Elston Manufacturing GA-800H User manual

GA-800H OWNER’S MANUAL

REV D

UPDATED 2021

F

i

Table of Contents

EVERY USE 16

EVERY SEASON OR 200 LBS. OF BAIT 16

GA-800 GREASE POINTS 16

6 Parts List...............................................................................................................................................G1

1 SAFETY INFORMATION 1

2 GENERAL INFORMATION

2

3 ASSEMBLY INSTRUCTIONS

3

4 USING YOUR GOPHER GETTER

9

ATTACHING GOPHER GETTER TO TRACTOR

9

SETTING UP SEEDER ASSEMBLY

9

ADJUSTING DEPOSITION RATE OF BAIT

10

ADJUSTING DEPTH BAIT

10

ADJUSTING DEPTH OF COULTER

11

OPERATING INSTRUCTIONS

12

OPERATING TIPS

15

ADDITIONAL INFORMATION

15

5 MAINTENANCE

16

Safety Information

1

1 Safety Information

The baits used in this machine are highly toxic and can cause serious injury or

death if used improperly. Always follow all precautions on the label for the bait

you use. Store bait as recommended between applications. Do not store bait in the

bait box.

Improper operation of a tractor with an implement can cause serious injury or

death. If you are the least bit unsure of your ability to safely operate a tractor with

an implement, find someone you respect with experience to show you how to

operate a tractor safely.

Please read this manual and all safety stickers on the gopher getter before

operating it.

Before continuing, there are several safety ideas that are always worth repeating.

Working for years without an accident is not the same as working safely. - It is possible to do

something unsafe for years and not be hurt. This does not mean it is alright to continue this unsafe

behavior; it just means you have been lucky. For example, a farmer who never had a serious accident

was not wearing his safety belt. He rolled his tractor while moving round bales out of a ditch and he

ended up underneath the tractor. Thankfully, in this case, he was only hurt, not killed, thanks to the good

hearing of a neighbor who heard his calls for help. We can agree that is not operating safely. There are

numerous stories of farm injuries with a similar theme. Please take the time to consider all those little

things you do before your luck runs out.

Do not take short cuts with safety when you are in a hurry. - It is tempting to think that just because

it will not take long nothing will go wrong. You might get lucky but then again you might end up as a

sad story in the newspaper. DO NOT take shortcuts.

General Information

2

2 General Information

Thank you for purchasing a Gopher Getter from Elston Manufacturing. We are confident this product

will provide you with years of service.

This gopher getter works by creating an artificial tunnel. The poison is dropped into the tunnel where the

gophers find it and die underground out of reach of other animals. The depth of the tunnel is adjustable

to better match the depth that the gophers are digging in your area.

The gopher getter will apply approximately two pounds per acre of Elston gopher getter bait when the

burrows are spaced 20 feet apart. When used with rolled oats and the seeder slide with the larger 7/8”

opening, the application rate will also be slightly less than 2 pounds per acre. These application rates

are an average for the whole field and will be higher for severe infestations.

We always welcome feedback on our products. If you have

comments, suggestions, or problems with the unit please contact

us at 1-800-845-1385 or email at sales@elstonmfg.com.

Assembly Instructions

3

3 Assembly Instructions

Table 1: Contents of Parts Kit if GA-800 is not pre-assembled

Before beginning assembly, please verify that all parts were shipped

with the Gopher Getter. The Gopher Getter is shipped from the factory

pre-assembled using the 5 pieces shown in Figure 1.

Figure 1: Disassembled Parts of GA-800

Label

Description

1

GA-800H Base Assembly

2

Plastic Bait Box

3

Coulter Shank

4

Coulter Blade

5

Coulter Arm

Assembly Instructions

4

Label

Qty

Description

A

2

Coulter Shank Clamps (G9-302)

B

2

3/8” UNF Bolts for G9-302

C

4

6” 1/2”-13 Hex Head Bolts (Grade 8)

D

4

1/2” Split Ring Lock Washers

E

4

1/2” Flat Washers

F

4

1/2”-13 Hex Nuts

G

2

Seeder Slides w/ Pin (G7-413)

H

4

Seeder Slide Springs (G7-429)

I

1

Retaining Strap for Coulter Bearing Cap

J

1

Parts Bag for Coulter Assembly

(4 carriage bolts, 4 lock washers, 4 nuts, 1 square head bolt, 1

roll pin, and 1 cotter pin)

K

1

Coulter Shank Casting

L

4

3/8” Serrated Flanged Hex Nuts

Figure 2: Parts Kit

Inside the bait box you will find a parts kit that includes the parts shown in Figure 2.

Assembly Instructions

5

Assembly of the GA-800 is straightforward, and all the parts attach to the base assembly, part #1 shown

in Figure 1. If after reading the assembly steps below, please refer to the parts list in the back of this

manual if you have any questions about assembly. The parts list presents part information, described in

the sections below, in a visual manner such that you can understand the assemblies better.

1. Install the legs to the base assembly if not already installed.

2. Attach the seeder slides and bait box to the base assembly.

From the parts package, you will need the 2 seeder slides (labeled L in Figure 2), 4 springs (labeled K),

and 4 serrated, flanged hex nuts (labeled J). You will also need the bait box.

a) Install the four springs to the attachment points on the seeder assembly. These attachment

points are found just behind the clear hoses that deliver the bait to the seeder tube.

If they are already installed slide and lock them into position to hold the gopher getter upright. When the

legs are in position, the GA-800 will look as pictured in Figure 3.

Figure 3: GA-800 Base Assembly with Legs

Assembly Instructions

6

b) Next place the seeder slides in the shallow slots they run in on the seeder assembly (see Figure

4). The side of the seeder slide with the larger flange and the two holes should be closer to the

front of the machine.

c) After that, place the bait box on top of seeder slides. The bait box should face with the clear

viewing windows facing toward the front of the machine as shown in Figure 5 and be secured

with the four hex nuts.

d) Attach the other side of the springs installed in step 2a to the holes on the seeder slides. Once

the step is done, the unit should look like it does in Figure 6.

Figure 4: Seeder Assembly Area on GA-800

Figure 5: Inside of Plastic Bait Box

Assembly Instructions

7

3. Attach the coulter assembly to the frame

For this step you will need the coulter shank, the coulter blade, the coulter arm, the coulter assembly

parts bag, and all the remaining parts in the parts bag.

a) Install the roll pin in the coulter assembly parts bag into the hole on one end of the coulter

shank.

b) Mount the parts that clamp the coulter shank to the frame. You will need the 2 coulter shank

clamps, the 2 square head bolts, and the 4 bolts, washers, lock washers, and nuts. These parts

should be assembled as shown in Figure 7.

c) Slide the coulter shank into position as shown in Figure 8. Clamp the coulter shank in place

by tightening each bolts a little at a time until the coulter shank is secured in place.

Figure 6: Finished Seeder Assembly

Figure 7: Assembled Coulter Shank

Assembly Instructions

8

d) Attach the coulter arm to the coulter shank using the coulter clamp to hold it in place.

Add the cotter pin to the hole in the bottom of the coulter shank. This pin will retain the

coulter arm if the bolt on the coulter clamp casting becomes loose.

e) Bolt the coulter blade to the coulter arm. Adjust the height of the coulter blade so the bottom

of the blade is aligned with the top of the torpedo tube. If the center line of the coulter blade

is not aligned with the center of the knife, loosen the coulter shank clamps and reposition

them to move them into alignment. Position the coulter clamp so the coulter is free to swing

around an arc centered on the knife and torpedo tube. Assembly of the coulter assembly is

now complete and should appear similar to that shown in Figure 9.

Your GA-800 Gopher Getter is now assembled. Refer to the next chapter for additional tips and

instructions for adjusting the machine before its first use.

Figure 8: Coulter Arm Mounted on

Coulter Shank

Figure 9: Completed

Coulter Assembly

Using Your Gopher Getter

9

4 Using Your Gopher Getter

Attaching Gopher Getter to Tractor

This machine was designed to attach to a Category 2 three-point hitch, Category 3 three-point hitch,

Category 3N three-point hitch, as well as Category 2, 3, and 3N quick hitches. The Category 2 lower

hitch pins are located inside of the 3-point framework and two Cat 2 - Cat 3 bushings should be installed

as sleeves around the two Category 2 lower hitch pins. Two properly sized upper link pins are installed

on the machine as well. The top link on the 3-point will need to be connected and adjusted so the torpedo

tube operates at a slight slope when being pulled through the ground at depth with the front point being

slightly lower than the back of the tube. An example of attaching to a Category 2 tractor is shown in

Figure 10.

Setting Up Seeder Assembly

This machine was originally designed to allow two different baits to be deposited at the same time with a

dual bait seeder mechanism. The original, steel bait box had a steel divider plate in the center of the box

to allow for two different baits. The new, hardened plastic bait box cannot deposit two different baits

unless modifications are made to the plastic bait box to create a divider plate like the one installed in the

original steel bait box. To deposit two different baits, simply fill one half of the bait box with one bait

and the other half with the other choice of bait. The seeder mechanism automatically alternates from side

to side to prevent the two baits from being dropped on top of each other. If you'd like to only use one

type of bait, simply fill both sides of the bait box or just remove the divider plate.

If applying Elston supplied Gopher Bait, which typically is a strychnine-based bait on milo sorghum

grain, no spacer plate should be used. If other types of bait are used, first check that the bait fits in the

slot for the seeder slide (between the seeder base and the seeder box). If it does not, add one or two

spacer plates until the gap is large enough to fit most pieces of the bait. If this is not done, the bait will

be significantly ground up and some parts in the seeder assembly wear much quicker than normal.

Figure 10: GA-800 Attachment to a Category 2

Three Point Hitch

Using Your Gopher Getter

10

Adjusting Deposition Rate of Bait

The bait application rate of the GA-800 is adjusted by moving the bait box and seeder slide base

backwards and forwards. One of the trippers located on the seeder drive axle may also be removed to

allow even less bait to be dropped. The seeder base, as shown in Figure 11, is attached to its mounting

bracket with 4 bolts and sliding it backwards (toward the packer wheel) will increase the bait application

rate. When applying Elston gopher bait, it should be adjusted so that the maximum opening of the hole in

the seeder slide is 1/2” (approximately 3/4 of the way toward the back) for an application rate of

approximately 2 pounds per acre with 20 feet between passes. For other types of bait, consult with the

bait dealer for recommended setup. If they do not have any recommendations, start with a maximum

opening in the seeder slide of approximately 1/2” and the number of spacer plates recommended in the

section above and measure the actual application rate. Adjust the application rate by shifting the seeder

base backward and forwards and potentially increase it by adding spacer plates (up to a total of 3). If you

are still unable to achieve the application rate you need, please contact us at Elston Manufacturing at 1-

800-845-1385.

Adjusting Depth Bait

The packer wheel determines how deep the torpedo tube or burrow builder travels through the ground.

The depth of the torpedo tube should match the depth of the gopher’s natural burrows in your area. This

can be determined by locating and digging up one of their main runways to see how deep they are

actively working and adjusting the packer wheel accordingly. It is not necessary that the depth of the

torpedo tube be exact; only that it is close enough to intercept the gopher’s main runways. The depth

adjustments are made with the two threaded rods located on either side of the knife assembly. When

standing behind the machine and facing the machine, the rod on the right side locks the wheel in place

once the decided position is set and the rod on the left side adjusts the packer wheel. To adjust the wheel,

loosen the two nuts on both rods that lock the adjustments in place. When the wheel is set in place, spin

the two nuts back in position and tighten to lock the wheel in place. Figure 12 shows a depiction of this

adjustment.

Figure 11: Adjusting Rate of Bait Application

Using Your Gopher Getter

11

Adjusting Depth of Coulter

This machine is provided with a spring-loaded coulter assembly mounted on a straight shaft to allow for

a wide range of adjustments in depth. Generally, the coulter should be set just deep enough so that the

blade cuts through the debris on the surface and the major roots below the surface so that the knife

passes cleanly through the soil. If not, the knife will catch on the uncut roots and rip the vegetation out

of the ground, typically resulting in blockage similar to that shown in Figure 13.

Figure 12: Packer Wheel Adjustment

Figure 13: Roots catching on knife due to coulter blade

set too shallow

Using Your Gopher Getter

12

• Adjust the coulter as deep as possible while keeping the bottom of the coulter blade at minimum 'A”

or so below the bottom edge of the torpedo tube as shown in Figure 14.

Figure 14: Coulter blade depth for treatments in alfalfa

In areas such as pasture:

• Tunnel depth of approximately 4 to 5 inches is recommended

in alfalfa fields:

Depending on your exact conditions, the depth may need to be varied somewhat from these

recommendations.

To adjust the depth of the coulter blade, loosen the bolt on the coulter clamp and slide the coulter up or

down on the coulter shank. Lock the coulter clamp when the desired position is found. For larger

adjustments, the bolts that hold the coulter shank to the front of the machine may also be loosened and

the shank slid up or down for further adjustments. Tighten the square headed bolts just tight enough to

hold the shank in normal operation (no more than 40 ft-lbf). Over-tightening these bolts will likely cause

one of them to fail when the coulter springs back after an impact with a rock or other obstruction.

Operating Instructions

The bait used in this machine is highly toxic and can cause serious injury or death

if used improperly. Always follow all precautions on the label for the bait you

use. Store bait as recommended between applications. Do not store bait in the bait

box.

Using Your Gopher Getter

13

A

CAUTION

NOTICE

To prevent accidents involving injury or death, do not allow anyone near the

tractor or Gopher Getter while the tractor is in motion. Always follow all safety

instructions provided with the tractor.

Risk of expensive damage and possible injury. Always check for and avoid

underground pipe or other lines in the area you will be working.

To avoid extensive damage to your machine,

• Never backup or turn while the machine is in the ground

•Always replace the shear bolt with an identical grade 5 bolt.

•Never over tighten the one-inch bolt attaching the knife to the frame or the shear

bolt. They should loosely clamp the knife and allow it to pivot when the shear bolt

fails.

•Always limit your speed to 5 mph or less.

•Avoid large rocks, tree roots, concrete, and culverts whenever possible. Limit

your speed further in areas with these hazards.

•Stop quickly when the shear bolt fails.

•Never add more than 500 lbs. combined of weight and down pressure to the

machine.

The advice and tips below are generalized ones for gopher getter users throughout the country. For

information specific to your area, please speak with the dealer that you purchased the unit from, your

local extension agent, or area farmers that use gopher getters.

Space your treatments 20 to 30 feet apart in straight, parallel lines in areas active with gophers or

bordering areas with high population of gophers that are not treatable (like a neighbors CRP).The gopher

getter will apply approximately two pounds per acre of Elston gopher getter bait when the burrows are

spaced 20 to 25 feet apart, as shown in Figure 15. These application rates are the average over a whole

field and assume an average infestation that requires approximately one third of the field to be treated. If

the infestation is more severe, the application can be as high as 6 lbs./acre with the factory setup. The

bait will be most effective if applied when gophers are active but high-quality food is scarce. Spring and

fall are the most effective times - especially spring. When you use any type of gopher bait during the

summer, expect reduced control results.

Using Your Gopher Getter

14

As you start and end a pass, smoothly raise, and lower the machine with the hydraulic cylinder to

minimize damage to the surface of the soil. In an emergency, the gopher getter can be quickly raised but

may disturb a significant amount of soil. To limit damage from erosion, avoid making burrows straight

down the slope of the hill.

This machine works best in moist soil. It is rarely a problem, but if the soil is too wet, it will stick to the

knife and the packer wheels and interfere with the depth setting of the gopher getter. A more common

problem is soil that is too dry. When it is, the machine will be very hard to get into the ground and it will

refill the tunnel (reducing the effectiveness of the bait). Depending on your soil type, you may find the

gopher getter works in a huge range of soil moisture conditions or that it works well in a narrow range of

conditions.

If you have certain types of soil or low soil moisture, the gopher getter may have trouble getting to full

depth (where the packer wheel will turn consistently). Typically, it works best when the torpedo tube is

sloping slightly downward into the soil (a few degrees). Try adjusting the angle of the frame by

changing the length of the lower arms on the three point. Next, reduce the depth of the coulter to reduce

the force required to get the machine into the ground. If this does not fix the problem, you may add

weight from 300 to 500 pounds, maximum.

The advice and tips above and below are generalized ones for gopher getter users throughout the

country. For information specific to your area, please speak with the dealer that you purchased the unit

from, your local extension agent, or area farmers that use gopher getters.

Figure 15: Application distance between application passes

Using Your Gopher Getter

15

Operating Tips

•Never turn or back up with the machine in the ground. This will damage the unit.

•Never over tighten the one-inch bolt attaching the knife to the frame. The large bolt must be

loose enough to allow the knife and the parts attached to it to pivot when the shear bolt fails.

•Never over grease the seeder slide. Too much grease will cause bait to build up on the interior

surfaces of the unit when it contacts the bait traveling through the opening in the seeder slide and

cause it to plug.

•Always replace the shear bolt with an identical grade 5 bolt. Using a higher-grade bolt, such a

grade 8, will greatly increase the risk of expensive damage to the frame when you hit a large

obstruction.

•Always check that there are no underground pipes or other lines in the area you will be working.

There is nothing worse to hit with your gopher getter. (Yes, it has happened.)

•Always start slowing especially if you are new to the gopher getter or operating in an unfamiliar

field. At no point should you go faster than 5 mph. In some conditions, especially hard or

rocky ground, it will be necessary to limit your speed further.

•Always stop quickly when the shear bolt fails. If you are moving quickly and/or the obstruction

that you hit is especially tenacious like a tree root or an oddly shaped rock, the tip can catch long

enough for the bait box to pivot around and damage itself on the frame.

Additional Information

If you are having trouble setting up or operating your Gopher Getter, please contact the dealer where you

purchased your GA-800. If you are unable to contact them or they were unable to answer your questions,

please contact Elston Manufacturing at 1-800-845-1385 or refer to our website at www.elstonmfg.com .

Maintenance

16

5 Maintenance

Every use

Inspect torpedo tube/point for excessive wear or damage

Inspect shear bolt for damage, replace if necessary

Every season or 200 lbs. of bait

Check if the unit needs to be greased. If so, lightly grease the unit at the grease points on the packer

wheel hub, as shown in Figure 16, and the packer wheel adjustment rod, as shown in Figure 17.

Check that the tire pressure is 20 psi.

Replace any safety decals that are no longer readable.

GA-800 Grease Points

Figure 16: Grease Points on Packer Wheel Hub

Maintenance

17

Figure 17: Grease Points on Packer Wheel Adjustment Rod

Table of contents

Other Elston Manufacturing Farm Equipment manuals

Popular Farm Equipment manuals by other brands

FARMTECH

FARMTECH SLASHER HD130-1500 Operators manual and parts lists

Claydon

Claydon 15m Straw Harrow Operator's manual and part's manual

Dion

Dion Scorpion 350 Operator's manual

Landoll

Landoll 5531 Operator's manual

KUHN

KUHN FC244 Operator's manual

Shelbourne

Shelbourne Powerspread Pro 1800-2300 Operator's manual

Claas

Claas DOMINATOR 208 MEGA III Operator's manual

Güttler

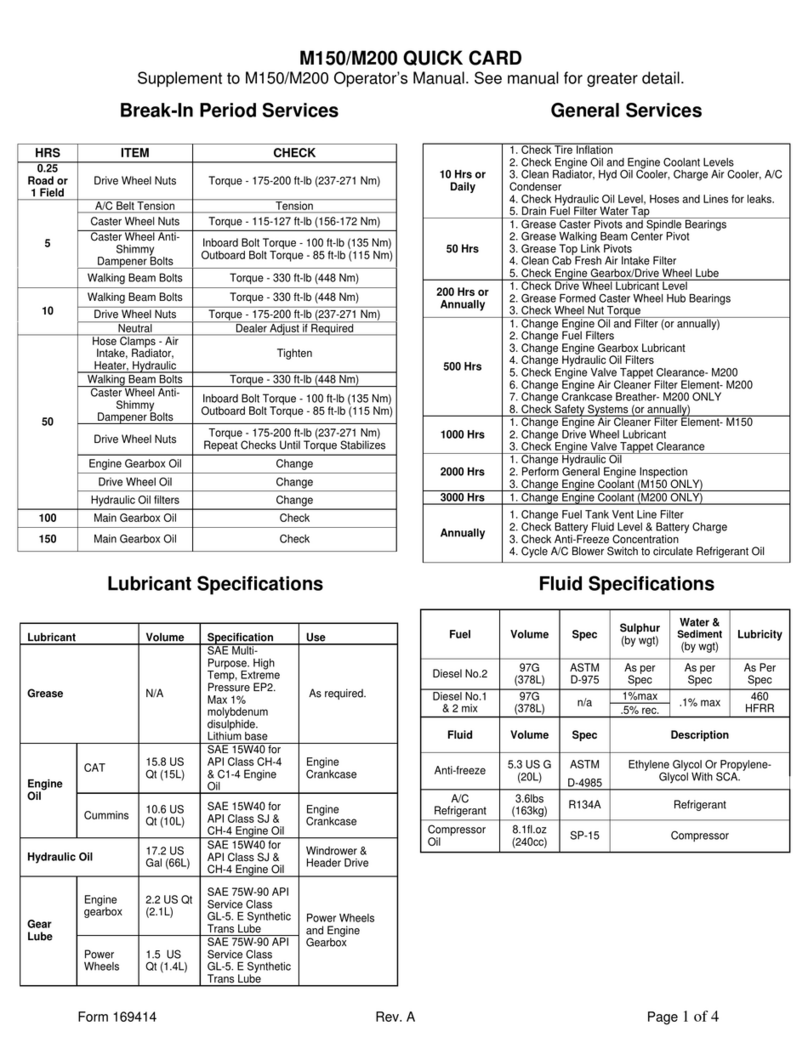

Güttler GreenMaster 600 instruction manual

MacDon

MacDon M150 Supplement manual

Hanskamp

Hanskamp Spider Installation and operating instructions

Kellfri

Kellfri 27-MD500 operating instructions

Powerfix Profi

Powerfix Profi KH 3221 operating instructions