elysator PUROTAP compenso 2 User manual

Other elysator Water Filtration System manuals

elysator

elysator 50c User manual

elysator

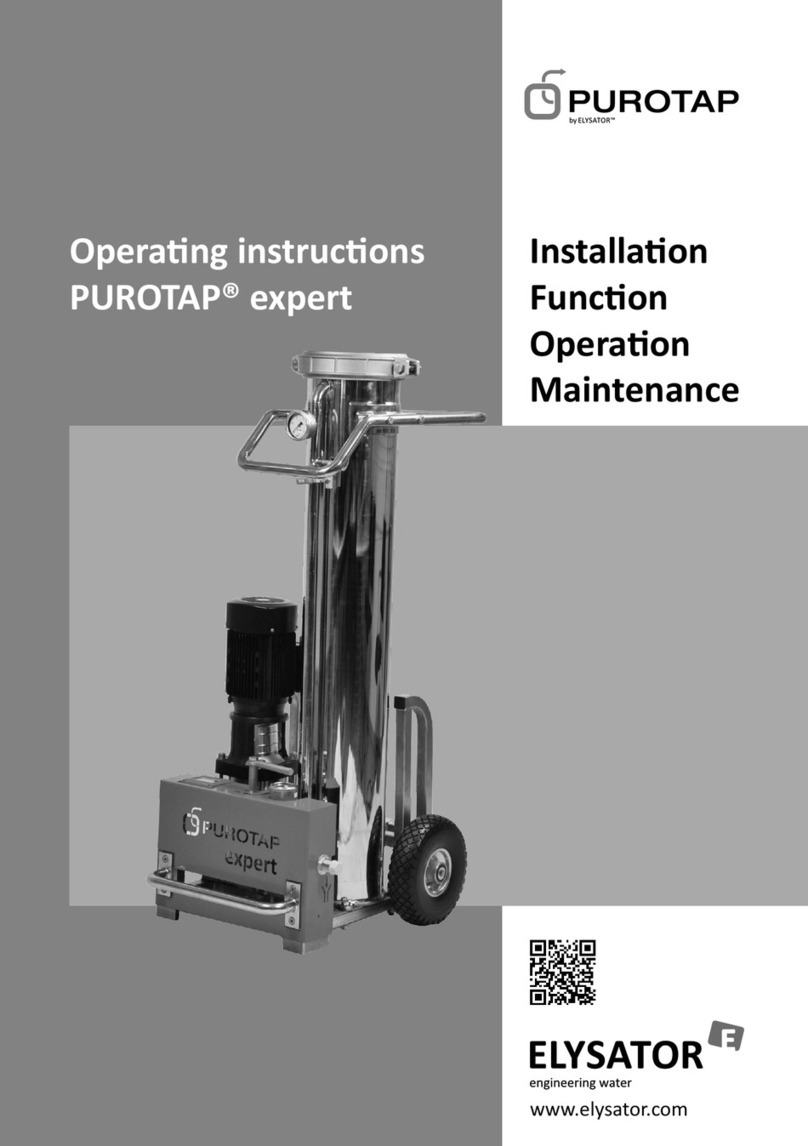

elysator PUROTAP expert Owner's manual

elysator

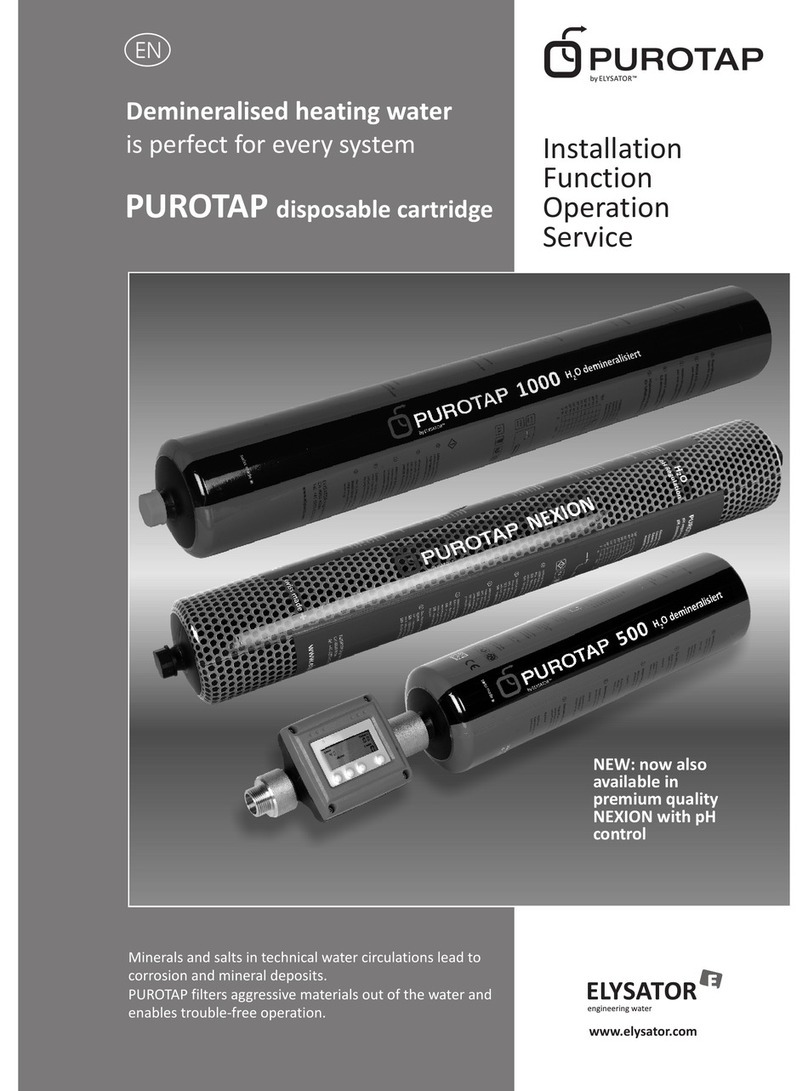

elysator PUROTAP 1000 Parts list manual

elysator

elysator PUROTAP expert Parts list manual

elysator

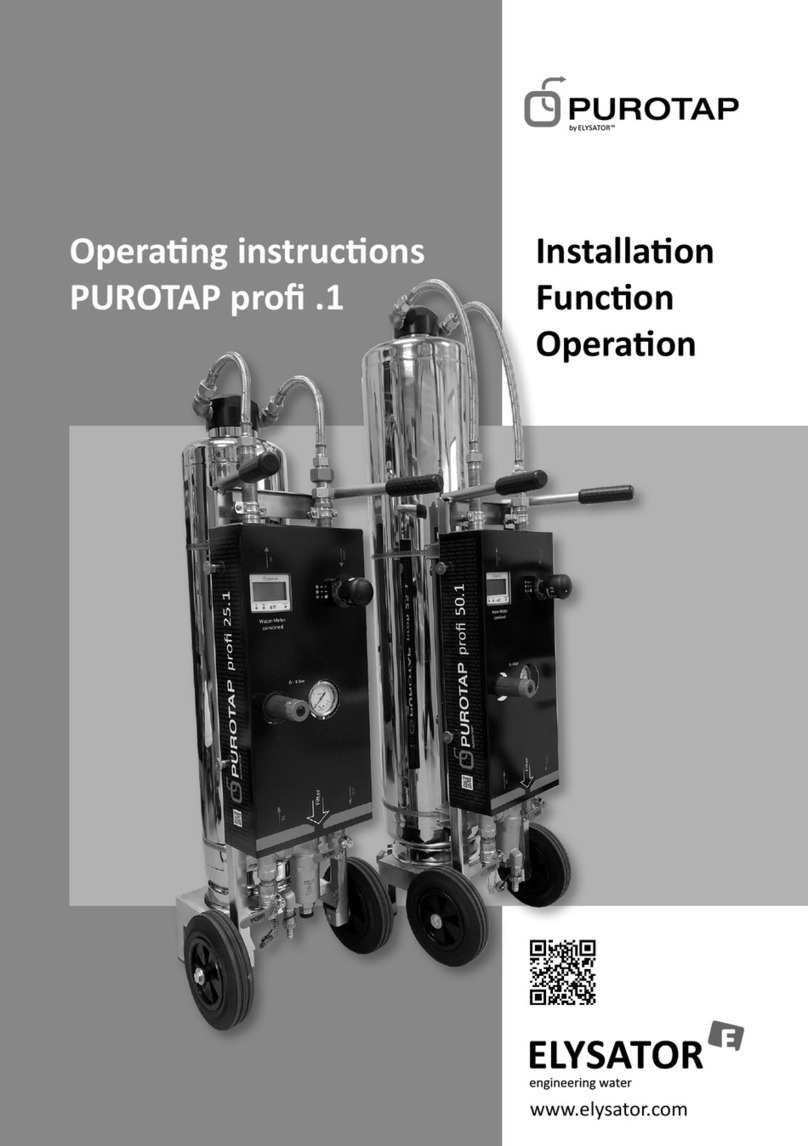

elysator PUROTAP profi 1 Series Parts list manual

elysator

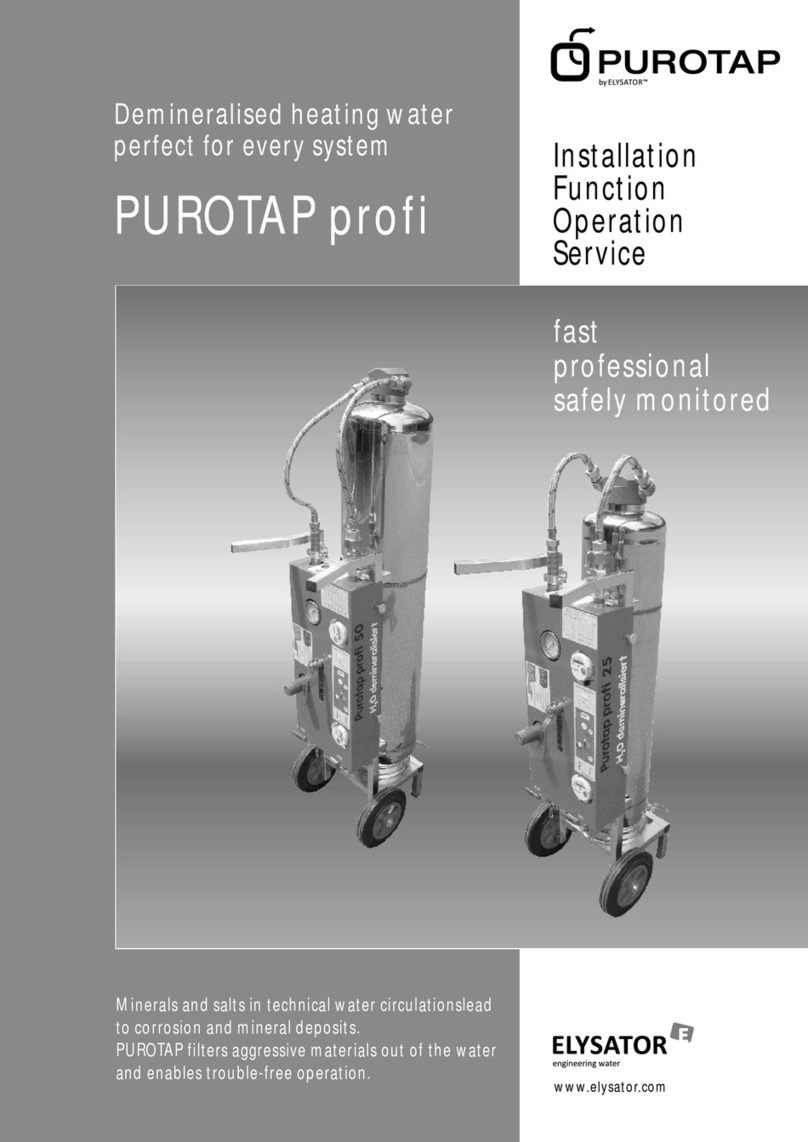

elysator PUROTAP profi Parts list manual

elysator

elysator PUROTAP profi 1 Series User manual

elysator

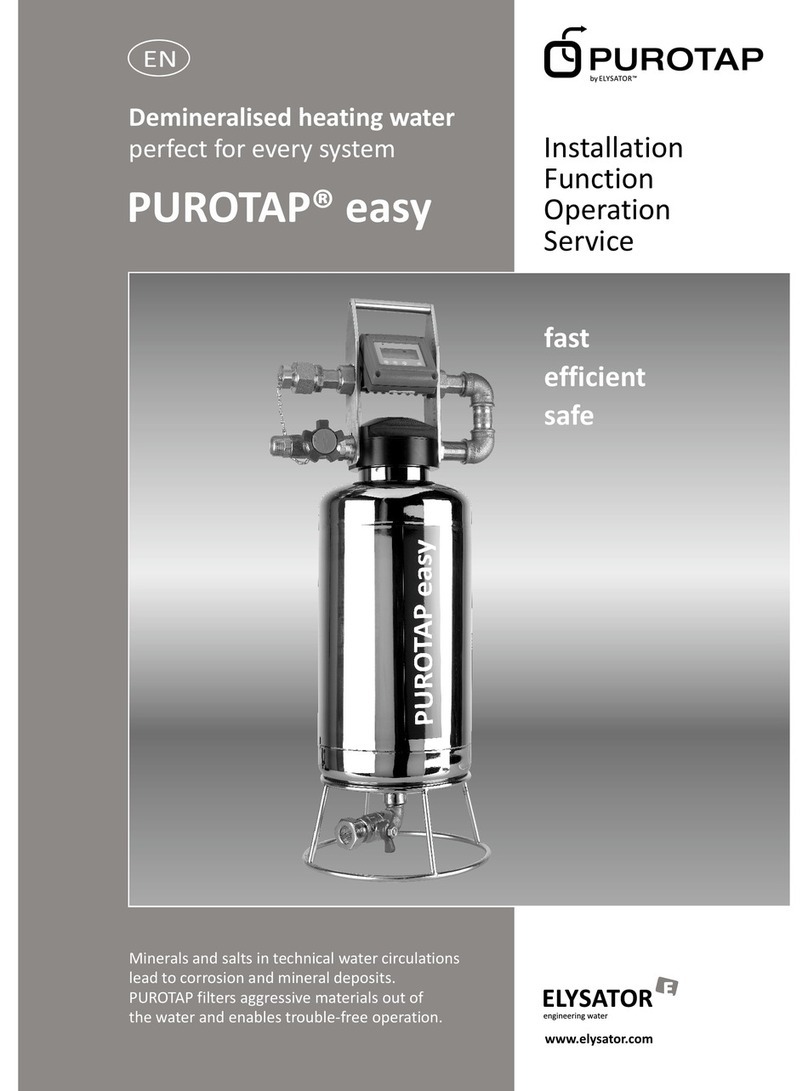

elysator PUROTAP easy II User manual

elysator

elysator PUROTAP easy Installation and user guide

elysator

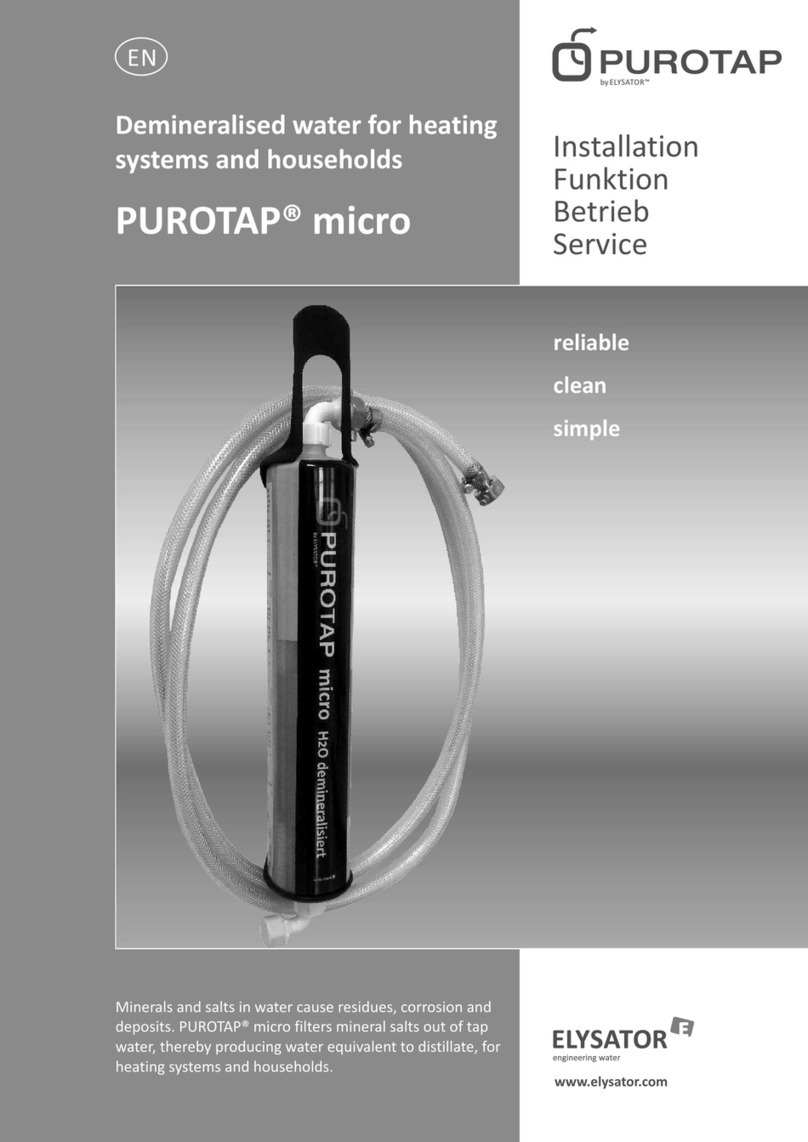

elysator PUROTAP micro User manual

Popular Water Filtration System manuals by other brands

Sony

Sony VF-30CPKXS operating instructions

Water Filter Tree

Water Filter Tree WLF-RO5 Installation and operation manual

Hommix

Hommix BMB-1000 Pro Nano Home installation guide

Watts

Watts PWRO4 Installation, operation and maintenance manual

Waterway

Waterway Clear Water II owner's manual

NTF

NTF OLFS Series instruction manual

Filtration Group

Filtration Group Facet HCS-222-1324 Installation operation & maintenance

Zip

Zip HydroTap G4 installation instructions

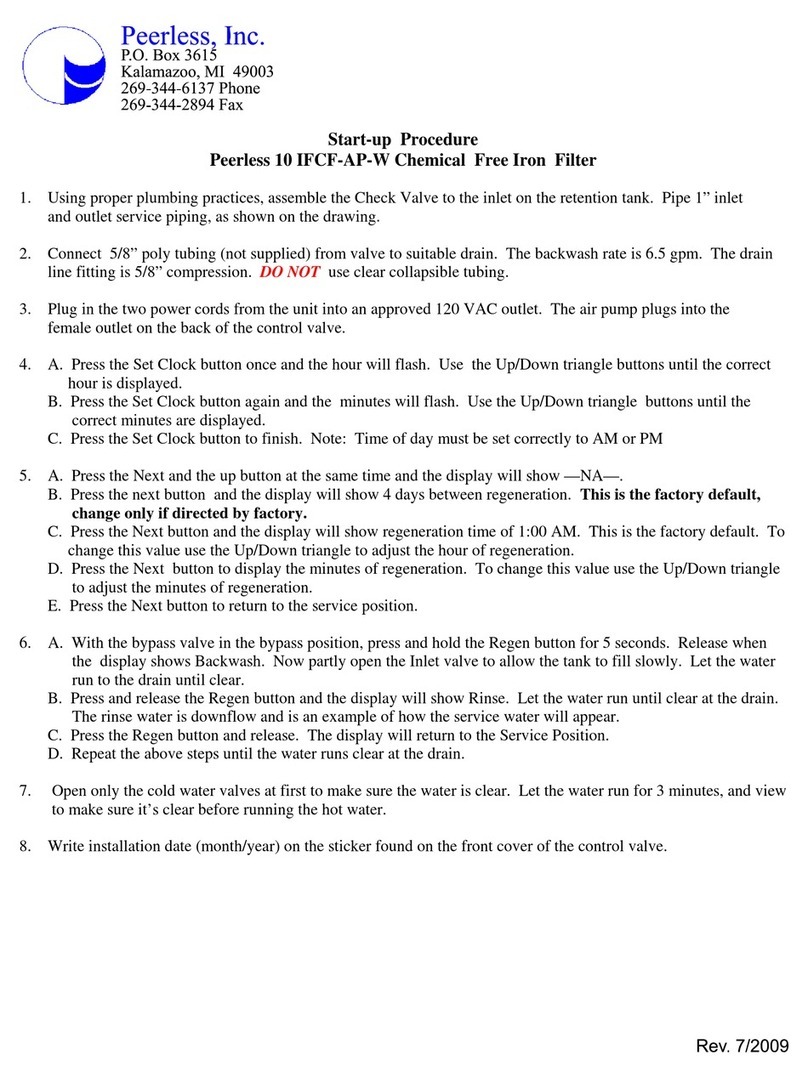

PEERLESS

PEERLESS 10 IFCF-AP-W Start-Up Procedures

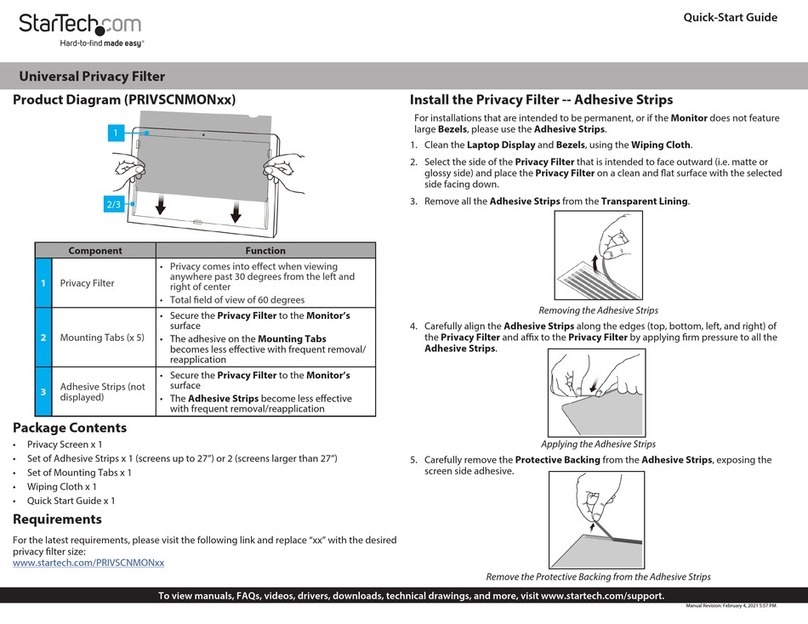

StarTech.com

StarTech.com PRIVSCNMON Series quick start guide

Aqua Comfort Technologies

Aqua Comfort Technologies Comfort-Chlor CC-350 owner's manual

Laica

Laica HYDROSMART METAL STOP quick start guide