i2P-100 Transducer

Instruction Manual

Form 5777

September 2004

8

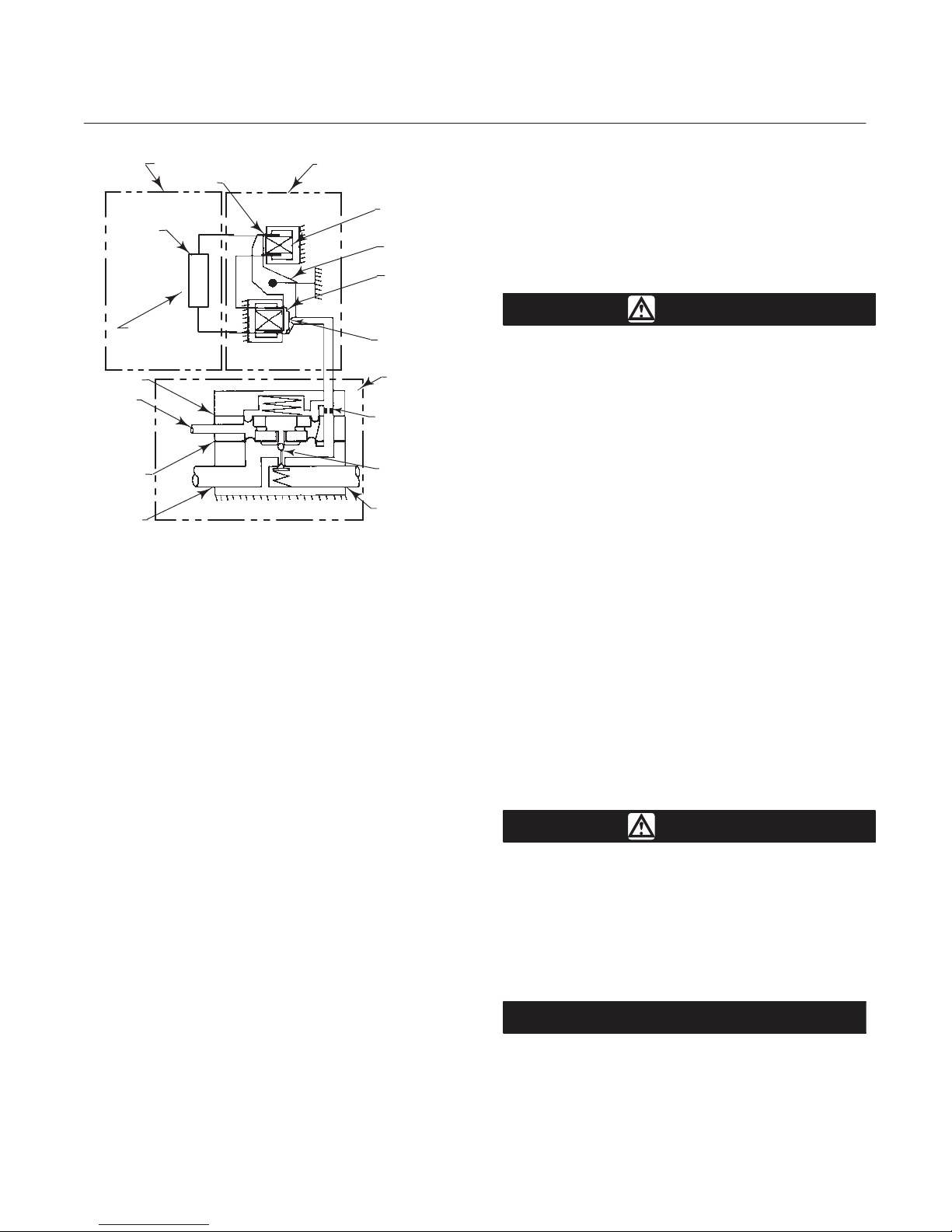

Vent

WARNING

This unit vents the supply medium into

the surrounding atmosphere. When

installing this unit in a non-hazardous

location with natural gas as the supply

medium, you must remotely vent this

unit to a safe location. Failure to do so

could result in personal injury or

property damage from fire or

explosion, and area re-classification.

When installing this unit in a

hazardous location remote venting of

the unit may be required, depending

upon the area classification, and as

specified by the requirements of local,

regional, and federal codes, rules and

regulations. Failure to do so when

necessary could result in personal

injury or property damage from fire or

explosion, and area re-classification.

Vent line piping should comply with

local and regional codes and should

be as short as possible with adequate

inside diameter and few bends to

reduce case pressure buildup.

If a remote vent is required, the vent line must be as

short as possible with a minimum number of bends

and elbows. To connect a remote vent, remove the

plastic vent (key 71, figure 13). The vent connection

is 0.25 inch NPT female. Use 0.375 inch tubing to

provide a remote vent.

Electrical Connections

WARNING

For explosion-proof applications, or

when using natural gas as the supply

medium, disconnect power before

removing the housing cap. Personal

injury or property damage from fire or

explosion may result if power is not

disconnected before removing the cap.

For intrinsically safe installations, refer

to the nameplate or to instructions

provided by the barrier manufacturer,

for proper wiring and installation.

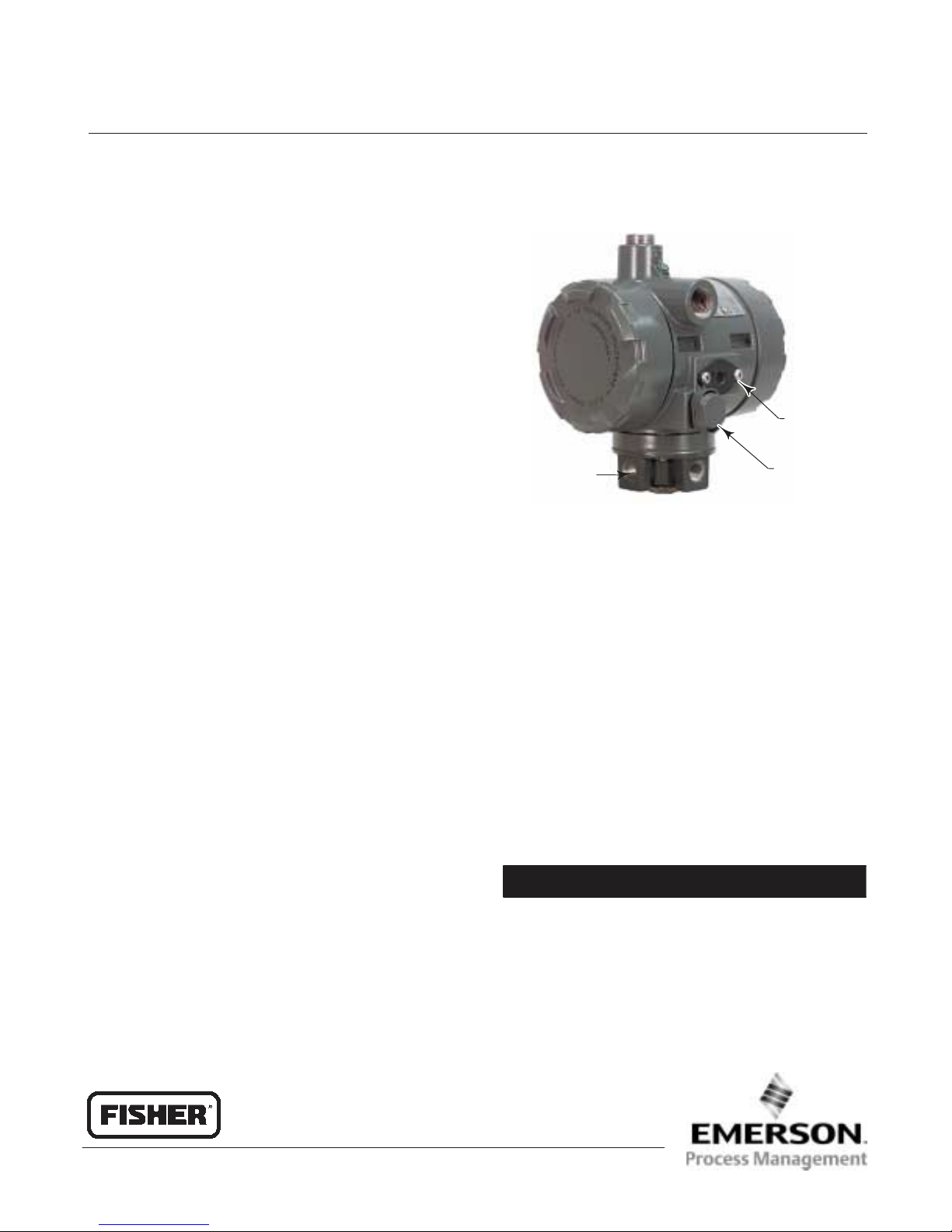

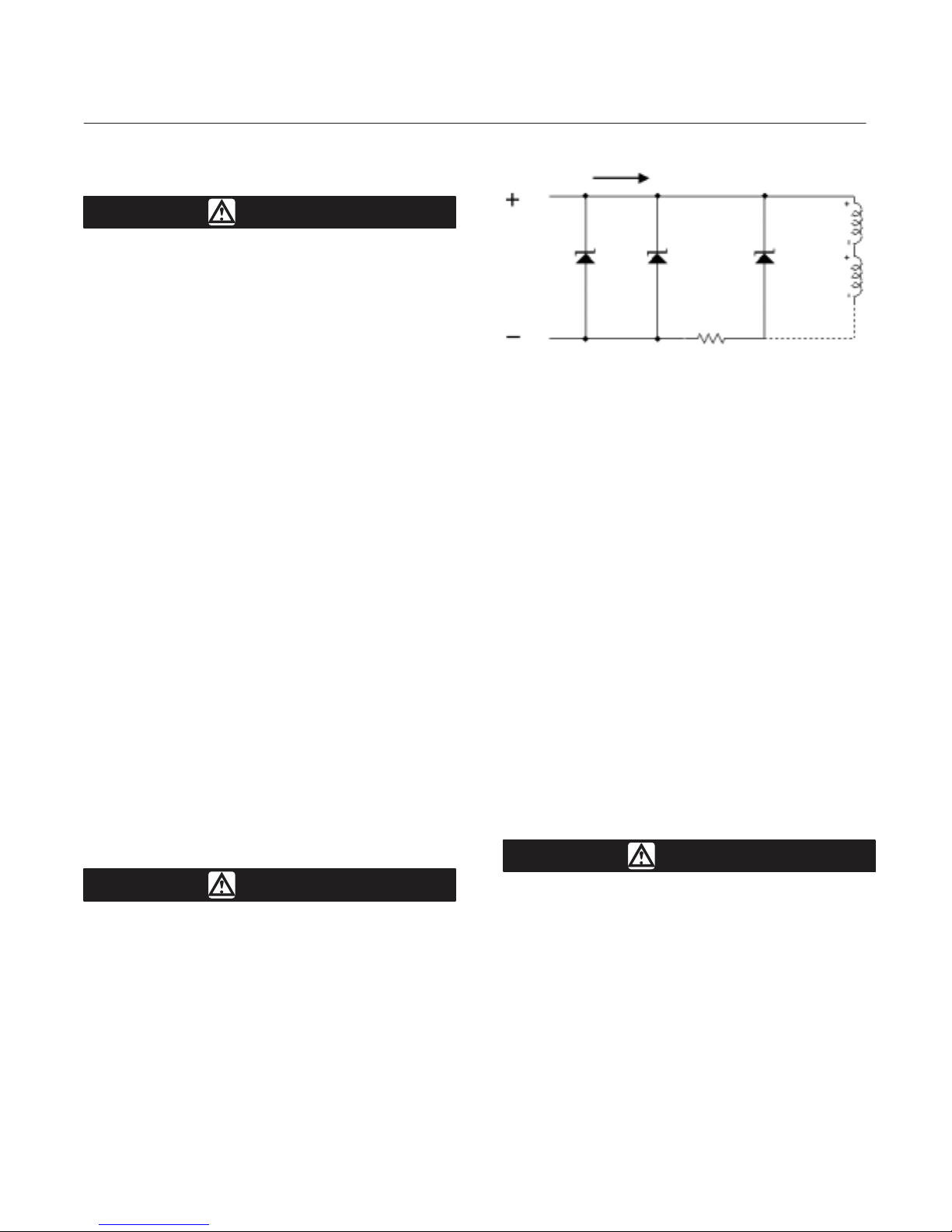

4 - 20 mA

6.8V 6.8V 4V

40 Ohm

Figure 9. Equivalent Circuit

Use the 0.5 inch NPT conduit connection, shown in

figure 5, for installation of field wiring.

Refer to figures 8, 9, and 10 when connecting field

wiring from the control device to the transducer.

Connect the positive wire from the control device to

the transducer ‘‘+’’ terminal and, the negative wire

from the control device to the transducer ‘‘-’’

terminal. Do not overtighten the terminal screws.

Maximum torque is 0.45 NSm (4 lbfSin.). Connect the

transducer grounding terminal to earth ground.

Grounding terminals are provided both inside and

outside the transducer housing.

Operating Information

The normal mode of operation for Type i2P-100

transducer requires that the pneumatic output

pressure be piped to the final control element. If this

is not done the resulting pneumatic output will vent

to the atmosphere.

Calibration

WARNING

On explosion-proof instruments, or

when using natural gas as the supply

medium, remove electrical power

before removing either of the the

housing caps in a hazardous area.

Personal injury or property damage

may result from fire or explosion if

power is applied to the transducer with

the cap removed in a hazardous area.

For intrinsically safe areas, current

monitoring during operation must be

with a meter approved for use in

hazardous areas.