EMD Millipore Pellicon XL User manual

PelliconPellicon

PelliconPellicon

Pellicon®®

®®

®XLXL

XLXL

XL

Pellicon XL Device

Operating Instructions

Pellicon XL Device

- 2 -

Operating Instructions

- 3 -

Please read all of the directions before you begin.

Pellicon XL devices are 100 % integrity tested.

A cerA cer

A cerA cer

A certificate of quality is included in evertificate of quality is included in ever

tificate of quality is included in evertificate of quality is included in ever

tificate of quality is included in every box.y box.

y box.y box.

y box.

The packaging contains a Pellicon XL device and anThe packaging contains a Pellicon XL device and an

The packaging contains a Pellicon XL device and anThe packaging contains a Pellicon XL device and an

The packaging contains a Pellicon XL device and an

Accessories Kit located in the section below the Pellicon XLAccessories Kit located in the section below the Pellicon XL

Accessories Kit located in the section below the Pellicon XLAccessories Kit located in the section below the Pellicon XL

Accessories Kit located in the section below the Pellicon XL

device. The components in the kit include:device. The components in the kit include:

device. The components in the kit include:device. The components in the kit include:

device. The components in the kit include:

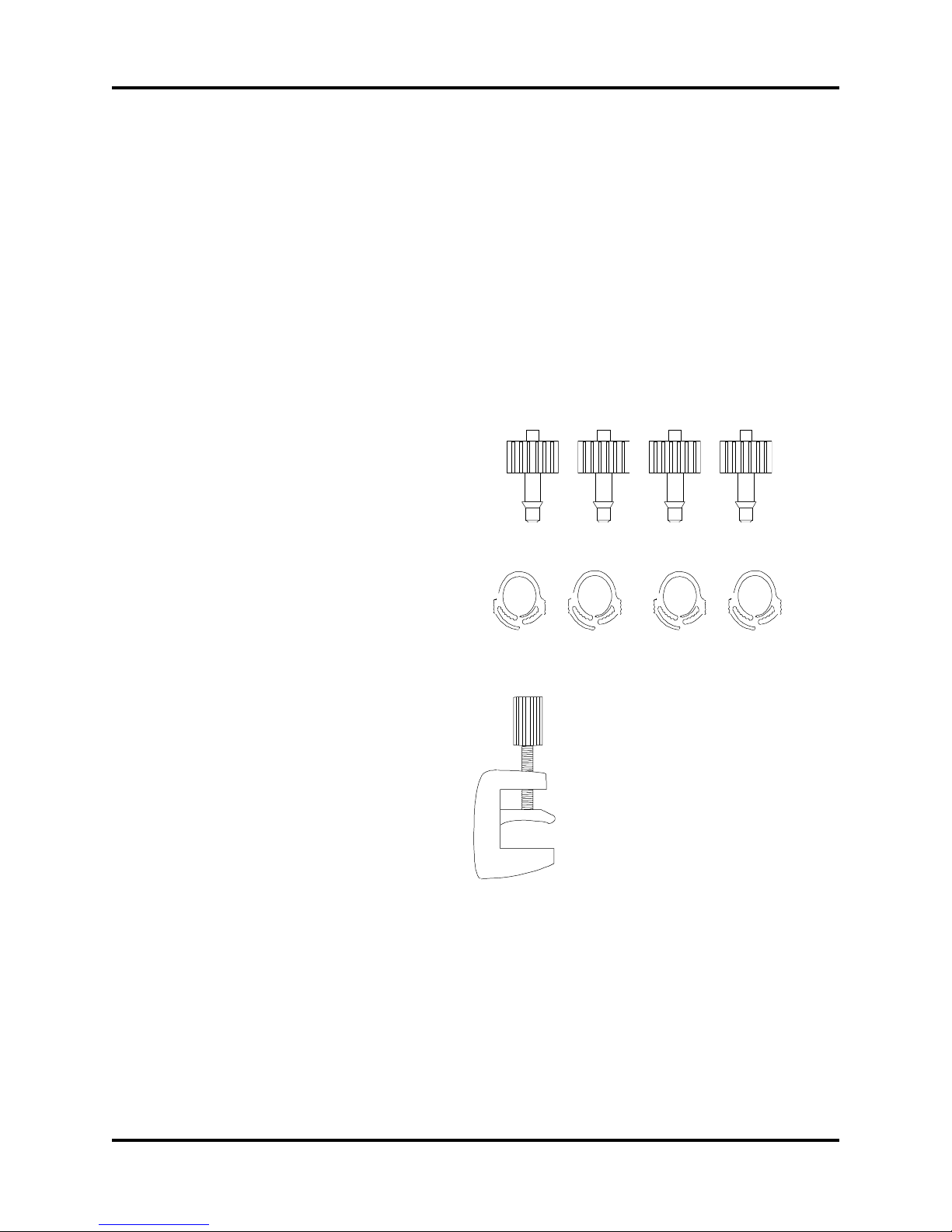

4 luer to barb fittings (Figure A)

4 tubing clamps (Figure B)

1 retentate clamp (Figure C)

4 ft of LFL Tygon®tubing

6mm (1/4”) OD 3mm (1/8”) ID

Pellicon XL Device

- 4 -

Equipment required but not provided:

Peristaltic pump drive, variable speed, 60-600 RPM (or

equivalent)

Pump head 480 mL/min at 600 RPM (or equivalent)

Suitable containers for feed, retentate and permeate

Optional equipment:

Ring stand with clamps or Pellicon XL stand

25 mL syringe

50 mL graduated cylinder

Stopwatch

Stir plate

Gauge kit

100 mL reservoir

Multimanifold

Scissors or tubing cutter

Operating Instructions

- 5 -

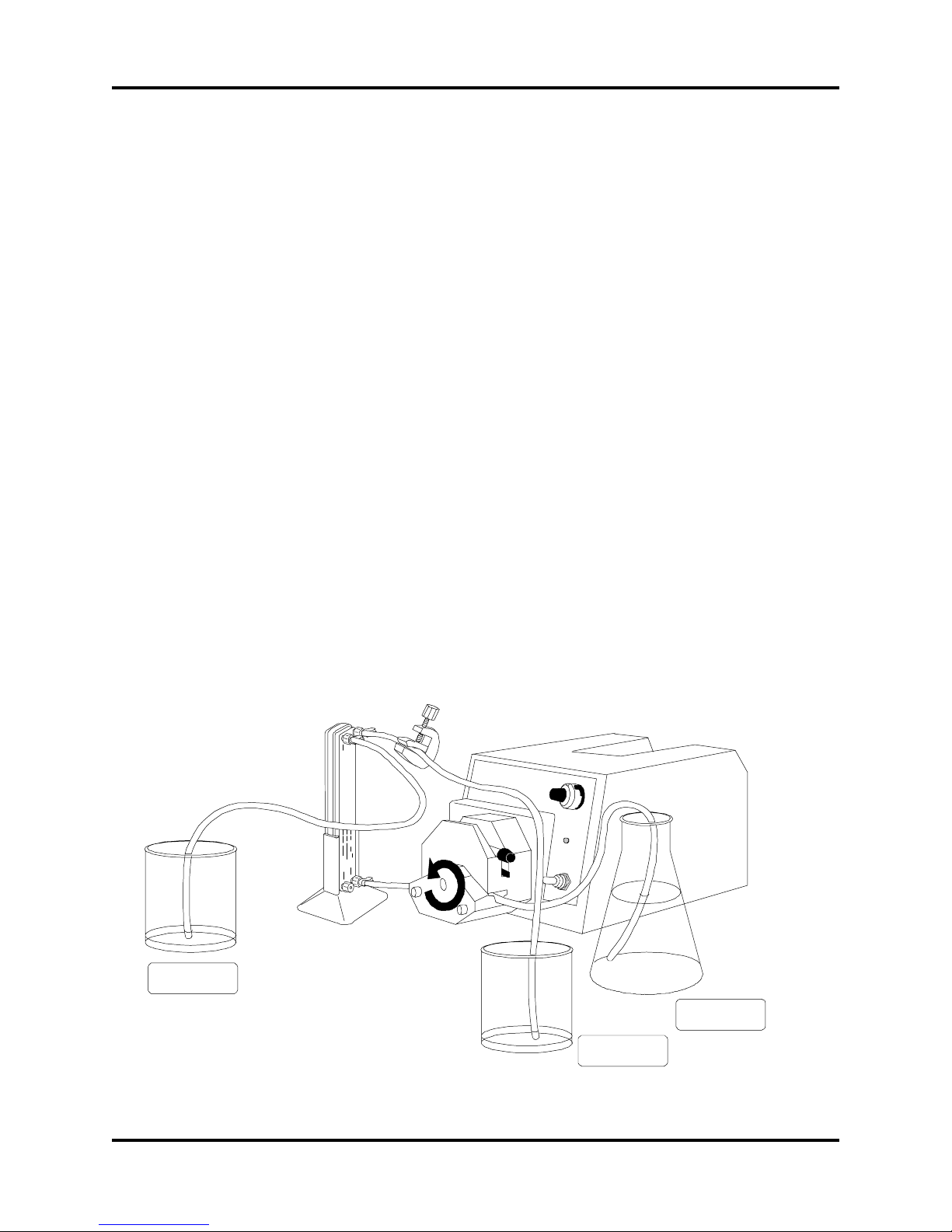

Section I. Set-up

1. Remove the Pellicon XL device from the plastic bag.

2. Cut three lengths of tubing, one for the retentate,

permeate and feed lines. The approximate length for

each piece of tubing for set-up and flushing as seen in

Figure 2 is 30 cm (12”) for the retentate and permeate

lines and 56 cm (22”) for the feed line.

Note:

To minimize hold-up volume shorten the tubing

lengths where possible.

3. Remove the luer caps (do not discard) from the Pellicon XL

device ports labeled perm 2, retentate and feed (Figure 1).

4. Secure a luer to barb fitting to the ports.

Perm 2

Retentate

Perm 1Feed

Figure 1: Device with Stand

Pellicon XL Device

- 6 -

5. Slip tubing clamps over the ends of the tubing.

6. Place the clamps over the barbs and secure the clamps.

7. Stabilize the Pellicon XL device. Place it in the stand

(Figure 1)—or a ring stand—to hold the device upright,

or lay it flat on the bench.

8. Place the retentate clamp on the retentate tubing

approximately 3.8 cm (1.5”) from the tubing clamp.

Secure but do not tighten the clamp.

9. Install the feed tubing into the pump head according to

the pump manufacturer’s directions.

10.Place the tubing ends into three separate containers.

(see Figure 2).

MILLIPORE

Pellicon XL

Permeate

Retentate

Feed

Figure 2: Setup

Operating Instructions

- 7 -

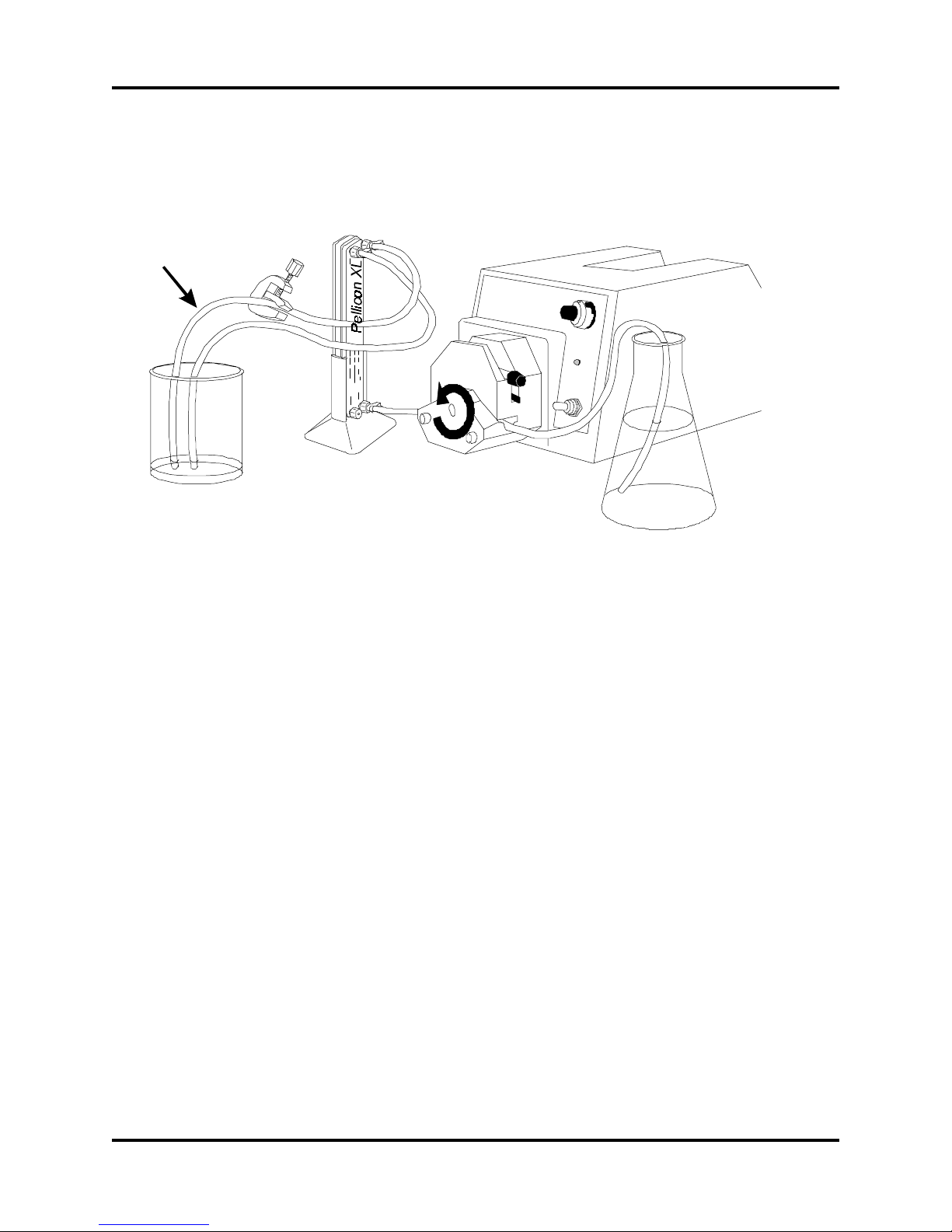

Section II: Flushing

The Pellicon XL device contains trace amounts of glycerine

and preservatives. To remove these trace amounts before

sample processing, follow the flushing procedure below

(Figure 3).

MILLIPORE

Permeate

Retentate

Feed

Pellicon XL

Figure 3: Flushing

Pellicon XL Device

- 8 -

1. Fill the feed container with 500 mL of purified water.

2. Turn on the pump. Set the retentate flow rate (crossflow)

to 30–50 mL/min. To measure the flow rate place the

end of the retentate tubing into a graduated cylinder

and collect water for 1 minute and measure volume

collected to obtain flow rate. Adjust pump speed if

necessary and measure again. Once the correct flow

rate is obtained, note the pump setting for future

reference.

3. Flush 150 mL through the retentate tubing.

4. Continue flushing until 300 mL are collected in the

permeate container. Add more feed liquid as required.

Permeate flow can be increased by tightening the

retentate clamp.

Note:

Do not restrict retentate flow completely.

5. Turn off the pump.

6. Empty all containers.

Operating Instructions

- 9 -

Section III: Integrity Testing (optional)

The following tools can be used for low-volume integrity

testing:

•mass flow meter

•inverted graduated cylinder

•rotameter

•liquid displacement in a graduated pipette

The procedure detailed below is for liquid displacement in a

graduated pipette.

Pipette Method

A clean air source with a pressure gauge is required for

integrity testing. Obtain test pressure to be used from

integrity testing section in the Certificate of Quality.

1. With the permeate ports open, connect a clean air

source to the feed port and blow across feedside of

membrane at 5 psi to remove as much liquid as possible

through the retentate port.

2. Turn off air source.

3. Place cap on retentate port and permeate 1 port.

4. Connect tubing to perm 2. Add approximately 0.1 mL

water to a 1 mL pipette.

Pellicon XL Device

- 10 -

5. Insert the pipette tip into the permeate tubing.

6. Turn on air source. Stabilize at test pressure (see

Certificate of Quality).

7. Measure air flow by timing displacement of liquid in the

pipette for 30 seconds and multiply by 2 to obtain an

air flow rate.

The Pellicon XL device is integral if the air flow is less than or

equal to the value in the Certificate of Quality.

Operating Instructions

- 11 -

Section IV: Preconditioning

1. Arrange clean containers and tubing as in Figure 4.

Figure 4: Preconditioning

2. Fill the feed container with 100–250 mL of an

appropriate buffer.

3. Turn on the pump which has been set at a crossflow

rate of 30–50 mL/min.

4. Pump approximately 30 mL of buffer through the

permeate tubing to remove residual water.

5. Turn off the pump. Remove the feed and retentate tubing

from the feed container

6. Empty the feed container.

7. Remove permeate tubing from the permeate port and

hold upright over the waste container to drain. Replace

permeate tubing.

MILLIPORE

Buffer

Waste

Feed

Pellicon XL

Pellicon XL Device

- 12 -

Section V: Sample Processing (concentration)

Mixing of the sample is recommended during processing. A

stir plate can be used.

1. Arrange clean containers and tubing connections as

in Figure 5.

2. Fill feed container with sample to be concentrated.

3. Turn on the pump which has been set at a crossflow

rate of 30–50 mL/min.

4. Filter the solution until the desired concentration or

volume is obtained. Permeate flow can be increased by

tightening the retentate clamp slightly.

Note:

Do not restrict retentate flow completely.

MILLIPORE

Sample

Permeate

Feed

Pellicon XL

Figure 5: Sample Processing

Operating Instructions

- 13 -

5. Turn the pump off. Remove the feed tubing from the feed

container.

6. Turn the pump on. Pump all the retentate and upstream

fluid into the feed container.

7. Turn the pump off. Remove the feed tubing from the

pump head.

Pellicon XL Device

- 14 -

Section VI: Product Recovery

To maximize product recovery follow the steps below.

Minimum working volume will vary depending upon tubing

length, container and pump setup. It is possible to get

15–20 mL final working volume.

1. Place the feed tubing in the feed container.

2. Remove the permeate tubing from the permeate port.

Replace with cap.

3. Remove the retentate tubing from the retentate port. Keep

the other end in the feed container.

4. Hold the end of the retentate tubing (with the tubing

clamp) higher than the feed container to allow sample to

drain out.

5. Fill a 25 mL syringe with 5 mL of permeate or buffer.

6. Attach the syringe to the retentate port.

7. Slowly push all the buffer or permeate into the Pellicon XL

device.

8. Disconnect the syringe.

9. Fill the syringe with air. Withdraw the syringe plunger to

the 10 mL mark.

Operating Instructions

- 15 -

10.Reconnect the syringe to the retentate port and push the

air into the Pellicon XL device.

11.Recover sample remaining in the feed tubing by

removing the tubing from the Pellicon XL device and

allow it to drain into the feed container.

Pellicon XL Device

- 16 -

Section VII: Cleaning

Recommended cleaning solutions (marked by X):

Do not exceed 30 psi inlet for cleaning cycle.

gninaelCgninaelC gninaelC gninaelCgninaelC

stnegAstnegA stnegA stnegAstnegA noitartnecnoCnoitartnecnoC noitartnecnoC noitartnecnoCnoitartnecnoC

eugolataCeugolataC eugolataC eugolataCeugolataC

srebmuNsrebmuN srebmuN srebmuNsrebmuN

xiferphtiwxiferphtiw xiferphtiw xiferphtiwxiferphtiw

BXPBXP BXP BXPBXP

xamoiBxamoiB xamoiB xamoiBxamoiB

MTMTMTMTMT

enarbmeMenarbmeM enarbmeM enarbmeMenarbmeM

-lusrehteylop(-lusrehteylop( -lusrehteylop( -lusrehteylop(-lusrehteylop(

)enohp)enohp )enohp )enohp)enohp

eugolataCeugolataC eugolataC eugolataCeugolataC

htiwsrebmuNhtiwsrebmuN htiwsrebmuN htiwsrebmuNhtiwsrebmuN

CXPxiferpCXPxiferp CXPxiferp CXPxiferpCXPxiferp

ecartlUecartlU ecartlU ecartlUecartlUll

l

ll

MTMTMTMTMT

PP

P

PPCLCLCLCLCL

enarbmeMenarbmeM enarbmeM enarbmeMenarbmeM

c(c(c(c(c(etisopmoetisopmo etisopmo etisopmoetisopmo

detarenegerdetareneger detareneger detarenegerdetareneger

)esolullec)esolullec )esolullec )esolullec)esolullec

eugolataCeugolataC eugolataC eugolataCeugolataC

htiwsrebmuNhtiwsrebmuN htiwsrebmuN htiwsrebmuNhtiwsrebmuN

,VXPxiferp,VXPxiferp ,VXPxiferp ,VXPxiferp,VXPxiferp

,HXP,GXP,HXP,GXP ,HXP,GXP ,HXP,GXP,HXP,GXP

DXPDXP DXP DXPDXP

eroparuDeroparuD eroparuD eroparuDeroparuD

®®

®

®®

enarbmeMenarbmeM enarbmeM enarbmeMenarbmeM

)FDVP()FDVP( )FDVP( )FDVP()FDVP(

pmeTpmeT pmeT pmeTpmeT

CºCºCºCºCºHpHpHpHpHp

emiTemiT emiT emiTemiT

)nim()nim( )nim( )nim()nim(

HOaNHOaN HOaN HOaNHOaNN5.0-1.0X 54-047.31-3106-03

HOaNHOaN HOaN HOaNHOaNN1.0X04-523106-03

LCOaNLCOaN LCOaN LCOaNLCOaNmpp052X X54-0411-0106-03

notirTnotirT notirT notirTnotirT

®®

®

®®

001X-001X- 001X- 001X-001X-%01.0XXX54-048-506-03

SDSSDS SDS SDSSDS%01.0XXX54-048-506-03

neewTneewT neewT neewTneewT

®®

®

®®

0808080808%01.0XXX54-048-506-03

emyz-a-greTemyz-a-greT emyz-a-greT emyz-a-greTemyz-a-greT

®®

®

®®

tnegreteDtnegreteD tnegreteD tnegreteDtnegreteD %02.0XXX54-0401-906-03

Operating Instructions

- 17 -

Arrange clean containers and tubing connections as

in Figure 6.

MILLIPORE

Retentate

Figure 6: Cleaning

1. Loosen retentate clamp.

2. Fill the feed container with 500 mL of cleaning solution.

3. Set the pump control to the same pump setting used in

the flushing step (30–50 mL/min)

4. Turn the pump on and collect 250 mL of cleaning

solution in the waste container.

5. Turn the pump off. Place the retentate tubing in the feed

container.

6. Turn the pump on. Slightly tighten the retentate tubing

clamp to increase permeate flow rate.

Pellicon XL Device

- 18 -

Note:

Do not restrict retentate flow completely.

7. Recirculate the cleaning solution for 30–60 minutes.

8. Turn the pump off and discard the cleaning solution.

Flushing:

Repeat flushing procedure detailed in Section II.

Operating Instructions

- 19 -

Section VIII: Storage

Recommended storage solutions:

Pump storage solution through the device or follow the steps

below.

1. Remove the retentate tubing from the device.

2. Remove the feed tubing from the pump head.

3. Fill a syringe with 10 mL of storage solution.

noitulosegarotSnoitulosegarotS noitulosegarotS noitulosegarotSnoitulosegarotSnoitartnecnoCnoitartnecnoC noitartnecnoC noitartnecnoCnoitartnecnoC

eugolataCeugolataC eugolataC eugolataCeugolataC

htiwsrebmuNhtiwsrebmuN htiwsrebmuN htiwsrebmuNhtiwsrebmuN

BXPxiferpBXPxiferp BXPxiferp BXPxiferpBXPxiferp

xamoiBxamoiB xamoiB xamoiBxamoiB

enarbmeMenarbmeM enarbmeM enarbmeMenarbmeM

-rehteylop(-rehteylop( -rehteylop( -rehteylop(-rehteylop(

)enohplus)enohplus )enohplus )enohplus)enohplus

eugolataCeugolataC eugolataC eugolataCeugolataC

htiwsrebmuNhtiwsrebmuN htiwsrebmuN htiwsrebmuNhtiwsrebmuN

CXPxiferpCXPxiferp CXPxiferp CXPxiferpCXPxiferp

lecartlUlecartlU lecartlU lecartlUlecartlUPP

P

PPCLCLCLCLCL

enarbmeMenarbmeM enarbmeM enarbmeMenarbmeM

etisopmoc(etisopmoc( etisopmoc( etisopmoc(etisopmoc(

detarenegerdetareneger detareneger detarenegerdetareneger

)esolullec)esolullec )esolullec )esolullec)esolullec

eugolataCeugolataC eugolataC eugolataCeugolataC

htiwsrebmuNhtiwsrebmuN htiwsrebmuN htiwsrebmuNhtiwsrebmuN

,GXP,VXPxiferp,GXP,VXPxiferp ,GXP,VXPxiferp ,GXP,VXPxiferp,GXP,VXPxiferp

DXP,HXPDXP,HXP DXP,HXP DXP,HXPDXP,HXP

eroparuDeroparuD eroparuD eroparuDeroparuD

enarbmeMenarbmeM enarbmeM enarbmeMenarbmeM

)FDVP()FDVP( )FDVP( )FDVP()FDVP(

HOaNHOaN HOaN HOaNHOaNN1.0X

HOaNHOaN HOaN HOaNHOaNN50.0X

losyLlosyL losyL losyLlosyL

®®

®

®®

)KAB()KAB( )KAB( )KAB()KAB(%1.0XXX

edizAmuidoSedizAmuidoS edizAmuidoS edizAmuidoSedizAmuidoS%50.0XXX

HH

H

HH

33

3

33

OPOPOPOPOP

44

4

44

N1.0XXX

Pellicon XL Device

- 20 -

4. Attach the syringe to the retentate port and slowly push

the solution into the device.

5. Disconnect the syringe and all tubing. Replace the caps

on the ports.

Store flat at 4–25 ºC.

Note:

After prolonged exposure to water, the tubing may

absorb a small volume of water. As a result, tubing color

may change from clear to opaque, which is normal. Air

or oven drying will return the color to clear.

Table of contents

Popular Laboratory Equipment manuals by other brands

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Evoqua

Evoqua WALLACE & TIERNAN BARRIER M Series operating manual

Integra

Integra VIAFLO 96 6000 quick start guide

Specac

Specac ARROW Quick start manual

NanoEnTek

NanoEnTek ADAM MC2 instruction manual

Sartorius

Sartorius PICUS user manual