BA-en-2083-1909_RX22 9

2.5 Work and operational safety

Warning!

Carefully observe the following notes and the complete chapter 2 "Safety”,

page 8!

• Before carrying out repairs, cleaning or maintenance work and before

resetting after malfunctions, switch off the unit and disconnect the

mains supply voltage (see chapter 5 "Maintenance”, page 15, chapter 6

"Trouble shooting”, page 17).

• Any work involving the units must be carried out by qualified electri-

cians (see chapter 5 "Maintenance”, page 15, chapter 6 "Trouble shoo-

ting”, page 17).

• Before carrying out any work involving the units, the machine which has

the RX22 ion blower unit STATICJET fitted must not be in operation

(see chapter 5 "Maintenance”, page 15).

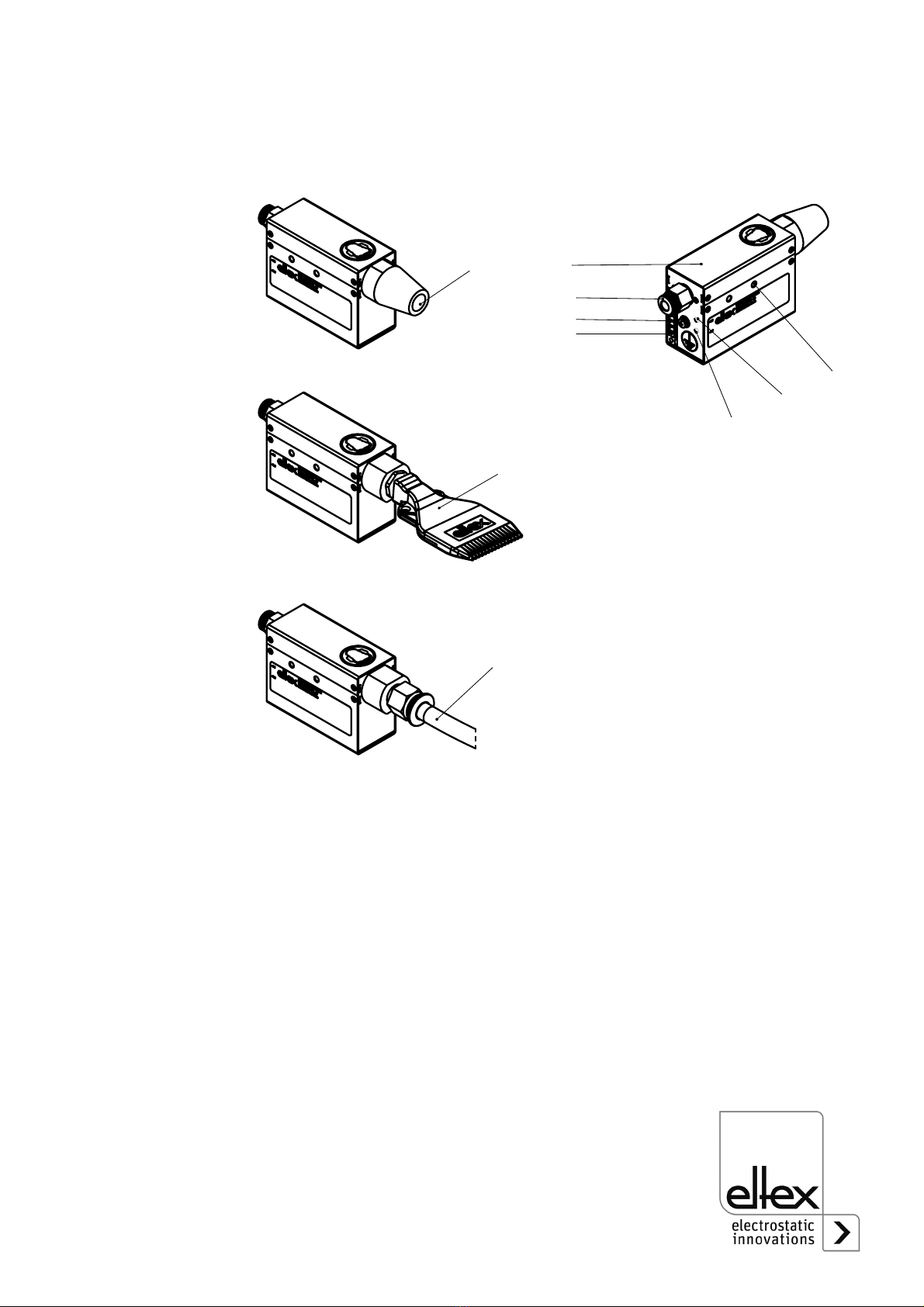

• A permanent ground contact must be made via the grounding connec-

tion (3, Fig. 1). The ground cable should have a minimum cross section

of 1.5 mm²(see chapter 3.2 "Ground connection”, page 12).

• A 24 VDC line current, designed for a min. current of 120 mA per unit, is

required for operating the RX22 ion blower unit STATICJET (see chap-

ter 3.4 "Connecting the supply voltage”, page 12, chapter 4 "Opera-

tion”, page 14).

• Before starting up the ion blower unit the user must make sure that the

unit has been installed and assembled correctly. Then first activate the

air and then the supply voltage (see chapter 4.1 "Startup”, page 14).

• The maximum rated pressure is 0.2 MPa (see chapter 3.3 "Connecting

the air hose”, page 12).

• The internal emission tip of the RX22 ion blower unit STATICJET must

not be damaged. For trouble-free operation, the tip must be straight and

sharply pointed (see chapter 5 "Maintenance”, page 15).

• Check the units at regular intervals and before startup for any damage.

Any damaged components must be repaired or replaced before conti-

nuing to operate the unit, or the units must be disabled.

• Make sure that the units are clean at all times.

Dirt results in malfunctions and in premature wear of the units.

Do not immerse the RX22 ion blower unit STATICJET in solvent.

Allow the solvent to evaporate completely before restarting the RX22

ion blower unit STATICJET (see chapter 5 "Maintenance”, page 15).

• The operation of the RX22 ion blower units STATICJET can generate

ozone. The ozone concentration levels developing near the units

depend on many diffe-rent factors such as site of installation, air circu-

lation, etc., and can therefore not be specified in general terms.

If the maximum allowable concentration of ozone must be observed at