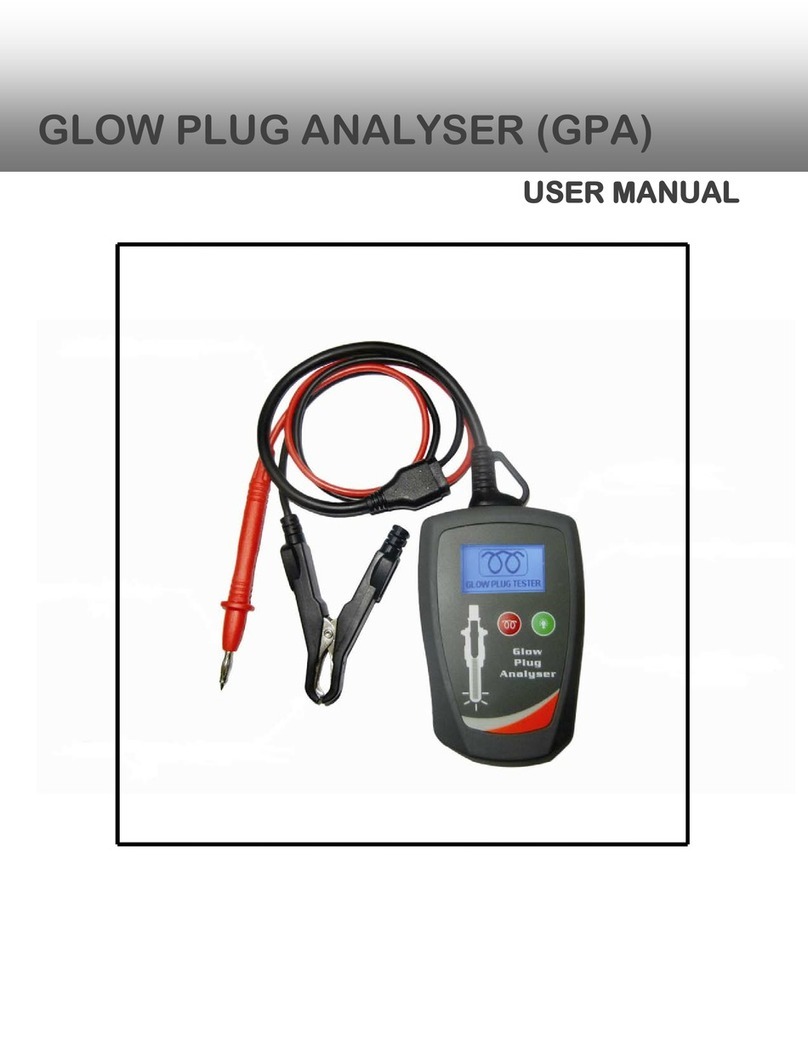

AETOOL BESA 11 User manual

Battery Electrical System

Analyser BESA 11

For testing all 12V automotive starting

batteries rated in CCA, DIN, IEC, JIS# and

EN. Also for testing vehicle Electrical

System.

Quick Start Guide

Product Specification:

Operating Voltage: 9V ~ 15V DC (max)

Analysing Capacity:CCA: 100 ~ 1700

IEC: 100 ~ 1700

JIS#: 100 ~ 1700

EN: 100 ~ 1000

DIN: 100 ~ 1000

Battery analysing time: Less than 5 seconds

1. BATTERY TEST

1.1 Connect the tester clamps to the

battery posts, red to the positive (+)

terminal and black to the negative (-)

terminal. Rock each clamp back and

forth for better contact.

1.2 Once the display lighted up, it will

prompt you with instructions to

proceed with the test. Follow the

instructions and if it ask you to select

the rating system: CCA, DIN, EN,

JIS#, IEC; select the one according

to the battery rating. If you cannot

find its rating then select Unknown.

1.3 It will run through a self-test and

when completed it displays the Main

Menu as shown below:

New: Clear Memory

•Clear the last tested results stored

in its memory

Continue Test…

•Continue the last test on the same

car from where you had stopped.

Last Test Result

•Review the test results of the last

tested car.

1.4 After you have made your choice,

selecting “New: Clear Memory” or

“Continue Test…” press ENTER will

proceed to the display below:

1.5 Pressing ENTER will proceed to

Battery Test as shown below.

BATTERY

ELECTRICAL

SYSTEM ANALYSER

BESA 11

New: Clear Memory

Last Test Result

Select Test

Continue Test . . .

Grounding Test

Starter Test

Alternator Test

Battery Test . . .

If the battery is rated in JIS#, EN, DIN

and EIC refer to the conversion list

provided to convert to CCA rating before

keying into the Analyser. If either is not

available on the battery label, select

Unknown.

1.6 Once you had the system rating in

mind, press ENTER key and the

display will show:

Key in the battery rating values using

the LEFT or RIGHT arrow key for

increase or decreases the values by

step of 100 units. For double digits

increase or decrease, use the UP or

DOWN key by step of 5 units each

press.

1.7 Once the CCA rating of the battery is

confirmed, press ENTER key will

start the testing process and will

display the result in less than 5 sec.

RESULTS: Good

•‘Good’ indicates the battery in good

condition. ‘Replace’ indicates that

the battery needs to be replaced.

Voltage: 12.46V

•This indicates the tested battery

voltage (12.46V). It depends on the

stage of charge on the battery:

CCA (Cold Cranking Amps): 406 CCA

•CCA rating is being used here. If

other rating (DIN or JIS# or EN or

IEC) then it will base on the

selected respective rating to

calculate the results.

Int. R (Internal Resistance): 6.72mΩ

•Internal resistance should fall

between 2.0mΩ ~ 15.0mΩ for

normal condition.

LIFE: 50%

•Indicates the battery life expectancy in

percentage. If the reading is greater

than 45%, RESULT will display Good.

It the reading is less than 45%,

RESULT display Replace.

ROUGH CCA GUIDE

Given below is a rough CCA ratings guide for

any unknown battery model basing on the

capacity of the vehicle:

100% Full Charge

13.20V

90% Charge

12.90V

75% Charge

12.45V

Vehicle

Capacity

Approximate Battery CCA

Rating

1200 ~ 1600 cc

350 CCA

1600 ~ 2000 cc

500 CCA

2000 ~ 3000 cc

650 CCA

3000 cc and

above

750 CCA

M. Benz over

3000 cc

760 CCA

EIC

EN

JIS#

DIN Unknown

Select Rating

CCA

CCA

to start

Input Value

500

Enter

Good

12.46 V 406 CCA

Int. R: 6.72 mΩ

Life: 50%

RESULTS

2. GROUNDING TEST

2.1 Make sure that the engine is

switched OFF. Attach the Analyser

clips onto the battery terminal posts

[Red to (+) and Black to (-)] the unit

will power up and momentarily

display LCD screen as shown below.

2.2 It will run through a self-test and

when completed it displays the Main

Menu as shown below:

2.3 Pressing DOWN key once will scroll

down to the “Grounding Test”

2.4 Pressing ENTER key will proceed to

the display as follows.

2.5 Press ENTER key again, it will start

analysing.

2.6 Once it has finished analysing, it will

prompt you with an instruction stating

that you should unclamp the black

battery clip from the battery negative

terminal and clamp it to the engine

body within 15 seconds time limit.

NOTE: 15 seconds is given to establish

the contact to the engine body failing

which the data obtained earlier will be

lost. Then you need to repeat the whole

testing procedures again.

2.7 Once the Black clip is clamped onto

the engine body it will start analysing.

New: Clear Memory

Last Test Result

Battery Test

Starter Test

Alternator Test

Grounding Test

Press to

Start

Grounding Test:

Enter

Analysing . . .

Please Wait!

▌▌▌▌▌▌▌▌

BATTERY

ELECTRICAL

SYSTEM ANALYSER

BESA 11

Select Test

Continue Test . . .

To clamp

Black clip to

Engine body,

then press

15 sec

Enter

Analysing . . .

Please Wait!

▌▌▌▌▌▌▌▌

2.8 If the measured resistance reading is

within limits, then it will display as

follows:

2.9 If the measured resistance reading

has gone beyond the limits, then it

will display the screen as follows:

Note: The above indicates that the ground

contact from the engine body to the battery

is bad. Check for rusted or corroded point

of contacts. If found, dismantle it for cleaning

or replace before fixing back. Repeat the test

again after fixing

2.10 If you did not follow the right

procedures during the testing, it will

display the results as follows:

2.11 To exit the program, pressing the

EXIT key at any moment will exit and

return back to he main menu screen

3. STARTER TEST

Note:Before performing this test, make sure

that the battery is fully charged and in good

condition.

3.1 With engine OFF, place the vehicle

transmission in NEUTRAL for Manual

and PARK for Automatic then apply

the parking brake.

3.2 Connect the Analyser clips onto the

battery terminal posts and it will

power up and lights up the LCD

display screen as shown:

3.3 After you have made your choice,

selecting “New: Clear Memory” or

“Continue…Test” will proceed to the

main MENU, select “Starter Test” by

scrolling down:

3.4 Press ENTER key to continue and

the display will show as follows:

OK

The measured

Resistance value

is within limits

12.65V

Crank engine now

Until it starts.

Then press Enter

Voltage

RESULTS:

High Resistance!

Clean contacts

and check cables

RESULTS:

Not detected . . .

Try again follow

right procedure

RESULTS:

New: Clear Memory

Last Test Result

Select Test

Continue Test . . .

Battery Test

Grounding Test

Alternator Test

Starter Test

3.5 Switch the ignition key to ON and

start cranking the engine until it

starts. Immediately after that press

ENTER key and the results will show

as follows:

3.6 If the voltage drop is too great during

the cranking, the tested results will

display as follows (Figure 45) and will

prompt you to check the starter

system.

If voltage reading less than 8.5V

3.7 During cranking when it detects that

there is no drop in voltage, it will

display the following screen:

3.8 To exit the program, pressing the EXIT

key at any moment will exit and return

back to the main menu screen.

4. ALTERNATOR TEST

This test is to check the MAX and MIN chargeng

voltages output of the alternator at 3000 RPM without

load and 2000 RPM with all loads ON. With this test

you can determine the alternator’s condition when in

reference with the vehicle’s Service Manual.

No load testing at 3000 RPM:

4.1 With engine OFF, place the vehicle

transmission in NEUTRAL for Manual

and PARK for Automatic and apply

the parking brake.

4.2 Attach the Analyser clips onto the

battery terminal posts and it will

power up and momentarily display

LCD screen as shown below:

4.3 It will run through a self-test and

when completed it displays the Main

Menu as shown below:

4.4 After you have made your choice,

selecting “New: Clear Memory” or

“Continue…Test” will proceed to the

main MENU, select “Starter Test” by

scrolling down:

MinVolts: 10.26V

VoltDrop: Normal

Result: OK

Cranking Test

Min Volts: 7.96V

HIGH

Chk Starter Sys

Battery has aged

VoltDrop:

Not detected . . .

Check connection

and test again

Cranking Test

Battery Test

Grounding Test

Starter Test

Alternator Test

BATTERY

ELECTRICAL

SYSTEM ANALYSER

BESA 11

New: Clear Memory

Last Test Result

Continue Test . . .

Select Test

4.5 Press ENTER key to continue and

the display will show:

Starts the engine then press ENTER

key again and the screen will prompt

you as shown below:

After that press ENTER key again and it

show as below:

4.6 Press ENTER key will show the

results of the test:

4.7 If either minimum or maximum

charging volts are not within the

voltage range limits then it will

display one of the screen as below

(Fig. 1 & Fig. 2) and it will prompt you

to check the alternator system for the

fault.

Fig. 1

Fig. 2

Testing with load at 2,000 RPM:

This test is to check the alternator’s behavior

during loading.

4.8 Continue from the previous test,

proceed to the next step by pressing

ENTER key will enter to the display

as follows.

Start Engine and

keep it running

Then press

Enter

Rev engine up to

3,000 rpm and

hold for 10 sec

Then press Enter

3000 RPM

Max 14.07 < 14.5 V

Min 13.5 > 13.3 V

Enter to proceed

13.96 V

Charge Volts: 13. 96V

Result: Good

Enter to proceed

NO LOAD TEST

Switch ON all

the Electrical

Loads, then

press

Enter

Min Charge: 12. 96V

Result: LOW

Check Alt System

NO LOAD TEST

Max Charge: 14. 96V

Result: HIGH

Check Alt System

NO LOAD TEST

You need to switch ON all loads (Head

Lights, Radio, Air-condition, Heater, etc)

and press enter key will display as

follow:

After that press ENTER key again and it

show as below:

4.9 Press ENTER key will show the

results of the test:

4.10 If either minimum or maximum

charging volts are not within the

voltage range limits then it will

display one of the screen as below

(Fig. 3 & Fig. 4) and it will prompt you

to check the alternator system for the

fault.

Fig. 3

Fig. 4

4.11 To exit the program, pressing the EXIT

key at any moment will exit and return back

to the main menu screen.

5. HELP KEY

Selecting this key will help you familiarize

with the analyser by explaining the various

functions and the results. To access to this

function, just press the HELP key during the

wakeup display:

Use the Up or Down key to scroll to the next

item. To exit this function, just press the EXIT

key will return back to the main menu display.

Rev engine up to

2,000 rpm and

hold for 10 sec

Then press Enter

2000 RPM

Max 13.96 < 13.5 V

Min 13.76 > 12.5 V

Enter to proceed

13.89 V

ChrgVolts: 13. 96V

Result: Good

LOAD TEST

Min Charge: 12. 0V

Result: LOW

Check Alt System

LOAD TEST

Max Charge: 13. 06V

Result: LOW

Check Alt System

LOAD TEST

How to operate▼

RESULTS

VOLTAGE

CCA

6. LIMITED WARRANTY

This Battery Electrical System Analyser BESA11

is warranted to be free from defects in material

and workmanship for a period of 12 months from

the date of purchase and is subjected to the

following terms and conditions:

6.1 Within the warranty period, the

manufacturer will repair or replace, at

their options, any defective parts and

return to the owner in good working

order.

6.2 Any repaired or replaced parts will be

warranted for the balance of the

original warranty or 90 days from the

date of repair, whichever is longer.

6.3 Cost of delivery charges incurred for

the repair of the product (to and from

the manufacturer) will be borne by

the owner.

6.4 The warranty covers only the defects

arises as a result of normal use and

does not cover those arise from:

•Unauthorized modification and

repair

•Improper operation or misuse

•Accident or neglect such as

dropping onto hard surfaces.

•Contact with water, rain or extreme

humidity or heat.

•Physical damages such as cables

broken, surface cracks, etc.

Caution: Never lay tools on the

battery top. You may short the

terminals together causing harm

to yourself, the tools or the

battery. Always follow Battery

Council International safety

recommendations.

Warning:

Battery terminals

contain lead compounds which

is hazardous to our body if

consumed. Please wash your

hand immediately after

handling.

Performing Battery Test while it is still in the

car:

Vehicle that was running has to have its engine

OFF first and then switch ON the headlights for

30 seconds to remove the surface charge. After

the headlights had switched OFF, let the battery

rest for at least 1 minute to recover before

testing commences.

The car engine and all other accessory loads

must be OFF during test in order to have an

accurate result. When attaching the analyser

clips, make sure that the battery posts were not

oxidized or badly corroded. Clean them first

before clamping to it. Do not clamp onto the

steel bolts directly which may give inaccurate

and inconsistent results.

Testing on stand-alone batteries:

Clean the battery posts with a wire brush prior

testing. For side- post batteries, install stud

adaptors. Do not use steel bolts for better

results.

Table of contents

Other AETOOL Measuring Instrument manuals