Equipment You May Need:

We are delighted that you have chosen the InSinkErator®

Instant Hot Water Dispenser to be a part of your home. This unique

appliance will save you time and effort in the kitchen, and you’ll enjoy

discovering new uses for it each day. That’s exactly why millions of people

are now using an InSinkErator Instant Hot Water Dispenser.

We are confident that by following our step-by-step instructions, you’ll

soon be enjoying the convenience of instant hot water.

nnFor your satisfaction and safety, read all instructions, cautions, warnings and dangers before installing

or using this instant hot water dispenser.

nnThis particular unit is not intended for commercial use.

nnMake sure that all electrical wiring and connections conform to local codes.

nnA standard 120-volt grounded electrical outlet is required under the sink for the dispenser’s electrical power.

nnThe wall outlet powering your dispenser must have power supplied to it continuously.

nnThis outlet must be fused and should not be controlled by the same wall switch that operates the

disposer, unless you have a SinkTop Switch™from InSinkErator®.

nnIf you suspect elevated levels of chlorine in your water, it is recommended to use our water

filtration system.

nnThe use of a water filter should NOT result in the water pressure to drop below 30 psi (207kPa).

If it does, this will prevent your unit from operating properly.

nnMoving parts inside the tank causing a rattling noise is normal.

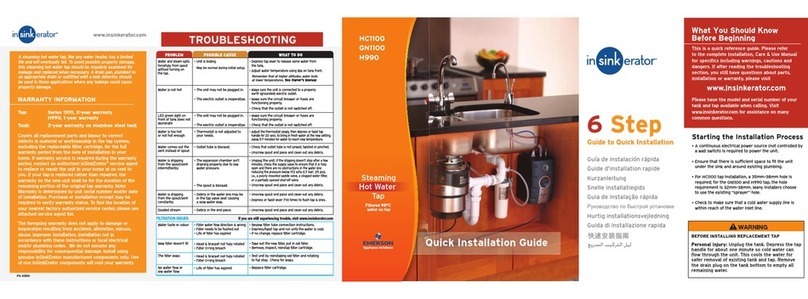

WHAT YOU SHOULD KNOW BEFORE YOU BEGIN

Equipment Required:

n Drill

n Compression fitting,

T-fitting or saddle valve

n Adjustable wrench

n Phillips and flat blade screwdrivers

n Pencil

n Tape Measure

n Level

nnAnchors for drywall

nnHole saw

nnBasin wrench

nnHole punch

If you intend to use the sprayer hole in your sink for your dispenser, you may need a basin wrench and a

1/8" plug or a 1/4" cap (not supplied) for the faucet spray hose line. See Step 1-B.

If you need to cut a mounting hole in your stainless steel sink, you may need a 11

⁄4" - 11

⁄2" hole saw made

for cutting stainless steel or a hole punch. Consult a professional if you are drilling into a surface other

than stainless steel.

WHAT YOU NEED TO GET STARTED

2

In-Sink-Erator Internet Dealer

www.NeedPlumbingSupplies.com 800-728-8890

In-Sink-Erator www.NeedPlumbingSupplies.com 800-728-8890