elysator PUROTAP 1000 Parts list manual

Other elysator Water Filtration System manuals

elysator

elysator PUROTAP expert Owner's manual

elysator

elysator PUROTAP easy Installation and user guide

elysator

elysator PUROTAP compenso 2 User manual

elysator

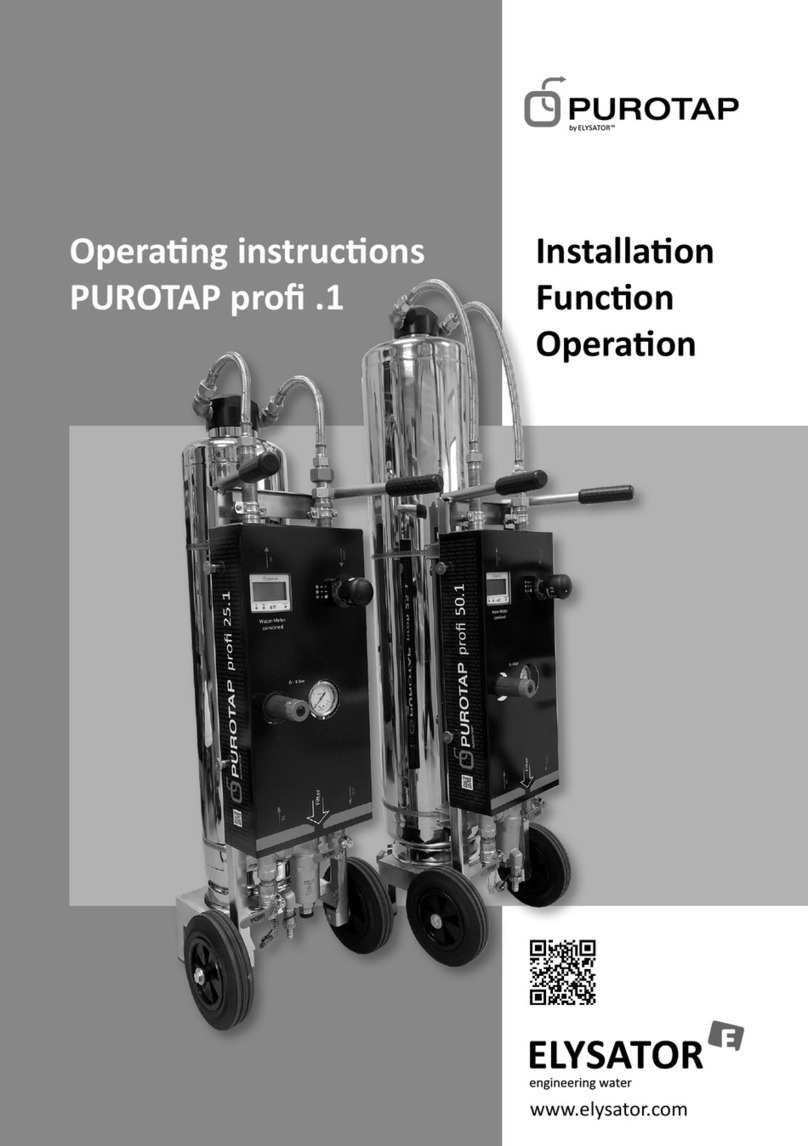

elysator PUROTAP profi 1 Series User manual

elysator

elysator PUROTAP micro User manual

elysator

elysator PUROTAP easy II User manual

elysator

elysator 50c User manual

elysator

elysator PUROTAP profi 1 Series Parts list manual

elysator

elysator PUROTAP profi Parts list manual

elysator

elysator PUROTAP expert Parts list manual

Popular Water Filtration System manuals by other brands

ICA

ICA TURBOJET PLUS instruction manual

Cuisinart

Cuisinart WCH-1500A Instruction booklet

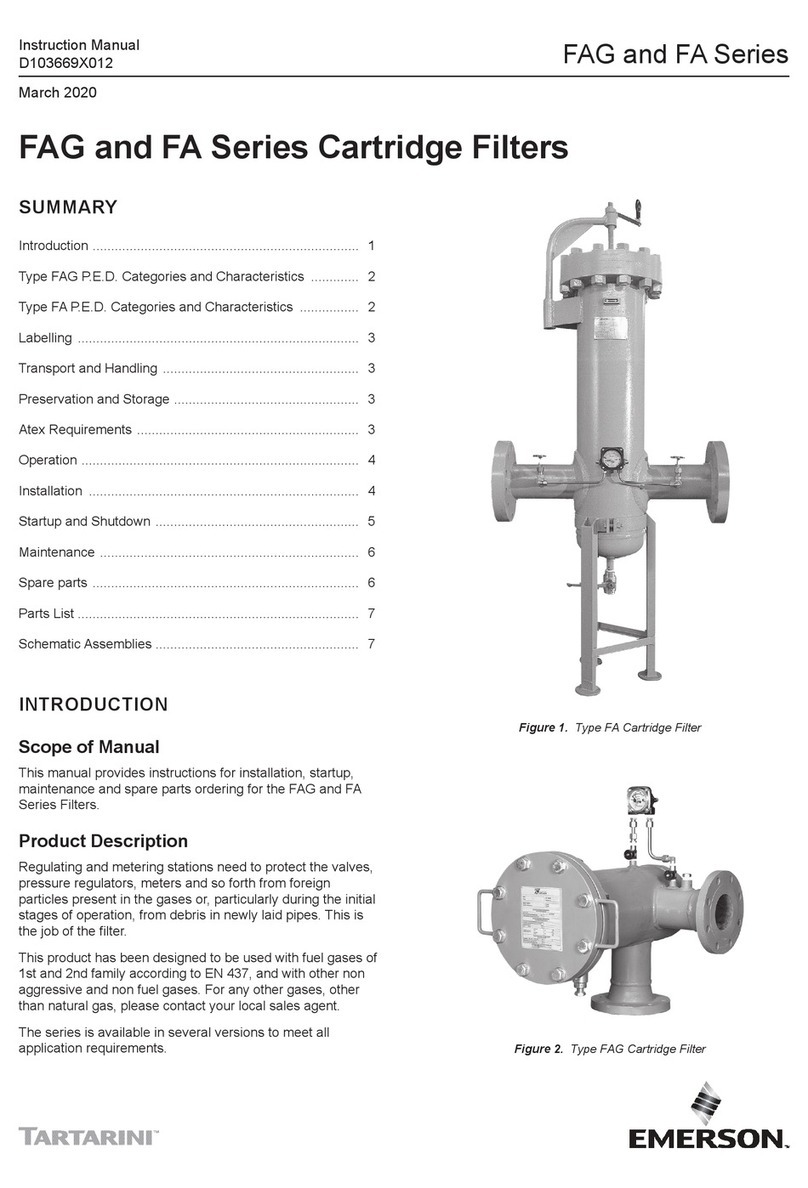

Emerson

Emerson TARTARINI FA Series instruction manual

Siemens

Siemens SINAMICS G130 operating instructions

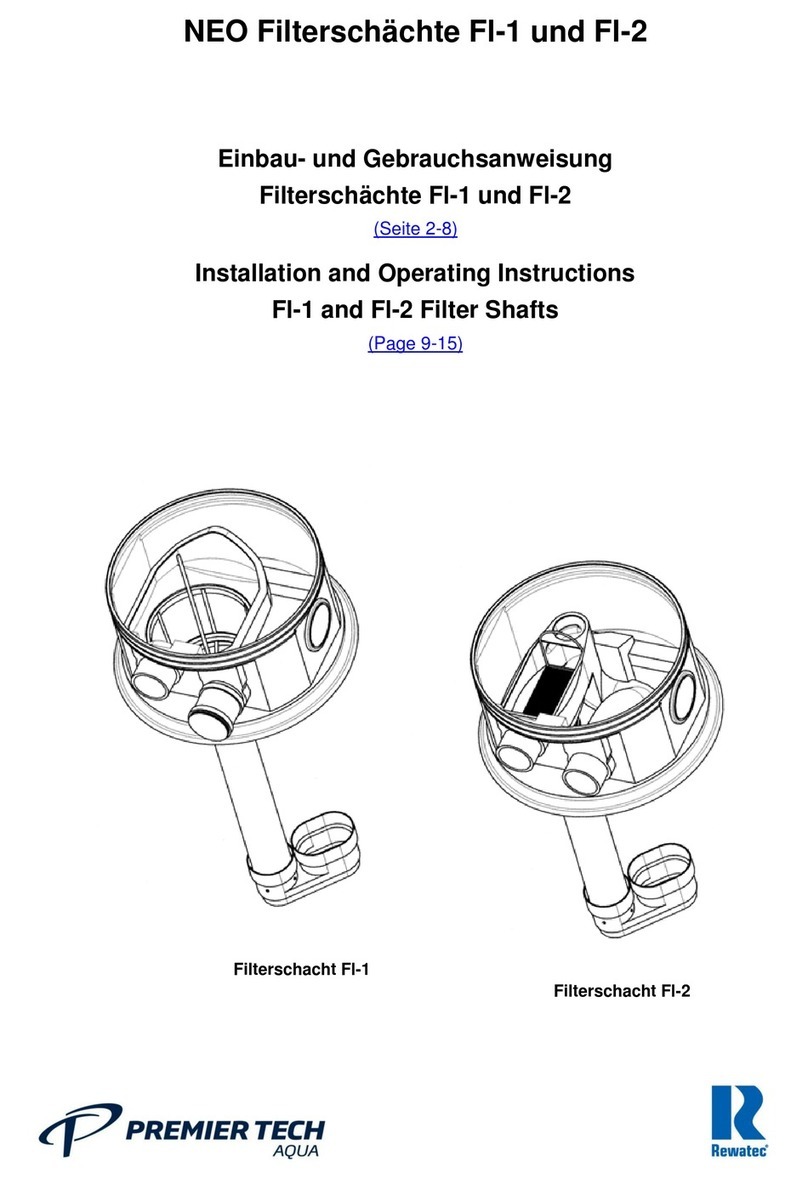

Premier Tech Aqua

Premier Tech Aqua Rewatec Fl-1 Installation and operating instructions

Lucent Technologies

Lucent Technologies AnyMedia PFU500 manual

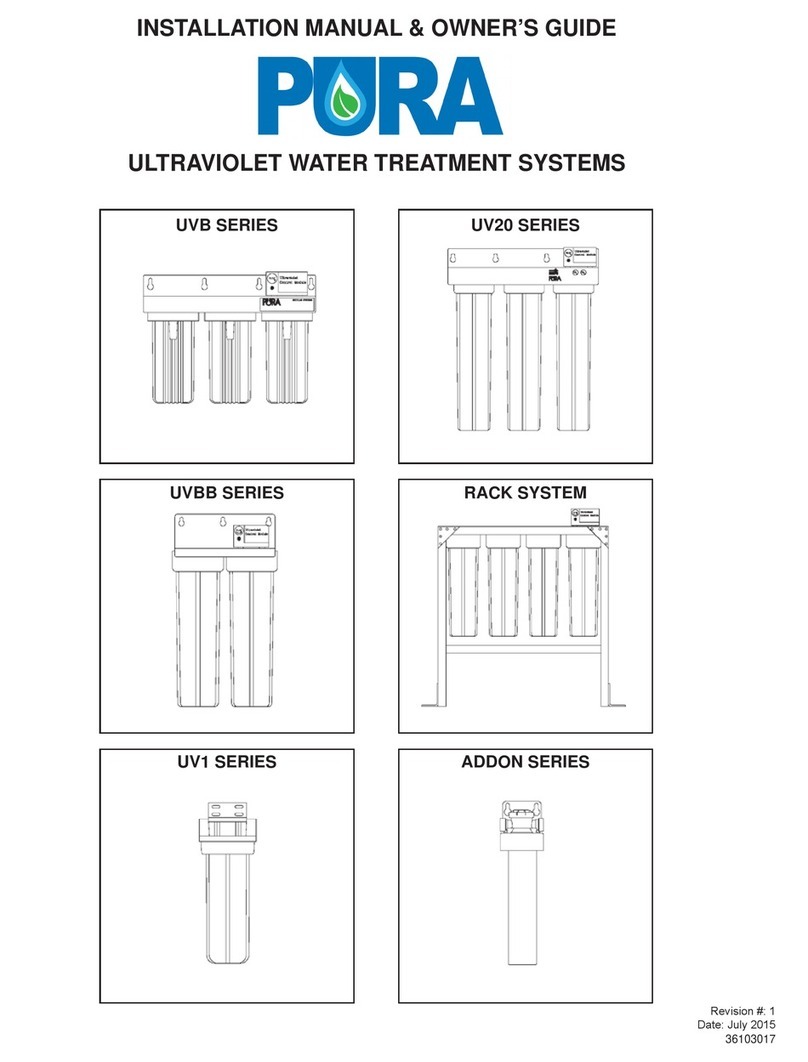

Pura

Pura UVB1 Installation manual & owner's guide

MARLO

MARLO MATD 9500 XT manual

Aries

Aries 931213 Installation and operation manual

WaterSoft

WaterSoft ISOBAR II Installation & operation manual

ASCENTO

ASCENTO PONDPRO F6000PP Operation manual

HYDAC International

HYDAC International RFLD Series Service and Parts