8BA-en-2019-2006_EXR5C

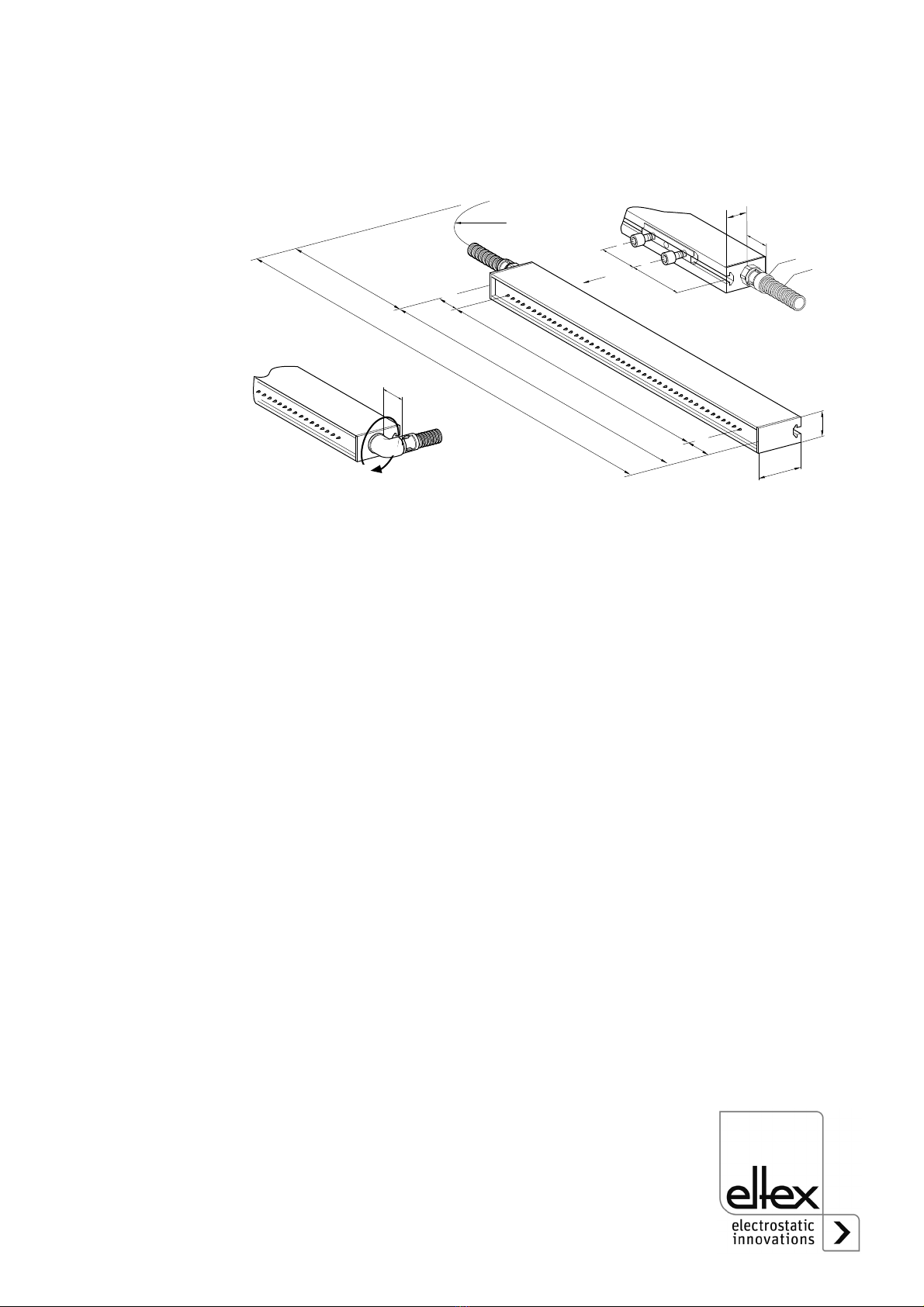

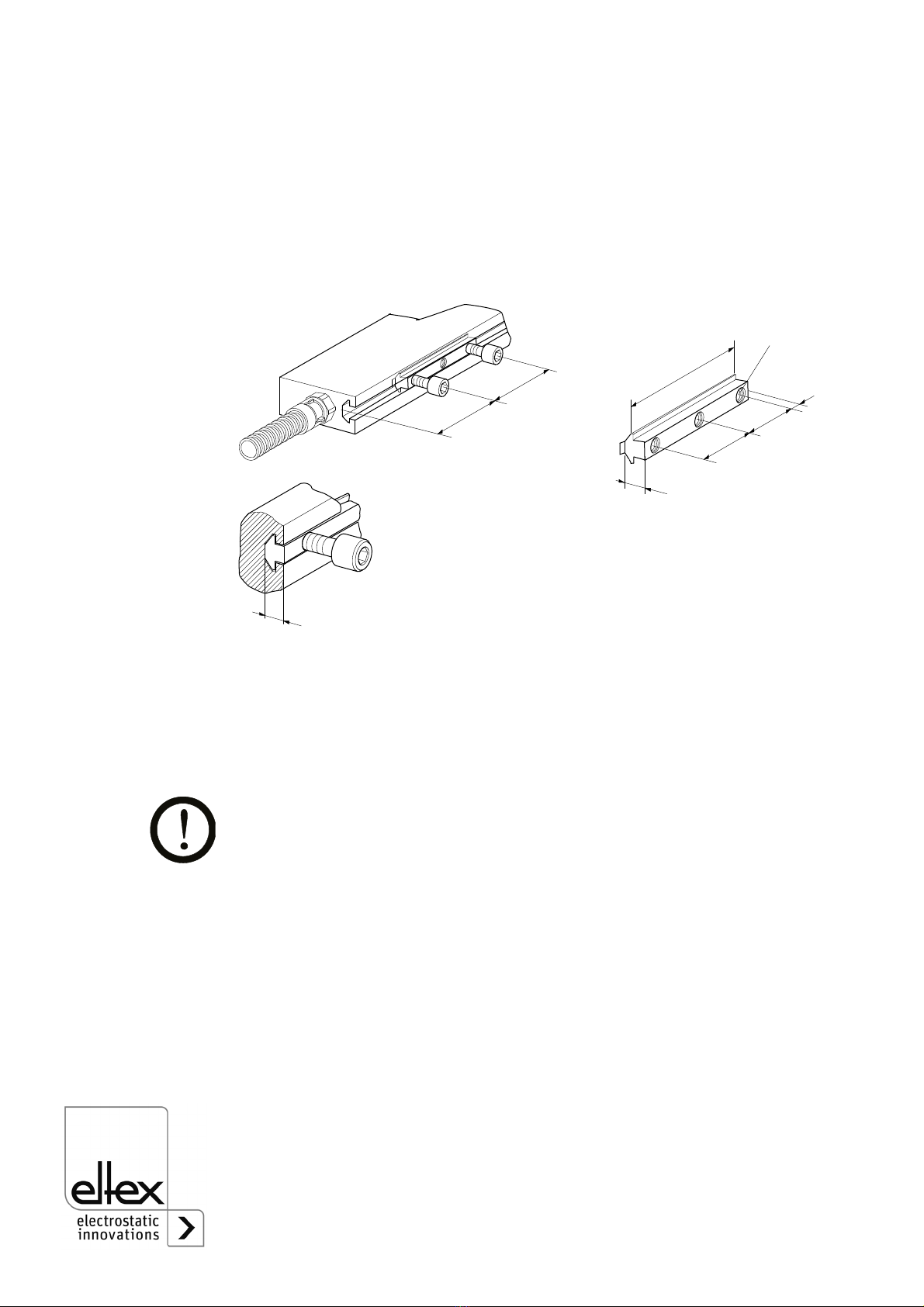

• In bilateral discharging, the bars must not be mounted in opposition to

each other. The distance between both bars should be greater than

twice the bar distance from the web (see chapter 3.1 "Assembling the

discharging bar”, page 10).

• Both the lengths of the high voltage cable and of the active bars are

limited, observe maximum lengths (see chapter 3.2 "Length of the high

voltage cable”, page 14).

• The maximum permissible angle of turn of the angle coupling is 360°

(see chapter 3.3 "Adjust the angle coupling”, page 14).

• Before connecting the high voltage cables to the power supplies / dis-

tributors, the machine which has the bars fitted must not be in operation

and the supply voltage to the power supply must be disconnected (see

chapter 3.4 "Connecting the high voltage cable to the power supplies

and the distributor boxes”, page 15, chapter 5 "Maintenance”, page 17,

chapter 6 "Trouble-shooting”, page 18).

• Check the discharging bars and the high voltage cables at regular inter-

vals for any damage. Damaged components must be repaired or

replaced before continuing to operate the unit, or the bar or cable must

be disabled.

• The function control of the discharging bars has to be done outside of

the explosion hazard area (see chapter 4.2 "Function control”,

page 16).

• Keep the bars clean at all times.

Dirt results in malfunctions and in premature wear of the units.

• When cleaning the bars do not soak the bars and the high voltage cable

in solvent and do not damage the emission tips; allow the solvent to

evaporate completely before restarting the unit (see chapter 5 "Mainte-

nance”, page 17), chapter 6 "Trouble-shooting”, page 18).

• In explosion hazard areas Group II Gas subdivision B it must be

ensured that the possibility of the discharge pins being effectively con-

nected together, e.g. by dirt or contamination, is avoided.

• Do not touch the emission tips - risk of injury.

If the high voltage supply is connected, reflex responses to electrical

irritation can lead to secondary accidents; the charging bar as such is

safe to touch. If contact is made (≤10 tips), the energy transferred is so

low that there is no risk of injury.

• Potential risk for wearers of cardiac pacemakers:

Moving the chest closer than 3.5 cm to the emission tips of the dis-

charging bars or making surface contact with several emission tips

(touching a single tip is not critical) can result in a temporary switchover

of the cardiac pacemaker into the fault mode. Permanent proximity or

contact can therefore cause severe problems. If it is likely that the chest

of such a person comes closer than 3.5 cm to the emission tips of the