoid risks and to ensure that the device performs in an optimal manner, no

changes or modifications that were not expressly authorized by the manufacturer may

be performed to the device.

Always keep all operating instructions on the device in easily legible condition. Renew

damaged or illegible instructions.

Observe settings values or value ranges stated in the instructions.

2.2 Intended use

The device is designed and constructed exclusively for its intended use as described here.

The Volume Conversion Device EK205 serves to convert a gas volume of a gas line in

basic condition measured by a meter in measurement conditions as well as to assign the

volumes measured to tariffs. In addition, using the device, further parameters can be

measured, recorded and monitored depending on the configuration set by the user.

Compliance with all the specifications in these operating instructions also falls under the

device's intended use. Any use of the device that goes beyond or deviates from its intended

use is considered a misuse of the device, and may lead to hazardous situations. Claims of

any kind due to loss resulting from non-intended use of the device are excluded.

WARNING!

Hazard from incorrect use!

Incorrect use of the device may result in hazardous situations.

Therefore:

–Use the device only as intended.

–Do not use the device to control the gas flow or other parameters influencing

the gas volume within the framework of the overall system.

14 Safety

2.3 Staff

WARNING!

Risk of injury in the event of insufficient qualification!

Improper use may result in considerable personal injury and material damage.

Therefore:

–Have all activities carried out by qualified staff only.

The following qualifications for different areas of activity are listed below in the instructions:

Instructed staff

was instructed by the plant operator in an informational session on the tasks assigned

to him or her, and on possible hazards in case of improper behaviour.

Specialist staff

has the ability, because of his or her technical training, knowledge and experience, as

well as his or her knowledge of the relevant regulations, to carry out the work to the

device assigned to him or her, and to recognize and avoid possible hazards on his or

her own.

Gas specialist

has the ability, because of his or her technical training, knowledge and experience, as

well as his or her knowledge of the relevant standards and regulations, to carry out

work to gas systems, and to recognize possible hazards on his or her own. A gas

specialist receives training for the specific location in which he or she works, and is

acquainted with the relevant standards and regulations.

Calibration officer

has the ability, because of his or her technical training, knowledge and experience, as

well as his or her knowledge of the relevant standards and regulations, to carry out

calibration-protected work to gas systems. The calibration officer is trained to work

with calibration-protected devices and systems, and is acquainted with the relevant

standards and regulations that apply.

Electrical expert

has the ability, because of his or her technical training, knowledge and experience, as

well as his or her knowledge of the relevant standards and regulations, to carry out

work to electrical systems, and to recognize and avoid possible hazards on his or her

own. A qualified electrician receives training for the specific location in which he/she

works, and is acquainted with the relevant standards and regulations.

WARNING!

Risk for unauthorized persons!

Unauthorized persons who do not fulfil the requirements described do not know the

hazards in the work area.

Therefore:

–Keep unauthorized persons away.

–In the event of doubt, speak to people and direct them out of the working area.

–Interrupt the work as long as unauthorized persons are in the working area.

Safety 15

Only persons are permitted as staff from whom it can be expected that they will perform their

work reliably. Persons whose reactivity is influenced, e.g. from drugs, alcohol or medication,

are not permitted.

When selecting personnel to operate the device, make sure you comply with the

specific regulations of the overall gas system that concern age and occupation.

2.4 Personal protective equipment

When working on the device within a gas system, wearing personal protective equipment is

required to minimize health hazards.

During the activity on the device, always wear the protective equipment required within

the relevant system.

Always observe the notes on the personal protective equipment provided in the

working area.

2.5 Special hazards

The risks arising on the basis of the risk assessment are specified below. Observe the safety

and warning instructions stated here in the further chapters to reduce health hazards and

avoid dangerous situations.

WARNING!

Risk of injury when handling batteries incorrectly!

Batteries need to be treated with special care.

Therefore:

–Do not throw batteries in the fire or expose them to high temperatures. There is a risk of

explosion.

–Do not charge batteries. There is a risk of explosion.

–Liquid being released in the event of incorrect use may result in skin inflammations.

Avoid contact with the liquid. Rinse the liquid with lots of water in the event of contact. If

the liquid enters the eyes, rinse the eyes for 10 mins with water and see a doctor

immediately.

WARNING!

Fire hazard from easily flammable substances!

Easily flammable substances, liquids or gases can ignite and cause severe to fatal injuries.

Therefore:

–Do not smoke inside the hazardous area and in the near proximity. Do not handle open

flames or sources of ignition.

–Keep a fire extinguisher ready.

–Report suspicious substances, liquids or gases to the person in charge immediately.

–Suspend work immediately in the event of fire. Leave the hazardous area until the all-

clear has been given.

16 Safety

2.6 Environmental protection

CAUTION!

Substances harmful to the environment!

When handling substances harmful to the environment, in particular in the event of

incorrect disposal, severe damage may arise for the environment.

Therefore:

–Observe the below notes at all times.

–Take suitable measures immediately if substances harmful to the environment enter the

environment by mistake. In the event of doubt, inform the municipal authorities in charge

of the damage.

The following substances harmful to the environment are used:

Batteries

Batteries contain poisonous heavy metals. They are subject to special waste treatment and

need to be disposed of at the municipal collection points or by a specialist company.

2.7 Operator liability

The device is used in industrial applications. The device operator is therefore subject to legal

obligations of occupational health and safety.

In addition to the safety instructions in these operating instructions, current regulations of

safety, accident prevention and environmental protection must be observed for the device

area of application. The following items especially apply:

The operator must ensure compliance with the current regulations of safety, accident

prevention and environmental protection that apply for the overall system in which the

device is integrated.

The operator must keep himself/herself informed of the applicable occupational health

and safety regulations, and determine, over the course of a risk assessment, the

additional risks that arise from the specific working conditions when the device is being

used. The operator must include these items in the form of operating instructions for

the device.

The operator must review, over the entire operational life of the device, whether the

operating instructions prepared by him or her correspond to the current status of the

bodies of regulations, and revise the instructions if necessary.

The operator must definitively regulate and establish the responsibilities for device

assembly, connection, commissioning, operation and maintenance.

The operator must ensure that all employees who work with the device have read and

understood these operating instructions. In addition, the operator must train these

personnel at regular intervals and inform them of the risks involved with the device.

The operator of the overall system in which the device is integrated must provide

personnel with the required protective equipment.

In addition, the operator is responsible for ensuring the device is always in technically perfect

condition. The following items therefore apply:

The operator must ensure that the installation and maintenance work described in

these operating instructions are performed properly.

The operator must have all safety installations checked regularly to ensure they

function correctly and are complete.

Technical data 17

3 Technical data

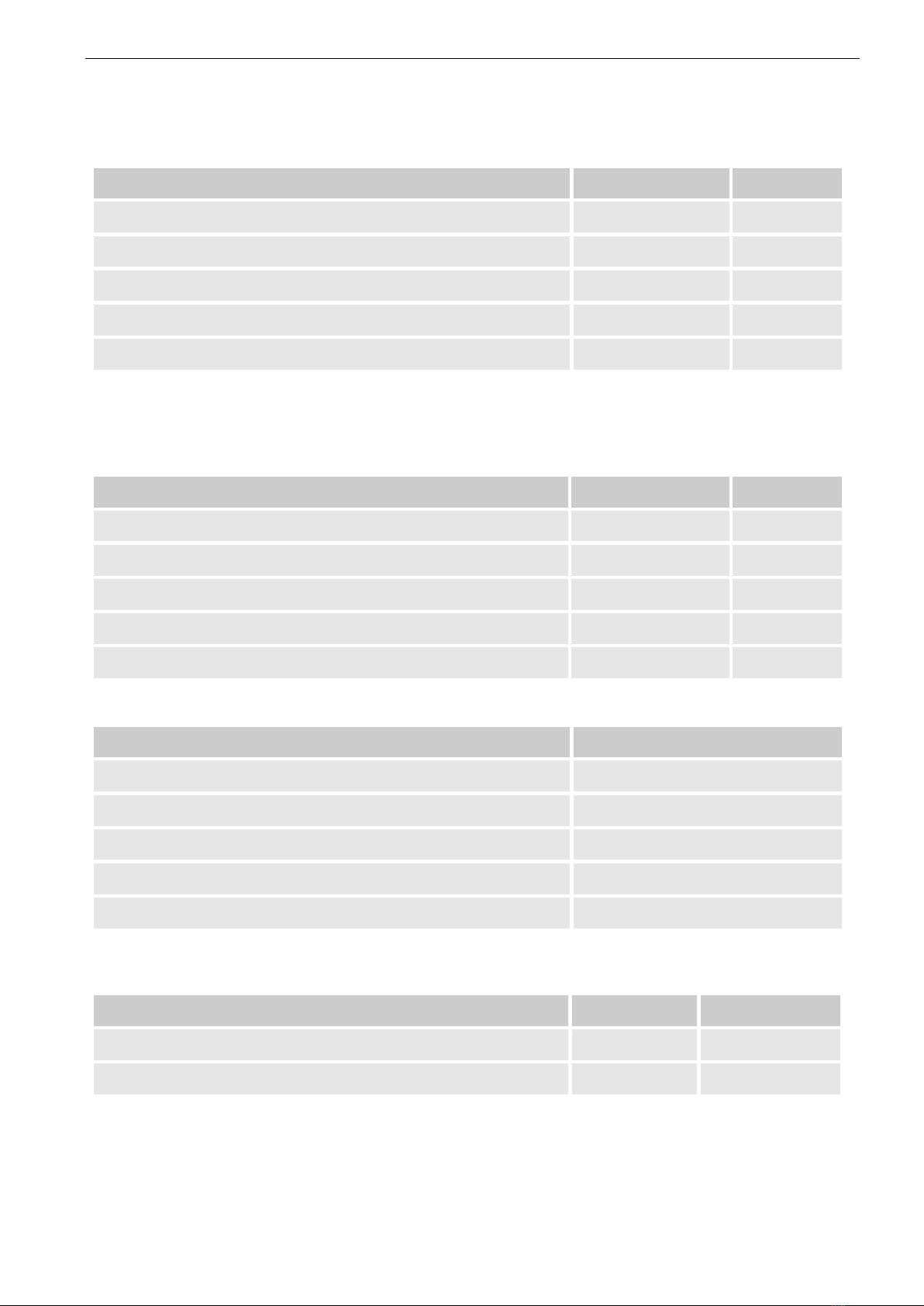

3.1 General data

Information

Value

Unit

Width (incl. hinges)

170

mm

Height (incl. cable screw connections)

180

mm

Depth

90

mm

Permissible ambient temperature range

-25 –+55

°C

Permissible gas temperature range

-30 –+60

°C

3.2 Power supply for EK205 without integrated mains adapter

3.2.1 Battery supply

Information

Value

Unit

Voltage

3.6

V

General nominal capacity

16.5

Ah

Usable capacity

13.0

Ah

Minimally required number of batteries

1

Unit

Minimal operating duration (in standard operation mode)

5

Years

The standard operation mode is defined as follows:

Information

Value

Measurement cycle

30 seconds

Mode input 1

Pulse input

Display active

60 minutes per month

Interface active

30 minutes per month

Ambient temperature

-10 –+50°C

3.2.2 External power supply for the basic device

Data

Value

Unit

Supply voltage

6.0 …9.0

VDC

Supply current, maximum

50

mA

18 Technical data

3.3 Pressure sensor

3.3.1 CT30 Type Pressure Sensor

Information

Value

Unit

External thread

M12 x 1.5

Usable thread length

About 10

mm

3.3.1.1 Absolute pressure ranges

Measuring range

Overload capacity

0.8 –5bar abs.

25 bar abs.

2.0 –10 bar abs.

40 bar abs.

1.0 –16 bar abs.

40 bar abs.

The pressure sensor is available as an internally completed variant.

You can find details at www.elster-instromet.com or see chapter Installation,

connection and commissioning.

Not applicable when used as a Temperature Conversion Device.

3.4 Temperature sensor

Information

Value

Unit

Measuring range

-30 –+60

°C

Measurement uncertainty

max. ± 0.1

%

Installation length

50

mm

Technical data 19

3.5 Digital inputs

3.5.1 Pulse and reporting inputs NF

The maximum meter frequency of the digital inputs can be set with the enSuite software. The

thresholds stated here for frequency and duration apply only if the so-called software

debouncing is deactivated.

Ex works, the software debouncing is activated to suppress fault pulses and so that safe

counting is limited to 2 Hz.

If the software debouncing is set to a higher frequency than 2 Hz, miscounting

from electromagnetic faults may arise under certain circumstances.

Information

Value

Unit

No-load voltage U0

2.0

V

Internal resistance Ri

About

500

kΩ

Short-circuit current Ik

About

4

μA

Switchpoint "on":

Resistance Re

max.

300

kΩ

Voltage Ue

max.

0.8

V

Switchpoint "off":

Resistance Ra

min.

5

MΩ

Voltage Ua

min.

1.8

V

Pulse duration te

min.

62.5

ms

Break duration ta

min.

62.5

ms

Meter frequency f

max.

10

Hz

Cable length

max.

10

m

3.6 Digital outputs

The digital outputs DA1 and DA2 can be set exclusively as low-frequency pulse or report

outputs.

Information

Value

Unit

Switching voltage

max.

30

V DC

Switching current

max.

100

mA DC

Voltage drop

max.

1

V

Remaining current

max.

0.001

mA

Pulse duration

min.

125

ms

Break duration

min.

125

ms

Output frequency

max.

4

Hz

Cable length

max.

10

m

20 Technical data

3.7 Optical serial interface

Information

Value

Unit

Baud rate

9600

Bd

Format

1 start, 1 parity, 1 stop bit

3.8 Electrical serial interface

Information

Value

Adjustable types

RS232 or RS485

Cable length

max. 10 m

3.8.1 RS485 type

Parameter

Value

Operating types

RS485 2-wire (semi-duplex)

RS485 4-wire (full-duplex)

Scheduling

No load resistor usable in the connected bus

participants

Maximum data transmission rate

19,200 baud

Number of bus participants

Drive performance at the outlet: max. 16 unit loads2

Received power at the input3:

- 6 unit loads (RS485, not electr. insulated)

- 3 unit loads (RS485, electr. separated)

Cable length

max. 10 m

3.9 Operating conditions

3.9.1 Environment

Information

Value

Unit

Temperature range

-25 –+55

°C

Relative humidity, maximum

93

%

Humidity conditions acc. EN12405-1

condensation

Point of use acc. EN12405-1

open

Mechanical ambient conditions acc. EN12405-1

M2

Electromagnetic ambient conditions acc. EN12405-1

E2

2

Unit load: Standard RS485 receiver with an input resistance = 12kOhm

3

Details on the connection of the RS485 interface, see application manual

Table of contents