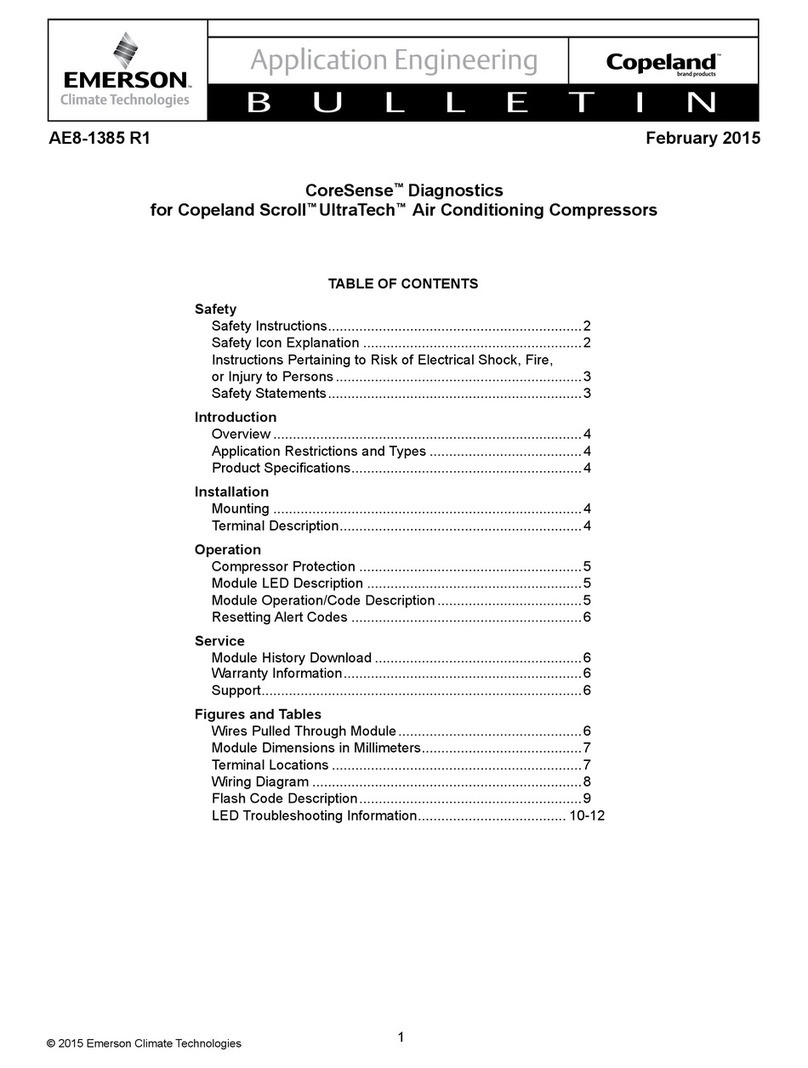

About these guidelines ...............................................................................................1

1Safety instructions...........................................................................................1

1.1 Icon explanation............................................................................................................... 1

1.2 Safety statements ............................................................................................................ 1

1.3 General instructions......................................................................................................... 2

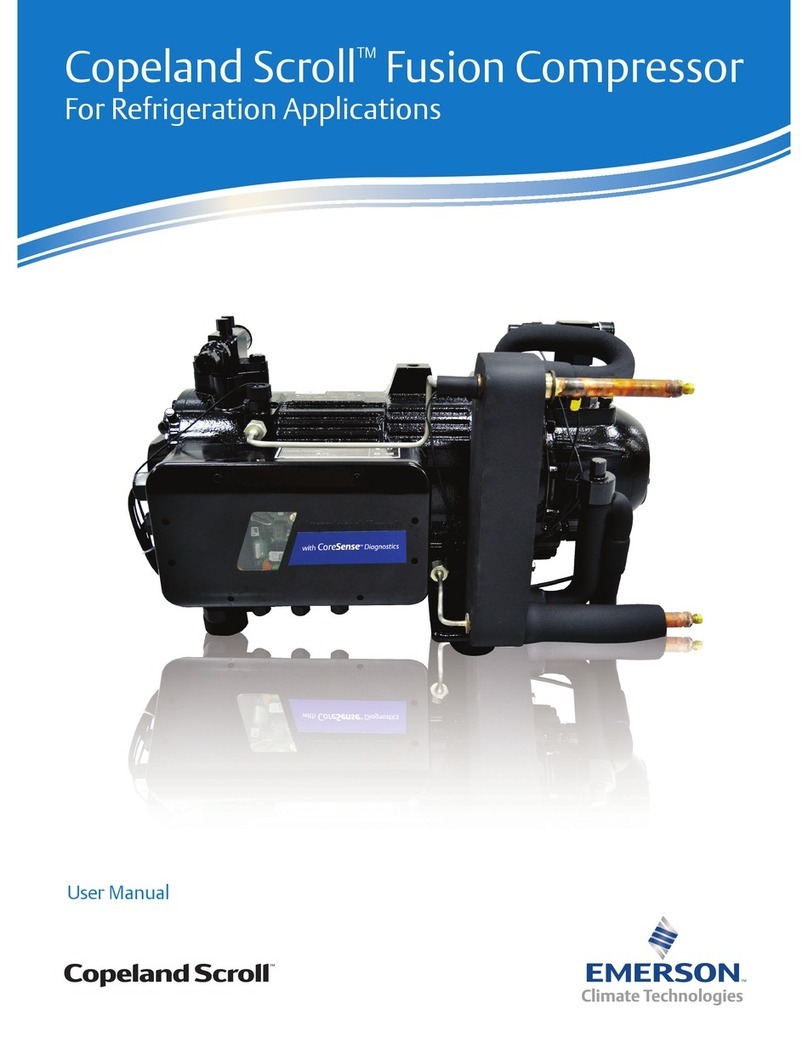

2Product description .........................................................................................3

2.1 Common information about Copeland Scroll Digital™ compressors............................... 3

2.2 Nomenclature................................................................................................................... 3

2.3 BOM Variation.................................................................................................................. 3

2.4 Dimensions ...................................................................................................................... 4

2.5 Application range ............................................................................................................. 6

2.5.1 Qualified refrigerants and oils .............................................................................. 6

2.5.2 Application limits and operating envelopes.......................................................... 6

3Installation........................................................................................................7

3.1 Compressor handling....................................................................................................... 7

3.1.1 Transport and storage.......................................................................................... 7

3.1.2 Positioning and securing...................................................................................... 7

3.1.3 Installation location............................................................................................... 7

3.1.4 Mounting parts...................................................................................................... 8

3.2 Solenoid valves for models ZRD*KRE compressors....................................................... 8

3.2.1 Solenoid valve installation –General recommendations..................................... 9

3.2.2 Solenoid valve installation –Tubing recommendations....................................... 9

3.3 Discharge check valve................................................................................................... 10

3.4 Brazing procedure.......................................................................................................... 10

3.5 Shut-off valves and adaptors......................................................................................... 11

3.6 Oil separator .................................................................................................................. 12

3.7 Accumulators ................................................................................................................. 12

3.8 Screens.......................................................................................................................... 12

3.9 Mufflers .......................................................................................................................... 12

3.10 Suction line noise and vibration..................................................................................... 13

4Electrical connection .....................................................................................14

4.1 General recommendations............................................................................................. 14

4.2 Electrical installation ...................................................................................................... 14

4.2.1 Terminal box....................................................................................................... 16

4.2.2 Motor winding..................................................................................................... 16

4.2.3 Motor protection ................................................................................................. 17

4.2.4 Protection devices.............................................................................................. 17

4.2.5 Crankcase heaters ............................................................................................. 17

4.3 Pressure safety controls ................................................................................................ 17

4.3.1 IPR valve (Internal Pressure Relief valve) ......................................................... 17