M150/M200 QUICK CARD

Form 169414 Rev. A Page 1 of 4

Supplement to M150/M200 Operator’s Manual. See manual for greater detail.

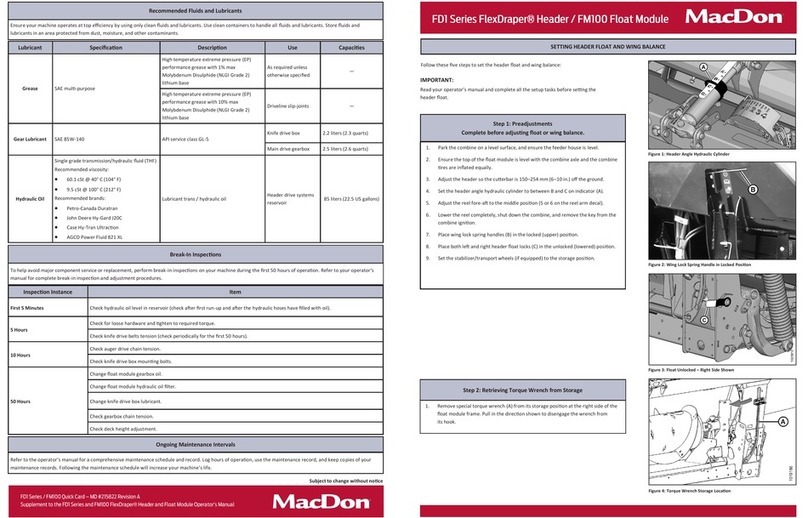

Break-In Period Services General Services

Lubricant Specifications Fluid Specifications

HRS ITEM CHECK

0.25

Road or

1 Field Drive Wheel Nuts Torque - 175-200 ft-lb (237-271 Nm)

A/C Belt Tension Tension

Caster Wheel Nuts Torque - 115-127 ft-lb (156-172 Nm)

Caster Wheel Anti-

Shimmy

Dampener Bolts

Inboard Bolt Torque - 100 ft-lb (135 Nm)

Outboard Bolt Torque - 85 ft-lb (115 Nm)

5

Walking Beam Bolts Torque - 330 ft-lb (448 Nm)

Walking Beam Bolts Torque - 330 ft-lb (448 Nm)

Drive Wheel Nuts Torque - 175-200 ft-lb (237-271 Nm)

10 Neutral Dealer Adjust if Required

Hose Clamps - Air

Intake, Radiator,

Heater, Hydraulic Tighten

Walking Beam Bolts Torque - 330 ft-lb (448 Nm)

Caster Wheel Anti-

Shimmy

Dampener Bolts

Inboard Bolt Torque - 100 ft-lb (135 Nm)

Outboard Bolt Torque - 85 ft-lb (115 Nm)

Drive Wheel Nuts Torque - 175-200 ft-lb (237-271 Nm)

Repeat Checks Until Torque Stabilizes

Engine Gearbox Oil Change

Drive Wheel Oil Change

50

Hydraulic Oil filters Change

100 Main Gearbox Oil Check

150 Main Gearbox Oil Check

10 Hrs or

Daily

1. Check Tire Inflation

2. Check Engine Oil and Engine Coolant Levels

3. Clean Radiator, Hyd Oil Cooler, Charge Air Cooler, A/C

Condenser

4. Check Hydraulic Oil Level, Hoses and Lines for leaks.

5. Drain Fuel Filter Water Tap

50 Hrs

1. Grease Caster Pivots and Spindle Bearings

2. Grease Walking Beam Center Pivot

3. Grease Top Link Pivots

4. Clean Cab Fresh Air Intake Filter

5. Check Engine Gearbox/Drive Wheel Lube

200 Hrs or

Annually

1. Check Drive Wheel Lubricant Level

2. Grease Formed Caster Wheel Hub Bearings

3. Check Wheel Nut Torque

500 Hrs

1. Change Engine Oil and Filter (or annually)

2. Change Fuel Filters

3. Change Engine Gearbox Lubricant

4. Change Hydraulic Oil Filters

5. Check Engine Valve Tappet Clearance- M200

6. Change Engine Air Cleaner Filter Element- M200

7. Change Crankcase Breather- M200 ONLY

8. Check Safety Systems (or annually)

1000 Hrs 1. Change Engine Air Cleaner Filter Element- M150

2. Change Drive Wheel Lubricant

3. Check Engine Valve Tappet Clearance

2000 Hrs 1. Change Hydraulic Oil

2. Perform General Engine Inspection

3. Change Engine Coolant (M150 ONLY)

3000 Hrs 1. Change Engine Coolant (M200 ONLY)

Annually

1. Change Fuel Tank Vent Line Filter

2. Check Battery Fluid Level & Battery Charge

3. Check Anti-Freeze Concentration

4. Cycle A/C Blower Switch to circulate Refrigerant Oil

Fuel Volume Spec

Sulphur

(by wgt)

Water &

Sediment

(by wgt) Lubricity

Diesel No.2 97G

(378L) ASTM

D-975 As per

Spec As per

Spec As Per

Spec

1%max

Diesel No.1

& 2 mix 97G

(378L) n/a .5% rec. .1% max 460

HFRR

Fluid Volume Spec Description

ASTM

Anti-freeze 5.3 US G

(20L) D-4985

Ethylene Glycol Or Propylene-

Glycol With SCA.

A/C

Refrigerant 3.6lbs

(163kg) R134A Refrigerant

Compressor

Oil 8.1fl.oz

(240cc) SP-15 Compressor

Lubricant Volume Specification Use

Grease N/A

SAE Multi-

Purpose. High

Temp, Extreme

Pressure EP2.

Max 1%

molybdenum

disulphide.

Lithium base

As required.

CAT 15.8 US

Qt (15L)

SAE 15W40 for

API Class CH-4

& C1-4 Engine

Oil

Engine

Crankcase

Engine

Oil

Cummins 10.6 US

Qt (10L) SAE 15W40 for

API Class SJ &

CH-4 Engine Oil

Engine

Crankcase

Hydraulic Oil 17.2 US

Gal (66L)

SAE 15W40 for

API Class SJ &

CH-4 Engine Oil

Windrower &

Header Drive

Engine

gearbox 2.2 US Qt

(2.1L)

SAE 75W-90 API

Service Class

GL-5. E Synthetic

Trans Lube

Gear

Lube

Power

Wheels 1.5 US

Qt (1.4L)

SAE 75W-90 API

Service Class

GL-5. E Synthetic

Trans Lube

Power Wheels

and Engine

Gearbox