Emcotec RC Electronic DPSI BMS User manual

Operating Manual

DPSI BMS Operating Manual Version 1.0

Page 2 of 32

Contents

1. Preface .............................................................................................3

2. Features ...........................................................................................3

3. Properties of the DPSI BMS ...........................................................6

3.1. LC-Display...............................................................................7

4. Packing Contents............................................................................8

5. Optional Accessories .....................................................................9

5.1. DPSI BMS Accessory Set........................................................9

6. Mounting Instructions ..................................................................10

6.1. Mounting of the DPSI BMS....................................................10

7. Soldering of the Battery Connectors ..........................................13

8. Charging Instructions for Batteries............................................. 15

9. Initial Operation.............................................................................16

9.1. Automatically Switching On/Off .............................................16

9.2. Manually Switching On/Off ....................................................18

9.3. The DPSI BMS in Operation..................................................18

9.4. LC-Display Indications for the 2 Channel DPSI BMS............19

9.5. LC-Display Indications for the 1 Channel DPSI BMS............23

10. Resetting the Memorized Values...............................................25

11. Programming the DPSI BMS......................................................26

12. Safety Instructions......................................................................27

13. Technical Data of the DPSI BMS................................................ 29

13.1. Measuring Parameters of the DPSI BMS ............................30

14. Warranty.......................................................................................30

DPSI BMS Operating Manual Version 1.0

Page 3 of 32

1. Preface

With the DPSI BMS (Dual Power System Interface – Battery

Monitoring System) you purchased a high quality and reliable

measuring system for battery power supplies. We thank you for your

faith in EMCOTEC GmbH and assure you that you have made the right

decision! Years of experience in development and manufacturing of

electronic systems went into the DPSI BMS. All products are

manufactured completely in house at EMCOTEC GmbH in Germany.

In-house manufacturing, careful quality assurance and a 100% test of

all shipped systems assure you of the highest reliability and

functionality.

Please read this operating manual carefully in order to use all functions

of the DPSI BMS optimally. We wish you continued success and

enjoyment with this high quality product!

2. Features

The DPSI BMS (Dual Power System Interface – Battery Monitoring

System) is the first monitoring and displaying system for batteries of

twin power supplies for use in large model airplanes.

For operation, the DPSI BMS is simply put in between both batteries

and the already mounted battery switch. Switching on and off occurs

fully automatically as soon as current is drawn (when equipment turned

on) or no current is drawn (when equipment turned off).

The DPSI BMS displays all relevant measured values in plain text.

Besides the battery voltages and currents of the connected consumers

(minimum / average / actual / maximum values), withdrawn capacity as

well as turn on time is displayed.

DPSI BMS Operating Manual Version 1.0

Page 4 of 32

Due to the manifold information indicated by the DPSI BMS,

malfunctions in the receiver set can be detected:

- Sticky control rods or defective servos can be diagnosed due

to higher current consumption.

- Eventual malfunction of a battery or in the battery switch

(e.g. inbalanced discharge of the batteries) can be detected

as well.

- Programming of end stops of servos is simplified where no

optical control is possible (e.g. throttle servo), because the

increasing current will indicate mechanical end stop.

As a specialty, both battery circuits in the DPSI BMS are galvanically

separated! This means, no electrical connection between each other

exists. This allows you to use one battery for the ignition system and

another one for the receiver set and operate both without any

influence. Due to the galvanic separation, it is also possible to operate

the DPSI BMS in connection with all battery switches currently

available on the market.

The measured values are derived from high precision 12 bit A/D

converters. Due to this elaborate design, constant currents of 10 amps

are permissible for each channel. Peak currents of up to 30 amps per

channel are permissible, thus allowing the usage of the DPSI BMS

even in big model airplanes where many servos are in use.

In case only one battery is to be monitored, a single channel version of

the DPSI BMS is available. Here, just one battery is connected and its

parameters (voltage, current, capacity, etc.) are displayed.

DPSI BMS Operating Manual Version 1.0

Page 5 of 32

Three printed circuit boards, equipped on both sides with most modern

parts allow for optimal space usage and are integrated into a stable

and ergonomic housing. Usage of pin-and-socket connectors allow for

simple exchange of connector cables and guarantees maximum

flexibility.

DPSI BMS: intelligent solutions ergonomically packaged!

DPSI BMS Operating Manual Version 1.0

Page 6 of 32

Summary:

The DPSI BMS allows for full control of two independent batteries. This

means:

Two independent batteries connectable (galvanically

separated)

Two 12 bit A/D converters for high precision data

acquisition

Automatic On/Off switching; therefore only single

switch necessary

LC-Display with indication of voltage, current, capacity,

operating time of each battery or both batteries together

with min./max.- and average values

1 channel version and 2 channel version available

3. Properties of the DPSI BMS

Displaying system for two separate batteries in battery switches or

other applications

Easily fitted between battery and consumer

Discharges the battery with only 10 µA in turned off state

Automatically switches On/Off without additional switch

2-4 cell LiIon / LiPo batteries usable

5-12 cell NiCad / NiMH batteries connectable

Up to 10A constant current per channel permissible

Up to 30A peak current durable

Programmable user language (German / English)

Wireless system, i.e. all leads is pluggable and therefore

exchangeable at any time

High-quality plastic housing including bracket for the battery

connectors

DPSI BMS Operating Manual Version 1.0

Page 7 of 32

Proof recognition of erroneous linkages (through increased

current consumption)

Proof recognition of defective or decrepit batteries

Three double side populated printed circuit boards for highest

packing density and therefore small dimensions

Each system 100% tested

3.1. LC-Display

The LC display shows all information in plane text using 2 lines, 8

characters each:

- Actual voltage battery 1 and battery 2

- Actual current battery 1 and battery 2

- Minimum voltage battery 1

- Minimum voltage battery 2

- Maximum voltage battery 1

- Maximum voltage battery 2

- Maximum current battery 1

- Maximum current battery 2

- Average current battery 1

- Average current battery 2

- Maximum current battery 1 + battery 2

- Average current battery 1 + battery 2

- Withdrawn capacity battery 1

- Withdrawn capacity battery 2

- Withdrawn capacity battery 1 + battery 2

- Flight time (Operating time in minutes)

The withdrawn capacity (in mAh) and the operating time (in minutes)

can be reset on demand.

DPSI BMS Operating Manual Version 1.0

Page 8 of 32

4. Packing Contents

Included in delivery of the DPSI BMS

DPSI BMS basis device

Screwing frame for M3 stop nuts

2 pieces of screws M3x20 with stop nuts

Bracket for securing the MPX connectors

Operating manual

EMCOTEC sticker

Carrying case

DPSI BMS Operating Manual Version 1.0

Page 9 of 32

5. Optional Accessories

5.1. DPSI BMS Accessory Set

The DPSI BMS accessory set contains two connector cables, 30 cm

(11.8”) each, which are put in between the DPSI BMS and the battery

switch (1 cable for the 1 channel version). Therefore, no soldering work

is necessary if MPX connectors are already in use (from the battery to

the battery switch).

The accessory set also contains a bracket (for spare) which serves as

a lock for the MPX connectors.

DPSI BMS Operating Manual Version 1.0

Page 10 of 32

6. Mounting Instructions

6.1. Mounting of the DPSI BMS

The DPSI BMS is designed as a cockpit instrument and therefore can

be mounted as such (especially interesting for scale models). Of

course, mounting on a small board inside the fuselage is also possible.

The mounting place should not be exposed to extreme vibrations (as is

the case at a fuselage’s side wall without a strengthening frame). The

DPSI BMS is solid mounted by the accompanying frame which serves

as a counter bearing. By the way, the frame can serve as a positioning

device for the cutout of the DPSI BMS.

The screwing connection is accomplished with the delivered M3

screws and stop nuts, which do not get loose even when exposed to

vibrations.

Dimensions for mounting:

After mounting, the connector cables can be put into their

corresponding plugs/sockets. In order to avoid loosening of the

connections caused by vibrations, the accompanied bracket is fed in

between the positive and negative pole of the connection cable and

locked at the sides of the housing of the DPSI BMS. Herewith, the

connectors are secured against vibrating loose.

DPSI BMS Operating Manual Version 1.0

Page 11 of 32

Connector clamping with bracket:

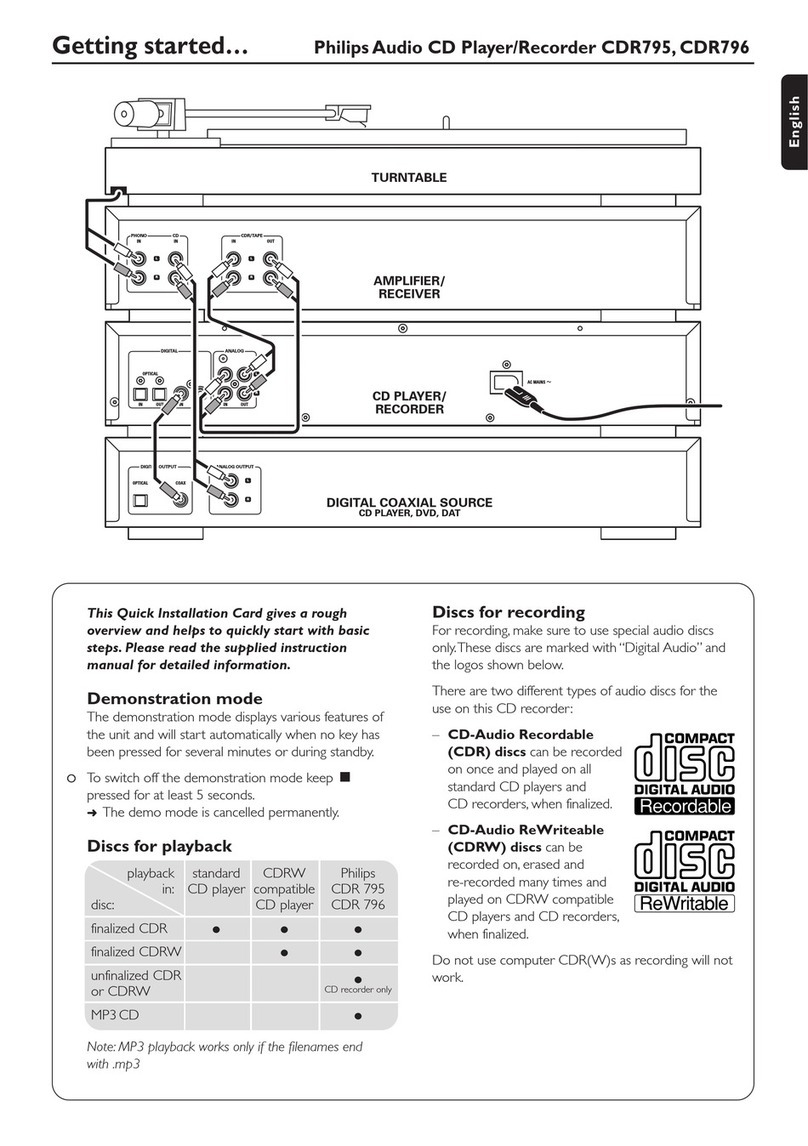

When using battery switches, the DPSI BMS is simply put in between

the batteries and the battery switch. This means: both batteries are

disconnected from the battery switch and connected to the inputs of

the DPSI BMS. The DPSI BMS outputs are then connected to the twin

power supply (e.g. a DPSI RV system) using appropriate patch cables

(e.g. out of the accessory set).

Abmessungen des DPSI BMS:

DPSI BMS Operating Manual Version 1.0

Page 12 of 32

DPSI BMS Operating Manual Version 1.0

Page 13 of 32

7. Soldering of the Battery Connectors

In case connector cables are manufactured by the user for connection

to the DPSI BMS, correct implementation must be observed. The MPX

high current connectors are marked + and – on their soldering side.

This marking must be strictly observed! The cables are first stripped

(approx. 5 mm / 0.2”) and then tin-plated. Before soldering the cables

to the connectors don’t forget to put the shrink hoses to the cable ends.

The cable is then soldered to all 3 pins, so it is located in their midst

(see photo). When using thin cables, the 3 pins can be bend to their

center (see photo). Sufficient tin has to be provided in order to connect

the cable to all 3 pins. The shrink hoses are then shrunk using a heat

gun.

DPSI BMS Operating Manual Version 1.0

Page 14 of 32

Soldering Multiplex connectors:

Hint:

It is necessary to use one shrink hose per cable (see photo) for isolation and not

to put a shrink hose over both cables! There must be enough space between the

positive and negative wire to accommodate the bracket.

DPSI BMS Operating Manual Version 1.0

Page 15 of 32

Hint:

Due to its design, the DPSI BMS is not polarity proof! Please make

sure, that the batteries are always correctly connected, i.e. the red

wire corresponds to positive and the black wire to negative.

Better double check!

8. Charging Instructions for Batteries

If batteries are to be charged while they are connected to the DPSI

BMS a second cable must be soldered to the batteries or the batteries

must be connected by a V-cable (LongGo batteries already do have a

charging connector integrated).

If in doubt, it is more reasonable and safer to disconnect the batteries

from the DPSI BMS for charging. Here, the bracket has to be released

(if mounted).

Hint:

Batteries, which are connected to the DPSI BMS during charging and having an

additional charging input (e.g. V-cable or charging connector), must be charged

separately, if the DPSI BMS is connected to a battery switch! Please observe the

operating manuals of the corresponding manufacturer of the battery switch.

Hint:

If the batteries are connected to the DPSI BMS during charging, a charger has to

be used which output voltage (charging voltage) never exceeds 20 volts (=>

limited step up converter). This is the case for all chargers of “ORBIT Electronic”.

Using an unlimited step up converter can cause damage to the DPSI BMS. Ask

your charger’s manufacturer if in doubt!

Hint:

Because batteries do not have any electrical connection among each other if

connected to the DPSI BMS, they can be of totally different types and can supply

their own consumers. Thus, a 2 cell LiPo battery can supply a receiver set and a

5 cell NiMH battery can be used to supply the ignition system for a gasoline

engine.

DPSI BMS Operating Manual Version 1.0

Page 16 of 32

9. Initial Operation

Initial operation, On/Off, Status Display:

The DPSI BMS is simply put in between battery and consumer (e.g.

between two LongGo batteries and a DPSI RV system).

Turning On/Off can take place in two different ways:

- Automatically turning On/Off

- Manually turning On/Off

9.1. Automatically Switching On/Off

Automatically turning on of the DPSI BMS always works. As soon as

the connected consumer (e.g. a receiver set connected to a battery

switch) draws current from battery 1 which exceeds approx. 100 to 150

milli amps, the DPSI BMS turns on automatically. Current drawn by a

receiver set using several servos usually clearly exceeds more than

150 milli amps per battery.

DPSI BMS Operating Manual Version 1.0

Page 17 of 32

However, automatic turning on only functions if current flows from

battery 1! If battery 1 is not loaded (but battery 2), the DPSI BMS is not

turned on.

Hint:

Whenever the current from battery 1 exceeds 100 to 150 milli amps, the DPSI

BMS automatically turns on. If the current is less (e.g. only a receiver without

servos is connected), the DPSI BMS does not turn on.

As soon as the current from battery 1 and battery 2 drops below 100 to

150 milli amps, the DPSI BMS turns off after approx. 10 seconds!

Hint:

As soon as the receiver set is turned off and the current from battery 1 drops

below approx. 100 to 150 milli amps, the DPSI BMS turns off automatically after

approx. 10 seconds.

Hint:

If the DPSI BMS turns itself on due to a short current pulse and the current

immediately drops below 100 to 150 milli amps, the DPSI BMS does not

necessarily turn off automatically, because the internal logic does not know

where the turn on command came from (automatic or push button).

Hint:

Current consumption of the DPSI BMS when turned off is just several µA.

Connected batteries therefore are not discharged!

DPSI BMS Operating Manual Version 1.0

Page 18 of 32

9.2. Manually Switching On/Off

In order to control the voltages of the batteries without turning on the

receiver set or the consumers (e.g. in winter), the DPSI BMS can be

turned on by a pushbutton (button “I”). A DPSI BMS turned on by the

button stays on until turned of by the off button (button “O”).

Hint:

If the DPSI BMS is turned on by the on button it stays on until turned off by the

off button.

An automatically turned on DPSI BMS can be turned off using the off button (but

will immediately turn on again if the current is higher than 150 milli amps).

9.3. The DPSI BMS in Operation

Hint:

For operation, battery 1 has to be connected because the electronics of the DPSI

BMS are supplied by battery 1. The micro controller and the LC display get their

voltage from battery 1!

As soon as the DPSI BMS is turned on, “EMCOTEC Germany” is

displayed for approx. 2 seconds in the LC display. Thereafter, both

voltages of the batteries are displayed (BMS 2 channel version) and

the DPSI BMS is in normal operating mode. The 1 channel version

displays the actual voltage as well as the actual withdrawn current of

the battery (battery 1).

Using both arrow keys (left side of housing) different information can

be retrieved.

If in sequence the button is pressed, values are displayed as

follows.

DPSI BMS Operating Manual Version 1.0

Page 19 of 32

9.4. LC-Display Indications for the 2 Channel DPSI BMS

This standard display in normal

operating mode shows the actual

voltages of both connected

batteries.

If battery 2 is not connected or its

voltage is too low, the value

“< 4.0V” is displayed.

If the voltage of one connected

battery exceeds 20 volts, “> 20V” is

displayed. CAUTION: only a max.

of 16 volts are allowed!

Display of actual current withdrawn

from battery 1 and battery 2.

If the DPSI BMS is turned on

(manually) for testing without any

consumer, the display indicates a

current of < 150 milli amps (0.15A).

Minimum battery voltage of battery

1 since last turned on.

DPSI BMS Operating Manual Version 1.0

Page 20 of 32

Minimum battery voltage of battery

2 since last turned on.

Maximum battery voltage of battery

1 since last turned on (maximum

value 20.0V).

Maximum battery voltage of battery

2 since last turned on (maximum

value 20.0V).

Maximum current from battery 1

since last turned on. If the value I is

< 150mA this is indicated

accordingly.

Maximum current from battery 1

since last turned on. This value

indicates the peak current which

was reached in the equipment and

can reach up to 13.00 amps.

Higher values are displayed as

“> 13.00A”.

Maximum current from battery 2

since last turned on. If there is no

current flow, the value “<0.15A” is

displayed.

Table of contents

Other Emcotec Recording Equipment manuals

Popular Recording Equipment manuals by other brands

Dangerous Music

Dangerous Music CONVERT-AD Plus user guide

Bespoke

Bespoke Scoreboards Play cricket scorer pro Set up and operating instructions

cymatic audio

cymatic audio LR-16 user manual

Northern Airborne Technology

Northern Airborne Technology AA224 series Installation and operation manual

Zoom

Zoom G1 Four quick guide

PASCO

PASCO UI-5001 reference guide