5850 CP OPERATOR’S MANUAL (79451) 3/08

8

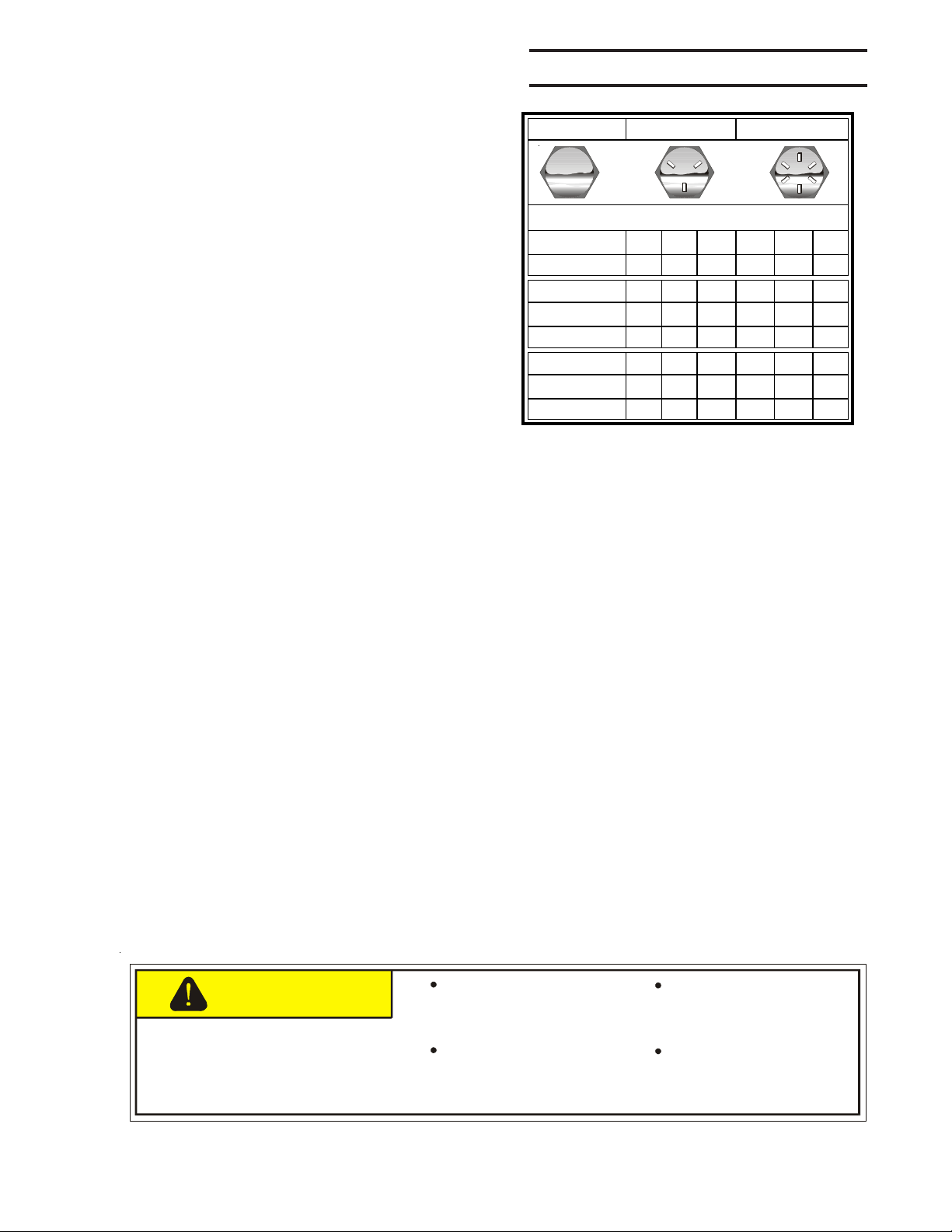

SAFETY Apersonwhohasnotreadandunderstoodall

operatingandsafetyinstructionsisnotqualified

tooperatethemachine. Anuntrainedoperator

exposesthemselvesandbystanderstopossible

seriousinjuryordeath.

Do not modify the equipment in any way.

Unauthorized modifications may impair the

functionand/orsafetyandcouldaffectthelifeof

theequipment.

ThinkSAFETY! WorkSAFELY!

GENERAL SAFETY BEFORE

OPERATING

Readandunderstandtheoperator'smanualand

allsafetysignsbeforeoperating,maintainingor

adjustingtheChiselPlow.

Reviewsafety related itemswithall operators

annually.

Useextremecarewhenmakingadjustments.

When working under or around the machine,

alwayslowertheChiselPlowtotheground.

Afterservicing,installandproperly secure all

shieldsandguardsbeforeoperating. Removeall

tools, parts, and service equipment from the

machine.

Haveafirst-aidkitavailablefor useshould the

needariseandknowhowtouseit.

Haveafireextinguisheravailableforuseshould

theneedariseandknowhowtouseit.

Clear the area of people and remove foreign

objectsfromthemachinebefore starting and

operating.

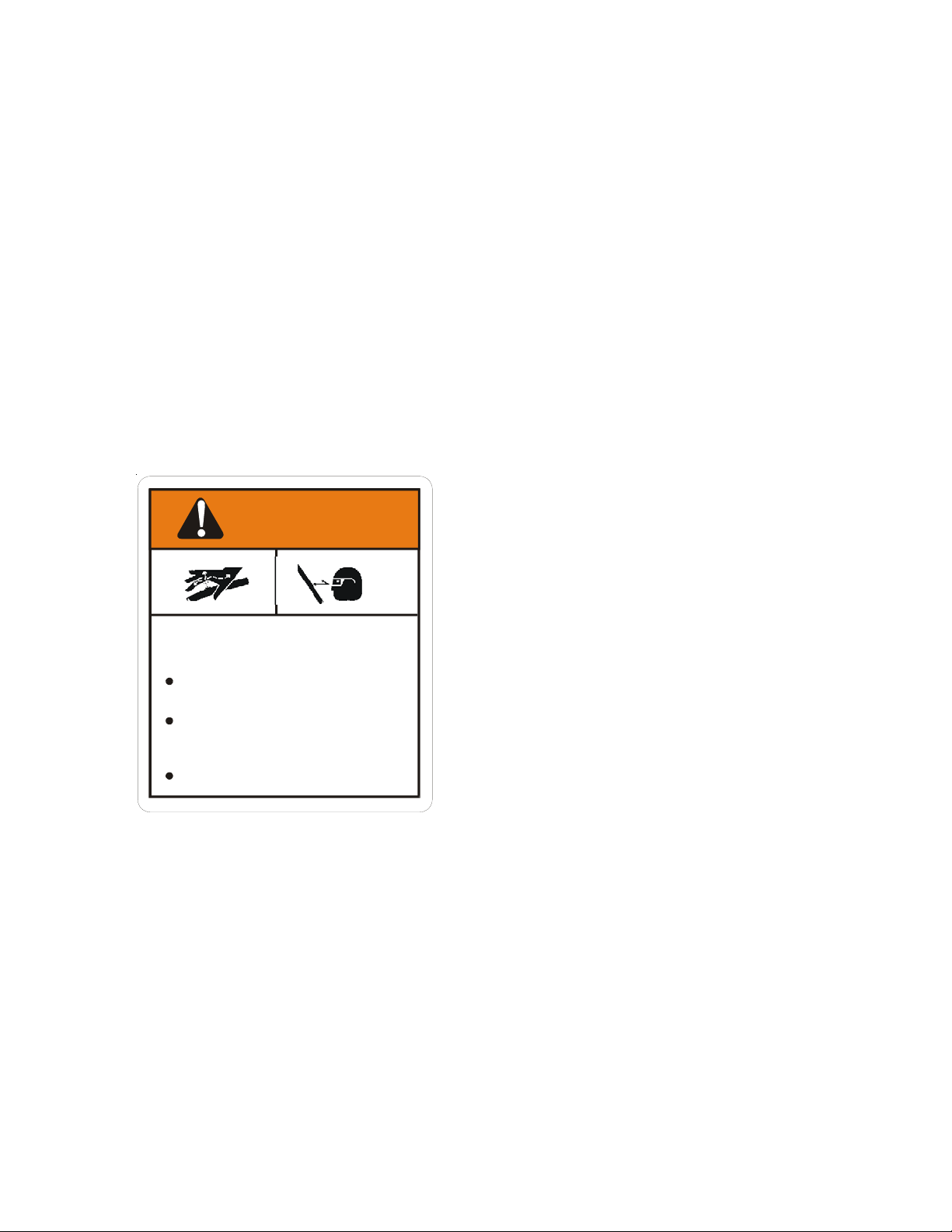

Alwayswearrelativelytightandbeltedclothing

toavoid entanglementinmoving parts. Wear

sturdy,rough-soledworkshoesand protective

equipmentforeyes,hair,hands,andhead. Wear

suitableearprotectionforprolongedexposureto

excessivenoise.

INFORMATION

YOUare responsible forSAFEoperation and

maintenanceofyourWil-RichChiselPlow. YOU

mustensurethatanyonewhoisgoingtooperate,

maintain or work around the Chisel Plow be

familiar with the operating and maintenance

procedures and related safety information

containedinthismanual. Thismanualwilltake

youstepbystepthroughyourworkingday,alerts

youto allgoodsafety practicesthat shouldbe

adheredtowhileoperatingthisequipment.

Remember,YOU are the keytosafety. Good

safetypracticesnotonlyprotectyoubutalsothe

people around you. Make these practices a

workingpartofyoursafetyprogram. Becertain

thatEVERYONEoperatingthisequipmentis

familiarwith therecommendedoperating and

maintenanceproceduresandfollowsallsafety

precautions. Mostaccidentscanbeprevented.

Donotriskinjuryordeathbyignoringgoodsafety

practices.

Chisel Plow owners must give operating

instructionstooperatorsandemployeesbefore

allowingthemtooperatethefieldcultivator,and

atleastannuallythereafterperOSHAregulation

1928.57.

The most important safety device on this

equipmentisasafeoperator.Itistheoperator's

responsibilitytoreadandunderstandALLSafety

andOperatinginstructionsinthemanualandto

followthem. Allaccidentscanbeavoided.

!