Embedded Artists EA-QSB-010 User manual

LPC4357 Developer’s Kit - User’s Guide

Copyright 2013 © Embedded Artists AB

EA2-USG-1208 Rev A

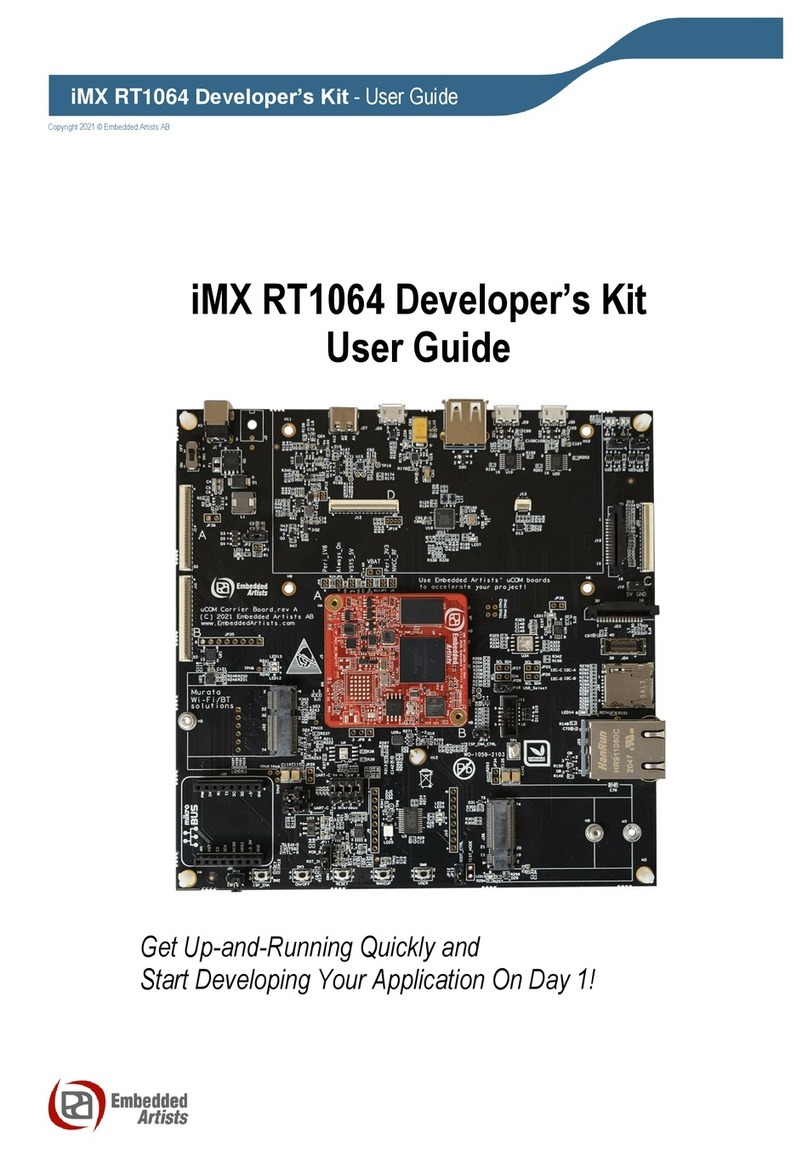

LPC4357 Developer’s Kit

User’s Guide

Get Up-and-Running Quickly and

Start Developing Your Application On Day 1!

LPC4357 Developer’s Kit - User’s Guide

Page 2

Copyright 2013 © Embedded Artists AB

Embedded Artists AB

Davidshallsgatan 16

211 45 Malmö

Sweden

info@EmbeddedArtists.com

http://www.EmbeddedArtists.com

Copyright 2013 © Embedded Artists AB. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or

translated into any language or computer language, in any form or by any means, electronic,

mechanical, magnetic, optical, chemical, manual or otherwise, without the prior written permission of

Embedded Artists AB.

Disclaimer

Embedded Artists AB makes no representation or warranties with respect to the contents hereof and

specifically disclaim any implied warranties or merchantability or fitness for any particular purpose.

Information in this publication is subject to change without notice and does not represent a

commitment on the part of Embedded Artists AB.

Feedback

We appreciate any feedback you may have for improvements on this document. Please send your

comments to support@EmbeddedArtists.com.

Trademarks

All brand and product names mentioned herein are trademarks, services marks, registered

trademarks, or registered service marks of their respective owners and should be treated as such.

LPC4357 Developer’s Kit - User’s Guide

Page 3

Copyright 2013 © Embedded Artists AB

Table of Contents

1Document Revision History 5

2Introduction 6

2.1 Features 6

2.2 ESD Precaution 7

2.2.1 ESD sensitivity on JTAG interface 8

2.3 General Handling Care 8

2.4 Code Read Protection 8

2.5 CE Assessment 8

2.6 Other Products from Embedded Artists 9

2.6.1 Design and Production Services 9

2.6.2 OEM / Education / QuickStart Boards and Kits 9

3LPC4357 OEM Board Design 10

3.1 Memory Layout 10

3.1.1 NAND Flash 10

3.2 SPIFI 11

3.3 Bootloader Mode Setting 11

3.4 Trace Connector 12

3.5 I2S and SGPIO Connectors 12

3.6 uSD Memory Card Interface 12

3.7 Board Options 13

3.8 1 kBit I2C E2PROM with EUI-48™ Number 13

4OEM Base Board Design 14

4.1 Modifications to OEM Base Board 14

4.2 SP2: OEM Board Connector 15

4.3 SP2: Current Measurements 15

4.4 SP3: Expansion Connectors 15

4.5 SP4: External Memory Bus 16

4.6 SP5: Debug Interfaces 17

4.7 SP6: Ethernet Interface 19

4.8 SP6: SD/MMC Memory Card Interface 20

4.9 SP6: VBAT/ALARM Handling 21

4.10 SP7: I2C Peripherals 22

4.11 SP8: Analog Input 23

4.12 SP8: Digital IO 24

4.13 SP8: Serial Expansion Connector 24

4.14 SP8: NXP/Jennic RF Module Interface 26

4.15 SP9: UART Multiplexing 27

4.16 SP9: RS232 Interface 28

LPC4357 Developer’s Kit - User’s Guide

Page 4

Copyright 2013 © Embedded Artists AB

4.17 SP9: RS422/485 Interface 29

4.18 SP10: CAN 30

4.19 SP10: IrDA 31

4.20 SP11: USB Channel 1 32

4.20.1 USB Channel 1 as USB Host 33

4.20.2 USB Channel 1 as USB Device 33

4.20.3 USB Channel 1 as USB OTG 33

4.21 SP12: USB Channel 2 34

4.21.1 USB Channel 2 (USB0 on LPC4357) as USB Host 35

4.21.2 USB Channel 2 (USB0 on LPC4357) as USB Device 35

4.21.3 USB Channel 2 (USB0 on LPC4357) as USB OTG 35

4.22 SP13: UART-to-USB Bridge 36

4.23 SP13: Power Supply 37

4.24 SP14: LCD Expansion Interface 37

4.25 SP15: I2S Audio Codec 38

4.26 Default Jumpers Positions 40

4.27 Usage of CPU Pins 41

5Getting Started 47

5.1 Powering 47

5.2 Demo Application 47

5.3 Installing USB Driver 49

5.4 Program Download 49

5.4.1 ISP over USB Program Download 50

5.5 Handling SO-DIMM Boards 54

5.6 Things to Note 54

5.6.1 Humming in Speaker 54

5.6.2 Current Consumption and Limits of USB Ports 55

5.6.3 LCD flickering 55

5.6.4 Initialization of External Memory Bus 56

5.6.5 USB OTG Transceiver 56

6LCD Expansion Connector 57

7Troubleshooting 60

7.1 No SWD/JTAG Connection 60

7.2 Powering 60

7.3 Contact with OEM Board MCU 61

7.4 Using Test Program to Verify Correct Operation 61

8Further Information 62

LPC4357 Developer’s Kit - User’s Guide

Page 5

Copyright 2013 © Embedded Artists AB

1 Document Revision History

Revision

Date

Description

PA1

2012-10-29

First version.

PA2

2012-12-08

Added information about ESD sensitive JTAG interface.

PA3

2013-01-21

Minor clarifications.

PA4

2013-04-08

Clarified that JP4 must be shorted (jumper installed) in order for the

LPC4357 SWD/JTAG interface to function.

LPC4357 Developer’s Kit - User’s Guide

Page 6

Copyright 2013 © Embedded Artists AB

2 Introduction

Thank you for buying Embedded Artists’ LPC4357 Developer’s Kit based on NXP’s ARM dual-core

Cortex-M4/M0 LPC4357 microcontroller.

This document is a User’s Guide that describes the LPC4357 OEM Board and the OEM Base Board

hardware design, which together form the LPC4357 Developer’s Kit.

2.1 Features

Embedded Artists’LPC4357 OEM Board lets you get up-and-running quickly. The small form factor

OEM board offers many unique features that ease your learning curve and program development. The

board has been designed for OEM applications with volume discount available.

NXP's ARM dual-core Cortex-M4/M0 LPC4357 microcontroller in BGA package, with 1 MByte

program FLASH and 136 KByte SRAM

16 MBit QSPI flash on SPIFI interface

External FLASH memories: 128 MB NAND FLASH

External data memory: 32 MB SDRAM (32-bit databus width)

12.0000 MHz crystal for maximum execution speed and standard serial bit rates, including

CAN and USB requirements

32.768kHz RTC crystal

100/10M Ethernet PHY/interface based on SMSC LAN8720

Buffered 32-bit data bus for external expansion

1 Kbit E2PROM with EUI-48™ number (for Ethernet MAC address)

200 pos expansion connector (SODIMM-200 format, 0.6mm pitch)

Most LPC4357 pins available (see LPC4357 OEM Board datasheet for details)

+3.3V only powering

Onboard reset generation

Compact SODIMM format: 68 x 50 mm

Eight layer PCB design for best EMC performance, with controlled impedance and length

matched routing for critical signals

There is an accompanying OEM Base Board that can be used for initial prototyping work. The features

of the board are:

Interfaces and Connectors

200 pos, 0.6mm pitch SODIMM connector for OEM Board

LCD expansion connector with control signals for touch screen interface

Expansion connector with all OEM Board signals

Ethernet connector (RJ45)

CAN interface & connector (provision for second CAN interface, but not mounted)

USB1: OTG or Host interface & connector

LPC4357 Developer’s Kit - User’s Guide

Page 7

Copyright 2013 © Embedded Artists AB

USB2: Device or Host interface & connector

Provision for NXP JN5148 RF module (former Jennic) interface (RF module not included)

Full modem RS232 (cannot be fully used on 32-bit databus OEM boards)

RS422/485 interface & connector

I2S audio codec (mic in, line in, line out, headphone out)

SWD/JTAG connector

Trace connector

Power

Power supply, either via USB or external +5V DC

Coin cell powering supported (CR1025 battery not incl.) for RTC and LED on ALARM sig.

Other

OEM Board current measuring

Parallel NOR flash on external memory bus

16-bit register and LEDs on external memory bus

5-key joystick

3-axis accelerometer (I2C connected)

LM75 temperature sensor (I2C connected)

5 push-button keys (four via I2C and one on P2.10)

9 LEDs (8 via I2C and one on P2.10)

Analog input

USB-to-serial bridge on UART #0 (FT232R) and ISP functionality

Reset push-button and LED

Speaker output on analog output from OEM Board, or from I2S audio codec

Compact size: 160x150 mm

2.2 ESD Precaution

Please note that the LPC4357 OEM Board and OEM Base Board come without

any case/box and all components are exposed for finger touches –and therefore

extra attention must be paid to ESD (electrostatic discharge) precaution.

Make it a habit always to first touch the metal surface of one of the USB or

Ethernet connectors for a few seconds with both hands before touching

any other parts of the boards. That way, you will have the same potential as

the board and therefore minimize the risk for ESD.

Never touch directly on the LPC4357 OEM Board and in general as little as possible on the OEM Base

Board. The push-buttons on the OEM Base Board have grounded shields to minimize the effect of

ESD.

Note that Embedded Artists does not replace boards that have been damaged by ESD.

LPC4357 Developer’s Kit - User’s Guide

Page 8

Copyright 2013 © Embedded Artists AB

2.2.1 ESD sensitivity on JTAG interface

Note that the LPC4357 MCU is sensitive to ESD on the JTAG port. Observe extra care around this.

Make sure the ground of the JTAG interface is connected to the OEM Base Board ground

before even connecting the JTAG interface. Never have the OEM Board unpowered while the

JTAG pod is powered.

2.3 General Handling Care

Handle the LPC4357 OEM Board and OEM Base Board with care. The boards are not mounted in a

protective case/box and are not designed for rough physical handling. Connectors can wear out after

excessive use. The OEM Base Board is designed for prototyping use, and not for integration into an

end-product.

For boards with LCD, do not exercise excessive pressure on the LCD glass area. That will damage the

display. Also, do not apply pressure on the flex cables connecting the LCD/touch screen. These are

relatively sensitive and can be damaged if too much pressure is applied to them.

Note that Embedded Artists does not replace boards where the LCD has been improperly

handled.

2.4 Code Read Protection

The LPC4357 has a Code Read Protection function (specifically CRP3, see datasheet for details) that,

if enabled, will make the LPC4357 impossible to reprogram (unless the user program has implemented

such functionality).

Note that Embedded Artists does not replace LPC4357 OEM boards where the LPC4357 has

CRP3 enabled. It’s the user’s responsibility to not invoke this mode by accident.

2.5 CE Assessment

The LPC4357 Developers Kit (consisting of the LPC4357 OEM Board and OEM Base Board) is CE

marked. See separate CE Declaration of Conformity document.

The LPC4357 Developers Kit is a class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate measures.

EMC emission test has been performed on the LPC4357 Developers Kit. Standard interfaces like

Ethernet, USB, serial have been in use. General expansion connectors where internal signals are

made available (for example processor pins) have been left unconnected. Connecting other devices to

the product via the general expansion connectors may alter EMC emission. It is the user’s

responsibility to make sure EMC emission limits are not exceeded when connecting other devices to

the general expansion connectors of the LPC4357 Developers Kit.

Due to the nature of the LPC4357 Developers Kit –an evaluation board not for integration into an end-

product –fast transient immunity tests and conducted radio-frequency immunity tests have not been

executed. Externally connected cables are assumed to be less than 3 meters. The general expansion

connectors where internal signals are made available do not have any other ESD protection than from

the chip themselves. Observe ESD precaution.

Note that the LPC4357 OEM board is classified as a component and is hence not CE marked

separately. It can perform different functions in different integrations and it does not have a direct

function. It is therefore not in the scope of the CE Directive. An end product, where an OEM Board is

integration into, is however very likely to need CE marking.

LPC4357 Developer’s Kit - User’s Guide

Page 9

Copyright 2013 © Embedded Artists AB

2.6 Other Products from Embedded Artists

Embedded Artists have a broad range of LPC1000/2000/3000/4000 based boards that are very low

cost and developed for prototyping / development as well as for OEM applications. Modifications for

OEM applications can be done easily, even for modest production volumes. Contact Embedded Artists

for further information about design and production services.

2.6.1 Design and Production Services

Embedded Artists provide design services for custom designs, either completely new or modification to

existing boards. Specific peripherals and I/O can be added easily to different designs, for example,

communication interfaces, specific analog or digital I/O, and power supplies. Embedded Artists has a

broad, and long, experience in designing industrial electronics in general and with NXP’s

LPC1000/2000/3000/4000 microcontroller families in specific. Our competence also includes wireless

and wired communication for embedded systems. For example IEEE802.11b/g (WLAN), Bluetooth™,

ZigBee™, ISM RF, Ethernet, CAN, RS485, and Fieldbuses.

2.6.2 OEM / Education / QuickStart Boards and Kits

Visit Embedded Artists’ home page, www.EmbeddedArtists.com, for information about other OEM /

Education / QuickStart boards / kits or contact your local distributor.

LPC4357 Developer’s Kit - User’s Guide

Page 10

Copyright 2013 © Embedded Artists AB

3 LPC4357 OEM Board Design

Please read the LPC4357 OEM Board datasheet and associated schematic for information about the

board. Some additional information about the LPC4357 OEM Board is presented below.

3.1 Memory Layout

The external memory controller on the LPC4357 defines eight memory regions. See table below for

details about usage.

Name

Control

signal

Address range

Memories on LPC4357

OEM Board

External memory bus

comment

Static memory #0

CS0

0x1C00 0000 –

0x1CFF FFFF

Available for external

use.

OEM Base Board can

connect a parallel NOR

flash to this chip select.

Static memory #1

CS1

0x1D00 0000 –

0x1DFF FFFF

NAND FLASH (1 GBit =

128 MByte in size)

Not available for

external use.

It is however possible

to disable NAND flash

chip by removing R25

on LPC4357 OEM

Board.

Static memory #2

CS2

0x1E00 0000 –

0x1EFF FFFF

Available for external

use.

OEM Base Board can

connect a 16-bit parallel

register to this chip

select.

Static memory #3

CS3

0x1F00 0000 –

0x1FFF FFFF

Available for external

use.

Dynamic memory #0

DYCS0

0x2800 0000 –

0x2FFF FFFF

SDRAM (256 MBit = 32

MByte in size)

Cannot be accessed on

external memory bus.

Dynamic memory #1

DYCS1

0x3000 0000 –

0x3FFFF FFFF

Cannot be accessed on

external memory bus.

As seen in the table above, it is only the static memory regions that are available on the external

memory bus from the LPC4357 OEM Board. The data bus buffers on the LPC4357 OEM Board are

controlled automatically and only enabled when a static memory region is accessed. The address and

control bus buffers are always enabled.

Note that the BLS0, BLS1, BLS2 and BLS3 pins must be initialize for these functionalities. Else the

buffer control will not work correctly.

3.1.1 NAND Flash

Note that the NAND flash is connected after the memory bus buffers, i.e., on the same side as the

LPC4357 OEM Board expansion signals. This is to allow flexibility in NAND flash usage and reduce

loading on memory bus that is directly connected to the SDRAM.

LPC4357 Developer’s Kit - User’s Guide

Page 11

Copyright 2013 © Embedded Artists AB

The NAND FLASH has an optional busy output that can be used for controlling the erase/program

operations with better precision. The signal is available on the expansion connector. If needed, the

signal can be routed to a suitable (i.e., free) input pin. The OEM Base Board can connect the signal to

GPIO72 by inserting a jumper between pin 3-4 on JP2. The busy status of the chip is also available

under software control.

3.2 SPIFI

There is a 16 MBit QSPI flash connected to the SPIFI interface of the LPC4357. This memory region is

available in the following address region: 0x1400 0000 –0x1800 0000.

3.3 Bootloader Mode Setting

There are several boot modes for the LPC4357 microcontroller. For details, read the LPC4357 User’s

manual. The LPC4357 OEM board has four sliders switches, JP1, where the boot mode can bet set.

Note that there are situations where the slider switch settings do not affect boot more. Read the

LPC4357 User’s manual for details about this, but in general the slider settings will be used to

determine the boot mode when P2_7 is pulled low during reset. This is accomplished by pulling pin

ISP_EN low, which in turn is accomplished by pressing SW6 on the OEM base board during reset. If

signal P2_7 is high during reset the LPC4357 boos from internal FLASH by default.

Schematic page 2 of the LPC4357 OEM board contains a list of the boot modes and associated slider

settings for JP1.

LED3 on the LPC4357 OEM board is connected to signal P1_1-A6-BS0, and is used by the

microcontroller to signal possible errors during booting. LED3 will flash with a 1 Hz rate for 60 seconds

if the boot process fails. After 60 seconds, the device is reset.

Slider switch JP1 is found on the top side of the LPC4357 OEM board, in the upper left corner.

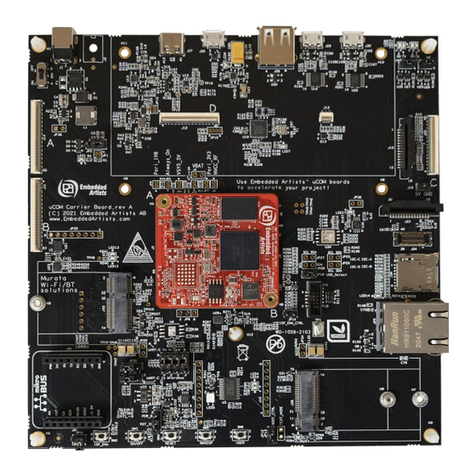

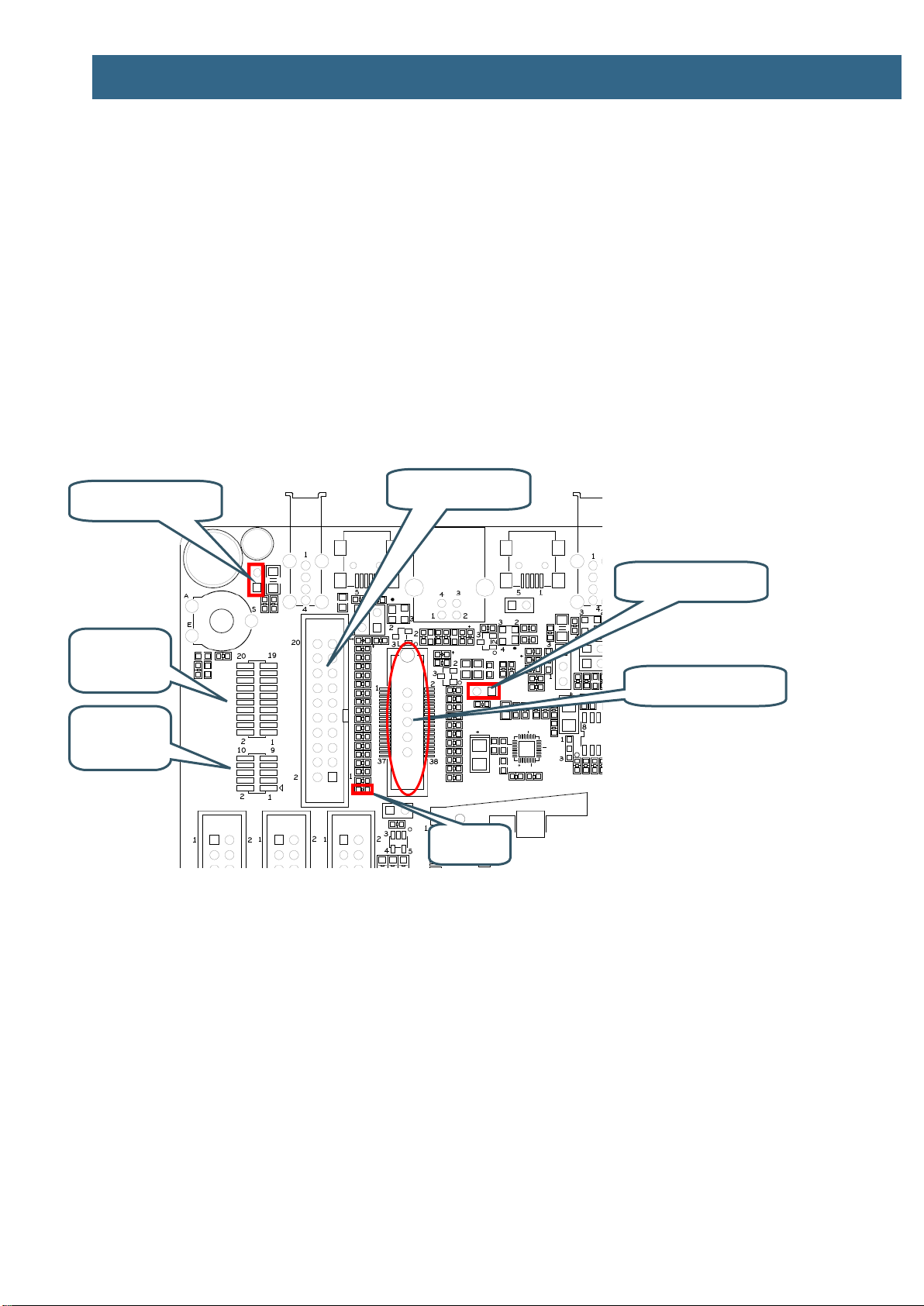

Figure 1 –LPC4357 OEM Board Picture, top side

J1

Trace connector

(Connector normally mounted)

JP1

From top to bottom;

BS0 setting

BS1 setting

BS2 setting

BS3 setting

0=’on’ pos, to the right

1=’off’ pos, to the left

J4 and J5

I2S, SGPIO and SCT expansion connectors

LED2

Memory card

interface powered

LPC4357 Developer’s Kit - User’s Guide

Page 12

Copyright 2013 © Embedded Artists AB

3.4 Trace Connector

There is a connector on the top side of the LPC4357 OEM board, carrying all signals needed for

debugging with trace. It is a standard 20 pos (50 mil pitch) trace connector as defined by ARM. Figure

1 illustrates where J1 is located on the board.

There is a trace connector on the OEM Base Board also, but this shall not be used for trace on the

LPC4357. It was not possible to get compatible pinning with other OEM boards. Instead J1 was added

to the design to support trace. Debugging without trace can be done either via J1 (on the LPC4357

OEM board) or the 10 pos debug connector (J7) on the OEM Base Board.

3.5 I2S and SGPIO Connectors

There are two 20-pos, 50 mil pitch connectors on the top side of the LPC4357 OEM board. See Figure

1 for location. These connectors carry selected I2S, I2C, SGPIO and SCT signals and can be used to

connect these signals to a separate expansion boards. For example an audio and video expansion

board. Note that some of the signals can be used on the OEM base board. Before using the signals,

always check for possible contentions.

3.6 uSD Memory Card Interface

There is a uSD/transflash memory card interface connector, J2, on the bottom side of the board. See

Figure 2 . LED2, on the top side, lights when the interface is powered. See Figure 1to locate LED2.

The signals on the SODIMM edge connector that are normally allocated for memory card interface (on

other OEM boards) carry other signals on the LPC4357 OEM board that have no relation to the

memory card interface.

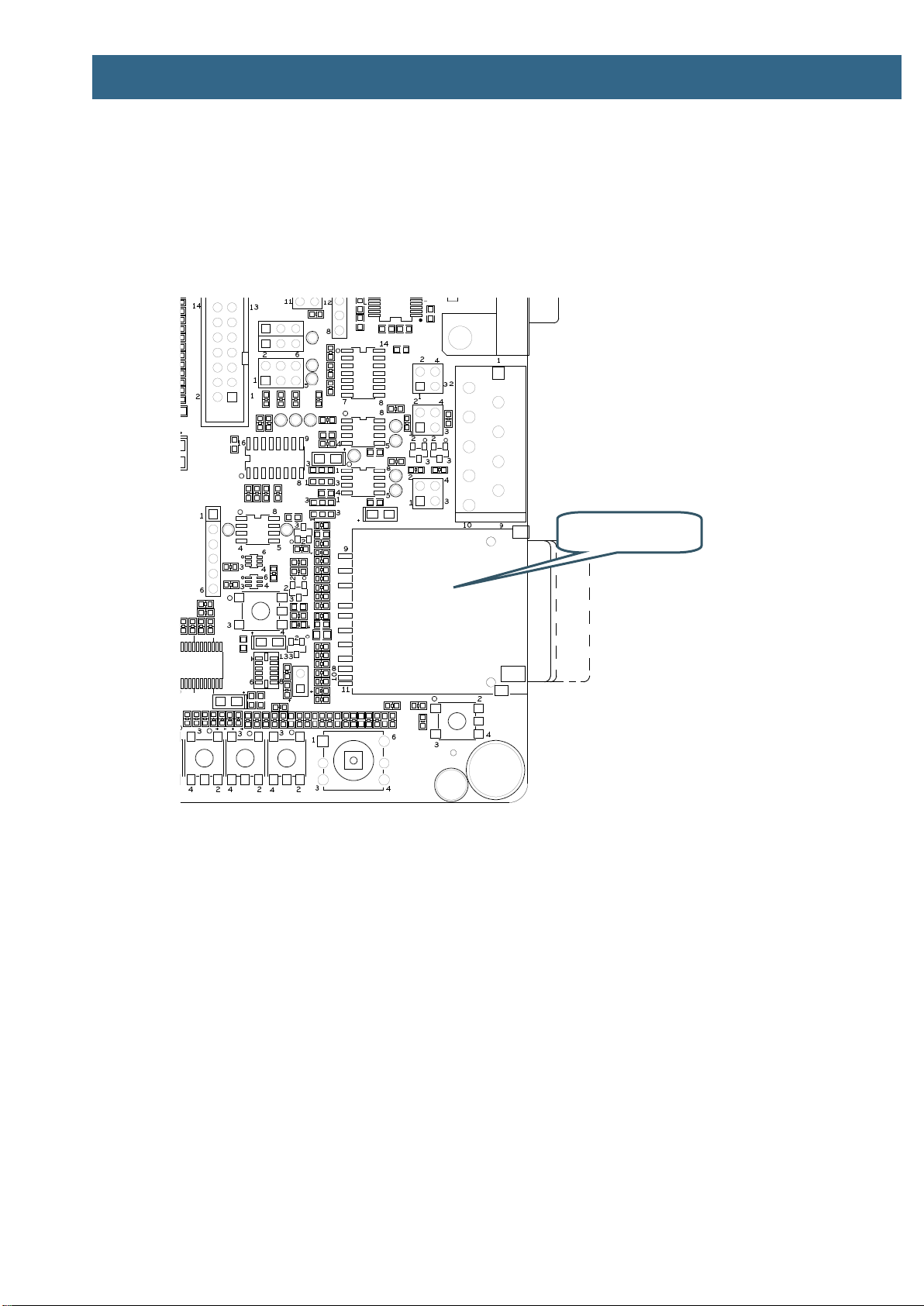

Figure 2 –LPC4357 OEM Board Picture, bottom side

J2

uSD/transflash connector

LPC4357 Developer’s Kit - User’s Guide

Page 13

Copyright 2013 © Embedded Artists AB

3.7 Board Options

The schematic for the LPC4357 OEM Board show some different mounting options, mainly via SJx

jumpers but also some resistors that are not mounted per default. The design has been prepared for

customized versions for different needs.

3.8 1 kBit I2C E2PROM with EUI-48™ Number

The LPC4357 OEM Board contains a small E2PROM, 24AA02E48 from Microchip that can be

accessed via I2C. The chip contains a globally unique 48-bit number (EUI-48™) that can be used as

Ethernet MAC address. See the 24AA02E48 datasheet for details.

LPC4357 Developer’s Kit - User’s Guide

Page 14

Copyright 2013 © Embedded Artists AB

4 OEM Base Board Design

This chapter contains information about the peripherals and general design of the OEM Base Board

and how to set the different jumpers on the board. The schematic can be downloaded in pdf format

from the support page, and is recommended to have printed out while reading this chapter.

Section naming begins with SPx, which is short for Schematic Page x.

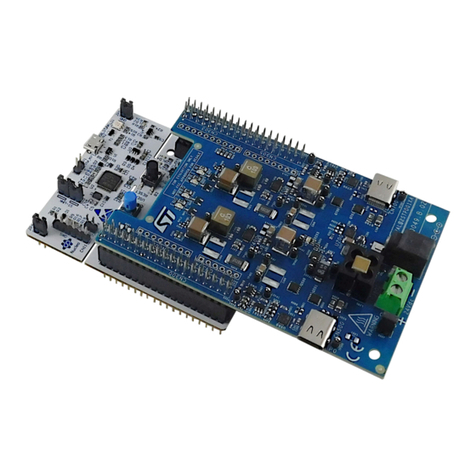

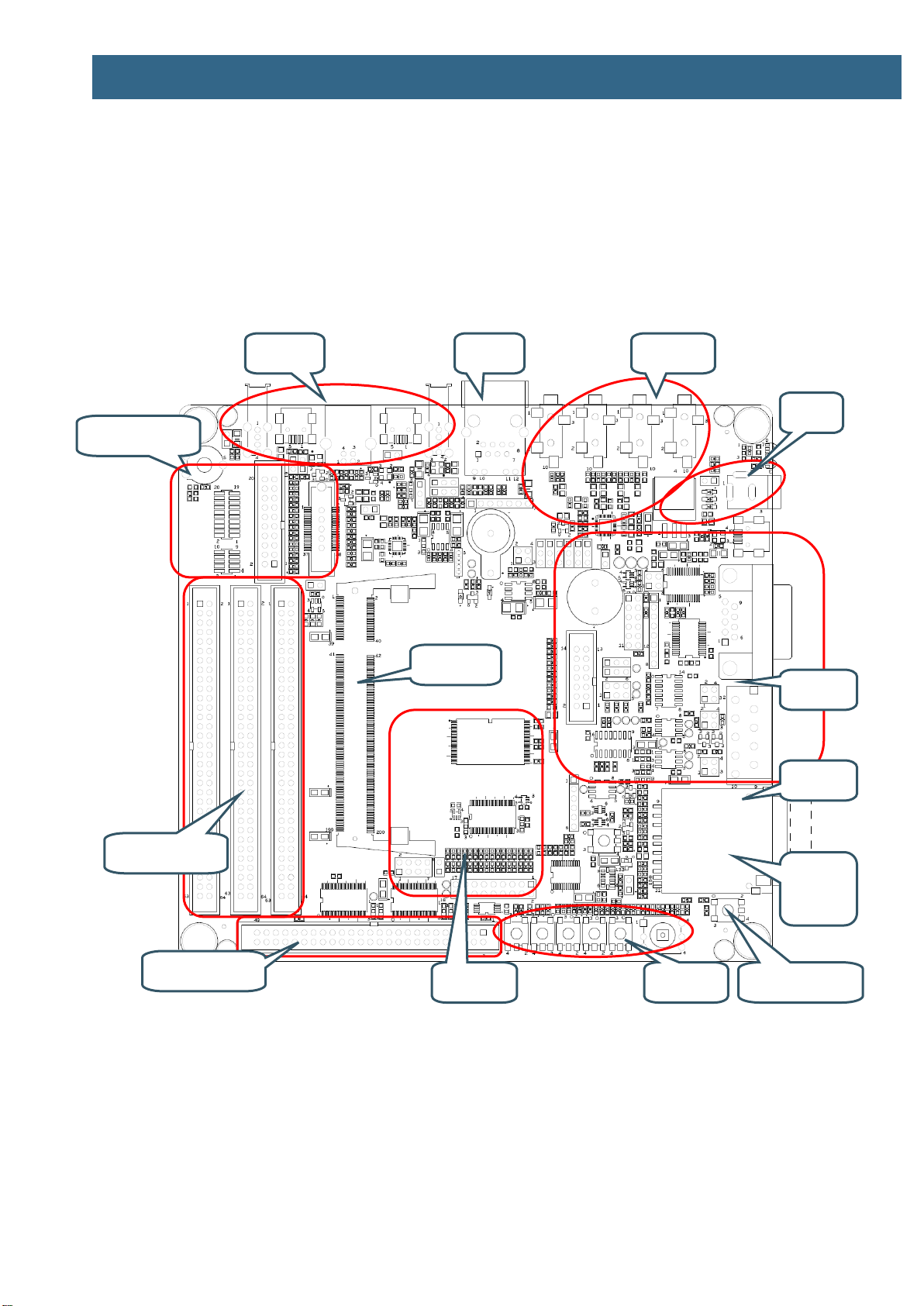

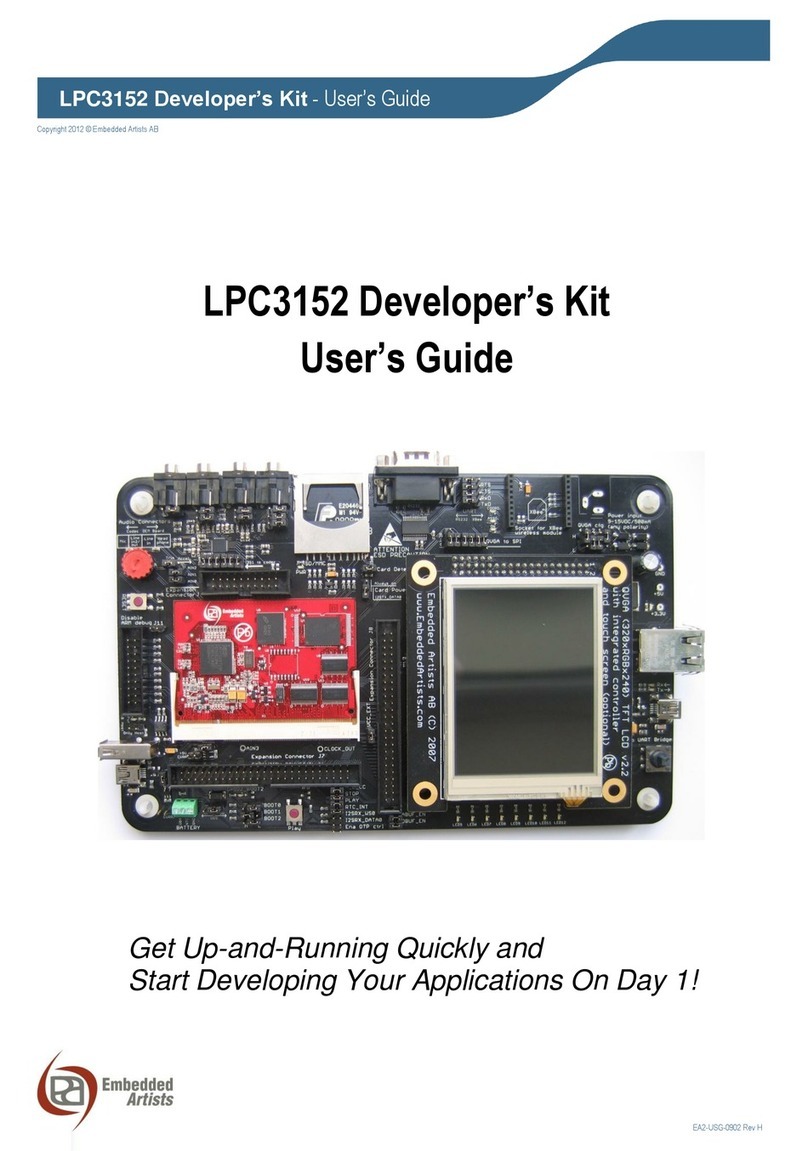

The picture below gives an overview of the OEM Base Board design.

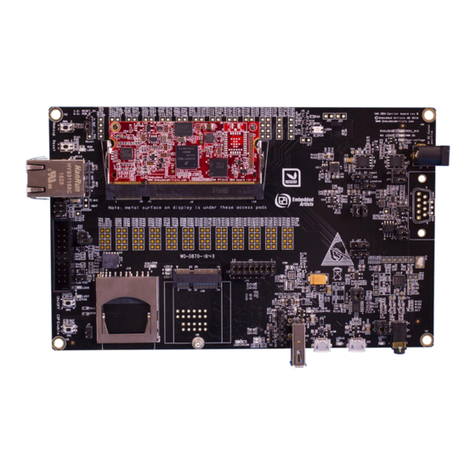

Figure 3 –OEM Base Board Overview

4.1 Modifications to OEM Base Board

The OEM Base Board has been designed to be flexible. Most options can be controlled via jumpers

but some options might need soldering. Note that modifications to the board are done at own risk and

void all warranties.

Debug Connectors

Expansion

Connectors

LCD Expansion

Connector

OEM Board

Connector

Serial

Interfaces

Audio

Interfaces

USB

Interfaces

Ethernet

Interface

Power

Supply

SD/MMC

connector

Pushbuttons

and LEDs

Memory Bus

Expansion

RF module

interface

on solder

side

Reset Push-button

SW1

LPC4357 Developer’s Kit - User’s Guide

Page 15

Copyright 2013 © Embedded Artists AB

4.2 SP2: OEM Board Connector

The LPC4357 OEM board connector is a standard DDR2 SO-DIMM socket with 200 positions and

0.6mm pitch. It has 1.8V keying (which is what DDR2 stands for). The JEDEC standard defining the

DDR2 SODIMM boards is called JEDEC MO-224.

The signal names are general and represent the OEM base board functionality, rather than the

LPC4357 signal names. This is because the OEM base board also supports other OEM boards.

4.3 SP2: Current Measurements

It is possible to accurately measure current consumption of the LPC4357 OEM board. This can be very

valuable when working with applications that make use of the low power modes of the LPC4357

processors. The circuit is based on the chip ZXCT1010 from Diodes/Zetex. This chip generates a

voltage output proportional to the current through R2. This voltage can be measured over J2. 100mA

gives a 500mV output voltage, or expressed differently, 1mV correspond to 0.2mA

It is possible to remove R1, R2 and/or R3 for measuring current with an external multimeter. Note that

VCC_MAIN and VCC_BUFFERS are connected on the LPC4357 OEM board so there is no difference

between these supplies. This division has been done for compatibility with other OEM boards.

Figure 4 –Current Measurement J2

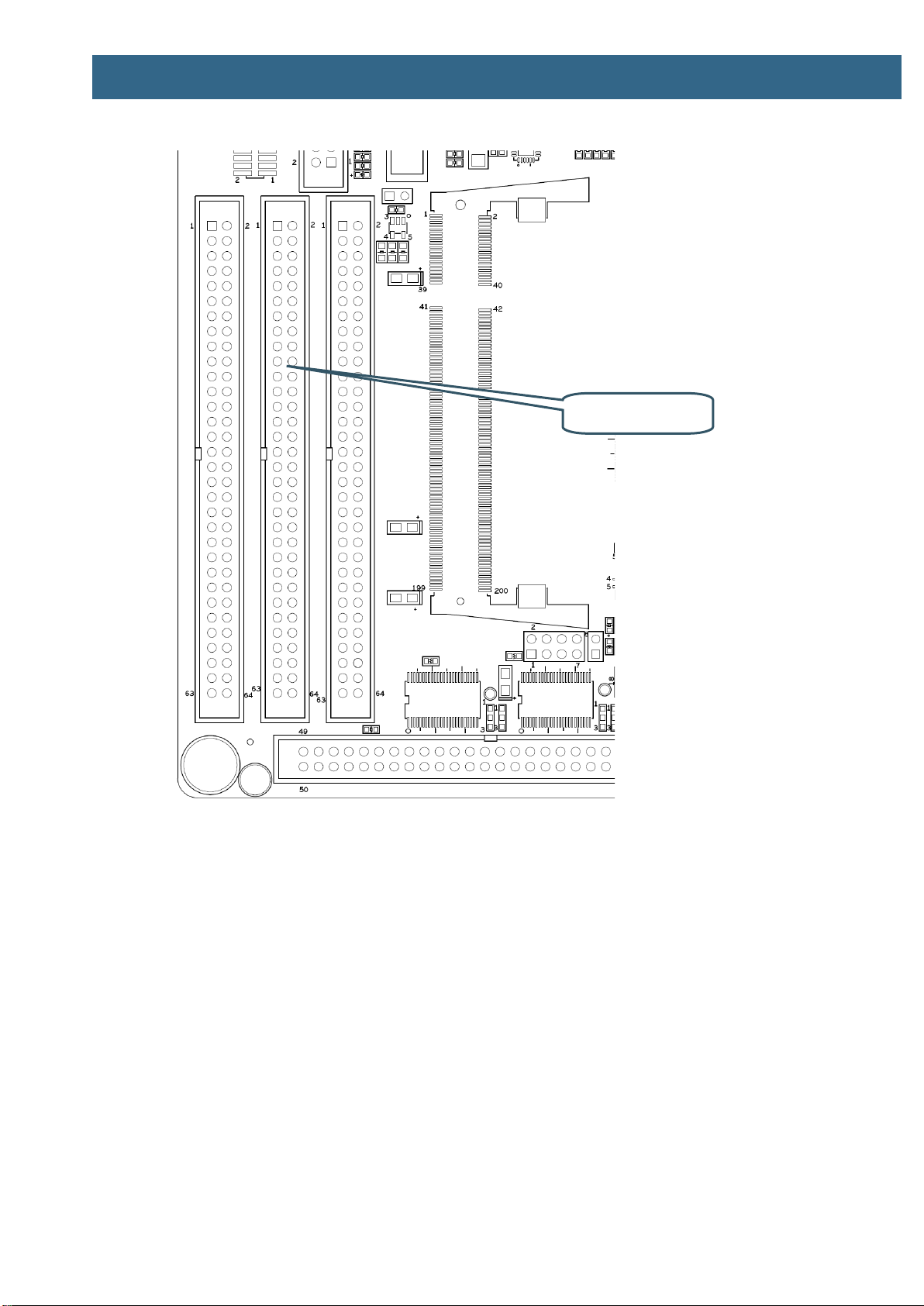

4.4 SP3: Expansion Connectors

All relevant OEM board signals are available for external use via three 64 pos IDC expansion

connectors; J3, J4 and J5. The expansion connectors are close to the SO-DIMM connectors to

minimize signal distortion.

Note that some OEM board circuits may need to be disconnected before externally used. Carefully

investigate the need for this before using a signal for external expansion.

Note that J4 has gathered all needed signals for expanding the memory bus (16-bit bus expansion). J4

is the expansion connector closest to the board edge. For 32-bit memory bus expansion, J3 is also

needed (for the upper 16 bits of the databus).

Current Measurement

J2 (left: signal, right: gnd)

LPC4357 Developer’s Kit - User’s Guide

Page 16

Copyright 2013 © Embedded Artists AB

Figure 5 –Expansion Connectors J3, J4, J5

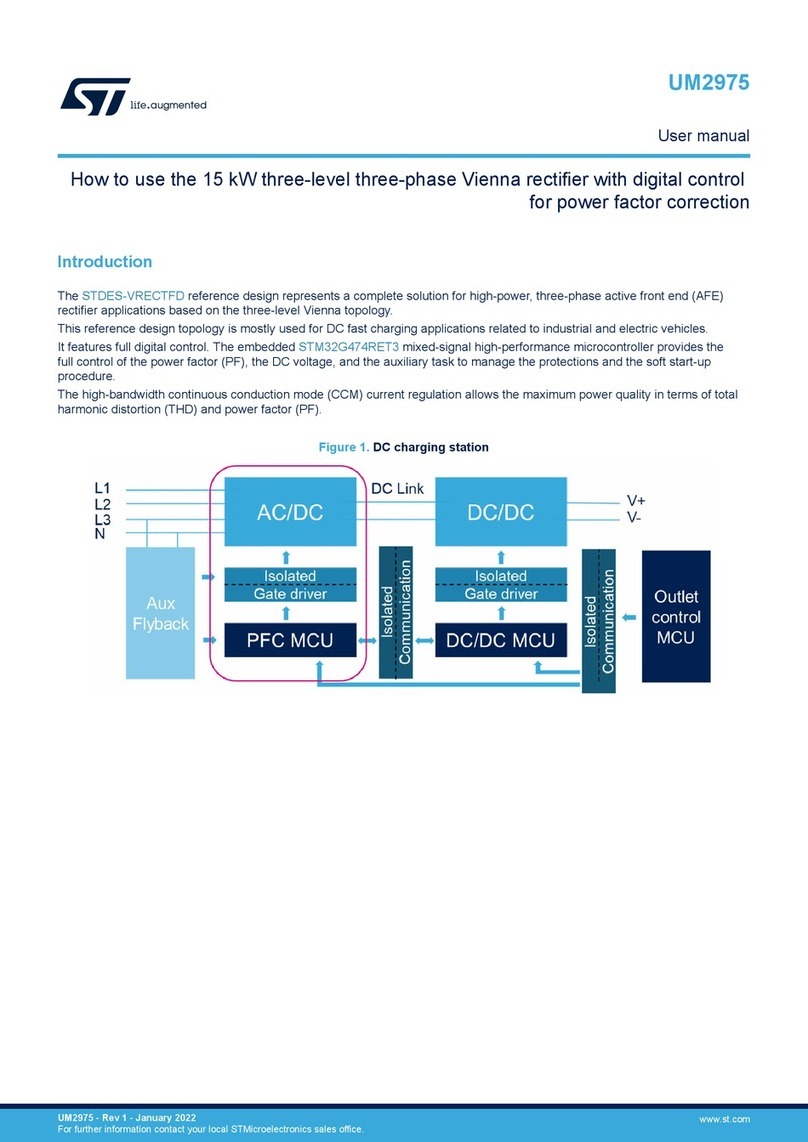

4.5 SP4: External Memory Bus

This part of the OEM Base Board demonstrates how the external memory bus can be used for

expansion of custom circuits. Two different devices are connected to the memory bus; a 16-bit parallel

NOR flash and a 16-bit register.

In order to be universal between 16- and 32-bit databus width OEM Boards, only the lower 16 bits are

connected.

The 16-bit parallel NOR flash is enabled when JP1 is inserted, see picture below for guidance where to

find JP1 on the OEM Base Board. Note that the signal name is cryptic since the OEM Base Board is

compatible with many different OEM Board. For the LPC4357 OEM Board, the signal BCSY is actually

signal BCS0. This means that the NOR flash is accessible in memory region: 0x1C00 0000 - 0x1CFF

FFFF.

Also, a 16-bit register is connected to the external memory bus. The 16 bits in the register directly

drives 16 LEDs (a high signal light a LED). The signals are also available on an expansion connector

(J6). It can for example connect to a logic analyzer, for high-bandwidth logging. The upper and lower 8

bits are individually writeable. Signals BBLS0/BBLS1 controls the lower and upper 8 bits, respectively.

Since the OEM Base Board is universal and supports many different OEM Boards, the chip select

signal is either signal BCSX or GPIO69. For the LPC4357 OEM Board, the signal BCSX is actually

Expansion Connectors

left to right: J4, J3, J5

LPC4357 Developer’s Kit - User’s Guide

Page 17

Copyright 2013 © Embedded Artists AB

signal BCS2. This means that the register is accessible in memory region: 0x1E00 0000 - 0x1EFF

FFFF. No jumper in JP2 is needed when working with the LPC4357 OEM Board.

SJ12 shall be in default position (pad 1-2 shorted) to let BCS2 control chip select of the 16-bit register.

SJ1 controls the output enable of the register. By default it is grounded (pad 1-2 is shorted) and hence

the register drives the LEDs and expansion connector, J6.

Figure 6 –External Memory Bus Circuit

4.6 SP5: Debug Interfaces

Note that the LPC4357 MCU is sensitive to ESD on the JTAG port. Observe extra care around this.

Make sure the ground of the JTAG interface is connected to the OEM Base Board ground

before even connecting the JTAG interface. Never have the OEM Board unpowered while the

JTAG pod is powered.

The multiple debug interfaces can look complex, but that is just because the board supports many

different OEM Boards. The connectors are:

J7 –this is the new and smaller footprint standard ARM debug connector. It has 2x5 pins in

50 mil pitch. The connector supports both the SWD and JTAG interfaces. Note that not all,

and in particular older, JTAG debug probes do not support the SWD interface standard.

Note where pin 1 is found (see picture below) for this connector.

J8 –this is the old and big footprint standard ARM debug connector. It has 2x10 pins in 100

mil pitch. The connector supports both the SWD and JTAG interfaces. Note that not all, and in

particular older, JTAG debug probes do not support the SWD interface.

J9 –this is the old and big footprint 38 pin Mictor connector for ETM trace for the LPC2478.

This connector is not mounted. It is not used when working with the LPC4357 OEM board.

The connector can be soldered to the board if needed. The connector can be bought from

16-bit register

U2

Parallel NOR FLASH

U3

JP2 and JP1

left: JP2

right: JP1

LEDs

left to right: LED16 - LED 1

Register CS

control

SJ12

Register OE-

control

SJ1

LPC4357 Developer’s Kit - User’s Guide

Page 18

Copyright 2013 © Embedded Artists AB

Tyco Electronics Amp and is a 38-way receptacle Mictor connector, 0.025” pitch, part number:

767054-1 or 2-5767004-2 (RoHS compliant).

J10 –this is the new and smaller footprint standard ARM Cortex-M3/M4 connector for trace. It

carries the trace signals as well as the debug signals found on J7. Note that this connector

is not used when working with the LPC4357. Instead a 20 pos trace connector, J1,

exists on the LPC4357 OEM board itself.

When working with the LPC4357 OEM Board, J7 is typically used. If an older and big footprint JTAG

debug pod is used, J8 can alternatively be used.

If trace is also used, use the connector J1 on the LPC4357 OEM board. Note that this requires an

advanced JTAG probe that supports trace.

Note that JP4 shall be shorted in order to enable the JTAG/SWD interface on the LPC4357. JP4

might not be inserted by default on the OEM Base Board.

JP3 is not used for debug purposes when working with the LPC4357 OEM Board.

Figure 7 –Debug Interfaces

Trace&Debug Connectors

J9 –not used

Trace&Debug

Connectors

J10 –not used

Debug Connectors

J8

Debug

Connectors

J7

ETM Control Jumpers

JP3 –not used

Reset LED

LED17

Debug Control Jumpers

JP4

LPC4357 Developer’s Kit - User’s Guide

Page 19

Copyright 2013 © Embedded Artists AB

4.7 SP6: Ethernet Interface

The board has an Ethernet interface, J11, which is a RJ45 connector with integrated magnetics. There

is also provision on the board for connecting a PoE interface. All signals can be accessed via

expansion pads, J12. Five 0 ohm resistors have to be removed in that case for isolating J11 from the

new connector (this is because J11 is not capable of handling a PoE interface so a new RJ45

connector must added). See picture below for where to find the relevant components on the board.

Figure 8 –Debug Interfaces

PoE modules that can be used for testing can for example be found at

http://www.silvertel.com/poe_products.htm. Select a version delivering +5V with enough current

capability for the specific application in mind. For example, using USB Host with power hungry external

devices will require more current. In most situations a 9-10W module will be sufficient.

Besides the PoE module, a RJ45 capable of handling PoE is also needed.

PoE Connector

J12, pin 1 leftmost

Isolation Resistors

R51/52/53/56/57

RJ45 with Magnetics

J11

LPC4357 Developer’s Kit - User’s Guide

Page 20

Copyright 2013 © Embedded Artists AB

4.8 SP6: SD/MMC Memory Card Interface

The board has a SD/MMC memory card interface, J13. Note that this interface SHALL NOT be used

for accessing the MCI peripheral interface of the LPC4350. Instead, there is a uSD/transflash memory

card interface on the bottom side of the LPC4357 OEM board.

There is visual indication via LED2 on the LPC4357 OEM board that supply voltage to the memory

card is present.

Figure 9 –SD/MMC Memory Card Interface –Not used

SD/MMC Connector

J13 –not used

This manual suits for next models

13

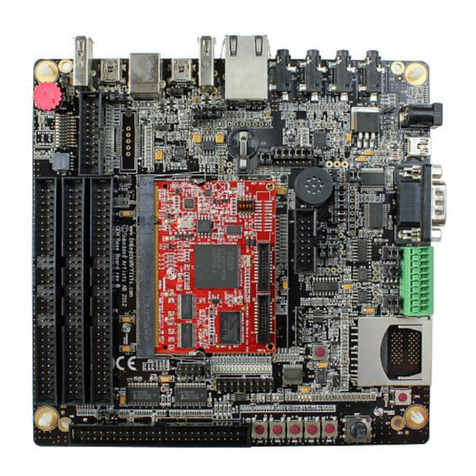

Table of contents

Other Embedded Artists Microcontroller manuals

Embedded Artists

Embedded Artists LPC3152 User manual

Embedded Artists

Embedded Artists LPC1343 User manual

Embedded Artists

Embedded Artists iMX Series User manual

Embedded Artists

Embedded Artists iMX RT1052 User manual

Embedded Artists

Embedded Artists iMX RT1062 User manual

Embedded Artists

Embedded Artists LPC4357 User manual

Embedded Artists

Embedded Artists LPC3250 User manual

Embedded Artists

Embedded Artists LPC11U35 User manual

Embedded Artists

Embedded Artists LPC1343 User manual

Embedded Artists

Embedded Artists LPC3131 User manual