www.element14.com

www.farnell.com

www.newark.com

www.cpc.co.uk

Page <8> V1.023/08/18

Important Notice : This data sheet and its contents (the “Information”) belong to the members of the Premier Farnell group of companies (the “Group”) or are licensed to it. No licence is granted

for the use of it other than for information purposes in connection with the products to which it relates. No licence of any intellectual property rights is granted. The Information is subject to change

without notice and replaces all data sheets previously supplied. The Information supplied is believed to be accurate but the Group assumes no responsibility for its accuracy or completeness, any

error in or omission from it or for any use made of it. Users of this data sheet should check for themselves the Information and the suitability of the products for their purpose and not make any

assumptions based on information included or omitted. Liability for loss or damage resulting from any reliance on the Information or use of it (including liability resulting from negligence or where the

Group was aware of the possibility of such loss or damage arising) is excluded. This will not operate to limit or restrict the Group’s liability for death or personal injury resulting from its negligence.

Tenma is the registered trademark of the Group. © Premier Farnell Limited 2016.

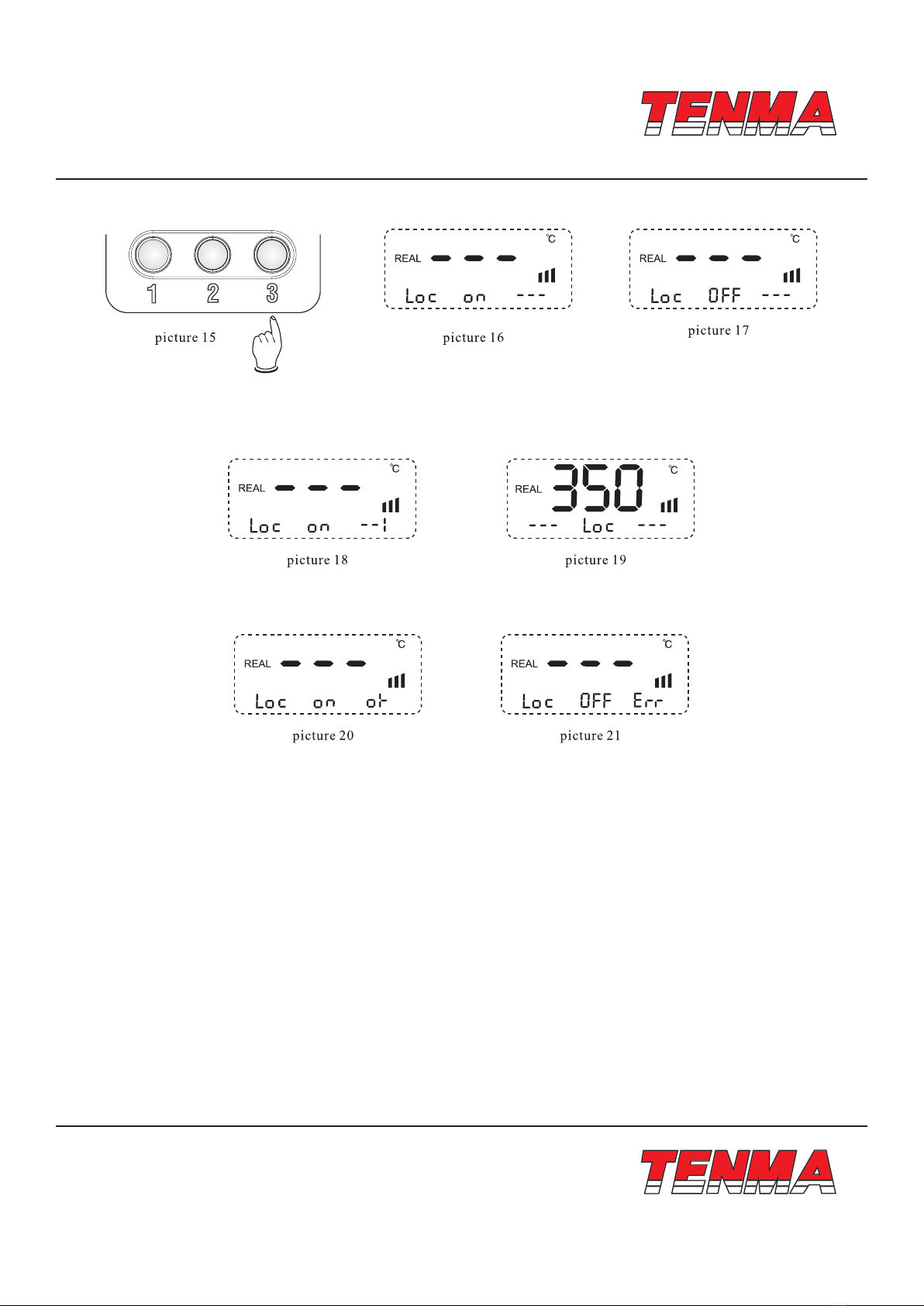

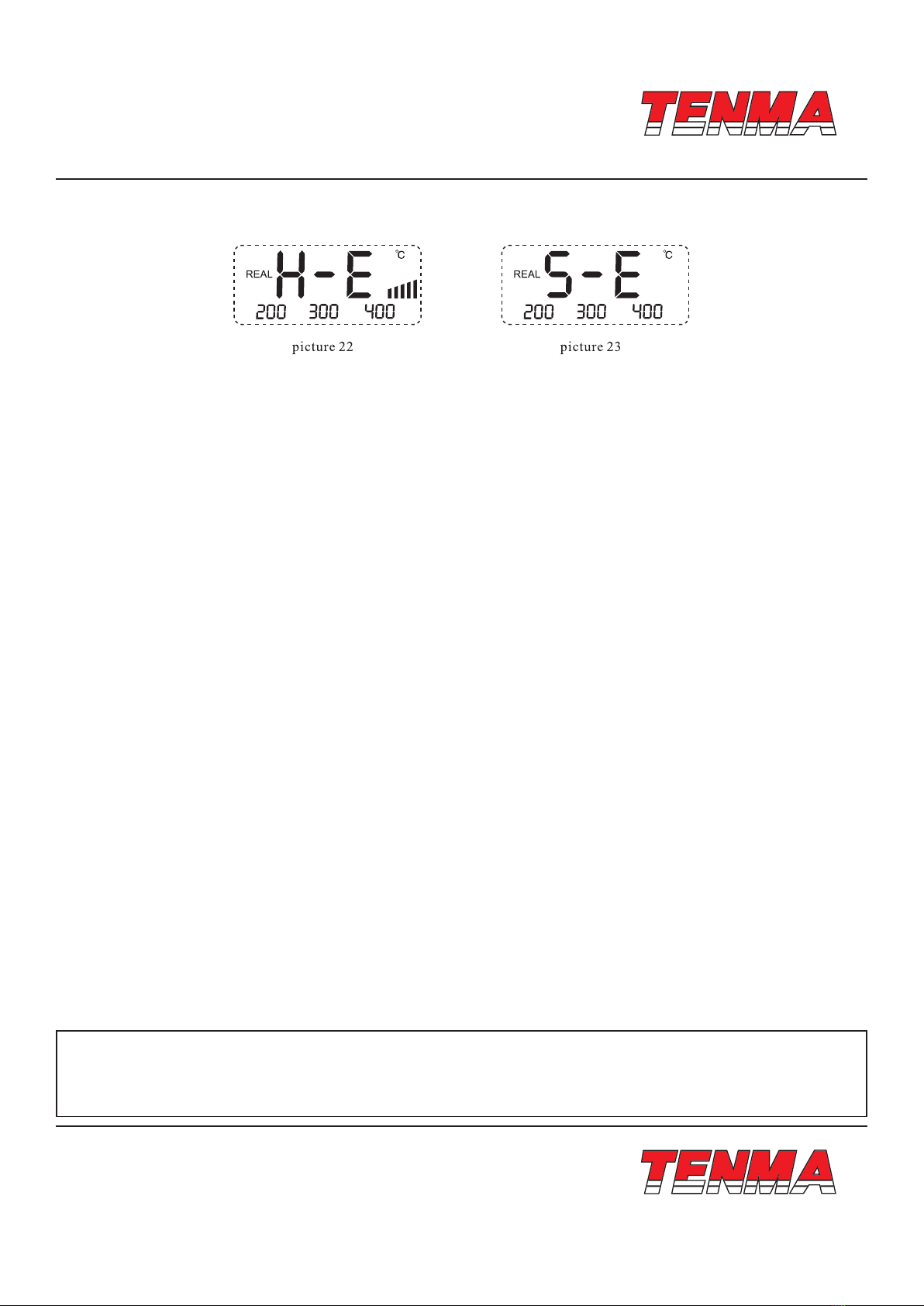

When “S - E” displays, accompanied with alarming of every 5 seconds (when opening fault alarming function). Maybe sensor

or relevant parts of circuit damages, check and replace sensor.

No any display on the screen, check power cord and re-connect.

Soldering tip is over - temperature or low - temperature, damaged or calibrated, please refer to “temperature calibration” or

replace the tip.

If there are illegible symbols, restart the machine.

When failure happens on the machine, repaired by only specied maintenance person or highly qualied technical personnel.

12. Soldering Tip Care and Use

a. Tip Temperature

High soldering temperatures can degrade the tip

Use the lowest possible soldering temperature. The excellent thermal recovery characteristics ensure efcient and effective

soldering even at low temperatures

When not in use, do not leave the soldering iron on at a high temperature as the tip’s solder plating will get covered by oxide,

reduction it’s heat conductivity

b. Cleaning

Clean the tip regularly with a cleaning sponge, as oxides and carbides from the solder and ux can form impurities on the tip.

These impurities can result in defective joints or reduce the tip’s heat conductivity

When using the soldering iron continuously, be sure to loosen the tip and remove all oxides at least once a week. This helps

prevent seizure and reduction of the tip temperature

After use, wipe the tip clean and coat with fresh solder. This helps prevent tip oxidation.

13. Changing the Soldering Tip

a. Always turn the power OFF when removing or inserting a soldering tip

b. Let the tip to cool down to room temperature before holding it with heat resistant pads

c. Loosen nut (1 in diagram 7)

d. Pull out the shaft of the soldering iron (2 in diagram 7)

e. Remove the old soldering tip and replace with new one (3 in diagram 7)

f. Reverse the process to secure the soldering tip

g. Preferred Soldering Tips : 21-10140, 21-10142, 21-10144, 21-10146, 21-10148, 21-10150, 21-10152, 21-10154, 21-10156,

21-10158