10

OPERATING GUIDELINES

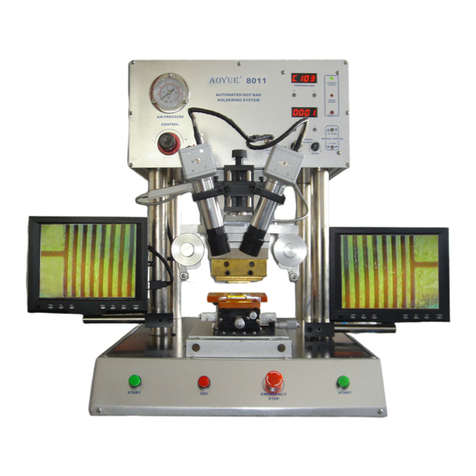

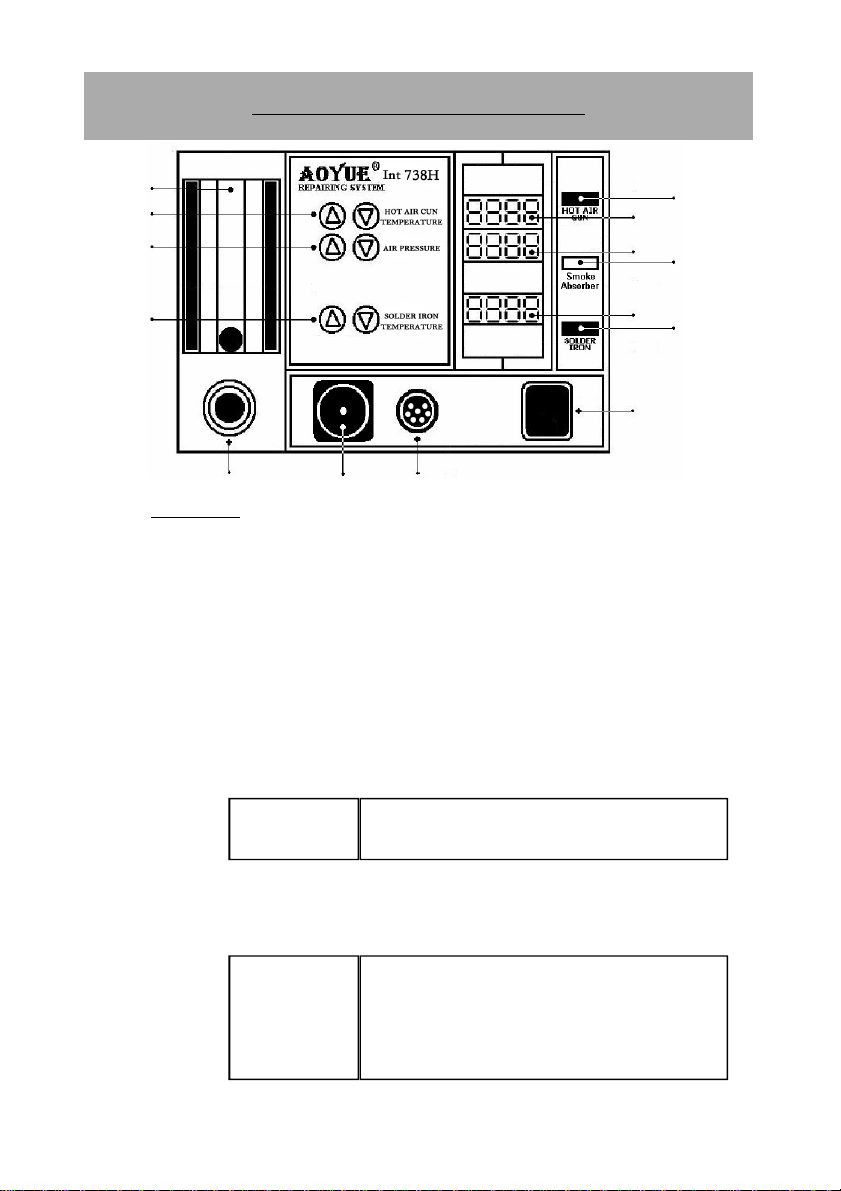

4. Adjust the air pressure level using the

Air Pressure Adjustment Buttons

(“3” from the control panel).

5. Adjust the hot air gun air temperature using the

Hot Air Gun

Temperature Adjustment Buttons

(“2” from the control panel). The

prefix of the display for Hot Air Gun Temperature will change from

“H” to “” indicating that temperature is being adjusted. It will return

to “H” (indicating actual temperature) while the temperature is

gradually increasing or decreasing until the set temperature is

reached.

6. Reworking task can be started 1 minute after the desired hot air

temperature and airflow level are reached, indicated on display

panels “10” and “12”, respectively.

7. When reworking is complete, return the Hot Air Gun to its holder

and DO NOT immediately turn OFF the

Main Power Switch

.

8. Turn OFF the

Hot Air Gun Function Switch

first in order to activate

the auto-cooling process. The system will start to blow air (at room

temperature) at a fast rate to reduce heat from the hot air gun and

bring down the temperature to a reasonable safe level of 90°C.

During this time, the prefix of the display for hot air gun

temperature will also change from “H” to “C” while temperature is

gradually decreasing. Likewise, the air pressure level is at its highest

reading as indicated from the display panel. Once the temperature

drops to approximately 90°C the system will halt and display “OFF”

on the panel. It is now safe to switch OFF the

Main Power Switch

.

9. Turn OFF the

Main Power Switch

.

10. Unplug the device from the main power source.

IMPORTANT: When adjusting the hot air gun temperature, it is

strongly advised to initially increase the airflow level in order to

manage the system temperature. This is to protect the heating

element inside the handle from excessive heat and avoid the pos-

sibility of subjecting adjacent components to thermal shock.