elysator PUROTAP profi Parts list manual

This manual suits for next models

2

Table of contents

Other elysator Water Filtration System manuals

elysator

elysator 50c User manual

elysator

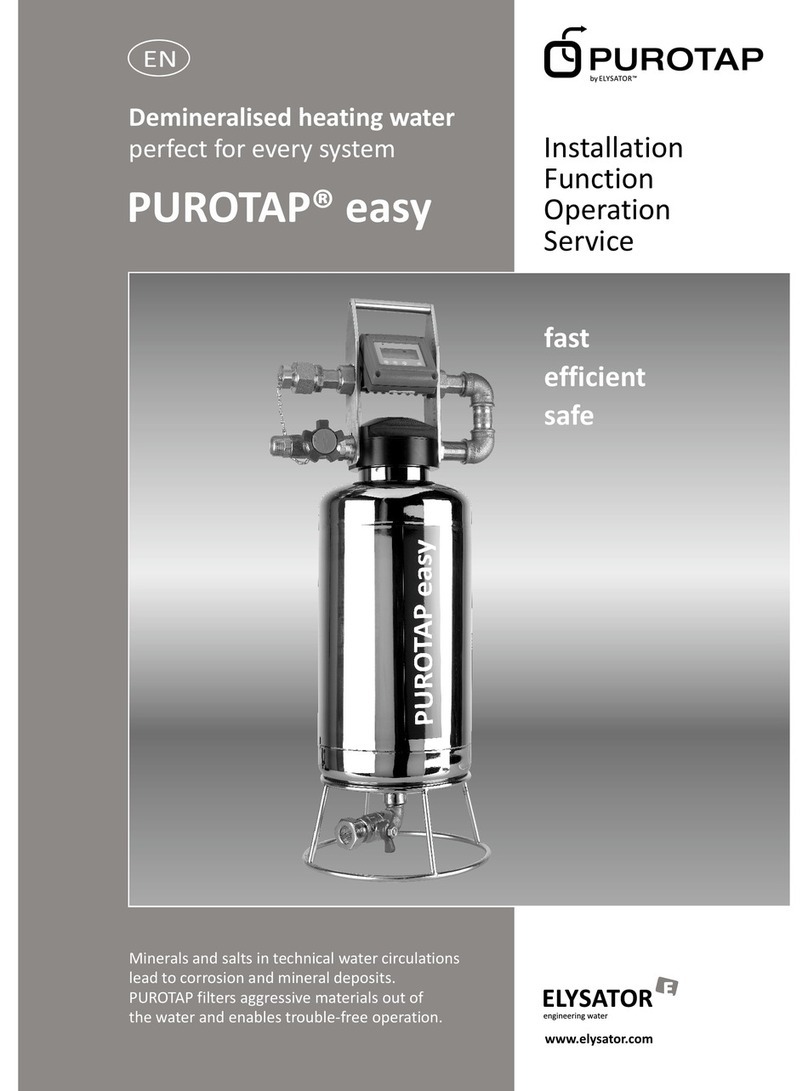

elysator PUROTAP easy Installation and user guide

elysator

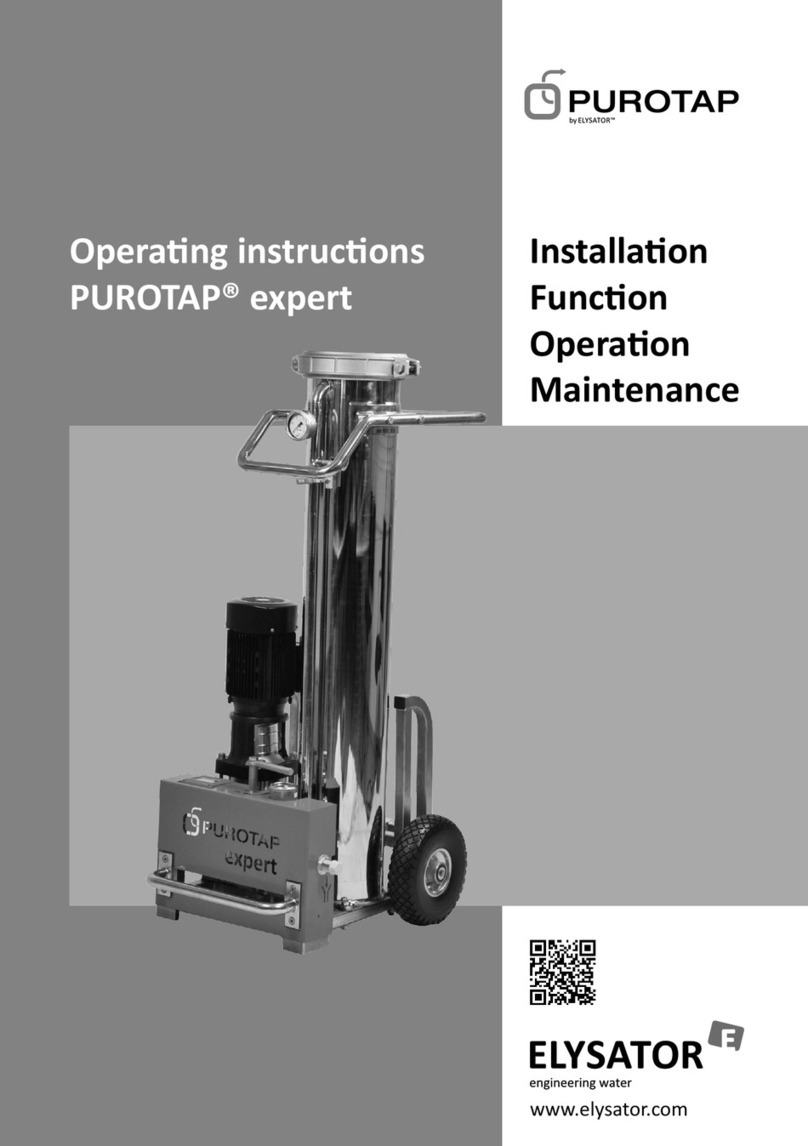

elysator PUROTAP expert Owner's manual

elysator

elysator PUROTAP expert Parts list manual

elysator

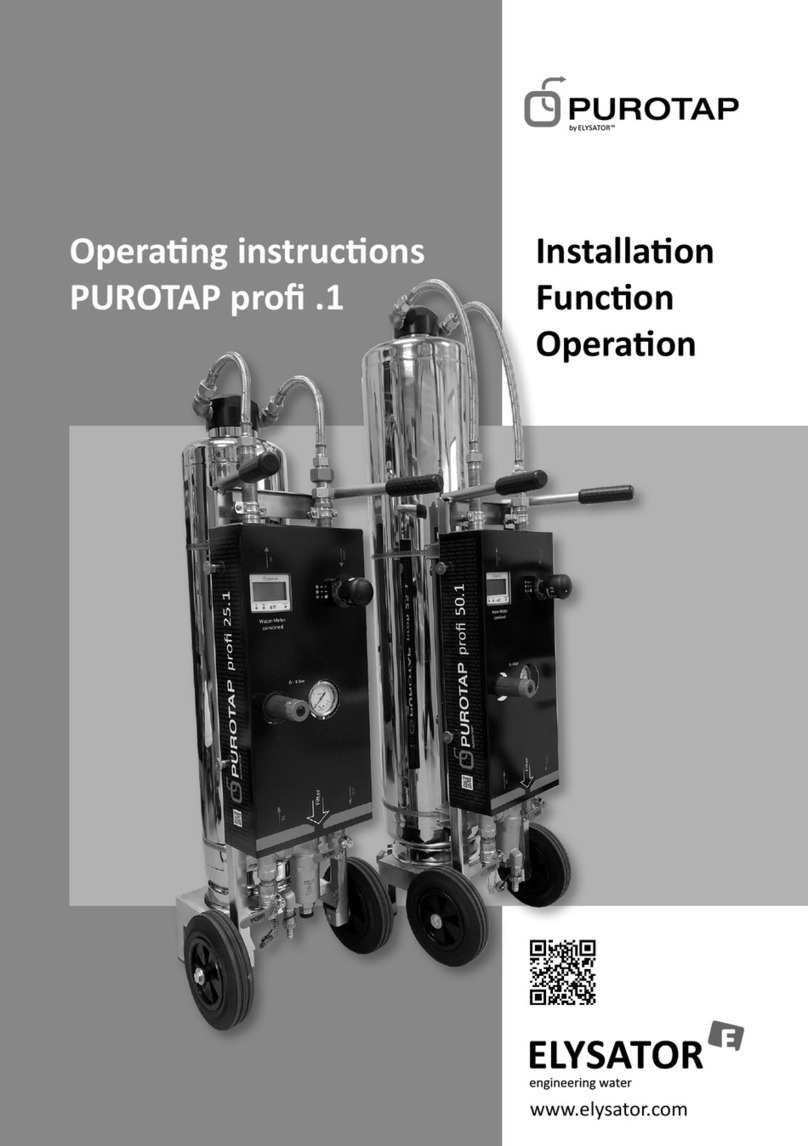

elysator PUROTAP profi 1 Series User manual

elysator

elysator PUROTAP compenso 2 User manual

elysator

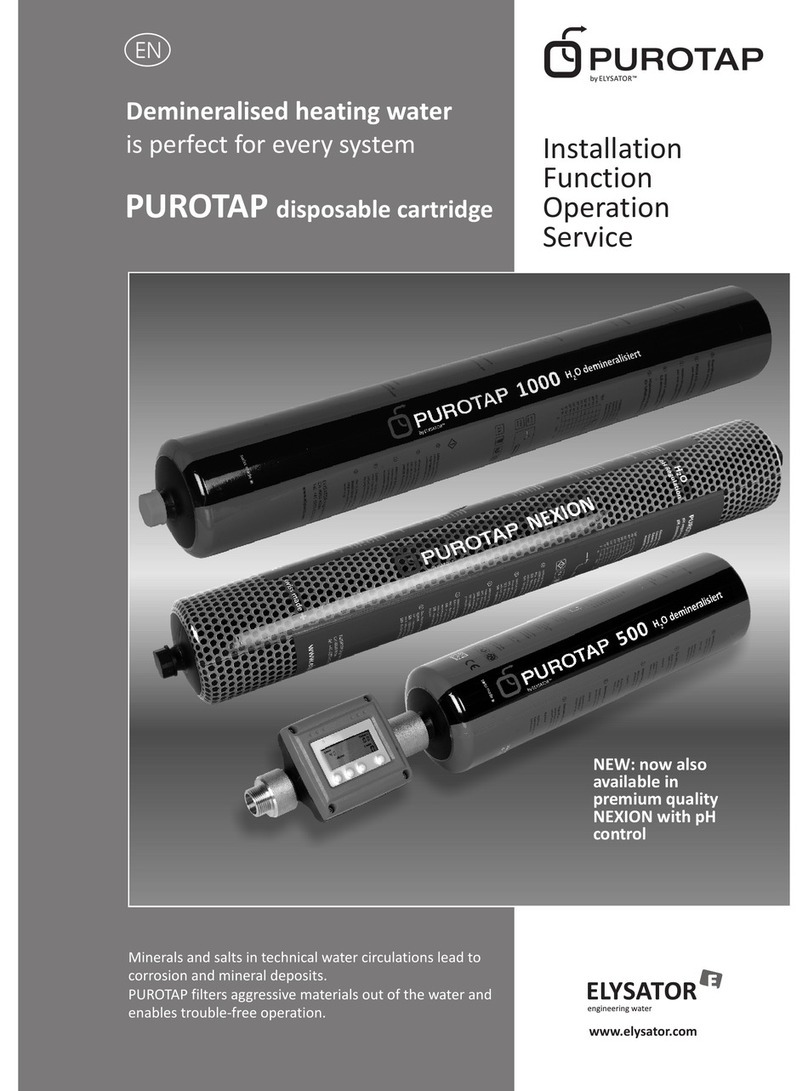

elysator PUROTAP 1000 Parts list manual

elysator

elysator PUROTAP easy II User manual

elysator

elysator PUROTAP profi 1 Series Parts list manual

elysator

elysator PUROTAP micro User manual

Popular Water Filtration System manuals by other brands

DRYDEN AQUA

DRYDEN AQUA DA-GEN 45 Service manual

Ultra Reef

Ultra Reef UAF-003 instruction manual

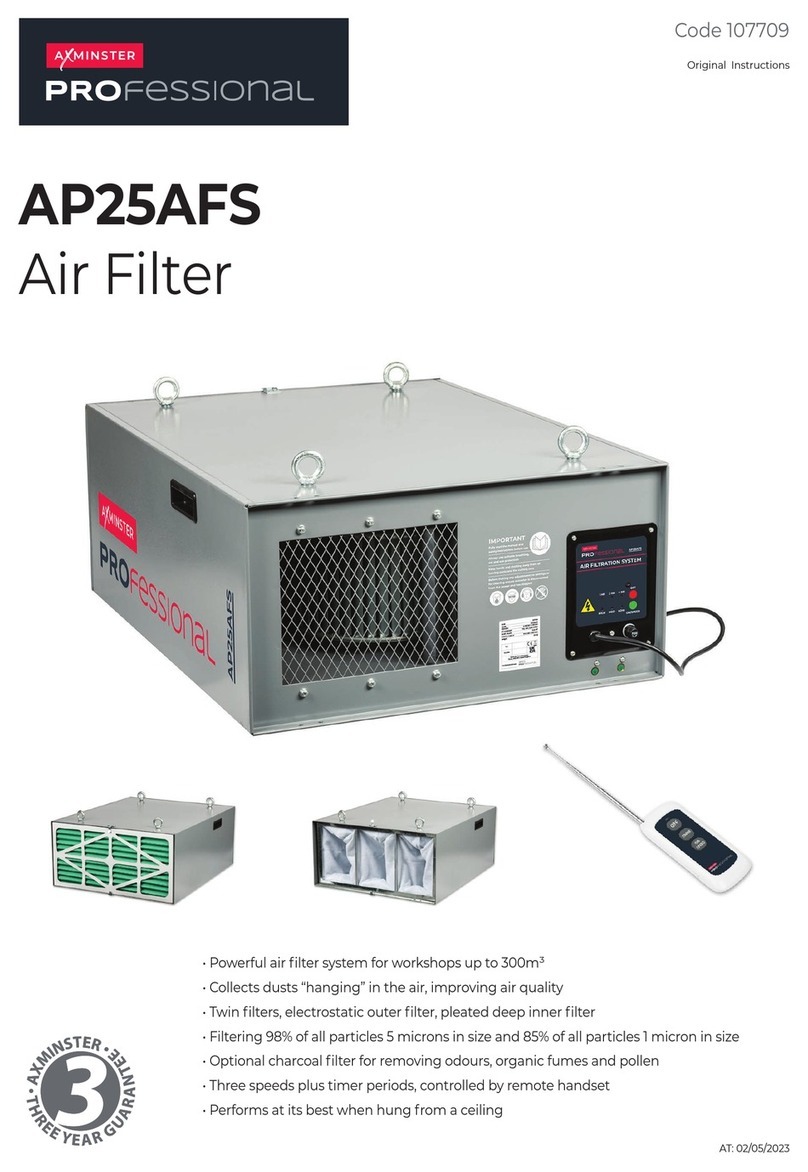

Axminster

Axminster PROFESSIONAL AP25AFS instructions

Culligan

Culligan HF-150A Installation and operating instructions

MOLDEX-METRIC

MOLDEX-METRIC 7000 Series quick start guide

Beko

Beko CLEARPOINT HP 100 Instructions for installation and operation

Ispring

Ispring WCFM500K Installation instructions & operating manual

Zip

Zip 803828 Installation & operating instructions

Aquasana

Aquasana AQ-CWM-RB1 Setup instructions

Puroserve

Puroserve HT series Operation manual

Ispring

Ispring RO1000 Series Installation instructions & user manual

Kohler

Kohler LISON 21729T-PP020-01R installation guide