Emcotec DPSI V-Match User manual

Bedienungsanleitung

DPSI V-Match Operating Instructions Version 1.0

Page 2 of 16

DPSI V-Match Operating Instructions Version 1.0

Page 3 of 16

Contents

1. Functionality....................................................................................4

2. Programming...................................................................................6

2.1. Changing Servo Direction........................................................7

2.2. Calibrating Servo Center .........................................................8

2.3. Calibrating End-Limits..............................................................9

2.4. Deleting all Programming ......................................................10

3. Additional Hints.............................................................................11

3.1. Adapting several Servos........................................................11

3.2. Changing the Model...............................................................12

3.3. Sequence of Programming....................................................12

3.3. Limiting Tuning Range...........................................................12

4. Technical Data...............................................................................14

5. Warranty.........................................................................................15

DPSI V-Match Operating Instructions Version 1.0

Page 4 of 16

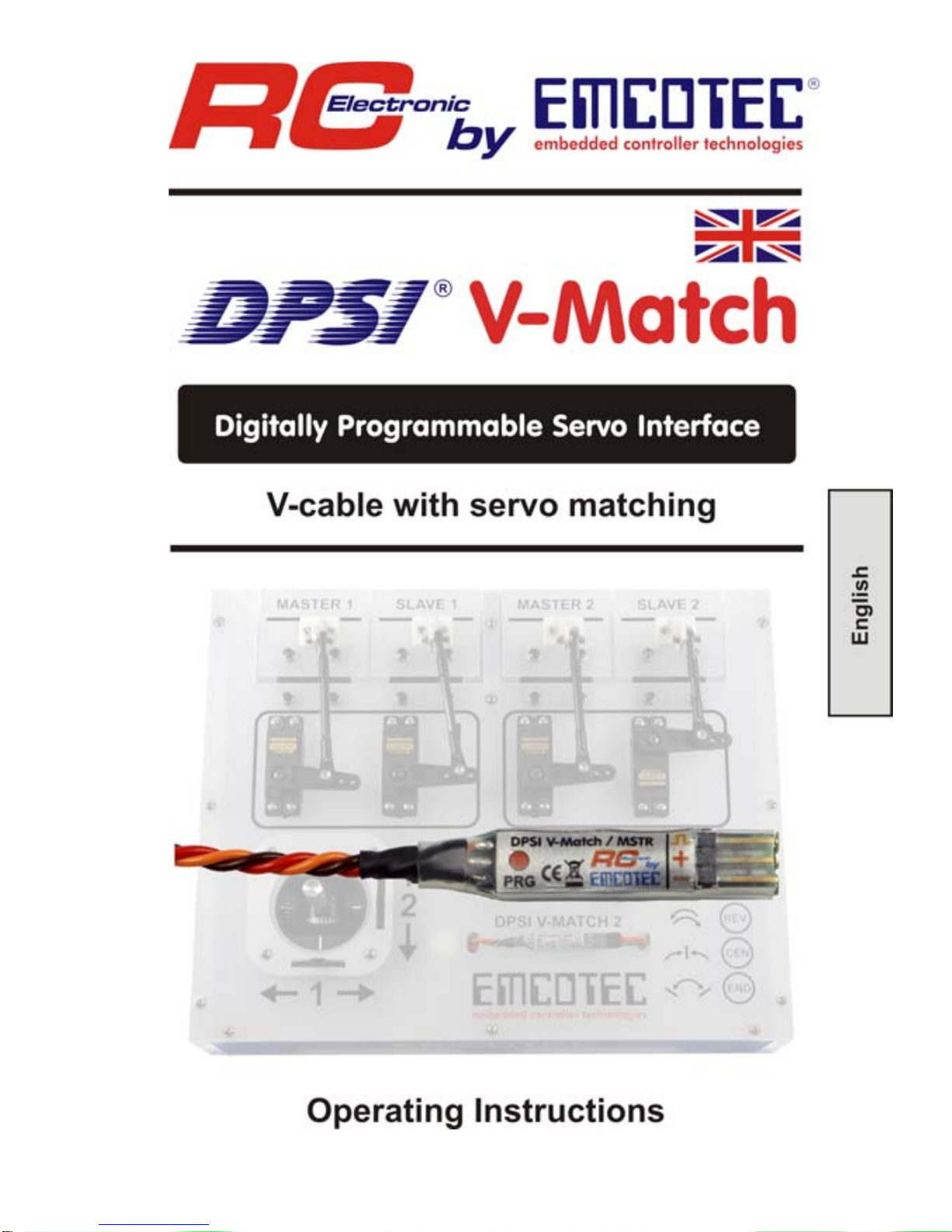

1. Functionality

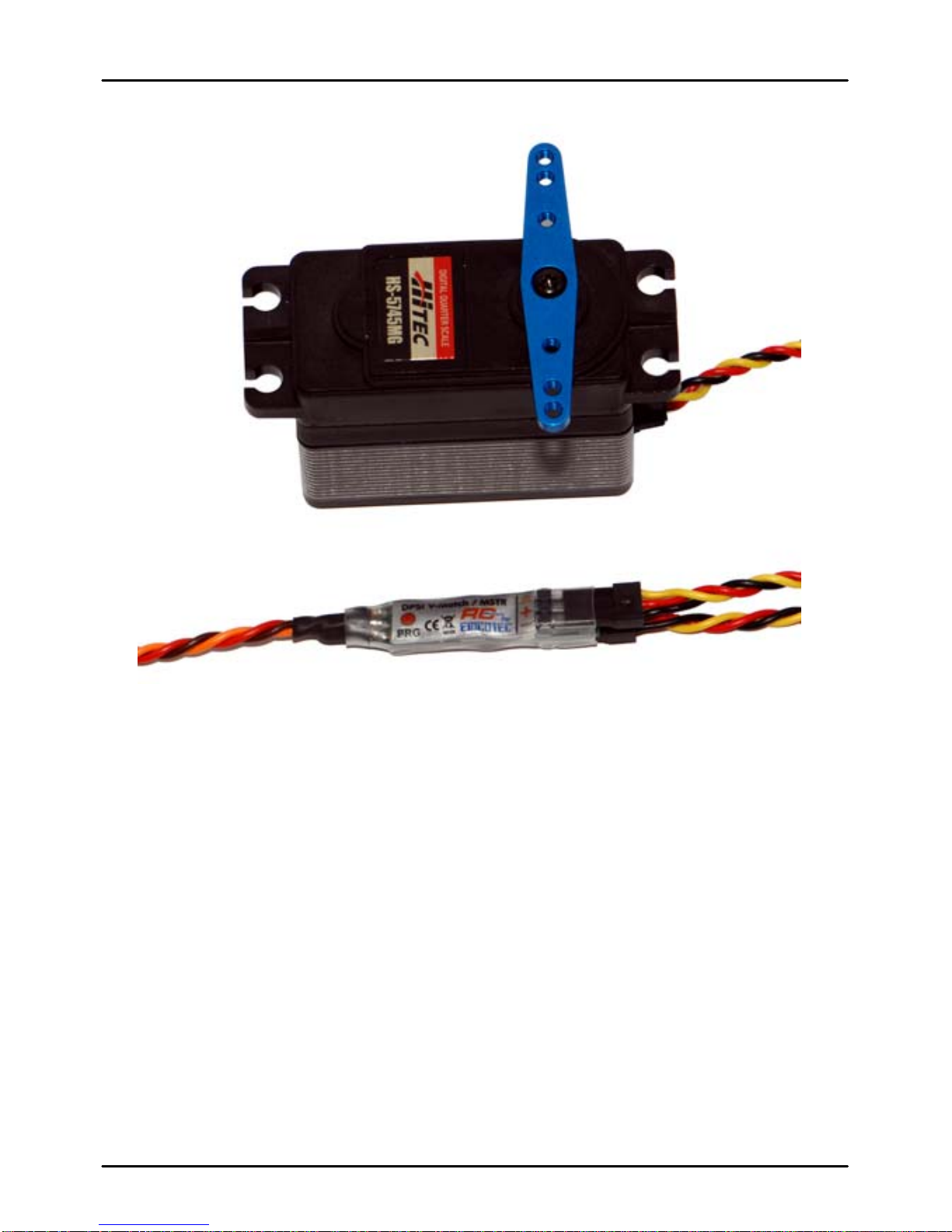

DPSI V-Match constitutes a servo V-cable

that accommodates two commercially

available servos.

As a special feature, one servo (SLAVE) is

programmable for direction, as well as

center position and end-limits. Therefore,

this servo adapts ("matches") to the main

servo (MSTR).

This is especially handy if two servos actuate on one rudder (e.g. two

servos on one aileron) and synchronism cannot be established by

mechanically means. Often, it suffices if one servo's direction can be

changed (e.g. counter rotating mounted servos for the airplane's

elevator). This too, is simply accomplished with DPSI V-Match.

Failsafe-Function:

A failsafe-function is added to its features. Both servos (MSTR and

SLAVE) remain at their current position (HOLD) when encountering an

erroneous or missing receiver signal until a valid signal is again

delivered by the receiver. A flashing red LED (at the PCB's side)

indicates this state and stays active (i.e. flashes) until power is turned

off.

Powerful Servos:

The electronically design of the DPSI V-Match allows for usage of

powerful digital servos; supply voltage ranging up to 8.4 volts. Due to

the PCB (4-layer) and the thick (0.34 mm2) connection cable, current

load is especially high.

DPSI V-Match Operating Instructions Version 1.0

Page 5 of 16

Pulse Amplifier & HF-Suppression:

Besides pulse amplifiers, which recognize and amplify even weak

servo signals, high effective noise filters are built into the DPSI V-

Match. Therefore, ferrite cores or other noise suppression measures

can be omitted.

High Precision:

Because of the intelligent software design and a highly accurate crystal

oscillator, a resolution of more than 3000 steps is obtained. Therefore,

the DPSI V-Match is also suitable for modern remote control systems

with high servo positioning precision (number of steps).

DPSI V-Match Operating Instructions Version 1.0

Page 6 of 16

2. Programming

There is no external programming device necessary, e.g. a PC or a

programming box for programming of the DPSI V-Match. Only a

delivered magnet serves for activation of the corresponding

programming functions. Everything else is conducted with the

transmitter and remote control equipment.

During programming, settings of the original servo (master = MSTR)

remain unchanged! Programming always refers to the slave servo

(SLAVE).

Hint:

Adjustment / programming of the slave servo is only possible within the first 10

seconds after power on. Afterwards, programming is inhibited for safety reasons!

Hint:

Before starting EACH programming, the corresponding transmitter stick (or

switch actuator) must be positioned in center position!

Hints:

If both servos MSTR and SLAVE actuate a common rudder, at least one

servo linkage must be released in order to avoid mechanical touch.

Hint:

Whenever a change e.g. of the servo center position takes place, the end-limits

should be reprogrammed as well!

Hint:

Basic adjustments in DPSI V-Match correspond to Graupner/JR equipment.

Center position is 1.50ms; end-limits are set to 100% each. Of course, all remote

control sets can be used with no limitation.

DPSI V-Match Operating Instructions Version 1.0

Page 7 of 16

Hint:

Whenever programming takes place, the integrated red LED blinks for controlling

purposes at a rate of 0.5Hz (1s on, 1s off) at the DPSI V-Match's side.

2.1. Changing Servo Direction

When changing the direction of the servo, all

other settings remain! For reversing direction of

the servo, hold the magnet close to position

"PRG" (red dot on sticker) within the first 10

seconds after power on. Distance of the magnet can be up to 8mm.

The magnet also operates through thin fuselage sidewalls, if the DPSI

V-Match is attached to the fuselage's inner sidewall using e.g. dual

adhesive tape.

2.5 seconds after positioning the magnet, the servo makes a short

move (10% stroke). If the magnet is removed within the next 5

seconds, the servo direction is reversed and permanently stored. The

DPSI V-Match now executes a restart.

DPSI V-Match Operating Instructions Version 1.0

Page 8 of 16

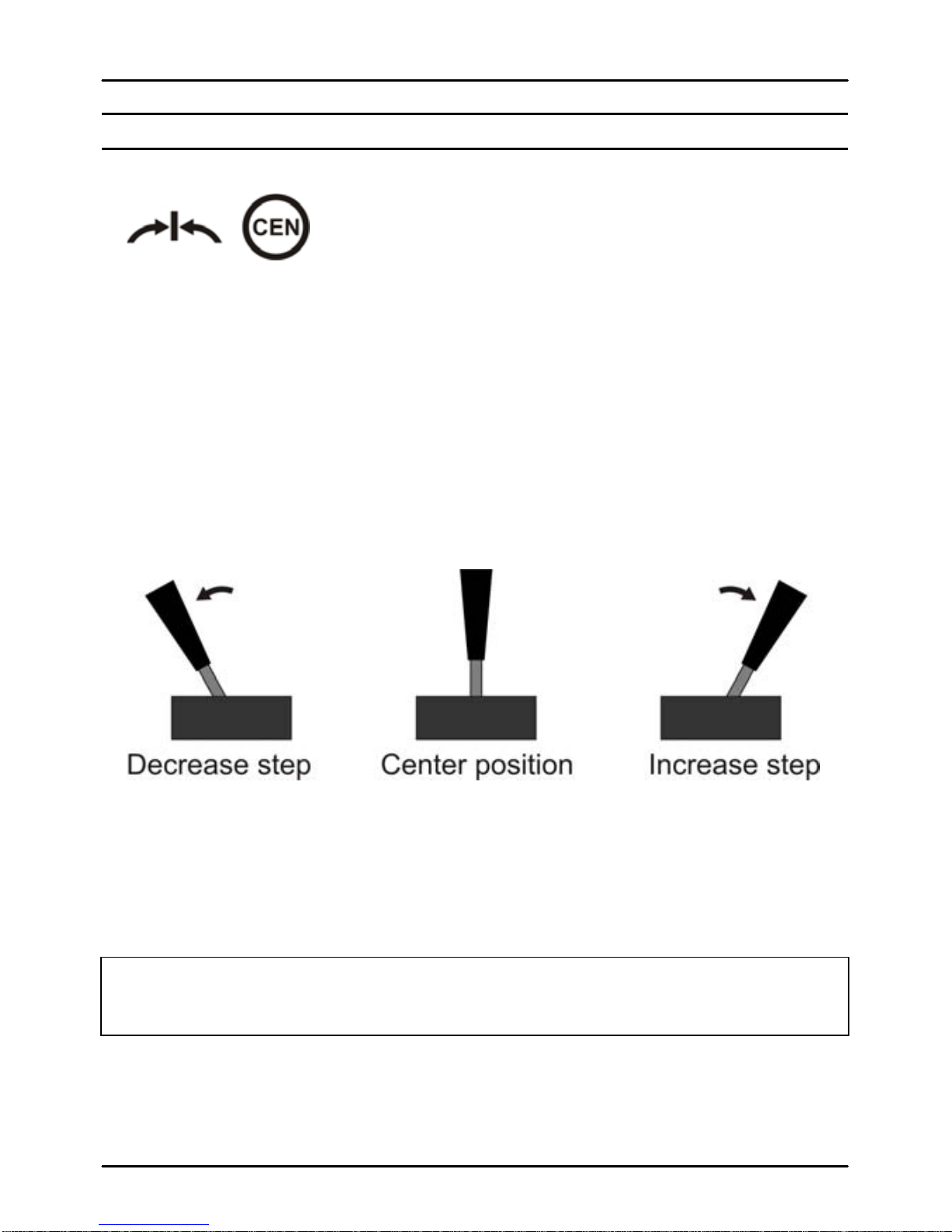

2.2. Calibrating Servo Center

Programming also starts by positioning the

magnet close to the red dot ("PRG"). The

slave servo makes a short move after 2.5

seconds (just like for servo reverse). The

magnet now is not removed, but rather remains at the "PRG" position.

The stick or switch actuator must not be moved now, i.e. it must remain

in center position. After 5 seconds, the servo makes a short move

again. Now, programming of servo center is active.

The master servo now remains centered and does not move anymore,

even if the stick is moved. With each movement of the transmitter stick

out of center, the servo position (servo center) is incremented or

decremented by one step.

If the stick remains in one end-position, steps automatically increment

or decrement after 2.5 seconds. This serves for quicker settings of the

values.

Hint:

Due to the high resolution of the DPSI V-Match, changes of the servo position

are possibly recognizable only after several steps.

DPSI V-Match Operating Instructions Version 1.0

Page 9 of 16

Remove the magnet from its red dot position ("PRG") as soon as the

slave servo reaches the desired center position. The DPSI V-Match

now starts with the newly programmed center position of the slave

servo.

Hint:

Reprogram the end-limits in order to obtain linear curves after programming the

servo center.

2.3. Calibrating End-Limits

Start programming of end-limits just like

programming servo center. Here, the

transmitter stick (or switch actuator) is set to

maximum position (servo end-limit) within 5

seconds after the servo makes its first short move. After these 5

seconds the servo moves again shortly and both servos remain in their

actual (maximum)-position. Reposition the stick to its center position –

servo positions do not alter!

DPSI V-Match Operating Instructions Version 1.0

Page 10 of 16

Here too, the stroke of the slave servo changes by increasing or

decreasing steps when moving the stick out of its center position.

Remove the magnet when the desired end position is reached.

Hint:

Whenever changing servo settings, all values should be reprogrammed, i.e.

center and end-limits! Sequence of programming (center, end-limits) does not

really matter.

Attention:

Programmable values for end-limits could possibly be higher than the mechanical

resolution of the servo. The servo therefore could be damaged or function

incorrectly (e.g. wheel spinning) when utilizing the full range. Therefore,

approximate the limiting values carefully. An additionally connected servo tester

(e.g. using the EMCOTEC Mini Servo Tester – part number A71050) can help if

in doubt, indicating the corresponding servo position digitally.

2.4. Deleting all Programming

Total reset of all programmed settings is

possible too. Position the magnet after power

on close to the "PRG" position and hold it

there for approx. 40 seconds. After 2.5

seconds and after additional 5 seconds the servo makes its short move

(just like when programming center/end-limits). The transmitter stick

must not be moved at that time and the magnet must remain at the

"PRG" position. After 40 seconds have elapsed, all settings are deleted

and a restart of the DPSI V-Match takes place. Now, the magnet can

be removed.

Hint:

Whenever programming takes place, the integrated red LED blinks for controlling

purposes at a rate of 0.5Hz (1s on, 1s off) at the DPSI V-Match's side.

DPSI V-Match Operating Instructions Version 1.0

Page 11 of 16

3. Additional Hints

These additional hints are valuable for the ambitious user who likes to

know more about the functions of the DPSI V-Match by explaining its

behavior under certain circumstances.

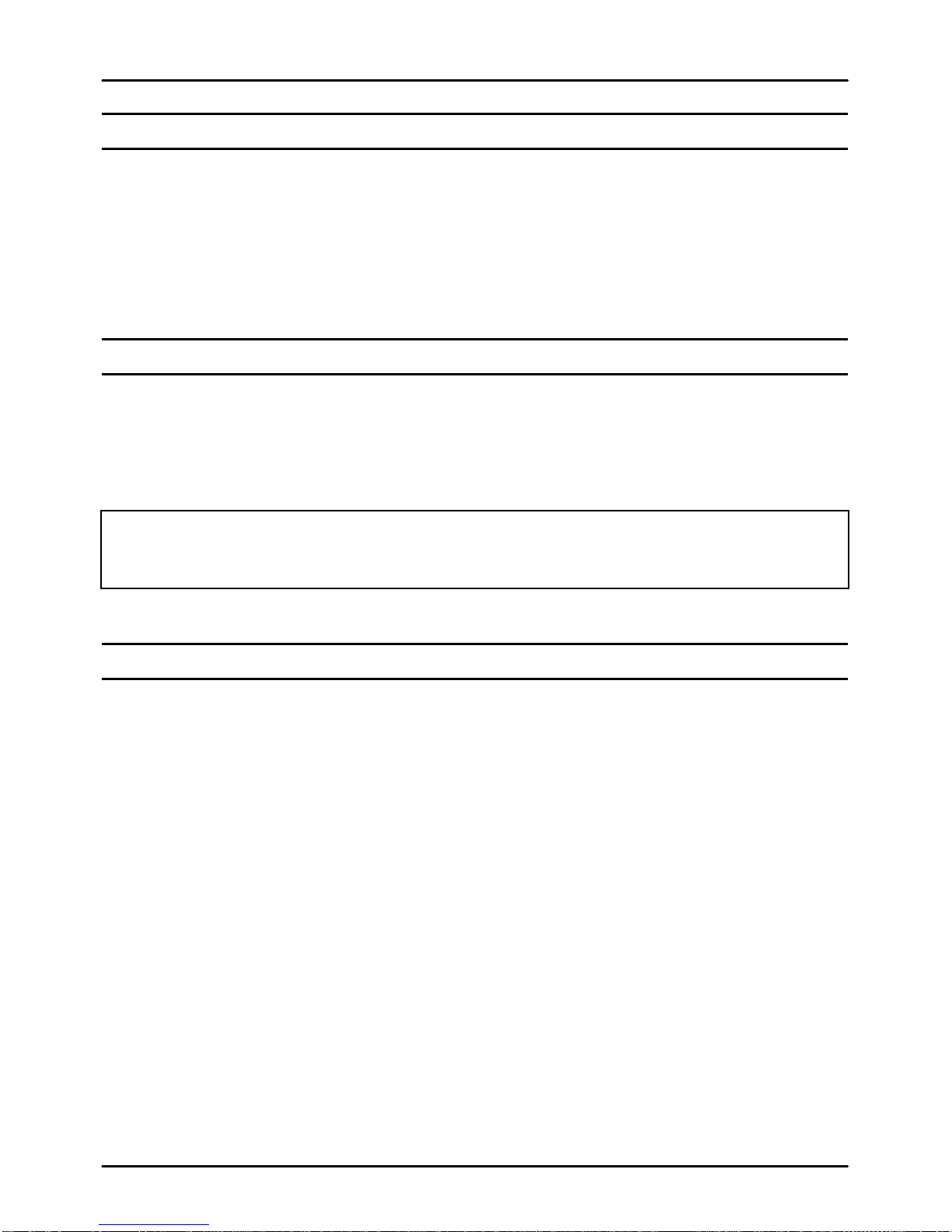

3.1. Adapting several Servos

If more than two servos need to be synchronized (e.g. three aileron

servos) two DPSI V-Match can be chained one after another. This

means: the input of the second DPSI V-Match connects to the MSTR

output of the first DPSI V-Match.

Now, a SLAVE output is available at the first DPSI V-Match, a MSTR

and a SLAVE output at the second one. Both SLAVE servos can now

be independently set up.

DPSI V-Match Operating Instructions Version 1.0

Page 12 of 16

3.2. Changing the Model

If a programmed DPSI V-Match is to be used in an other application

(e.g. changing a model), generally all settings should be deleted (see

also "Deleting all Programming"). This is also true if a servo with a

different rotating direction is to be built in.

3.3. Sequence of Programming

When programming the slave servo, the rotating direction (if

necessary) should always be programmed first. Then center position

and end-limits follow, sequence is unimportant.

Hint:

Whenever there is a change, e.g. serve center position, the end-limits should be

programmed, too!

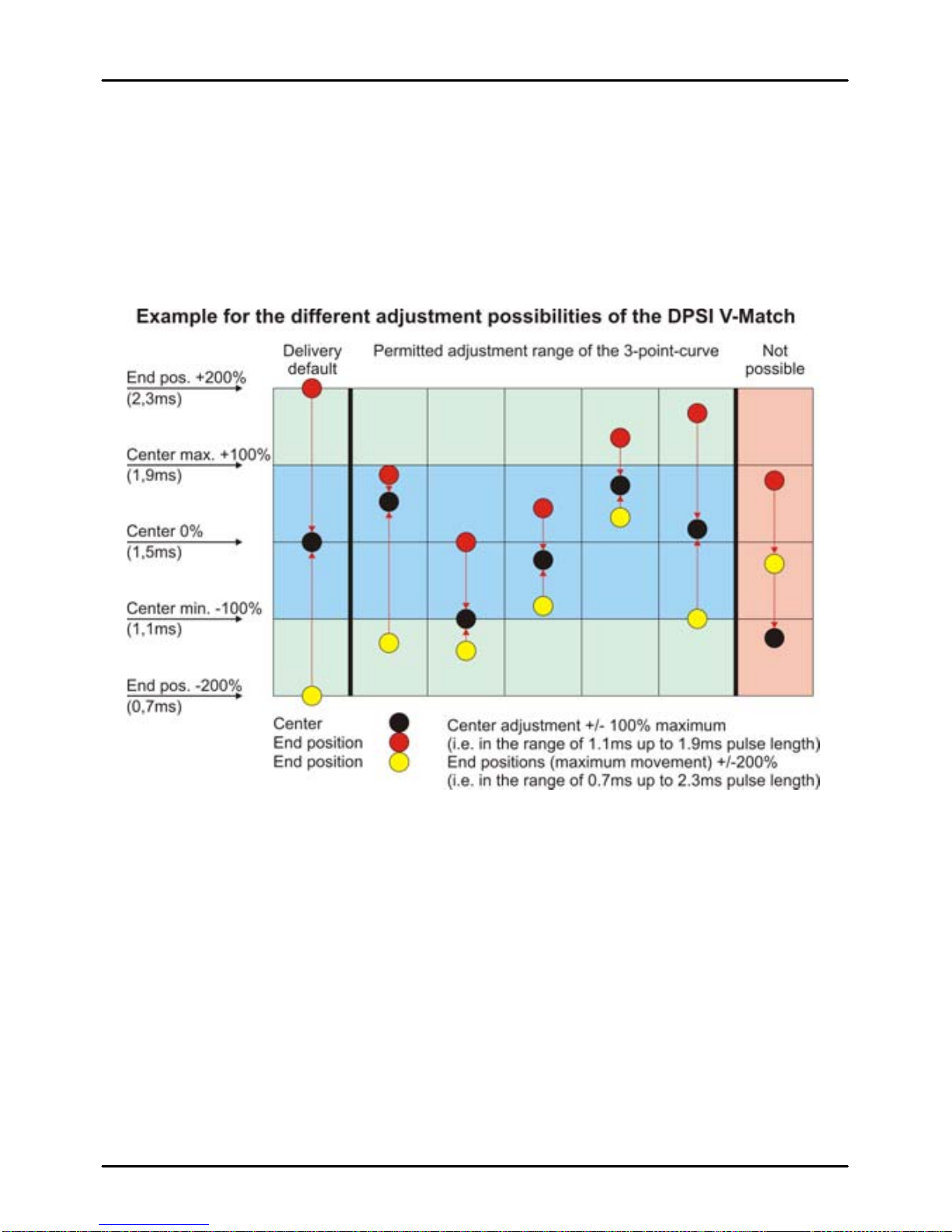

3.3. Limiting Tuning Range

The DPSI V-Match only allows for certain values when programming

or adjusting the slave servo. Because the slave servo is to be adapted

to the master servo, both servos should have similar base adjustments

in the first place, e.g. comparable center positions.

If the center of the master servo already is over 100% of the possible

servo stroke it does not make much sense to adjust the slave servo

even further. Therefore, only a maximum of +/-100% (referring to JR

values) of the servo center position is possible.

Adjustment of the slave servo is carried out by a so-called 3-point

curve (i.e. center, maximum value left/top, maximum value

right/bottom).

DPSI V-Match Operating Instructions Version 1.0

Page 13 of 16

The "distance" of the maximum position of a servo in respect to its

center must be at least 20%, otherwise the value is not programmable.

Range checking accompanies each programming. It is therefore not

possible to position the servo center position off limits. Malfunctions are

avoided this way (e.g. V-curve of the servo).

DPSI V-Match Operating Instructions Version 1.0

Page 14 of 16

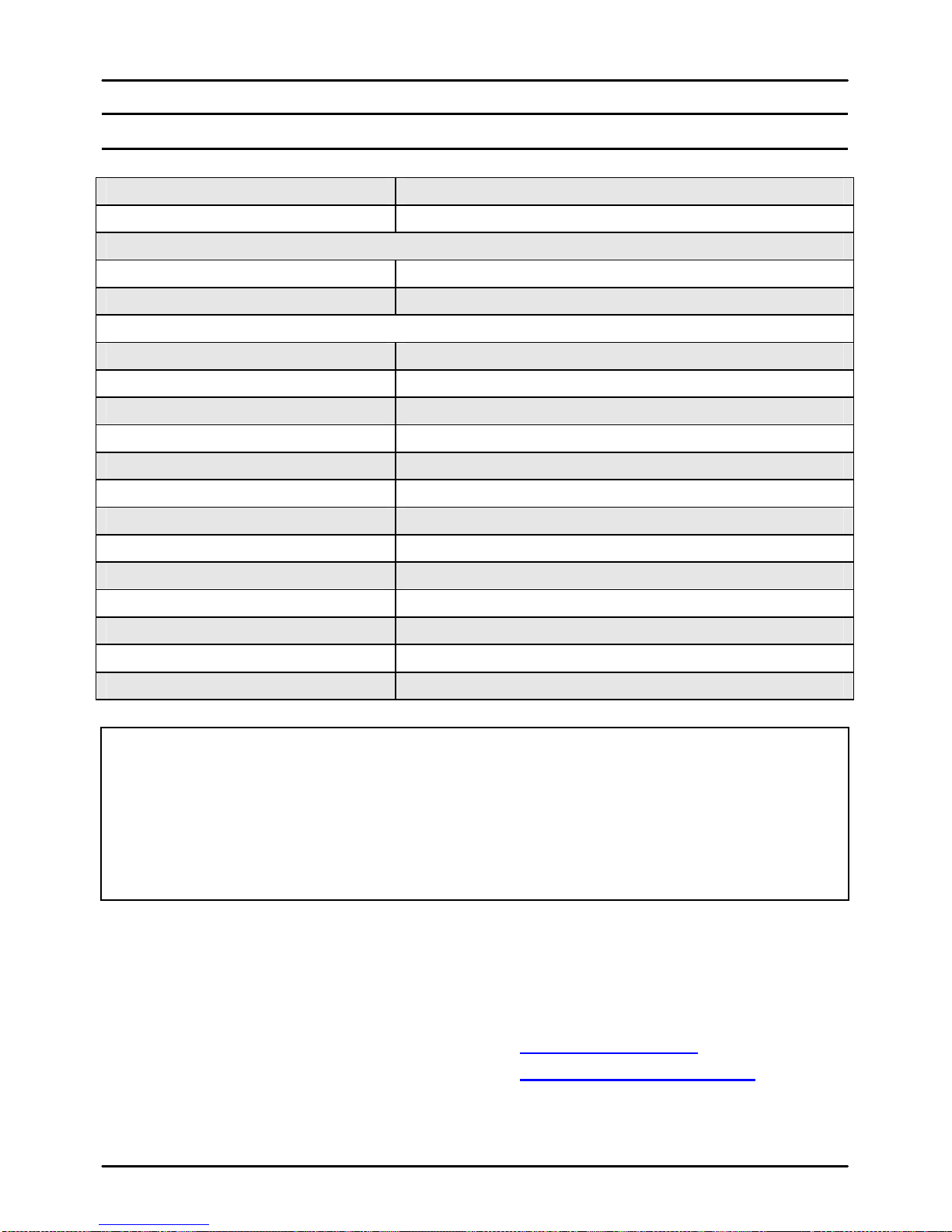

4. Technical Data

Operating Voltage Range 4V .... 8.4V

Current Consumption Approx. 4.7mA

Servo Signal Level Input:

Low-Level 0V ... 0.8V

High-Level 2.0V ... 8.4V

Servo Signal Level Output:

Supplying > 5.1V Approx. 5.0V

Supplying < 5.1V Supply voltage -0,1V

Maximum Allowable Current 8A continuous, 20A peak

Allowable Center Position +/-100% (1.10ms .... 1.90ms)

Allowable End-Limits* +/-200% (0.70ms .... 2.30ms)

Allowable Signal Cycle Time Min. 6.9ms, max. 34.868ms

Resolution (Steps) 3200

CE-Test According to 2004/108/EC

Temperature Range -20°C .... +85°C

HF-Noise Suppression -30dB attenuation @ 35MHz

Dimensions approx. 50mm x 8.4mm x 7.2mm

Weight Approx. 4.5g

Warranty 24 month

* Attention:

Programmable values for end-limits could possibly be higher than the mechanical

resolution of the servo. The servo therefore could be damaged or function

incorrectly (e.g. wheel spinning) when utilizing the full range. Therefore,

approximate the limiting values carefully. An additionally connected servo tester

(e.g. using the EMCOTEC Mini Servo Tester – part number A71050) can help if

in doubt, indicating the corresponding servo position digitally.

Technical modifications and errors excepted!

(C) EMCOTEC embedded controller technologies GmbH

(P) July 2008 Version 1.0 from July 15. 2008

Robert Hussmann www.emcotec.de

www.rc-electronic.com

DPSI V-Match Operating Instructions Version 1.0

Page 15 of 16

5. Warranty

EMCOTEC GmbH shall issue a 24-month warranty on the DPSI V-Match. The

guarantee period shall begin with delivery of the equipment by the retailer and

shall be not extended by any guarantee repair or guarantee replacement.

During the period of guarantee, the warranty shall cover the repair or

replacement of any proven manufacturing or material defects at no charge. There

shall be no specific entitlement to repair work. In case of a guarantee claim, the

manufacturer shall reserve the right to exchange the equipment for a product of

equal value if repair of the item is not feasible for economic reasons. There shall

be no assumption of liability for consequential damages that are brought about by

a proven defect during operation of the DPSI V-Match. There shall be no

extended claims for damages.

All transportation, packaging and travel expenses shall be borne by the

purchaser.

No liability shall be assumed for any damages during transport.

If repair is needed, the equipment must be sent to the appropriate service

center of the respective country or directly to EMCOTEC GmbH.

The guarantee shall only be valid when the following conditions are met:

The guarantee document (original invoice) must include the delivery date,

the company stamp, the serial number and signature of the retailer.

No intervention in the equipment may have been undertaken.

It must have been operated in accordance with our operating instructions.

Only the power sources and other accessory devices and components that

were recommended by us may have been used.

The guarantee document (original invoice) and other pertinent information

regarding the malfunction (a short description of the defect) must be

included with the transmittal.

The equipment must still be the property of the initial purchaser.

If equipment is sent in that later proves to be functional following an initial

inspection, we shall impose a flat processing fee of € 15,-.

In all other respects, the general business terms and conditions of

EMCOTEC embedded controller technologies GmbH shall apply for any

items not listed.

DPSI V-Match Operating Instructions Version 1.0

Page 16 of 16

Legal information:

Trademarks:

The following names are registered trademarks:

-EMCOTEC

-DPSI

-DPSI RV

Other product names mentioned in this manual may also be trademarks or registered

trademarks of their respective owners.

Copyright information:

This manual is copyrighted by EMCOTEC GmbH. All rights reserved. This document may not

be copied either entirely or in part, nor may it be transferred to any type of medium or

translated into any other language without the express written approval of EMCOTEC GmbH.

Manual Note:

EMCOTEC GmbH reserves the right make changes to this manual and to equipment

described herein without notice. Considerable effort has been made to ensure that this manual

is free of errors and omissions. We shall not assume responsibility or liability for any errors that

may be contained in this manual nor for any incidental, concrete or consequential damage that

may arise from the provision of this manual, or the use of this manual in operating the

equipment, or in connection with the performance of the equipment when so operated.

Table of contents

Other Emcotec Recording Equipment manuals