elv LS 50 User manual

1

ELV Elektronik AG • Postfach 1000 • D-26787 Leer • Telefon 0491/600-888 • Telefax 0491/6008-244

Programmable

Soldering Station

LS 50

User Manual

32

List of contents

Page

Introduction ...................................................................................... 2

Proper Use ....................................................................................... 2

List of Contents ................................................................................ 3

Safety Instructions............................................................................ 4

Description of Functions................................................................... 5

Brief Summary of Instructions for Use ............................................. 6

Instructions for Use .......................................................................... 6

1. Setting up ................................................................................... 6

2. Switching on ............................................................................... 7

3. Adjusting the set point temperature with the ,,+”/ ,,-” keys ......... 7

4. Selecting one of the programmed set point temperatures ......... 7

5. Modifying the programmed set point temperatures .................... 8

6. Manual standby function ............................................................ 8

7. Timer-controlled standby function ............................................ 10

8. Automatic power-off function .................................................... 11

9. Disabling the power bar-chart .................................................. 11

10. Switching over between °C and °F ......................................... 12

11. Calibrating the temperature reading by software .................... 12

12. Potential equalization ............................................................. 13

13. Attaching a new soldering tip .................................................. 13

Handling ......................................................................................... 14

Maintenance................................................................................... 14

Disposal ......................................................................................... 16

Troubleshooting.............................................................................. 16

Technical Data ................................................................................ 16

Introduction

Dear customer, First of all we should like to thank you for purchasing

this product.

You have, with this soldering station, acquired a product whose design

and construction are completely state-of-the-art. To ensure safe

operation, you as the user must always observe these Operating

Instructions

Proper Use

●This soldering station is intended exclusively for the purposes of

soldering and unsoldering electrical and electronic components

on printed circuit boards and modules, for solder-coating conductive

patterns and cable ends, and for manufacturing cable connectors.

●It is not allowed to use the soldering station to heat liquids or plastics.

●The soldering station may only be used indoors, i.e. not in the

open air. Contact with dampness or humidity, e.g. in a bathroom

etc., must be avoided under all circumstances.

●Use other than that described above will result in damage to this

product and involves the risk of hazards such as short-circuit, fire,

electric shock, etc. The case must not be opened and no part of

the product may be modified or converted.

●The Safety Instructions must be observed under all circumstances.

54

●The appliance is not intended for use by young children or infirm

persons without supervision.

●Do not leave the packaging material Iying around. In the hands of

children, plastic film / bags, polystyrene foam, etc. may become a

dangerous toy.

●In commercial premises, the accident prevention regulations of the

Association of Industrial Professional Associations with respect to

electrical systems and operating equipment must be observed.

●In schools, training institutions, and hobby and self-help workshops,

use of any device operated via mains power must always be

supervised by responsible and properly trained personnel.

●Warning- The soldering iron must be placed on its stand when not

in use.

Description of Functions

The LS 50 soldering station is made for excellent soldering

convenience. Thanks to its processor control it has been possible to

implement a wide variety of useful features, e.g. the direct selection of

up to three programmable set point temperatures, the standby and

automatic power-off functions, plus a liquid-crystal display (LCD).

Particularly in day-to-day operation, the user quickly learns to

appreciate the advantages of a soldering station with special

convenience features of this nature.

With the LS 50 it is possible not only to adjust the set point temperature

by means of the „+” / „-” keys but also to program up to three

temperatures (or, alternatively, two temperatures plus a standby

temperature) which can be quickly selected at the touch of a button.

The soldering station can thus be prepared on an individual, task-

oriented basis for the most varied soldering jobs, e.g. PCB work, wiring,

or soldering an insulating case.

The multi-function LCD provides clear, at-a-glance indication of all the

important parameters. It displays the current actual temperature in

extra large digits. At the same time it also displays the three

programmed set point temperatures. It can also display a bar-chart

providing a clear overview of the heat currently being supplied to the

soldering iron.

Further features, particularly useful in day-to-day use, are the integrated

Safety Instructions

●The warranty will become void in the event of any damage caused

by failure to observe these Operating Instructions. We cannot

accept any liability for consequential damage.

●We cannot accept any liability for damage to property or physical

injury caused by improper use or failure to observe the Safety

Instructions. The warranty will become void in such cases.

●For reasons of safety and of certification no conversion or

modification of the soldering station is permitted.

●The only power source permitted is an approved mains socket

(230-240 volts / 50 Hz) properly installed and connected to the

public power supply grid.

●Please ensure that the soldering station is set up, switched on,

and operated in a proper, workmanlike and technically correct way,

always carefully observing these Operating Instructions.

●If you have any doubt regarding the connection, safety measures

or operation of this device, please contact a specialist.

●Having switched the soldering station on, never leave it unattended

in this condition.

●Never use the soldering station in the proximity of any easily

inflammable, ignitable or combustible substances or gases.

●Soldering releases vapours that represent a health hazard.

●Always ensure that the workplace is well ventilated or use a suitable

extractor system.

●Always be sure to protect your eyes and body from solder splashes

by wearing suitable goggles and clothes.

●Always ensure when setting up the soldering station that the mains

cable cannot be squashed or damaged by any sharp edges.

●Never place the soldering station in the proximity of any easily

inflammable or combustible materials, e.g. curtains.

●Never expose the soldering station to any high temperatures, strong

vibrations, or humidity.

●No device operated via mains power should be treated as a children

toy.

●Young children should be supervised to ensure that they do not

play with the appliance.

76

2. Switching on

The soldering station can be switched on by means of the „Power”

switch. The processor then performs a segment test, i.e. all 108

segments are activated for approximately two seconds.

This is followed by the heat-up phase. The soldering iron heats up

until it reaches the set point temperature in effect just before the device

was switched off the last time. The LCD shows the current actual

temperature in the main display section and the „Power” bar-chart

(which can be disabled) indicates the heat being supplied to the

soldering iron; (see Figure 1). As soon as the set point temperature is

reached, the soldering iron is maintained constant at this temperature.

Figure 1

C

Power

3. Adjusting the set point temperature with the „+” / „-” keys

The set point temperature can be adjusted inter alia by means of the

„+” and „-” keys.

As soon as one of these keys is pressed, the main display section

(see Figure 1) changes to show the set point temperature. This set

point temperature can then be jogged up or down in steps of 1°each

time the key in question is pressed. If the key is pressed and held

down, the set point temperature is incremented / decremented initially

in 1°steps for the first 10 digits and then subsequently in 10°steps. As

soon as the desired value is reached, the key must be released.

The main display section, after approximately three seconds, switches

back to showing the current actual temperature.

4. Selecting one of the programmed set point temperatures

The feature with the programmed set point temperatures provides real

soldering convenience. For different soldering jobs the most suitable

temperatures can be selected quickly and conveniently at the push of

standby and automatic power-off functions. The standby / automatic

power-off timer can be adjusted in 5-minute steps up to a maximum of

9 hours and 55 minutes. On expiry of this programmed timeout the

LS 50 automatically sets the preprogrammed standby temperature or

switches off completely. The standby mode can of course be activated

and deactivated at any time at the push of a button.

The soldering iron on the LS 50 operates with 48 W. It can thus heat

up to the desired working temperature very quickly and with plenty of

power in reserve. The processor determines the current actual

temperature via the integrated temperature sensor and regulates the

power of the soldering iron accordingly. As and when necessary a

new soldering tip can be attached very easily and quickly by simply

undoing the screw connector.

Brief Summary of Instructions for Use

1. Set up the device and insert the soldering iron plug in the DIN socket

on the station.

2. Switch on by means of the ,,Power” switch.

3. Adjust the set point temperature as desired by pressing the „+”/„-”

keys.

4. You can select one of the programmed set point temperatures by

pressing the appropriate „T1” /„T2”/„T3”key.

5. You can modify a programmed set point temperature by pressing

and holding down the appropriate „T1” / „T2”/ „T3” key and, while

doing so, adjusting by means of „+” or „-”.

Instructions for Use

In order to ensure that the device is used properly and as intended,

please be sure, before using the device, to read through these

Operating Instructions and Safety Instructions carefully and completely.

1. Setting up

First the device must be set up at your workplace and connected to a

mains socket. The plug from the soldering iron must then be inserted

in the DIN socket located on the front of the station. The solder sponge

must be laid in the stand and moistened.

98

C

Power

Standby

Standby

C

Power

Standby

Prog

C/FPower

C

Power

Standby

Prog

C/FPower

Figure 3

The device is shipped with the manual standby function disabled. If

you prefer to have this function enabled, the LS 50 must first be

switched to programming mode. To do so, press keys „T1”, „T2” and

„T3” together at the same time. When the LS 50 is in programming

mode, this is indicated by the ,,Prog” segment; (see Figure 4).

Figure 4

Now in programming mode the manual standby function can be

enabled by pressing key „T1". The arrow segment appears above this

key; (see Figure 5). Pressing „T1” again disables the function again

and the arrow segment disappears. After a period of three seconds

after the last time a key was pressed the LS 50 quits programming

mode automatically and returns to normal display.

Figure 5

a button. The device is shipped with the following set point temperatures

already programmed: 150 °C, 300 °C, and 400 °C.

These programmed set point temperatures are indicated above the

keys „T1”, „T2” and „T3” in the display. When one of these keys is

pressed, the assigned temperature is used as the set point. After one

of these keys has been pressed, the main display section shows the

assigned temperature for approximately three seconds and then

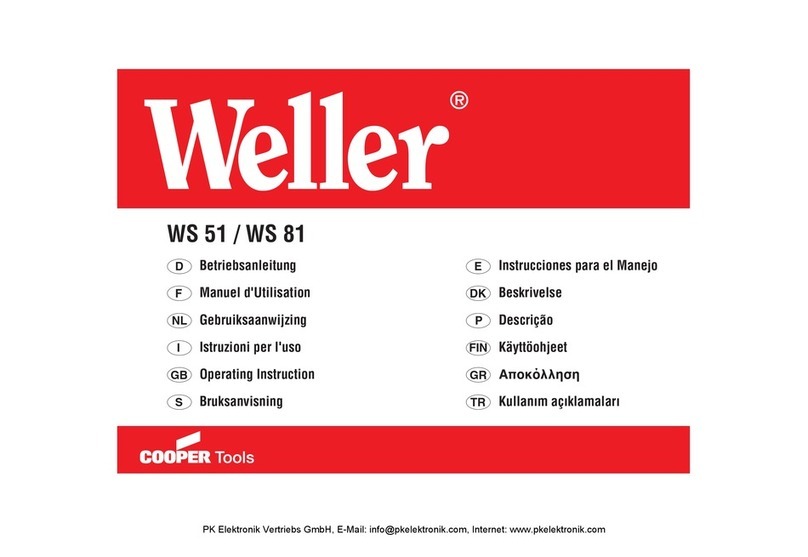

switches back to showing the current actual temperature.

An arrow above one of these keys signals that the assigned programmed

temperature has been activated as set point; (see Figure 2).

Figure 2

C

Power

5. Modifying the programmed set point temperatures

If you prefer to have different set point temperatures programmed,

these can easily be modified. To do so, the key below the temperature

you wish to change (T1, T2, T3) must be pressed and held down.

While this key is held down, the assigned temperature can be adjusted

up or down by pressing the „+” / „-” key. As soon as you release the

keys, the new temperature value is saved.

6. Manual standby function

In jobs involving long pauses between soldering actions it makes good

sense to lower the temperature of the soldering iron. This reduces

energy consumption and saves wear on the soldering tip. To do so,

key „T1” can be reprogrammed as stand by key. Subsequently, when

this key is pressed, the soldering iron starts cooling down to the

programmed set point temperature „T1”. This is indicated in the display

by the ,,Standby” segment; (see Figure 3). And as soon as the key is

pressed again the previous set point temperature is re-activated.

1110

8. Automatic power-off function

It is also possible to program the LS 50 so that the soldering iron, after

a programmable timeout, automatically switches off. The LS 50

indicates this by displaying „OFF” in the main display section. As soon

as any key is pressed, the device quits the power-off mode.

The device is shipped with the power-off function disabled. If you prefer

to have this function enabled, the LS 50 must first be switched to

programming mode. To do so, press keys „T1”, „T2” and „T3” together

at the same time. When the LS 50 is in programming mode, this is

indicated by the „Prog” segment; (see Figure 4). Now in programming

mode the power-off function can be enabled by pressing and holding

down key „T2”. The power-off timeout can now be adjusted in 5-minute

steps up to a maximum of 9 hours and 55 minutes by means of the

„+”/„-” keys; (see Figure 7).

Figure 7

If the power-off timeout is set to „0”, the power-off function is disabled

again and the timeout display disappears. After a period of three

seconds after the last time a key was pressed the LS 50 quits

programming mode automatically.

Notice: After programming the Automatic Power-Off time the

programmed data only becomes valid after switching the solder station

off and then back on.

9. Disabling the „power” bar-chart

The „power” bar-chart display can be disabled. To do so, the LS 50

must first be switched to programming mode by pressing keys „T1”,

„T2” and „T3” together at the same time; (see Figure 4). Now in

programming mode the „power” bar-chart can be disabled by pressing

key „T2”. The arrow segment above this key disappears; (see Figure 8).

Pressing „T2” again re-enables the bar-chart display. After a period of

C

Power

Standby

Prog

C/FPower

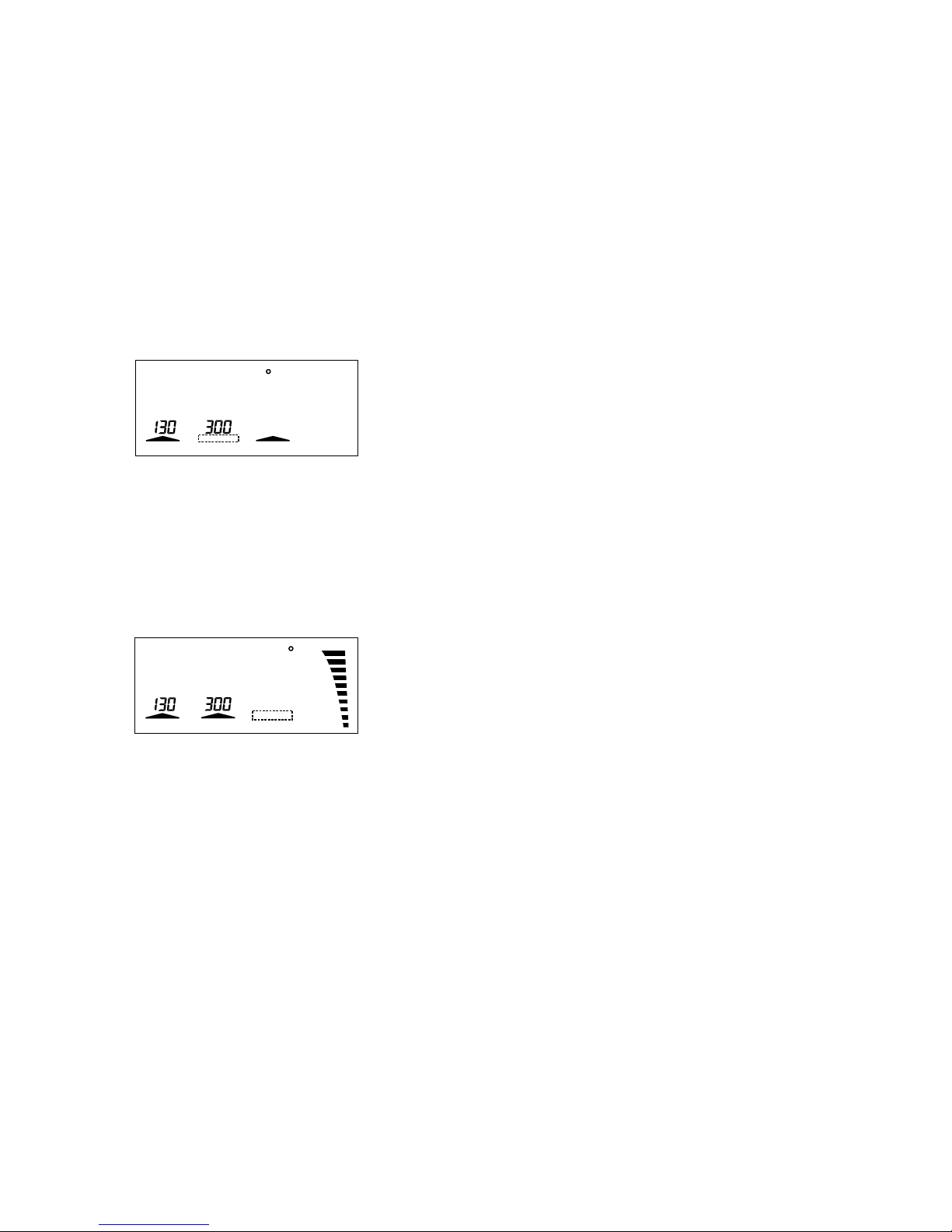

7. Timer-controlled standby function

The timer-controlled standby function has the effect of lowering the

working temperature automatically after expiry of a programmable

timeout. This timeout is calculated from the last time a key was pressed.

If the standby period has been programmed e.g. as one hour, the

soldering station switches to standby mode exactly one hour after the

last time a key was pressed. In this condition, as soon as any key is

pressed, the soldering station quits standby mode again.

The device is shipped with the timer-controlled standby function disabled.

If you prefer to have this function enabled, the LS 50 must first be

switched to programming mode. To do so, press keys „T1”, „T2” and

„T3” together at the same time. When the LS 50 is in the programming

mode, this is indicated by the „Prog” segment; (see Figure 4).

Now in programming mode the timer-controlled standby function can

be enabled by pressing and holding down key „T1”. The standby

timeout can now be adjusted in 5-minute steps up to a maximum of 9

hours and 55 minutes by means of the „+”/ „-” keys; (see Figure 6).

If the standby timeout is set to „0”, the timer-controlled standby function

is disabled again and the timeout display disappears.

After a period of three seconds after the last time a key was pressed

the LS 50 quits programming mode automatically.

Notice: After programming the standby time the programmed data only

becomes valid after switching the solder station off and then back on.

Figure 6

C

Power

Standby

Prog

C/FPower

1312

For this purpose you should use a measuring unit with stable operation

up to a temperature of at least 350 °C.

In order to activate calibration mode, you must, during the switching-

on process, press key „T1”. „CAL 20” appears in the display together

with the soldering iron temperature, which should correspond to room

temperature. If the soldering iron is still warm, you must first allow it to

cool down to room temperature before proceeding further.

Having ensured that the soldering iron has cooled down to

approximately 20 °C, you must confirm this by pressing key „T1”.

Now key „T2” must be pressed. In the display „CAL 350” appears. The

LS 50 begins to heat up the soldering iron to 350 °C. If there is a

discrepancy between the display on the connected temperature

measuring unit and the LS 50 display, the latter can now be calibrated

by pressing the „+” / „-” keys. If both displays agree, you should now

press key „T3”. This concludes the calibration process. The new

calibration data is saved to the non-volatile memory on the LS 50.

12. Potential equalization

For soldering work on critical components the potential at the soldering

tip should be adapted to the circuit potential by operating via the

„Potential Equalization” socket. The voltage difference must be no more

than maximum 42 V.

13. Attaching a new soldering tip

The soldering tip can be replaced very easily and quickly thanks to

the soldering irons quick-action screw connector. If the soldering iron

is cold, the screw connector can be undone directly on the shank. The

sleeve can then be moved forward and withdrawn. The soldering tip is

now freely accessible.

The soldering iron must never be operated without a soldering tip attached.

This would damage the heating element and the temperature sensor.

The soldering iron is shipped with the following soldering tip attached:

0.8 mm soldering tip.

The following alternative soldering tips are available:

●1.6 mm soldering tip

●3.2 mm soldering tip

F

Power

Standby

Prog

C/FPower

three seconds after the last time a key was pressed the LS 50 quits

programming mode automatically.

Figure 8

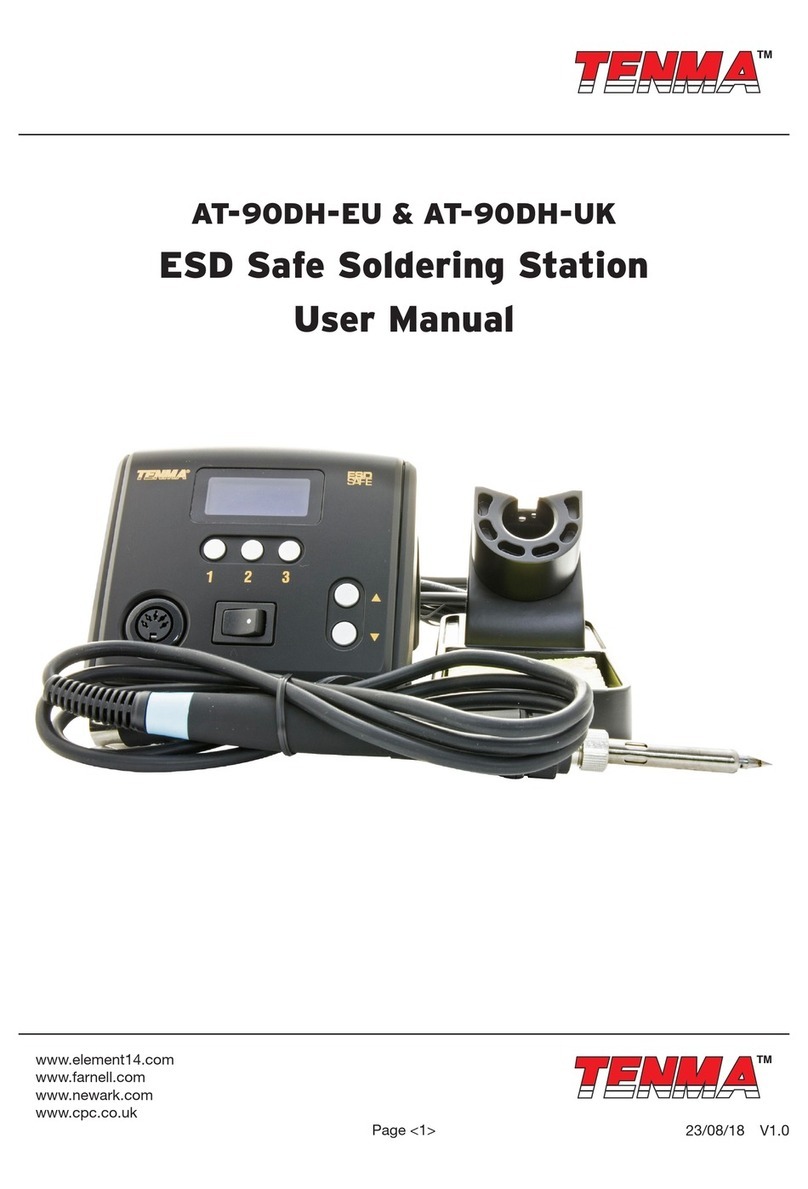

10. Switching over between °C (Celsius) and °F (Fahrenheit)

If you prefer to have the temperature displayed in °F, the LS 50 must

first be switched to programming mode by pressing keys „T1”, „T2”

and „T3” together at the same time; (see Figure 4). Now in programming

mode the temperature displays can be switched over to °F by pressing

key „T3”. The arrow segment above this key disappears; (see Figure 9).

By pressing „T3” again the temperature displays can be switched back

to °C. After a period of three seconds after the last time a key was

pressed the LS 50 quits programming mode automatically.

Figure 9

C

Standby

Prog

C/FPower

11. Calibrating the temperature reading by software

The LS 50 is already adjusted in the production stage to a very high

level of precision. However if recalibration should prove necessary,

this can be performed using the integrated calibration mode.

Warning: As soon as calibration mode is activated, all previous

soldering iron data will be irrevocably deleted.

Before even starting the calibration process you must ensure that the

soldering iron temperature can be measured with sufficient accuracy.

1514

conditions, or

- the device has been subjected to heavy stress during

transportation.

Before carrying out cleaning or maintenance on the device, please be

sure to observe the following Safety Instructions:

●When opening covers or withdrawing parts, live electric components

may be exposed.

●Therefore, before carrying out any maintenance or repair, the device

must be disconnected from all voltage sources.

●Even after the device has been disconnected from all voltage

sources, it is always possible that capacitors in the device may still

be charged.

●Repair may only be carried out by a specialist aware of the

associated risks and familiar with the relevant directives.

●If it becomes necessary to change a fuse, please note that only

fuses of the type and rated current indicated may be used as

replacements.

●Makeshift repair of the defective fuse or bridging the fuse holder

are not permitted.

●The LS 50 is fitted with a slow-blowing fine-wire 1 A fuse. In the

event of a failure, this can be easily exchanged but before doing

so, the device must first be disconnected from the 230 V mains

voltage supply.

To access the fuse the fuse-holder on the underside of the device

must be unscrewed using a screw-driver turning in the direction

indicated by the arrow. Once this is open, the fuse can be removed

and replaced with a new one of the same type. Then carefully

screw the fuse cap back again into the fuse-holder.

Only after this whole process has been completed can the device

be returned to operation.

●To clean the device use only a dry linen cloth. If the device is

unusually dirty, the cloth may be very slightly moistened. Never

use any cleaning agent that may contain solvents. Ensure that

absolutely no humidity is allowed to penetrate inside the device.

Handling

●Never switch on your soldering station immediately after bringing

it from a cold room into a warm room. The resulting condensation

may in worst case circumstances actually lead to the device being

damaged beyond repair.

●Allow the soldering station in its non-switched-on condition to first

attain ambient room temperature.

●So long as the device is switched on, always ensure that the case

is sufficiently ventilated and never allow the device to be covered

up.

●Place the soldering station on a flame-resistant, fire-retardant base-

pad in such a way that air can circulate freely in the case.

●The soldering station must not be placed in a damp, humid location.

It must not be exposed to natural precipitation or splashing water,

to dust, or to prolonged direct sunlight.

●Avoid subjecting the device to heavy mechanical stress. Do not

place the device on an uneven or unstable base. If the device falls

over, staff might be injured.

●If you are using the original soldering iron stand LA 50, the soldering

iron must be inserted in the receptacle as far as it will go.

●The soldering iron attains working temperatures in the range from

150 °C up to 450 °C. Contact with any of its metallic parts may

cause serious burns to people or animals.

Maintenance

●Check the soldering station at regular intervals with regard to its

technical safety, e.g. Iooking for damage to the mains cable or the

case.

●If you suspect that the device is no longer safe to use, it must be

kept switched off and secured against being switched on again

unintentionally. The mains plug must be withdrawn from the power

socket.

●It can be assumed that the device is no longer safe to use if any of

the following applies:

- the device is visibly damaged,

- the device has ceased to function,

- the device has been stored for a long period under unfavourable

16

Disposal

In the event that the LS 50 has become unusable, it must be disposed

of in accordance with the applicable statutory regulations.

Troubleshooting

You have, with this soldering station, acquired a product whose design

and construction are completely state-of-the-art and whose operation

is completely reliable.

Do not open the device yourself. It contains no parts needing

maintenance. In the event of failure please send the device to our

service centre. Opening the device yourself first involves the risk of

electric shock and second will automatically invalidate the warranty

for this product.

In the event of the soldering station becoming in any way defective, it

must be disconnected immediately from the mains power supply and

secured against being switched on again unintentionally.

Please ensure that the Safety Instructions are observed at all times.

Technical Data

Soldering temperature: ........................................... 150 °C to 450 °C

Resolution: ................................................................................. 1 °C

Soldering iron: ................................................................. 24V / 48W

Power supply:........................................... 230 -240 V / 50Hz / 70VA

Dimensions, soldering station: ..... 110 x 120 x 135 mm (W x H x D)

Dimensions, soldering iron: ......................................... 200 x 30 mm

Table of contents