Emcotec RC Electronic DPSI RV User manual

Operating Instructions

DPSI RV Family Operating Instructions Version 2.0

Page 2 of 48

DPSI RV Family Operating Instructions Version 2.0

Page 3 of 48

Contents

1. Foreword..........................................................................................4

2. Features ...........................................................................................6

3. The DPSI RV-Family in Headwords.............................................11

3.1. HFIB (High Frequency Interference Blocking).......................13

3.2. APP (Advanced Push Pull Servo Pulse Amplification)..........13

3.3. IVM (Intelligent Voltage Monitoring).......................................14

3.4. Safety Features of the DPSI RV Systems.............................14

4. Packing Contents..........................................................................16

5. Installation Instructions and Programming................................17

5.1 Installing the DPSI RV............................................................17

5.2. Hole spacing for Fastening....................................................19

5.3. Connecting the Switch transmitter.........................................20

5.4. Connecting the Receiver .......................................................23

5.5. Selecting the Batteries...........................................................25

5.6. Soldering the Battery Connectors..........................................28

5.7. Charging the Batteries...........................................................29

5.8. Setting the Voltage ................................................................30

5.9. Programming of the Batteries................................................32

5.10. Connecting the Servos ........................................................35

5.11. Connecting Accessories......................................................37

5.12. EMCOTEC Filter Capacitor .................................................38

6. Operation ....................................................................................... 39

7. Error Indication .............................................................................40

8. Safety Instructions........................................................................42

9. Technical Data of the DPSI RV-Systems..................................... 44

10. Warranty.......................................................................................46

DPSI RV Family Operating Instructions Version 2.0

Page 4 of 48

1. Foreword

With the EMCOTEC DPSI RV (Dual Power Servo Interface –

Regulated Voltage) you purchased a high grade, modern and secure

product. We appreciate your trust and assure you that you made the

right choice!

Long lasting experience for years in development and manufacturing of

electronically systems as well as the knowledge of the world’s best

model airplane pilots has influenced the development of the DPSI

systems. All products are manufactured at EMCOTEC GmbH in

Germany on our own production line. Extensive optically and

electronically end tests for every system, which leaves our house,

assure that you, our customer acquire an absolute reliable product,

which considerably increases the reliability of your valuable RC-Model.

Of course, the products of the DPSI family not only have been tested

extensively in the laboratory, but also went through intensive flight-

testing. Extensive series of tests with especially in house developed

data loggers have been accomplished to measure the real current

consumption in model airplanes. Like done in the automotive industry

an FMEA (Failure Mode and Effective Analysis) reduces the possibility

of damage and malfunction on operating errors to a minimum.

We kindly ask you to read these operating instructions carefully and to

observe the installation hints. Thus, errors can be avoided in advance.

We are all ears for your wishes and questions. Challenge us!

Bobingen, June 2006

The Staff of EMCOTEC GmbH

DPSI RV Family Operating Instructions Version 2.0

Page 5 of 48

Connection sam

p

le of the DPSI RV Mini 5

DPSI RV Family Operating Instructions Version 2.0

Page 6 of 48

2. Features

A DPSI RV is used as a redundant power supply and current distributor

for receivers and servos in RC-Models. The redundancy is

accomplished by using two connected batteries. If one battery fails, the

second battery guaranties safe operation. In the normal case, both

batteries are discharged simultaneously. Furthermore, current is cut in

half in each single battery by the two “parallel” connected batteries,

which allows for batteries with lower ampacity.

All servos directly connected to a DPSI RV are supplied with full power

and each servo obtains maximum current without burden the

damageable receiver.

Due to switching the supply voltage electronically (the switch

transmitter does not switch on the current but only supplies a switch-on

signal), there is no power loss, weak contacts or transition resistance.

For all DPSI RV systems, the electronically switches are built

separately, i.e. the electronically parts are doubled. The switches are

failsafe and are driven by self-holding circuitry, rather by a micro-

controller. Thus, an operating DPSI RV stays powered on, even if the

on/off switch transmitter is removed or broken or if the microcontroller

is malfunctioning.

Using DPSI RV systems, RC receiver sets reach new dimensions. In

particular, a stabilized output voltage, which supplies the receiver as

well as all servos, accounts for. A DPSI RV therefore offers:

Battery switching function

Complete voltage regulation for all RC components

Electronically, failsafe switches

Current distribution with HF filtering

Battery voltage monitoring with acoustically warnings

DPSI RV Family Operating Instructions Version 2.0

Page 7 of 48

Voltage Regulation:

Until now, the receiver set was supplied directly by the connected

battery (or a corresponding battery switch). The output voltage

depends heavily on the current discharge state. Because virtually

always 5-cell NiCad or NiMH batteries are being used in large model

airplanes, a fully charged battery reaches up to 7.5 volts after the

charger shuts off (depending on the charging current and the internal

resistance). This peak voltage drops relatively fast, but can cause

reduced lifetime of the servos in unfavorable cases, because the

manufacturers usually allow only up to 6 volts. Due to the increased

usage of Lithium-Polymer batteries (e.g. LONGGO) voltage regulation

is mandatory, because the batteries nominal voltage is 7.4 volts.

The electronics of the DPSI RV systems make sure, that the voltage of

the batteries is reduced to an acceptable value, independent of the

provided input voltage of the batteries. Using a jumper (a small

connector), the output voltage can be adjusted in four steps (except for

the DPSI 2001 RV – here the voltage is fixed). Thus, the power

requirements can be adjusted to the pilots needs.

Low voltage warning:

In order to inform the user about the discharging state of his batteries,

a microcontroller using an intelligent algorism is integrated into the

DPSI RV systems, to monitor all voltages. Errors (e.g. battery voltage

too low) are unambiguously communicated through a built in buzzer

acoustically and in the switch transmitter by the central LED optically.

Additionally, the DPSI RV allows for direct connection of external LED

displays (battery controllers). In order to use different battery types, a

DPSI RV can be “programmed” for the battery being used. Thus,

through simple programming you can select between 5-, 6-, 7-cell

NiCad/ NiMH batteries or LiPo batteries (e.g. LONGGO).

DPSI RV Family Operating Instructions Version 2.0

Page 8 of 48

Hint:

On delivery, the DPSI RV system’s low voltage recognition is programmed for 2-

cell LiPo batteries. For using other battery types, the corresponding type must be

programmed first (see chapter 5.9)!

The output voltage is set to 5.6 volts on delivery (DPSI 2001 RV 5.9 volts – other

values on customer request possible).

Different versions:

In order to satisfy all applications, different DPSI RV versions are

available:

The DPSI RV Mini 5 addresses pilots of the 2 to 2.5 meter aerobatic

class, who do not need too many servos for their model and where

only up to two servos maximum work on one flap. Therefore, only

heavily loaded rudders are supplied by the DPSI (aileron, elevator, yaw

rudder). Servos for further functions can be connected directly to the

receiver (e.g. engine throttle, retractable gear, etc.)

The DPSI RV Mini 6 is primarily intended for jet- and glider-pilots (but

suits motorized models too), where more channels are needed but

where only one servo works on a flap. Here too, additional servos can

be connected directly to the receiver.

DPSI RV Family Operating Instructions Version 2.0

Page 9 of 48

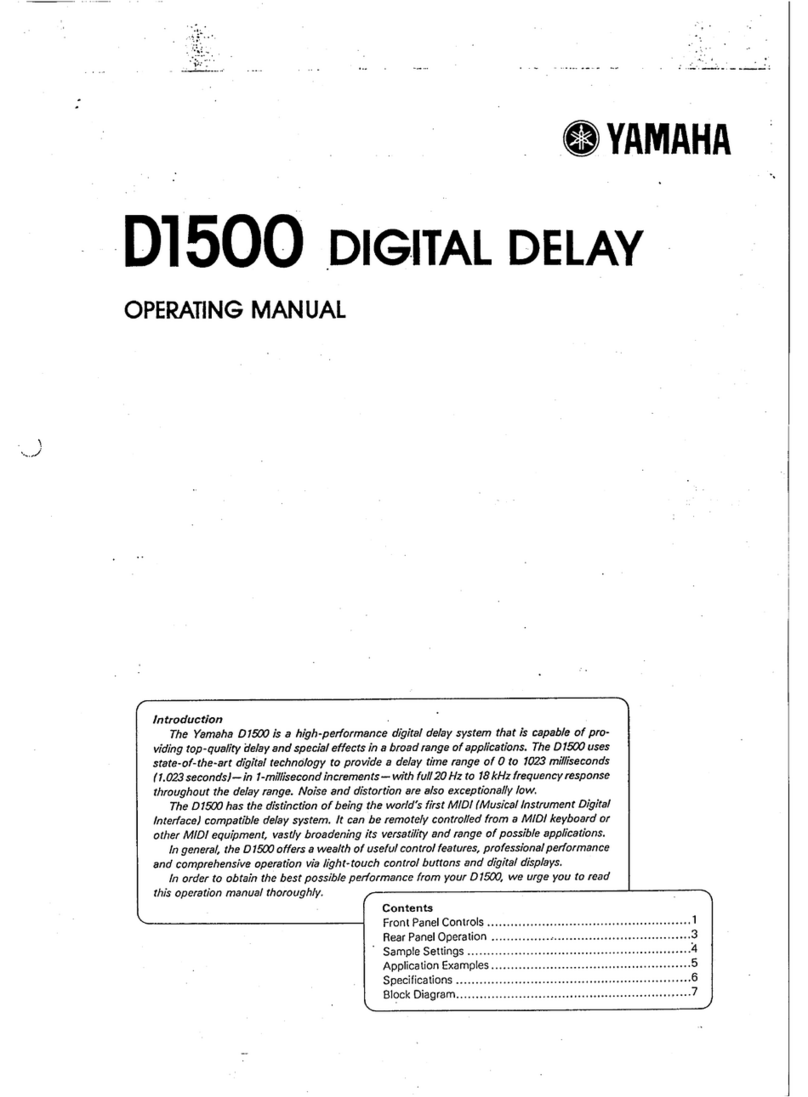

The DPSI 2001 RV is the enhancement of the DPSI 2001 and supplies

26 servos altogether, which result from 10 receiver channels.

Therefore, it is predestinated for all kinds of large model airplanes,

which need many servos (e.g. 40% size models). Two additional

outputs (MPX connectors) allow for connection of consumer loads,

which can be supplied with unregulated battery voltage (e.g. 7.4 volts

high load servos, smoke pumps, illumination etc.).

The DPSI RV allows for connecting of up to 32 servos, which result

from 12 receiver channels. Especially large-glider- and airliner-pilots

missed this variety. Due to the higher number of servos, the DPSI RV

is a little larger and heavier then the smaller systems. Because more

heat dissipation is encountered, a larger heat sink is necessary. The

DPSI RV contains two complete separate current paths and voltage

regulators. Even the breakdown of an electronically part does not lead

to a malfunction – everything is built up redundantly.

DPSI RV Family Operating Instructions Version 2.0

Page 10 of 48

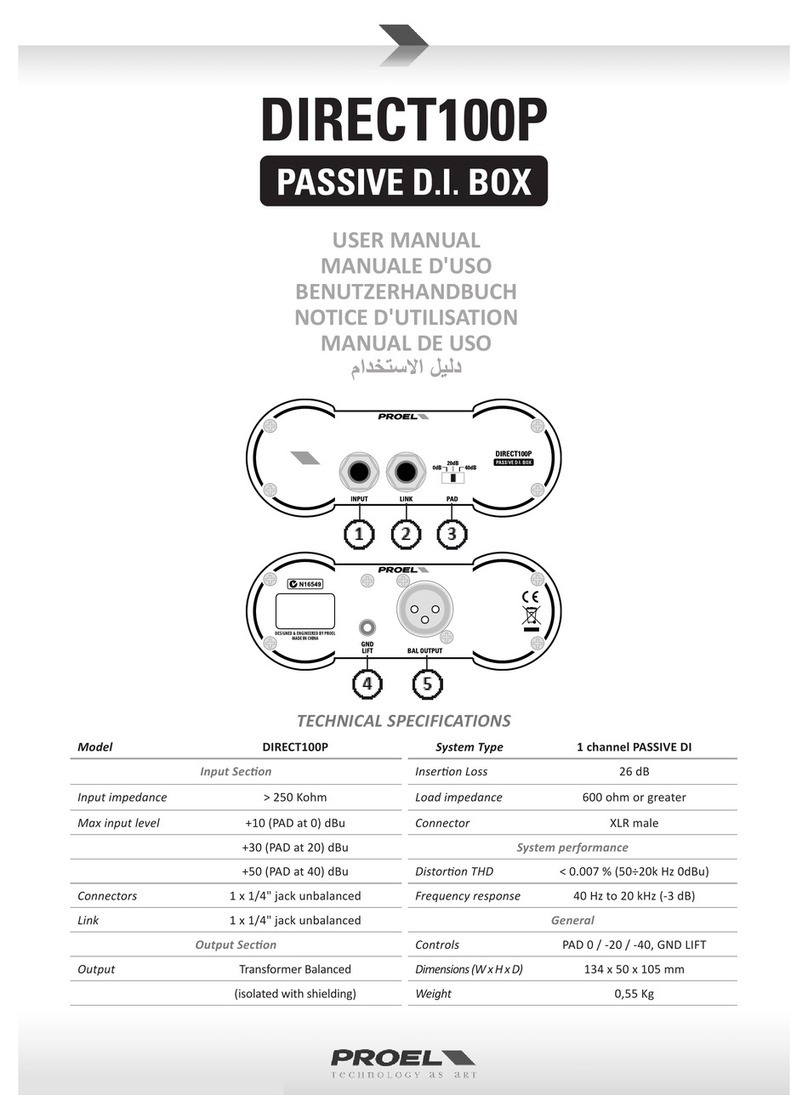

The DPSI RV Mini ESP versions (Extra Servo Power) correspond to

the DPSI RV Mini 5 and 6, but possess 3 additional connectors, which

carry the unregulated voltage of the batteries and therefore are

applicable for consumer loads with higher output voltage (e.g.

Tonegawa servos, smoke pumps, illumination, etc.).

DPSI RV Family Operating Instructions Version 2.0

Page 11 of 48

DPSI Version Receiver-

Channels Servo-

Connections Specialty

DPSI RV Mini 5 5 8* ---

DPSI RV Mini 6 6 7* ---

DPSI 2001 RV 10 26* 2 outputs for unreg.

battery voltage

DPSI RV 12 32 ---

DPSI Mini 5

ESP 5 8* 3 outputs for unreg.

battery voltage

DPSI Mini 6

ESP 6 7* 3 outputs for unreg.

battery voltage

* Connect additional servos directly to the receiver

3. The DPSI RV-Family in Headwords

Dual power supply with regulated supply voltage for receiver AND

servos

Output voltage adjustable in 4 steps from 5.0 volts to 5.9 volts

(5.9 volts for DPSI 2001 RV)

Compliant to all manufacturers RC receiver sets

Continuously constant servo power through constant supply

voltage

LiIon / LiPo cells usable

5-, 6-, and 7-cell NiCad / NiMH batteries usable

Electronically, failsafe on/off switch transmitter with additional

connectivity for external LED voltage displays

Short-circuit-proof servo pulse amplification in current saving

APP-Technology (Advanced Push Pull)

HFIB (High Frequency Interference Blocking) blocking of HF

interference caused by long servo cables (for each servo

individually)

DPSI RV Family Operating Instructions Version 2.0

Page 12 of 48

Loadable up to 60 amps peak (15 amps for DPSI RV Mini)

Up to 12 receiver channels including current distribution of up to

32 servos (depending on used system)

IVM (Intelligent Voltage Monitoring) – intelligent voltage

monitoring with acoustically and optically status indication for four

different battery types (programmable)

Reduced counter electro automotive force effect (CEAF) from

servos through usage of plenty filter capacitors

Cable free systems, i.e. all connections are pluggable and

therefore replaceable anytime (except DPSI 2001 RV)

Problem free operation of two receivers possible (DPSI 2001 and

DPSI RV)

Special grounding concept for undisturbed operation and most

safety

High grade plastic injection molding with integrated brackets for

the battery connectors and reverse voltage protection of the servo

connectors (except DPSI 2001 RV)

Large surface heat sink for deduction of lost heat

Each system 100% tested and provided individual serial number

Developed and manufactured by market leader (Made in

Germany)

DPSI Version Power Semiconductor Max. Power

Dissipation

DPSI RV Mini 5 6 8W *

DPSI RV Mini 6 6 8W *

DPSI 2001 RV 7 15W *

DPSI RV 10 15W *

DPSI Mini 5 ESP 6 8W *

DPSI Mini 6 ESP 6 8W *

* Higher power dissipation (higher maximum current) possible when using active

cooling (airflow) or larger heat sink (on request)

DPSI RV Family Operating Instructions Version 2.0

Page 13 of 48

3.1. HFIB (High Frequency Interference Blocking)

In order to increase safety, highly effective T-Filters are inserted in

DPSI RV systems for every single servo (e.g. 32 pieces for DPSI RV).

Although this is more expensive than simple filtering the receiver

channels – disturbances are eliminated directly at the servo connector

and therefore do not run through the whole printed circuit board. These

filters reduce HF disturbances by up to 90% which can be “caught” by

long servo cables. Rings of ferrite, which were used until now, can be

omitted, which saves cost and weight.

Radio interference suppression of the DPSI RV is considerable more

effective than radio interference suppression by ferrite rings. Naturally,

error free operation of digital servos is possible with these deployed

filters, too.

3.2. APP (Advanced Push Pull Servo Pulse Amplification)

Each servo is provided with optimally prepared amplified pulses from

the receiver. Servo signals usually are weakened if servo cables are

connected in parallel (V-cable), which makes them interference prone.

The servo pulses stay fully maintained in DPSI RV systems, even if

four servos are connected on one channel. Short circuit proof ness to

the negative and positive lines is a specialty of the pulse amplification.

If a mistake happens during wiring, which short cuts the pulse wire of a

servo to negative or positive, the amplifiers are not destroyed and all

other servos even on the same channel continue their operation

problem free. An additional advantage is the current saving APP-

Technology. The amplifiers are based on Push Pull output stages,

which drive the low- as well as the high-phase of the servo pulse.

Herewith, the high switching current is not applicable like in

conventional open collector end stages, where the low phase of the

servo pulse is generated via a resistor as a “short cut current”.

DPSI RV Family Operating Instructions Version 2.0

Page 14 of 48

3.3. IVM (Intelligent Voltage Monitoring)

An internal 8-bit microcontroller monitors all voltages by using an

intelligent algorithm and shows various faults (overload, low voltage,

voltage faults) acoustically by means of a built-in piezo buzzer.

Furthermore, errors are displayed through blink codes of the LED in

the switch transmitter.

3.4. Safety Features of the DPSI RV Systems

Short circuits on the servo signal wires, regardless of whether they are

toward the positive or negative wire of the servo cable, do not result in

damage to the DPSI RV. All other servos of the channel in which the

short circuit occurs remain fully functional. Even if the servo’s polarity is

reversed, the DPSI RV is not damaged.

A servo cable that is accidentally short-circuited will generally burn out

or melt, without damaging the DPSI RV. The heat sink of the DPSI RV

naturally becomes very hot when this type of short circuit occurs!

The decoupling of the two batteries as well as the electronic switches

is completely separate (including peripheral electronics) and therefore

carried out twice. No double diodes are used (two diodes in one

housing). Thus, the failure of one component can never lead to the

failure of the entire system. The switching mechanism has already

proven to be outstanding in several thousand systems.

The DPSI RV does not need to be separated from the batteries during

long breaks (e.g. in winter), since the self-discharging of the batteries is

considerably greater than the quiescent current consumption of the

DPSI RV, which is virtually immeasurable.

To enable optical switch-on control, an ultra-bright light-emitting diode

was installed into the switch transmitter of the DPSI RV. This signals

that the system is turned on, even at great distances and indicates

through blinking low voltage of the battery / batteries.

DPSI RV Family Operating Instructions Version 2.0

Page 15 of 48

All commercial remote control systems (Graupner JR, Multiplex,

Futaba) were successfully tested in all types of modulation (PCM,

SPCM, PCM1024, PPM, IPD) in connection with the DPSI RV. Thus,

all systems can be used trouble-free.

The DPSI 2001 RV as well as the DPSI RV offers the option of

connecting a second receiver. Both receivers should be of identical

type (the type of modulation must always be the same). We

recommend the DPSI TWIN for complete redundancy of the receiver

set.

Due to the elaborated safety properties in connection with extensive

tests, operating errors and external influences usually do not lead to

damage of the DPSI RV.

DPSI RV Family Operating Instructions Version 2.0

Page 16 of 48

4. Packing Contents

Shipment of DPSI RV Mini 5 (6) (ESP):

“DPSI RV Mini 5 (6)“ base device

On/Off switch transmitter

5 (6) pieces of receiver connection cable (including servo

connectors at both ends => patch cable)

2 pieces MPX high current sockets for the batteries

4 pieces shrink hose for the MPX high current sockets

Operating instructions

EMCOTEC sticker

Shipment of DPSI 2001 RV:

“DPSI 2001 RV“ base device

On/Off switch transmitter

2 pieces MPX high current plugs for the DPSI 2001 RV

2 pieces MPX high current sockets for the batteries

8 pieces shrink hose for the MPX high current connectors

Operating instructions

EMCOTEC sticker

Shipment of DPSI RV:

“DPSI RV” base device

On/Off switch transmitter

12 pieces receiver connection cable (including servo

connectors at both ends => patch cable)

2 pieces MPX high current sockets for the batteries

4 pieces shrink hose for the MPX high current sockets

Operating instructions

EMCOTEC sticker

Each DPSI RV system carries its own serial number and for each

function, it is tested several times before delivery.

DPSI RV Family Operating Instructions Version 2.0

Page 17 of 48

5. Installation Instructions and Programming

5.1 Installing the DPSI RV

The simplest method of installation is to glue the receiver directly to the

DPSI RV using double-sided adhesive cellular rubber strips (5-10 mm

thick). The receiver can also be attached separately. In the case of

very high current (a large number of servos) and under combat

conditions, the upper side of the DPSI RV should always remain open

to allow for unobstructed dissipation of heat.

Receiver fastening with double-sided adhesive cellular rubber:

Hint:

The lower side of the DPSI RV where the heat sink resides, may not have

anything pasted on it and may not be covered up and should be at an interval of

at least 30mm (1.2”) from the nearest surface (fuselage floor or similar)! Good

ventilation is required (such as with air scoops or conducted cooling air),

especially if there are numerous servos.

DPSI RV Family Operating Instructions Version 2.0

Page 18 of 48

Since the DPSI (2001) RV is most often used in large models, it is

advisable to fasten the entire package with rubber bands on 4 sides,

oscillating freely in the fuselage (see photo).

The DPSI RV Mini versions were developed for smaller models, which

are narrower. Fastening onto 4 silicone hose pieces has proven to

work well in this case. Thus, the entire package is fastened to 4 “stilts”,

with vibration reduction, as shown in the photo. This method of

fastening is of course possible with the larger DPSI RV as well.

DPSI RV Family Operating Instructions Version 2.0

Page 19 of 48

Generally, you must always ensure that the fastening is as vibration-

free as possible and has sufficient air circulation. Reduction of vibration

is particularly important for the receiver, since it reacts far more

sensitively to mechanical vibrations than the DPSI RV.

5.2. Hole spacing for Fastening

DPSI RV Family Operating Instructions Version 2.0

Page 20 of 48

5.3. Connecting the Switch transmitter

With a mechanical switch, one risks a breakdown. There are intense

vibrations at the sidewall of the fuselage. Thus, malfunctions of

mechanical switches were observed many a time. In order to avoid

mechanical influences, electronically switches including self-holding

circuitries are used in DPSI RV systems. The receiver set is turned on

and off using a pin, which just delivers an on / off signal. Putting the pin

into the on-socket (red) turns the DPSI RV on. Putting the pin into the

off-socket (black) turns it off. The DPSI RV stays turned on, even if the

pin gets lost.

A DPSI RV can only be turned off, if the pin is put into the off-socket

(i.e. changing from red to black)! There may be not a pin in each

socket although this does not damage the DPSI RV. In this case, the

equipment would be turned off and the batteries would be discharged

slowly with 12 mA.

During operation, the contacting pin should always be left in the on-

socket!

In the case of a lost pin, you can help yourself by using a 2 mm (0.08”)

wire or screw, which is simply put into the corresponding socket.

The On/Off switch transmitter can be placed wherever desired (e.g. on

a fuselage sidewall). The connection cable with plug is plugged into the

respective multiple plug of the DPSI RV until it locks into place on

impact (see photo). In the event that replacement or removal is

necessary, the plug can be disengaged from the multiple plugs upward

by carefully pulling it out (take hold of the cable directly at the plug).

This manual suits for next models

5

Table of contents

Other Emcotec Recording Equipment manuals

Popular Recording Equipment manuals by other brands

Yamaha

Yamaha QY10 supplementary guide

Extron electronics

Extron electronics IPL T SF Series Setup guide

Pyle Pro

Pyle Pro PDSP850 owner's manual

National Instruments

National Instruments PXI-PCI 8330 Series user manual

Yamaha

Yamaha TG300 owner's manual

M-Audio

M-Audio Fast Track Pro 4 x 4 Mobile USB Audio/MIDI Interface with... user guide

esera automation

esera automation ESERA-Station 200 user guide

Dakota Digital

Dakota Digital BIM-01-2-HAL quick start guide

Keithley

Keithley 1973 instruction manual

Panasonic

Panasonic AJSPD850P - P2 DECK Menu information

Tascam

Tascam SD-20M owner's manual

Power Dynamics

Power Dynamics PDX20 instruction manual