EMIT Mini Zero Volt Ionizer 2 Technical Document

TB-6590 Page 1 of 5 © 2018 DESCO INDUSTRIES INC

Employee Owned

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Website: DescoEMIT.com

Mini Zero Volt Ionizer 2

Installation, Operation and Maintenance

Description

The EMIT 50642 Mini Zero Volt Ionizer (ZVI) 2 is a compact

bench top ionizer used for neutralizing electrostatic charges

on insulators and ungrounded conductors in a 6" x 24"

coverage area. Its compact size (5.3" high x 3.5" wide x

1.7" deep with stand) allows it to be used in confined spaces

such as environmental chambers and automated equipment.

It may also be used at standard ESD workstations. Its fast

discharge times (< 3 seconds at 12") and ±5 Volt offset

voltage exceed the required limits of ANSI/ESD S20.20 and

ESD TR53. Steady-State DC emitters are spaced farther

apart to prevent ion recombination, increase decay efficiency

and provide a broader coverage area of ionization. The

Mini ZVI 2’s two-speed fan (33 CFM to 51 CFM) produces

consistent performance at both the low and high speeds.

Low airflow may be used when working with small parts and

components that may move with higher airflow. The Mini ZVI

2 features a stainless steel enclosure and multi-mount stand

to minimize contamination and corrosion when used in clean

or sensitive areas.

Ionizers are useful in preventing electrostatic charge

generation, electrostatic discharge, electrostatic attraction,

as well as preventing equipment latch-up. Per ANSI/ESD

S20.20 section 6.2.3.1. Protected Areas Requirement states:

“Ionization or other charge mitigating techniques shall be

used at the workstation to neutralize electrostatic fields

on all process essential insulators if the electrostatic field

is considered a threat.” “Air ionization can neutralize the

static charge on insulated and isolated objects by producing

separate charges in the molecules of the gases of the

surrounding air. When an electrostatic charge is present

on objects in the work environment, it will be neutralized

by attracting opposite polarity charges from the ionized

air. Note that ionization systems should not be used as a

primary means of charge control on conductors or people.”

(Reference: EN 61340-5-2:1 clause 5.2.9)

July 2018

“The primary method of static charge control is direct

connection to ground for conductors, static dissipative

materials, and personnel. A complete static control program

must also deal with isolated conductors that cannot be

grounded, insulating materials (e.g., most common plastics),

and moving personnel who cannot use wrist or heel straps or

ESD control flooring and footwear.

Air ionization is not a replacement for grounding methods.

It is one component of a complete static control program.

Ionizers are used when it is not possible to properly ground

everything and as backup to other static control methods. In

clean rooms, air ionization may be one of the few methods

of static control available.” (ESD Handbook ESD TR20.20

Ionization, section 5.3.6.1 Introduction and Purpose / General

Information)

The EMIT Mini Zero Volt Ionizer 2 operates on Steady-State

DC. Steady-State DC systems consist of separate negative

and positive ion emitters connected by a pair of high-voltage

cables to their respective high-voltage power supplies. DC

power is constantly applied to the emitter points. The ionizer

utilizes feedback from the internal sensor grill to continuously

adjust the output to maintain balance.

EMIT offers the following accessories for the Mini Zero Volt

Ionizer 2:

Item Description

50658 Emitter Pin Cleaner, 20 Pack

50668 Replacement Emitter Pins, 8 Pack

19263 Power Adapter, 24VDC Output

Packaging

1 Mini Zero Volt Ionizer 2

1 Power Adapter, 24VDC, with interchangeable plugs

(North America, UK/Asia, Europe)

1 Ground Cord

1 Emitter Pin Cleaner Pack

1 Certificate of Calibration

TECHNICAL BULLETIN TB-6590

Figure 1. EMIT 50642 Mini Zero Volt Ionizer 2

Made in the

United States of America

Figure 2. Interchangeable power adapter plugs included

with the Mini Zero Volt Ionizer 2

TB-6590 Page 2 of 5 © 2018 DESCO INDUSTRIES INC

Employee Owned

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Website: DescoEMIT.com

Features and Components 3. Connect the power adapter to the ionizer to turn it on.

When the unit is first turned on, it conducts a self-test.

The audible alarm will sound, and the status LED will

cycle through orange and green. The LED will remain

green during normal operation.

A. Ground Jack: Insert the banana plug end of the included

ground cord to this jack. Connect the ring terminal end of the

cord to equipment ground.

B. 24VDC Power Jack: Connect the power adapter here to

power the Mini ZVI 2.

C. Fan Speed Switch: Slide the switch down to set the fan

speed to LOW. Slide the switch up to set the fan speed to

HIGH.

D. Balance Adjustment Potentiometer: Turn the

potentiometer clockwise for positive adjustment. Turn the

potentiometer counter-clockwise for negative adjustment.

E. Status LED: The LED will illuminate green when the

ionizer runs normally. It will illuminate orange and sound

the buzzer should the ionizer experience circuit failure or its

emitter pins become too dirty to operate effectively.

Installation

Place the unit at a desired location where that the airflow

will not be restricted. The Mini ZVI 2’s compact size and

mountable stand allow it to be installed in confined spaces

such as enviornment chambers and automated machinery.

Connect the ground cord to the ionizer’s ground jack. Attach

the ring terminal end of the ground cord to a ground point.

The face plate screw of a grounded AC wall outlet may

provide a convenient connection point.

Operation

1. Set the fan speed switch to the LOW or HIGH position.

Higher airflow will result in faster neutralization rates.

2. Position the ionizer so that maximum airflow is directed

towards the items or area to be neutralized.

Figure 3. Mini Zero Volt Ionizer 2 features and

components

B

A

C

D

E

Figure 4. Using the Mini Zero Volt Ionizer 2 at a

workstation.

Figure 5. Using the Mini Zero Volt Ionizer 2 inside

automated machinery.

TB-6590 Page 3 of 5 © 2018 DESCO INDUSTRIES INC

Employee Owned

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Website: DescoEMIT.com

Maintenance

CLEANING THE EMITTER POINTS

Under normal conditions, the ionizer will attract dirt and dust

(especially on the emitter points). To maintain optimum

neutralization efficiency and operation, cleaning should be

performed on a regular basis.

In the event of circuit failure or dirty emitter pins, the

Mini Zero Volt Ionizer 2 will alarm and its status LED will

illuminate orange.

The emitter points should be cleaned using the included

50658 Emitter Point Cleaners or a swab dampened with

Isopropyl alcohol.

1. Turn the unit OFF by disconnecting its power

adapter.

2. Remove the rear screen by removing the 4 screws.

3. Clean the emitter points using the included 50658

Emitter Point Cleaners or a swab dampened with

Isopropyl alcohol

4. Reattach the rear screen.

5. Reconnect the power adapter to turn on the ionizer.

6. Verify the performance of the ionizer by using a charged

plate monitor or ionization test kit.

The emitter points should not require replacement during

the life of the unit with normal handling. If necessary, item

50668 Replacement Emitter Points are available for order.

Adjustments and Compliance Verification

BALANCE OFFSET VOLTAGE ADJUSTMENT

The Mini Zero Volt Ionizer 2 is an auto-balancing unit.

However, tuning or manual adjustment can be accomplished

by turning the balance adjustment potentiometer located at

the left-side of the unit. To increase the output in a positive

direction, turn the potentiometer clockwise. To increase

the output in a negative direction, turn the potentiometer

counter-clockwise.

Compliance Verification should be per ESD TR53. Offset

voltage (balance) and both polarity’s discharge time should

be checked on every ionizer periodically using an Ionization

Test Kit or a Charged Plate Analyzer. Clean the emitter

points (with electrical power off), adjust offset voltage

(balance) to zero and then re-test for offset voltage (balance)

and discharge times recording the measurements.

TB-6590 Page 4 of 5 © 2018 DESCO INDUSTRIES INC

Employee Owned

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Website: DescoEMIT.com

Neutralization (Discharge) Times

All data was taken with the fan speed set to high. All time measurements are in seconds.

NOTE: Discharge times in seconds are representative only and are not a guarantee. Discharge times are actual

measurements recorded in a factory ambient environment.

Per ANSI/ESD S20.20, the test method for Product Qualification test is ANSI/ESD STM3.1, and for Compliance Verification

is ESD TR53 which advises “Measurements should be made at the location where ESD sensitive items are to be ionized.”

A larger area may require additional ionizers. Per S20.20 the required limit for ionizer discharge time is user defined. Use

Table to determine the number of ionizers to achieve ionization of area to be neutralized to meet your company’s ESD control

plan specified discharge times.

The comparative efficiency of bench top ionizers is determined by a standard test published by the ESD Association: ANSI/

ESD STM 3.1. Typical positive and negative decay times (1000V - 100V) measured using this standard are shown in Figure

5. The performance of the ionizer was measured with the unit positioned as shown, with the fan speed on high and without a

filter.

TP1 +35.3

-32.1

12" 12"

12"

12"

TP4 +15.1

-23.0

TP7 +14.0

-20.9

TP2 +1.6

-2.3

TP5 +2.9

-4.4

TP8 +4.8

-7.4

TP3 +48.2

-60.7

TP6 +14.2

-25.3

TP9 +14.0

-17.3

Mini Zero

Volt Ionizer

Air Flow

Charged Plate

12"

Figure 6. Neutralization (Discharge) Times

Optimal

Coverage

Area

TB-6590 Page 5 of 5 © 2018 DESCO INDUSTRIES INC

Employee Owned

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Website: DescoEMIT.com

Specifications

Air Flow

Two speed fan (33 CFM, 51 CFM)

Balance (offset voltage) at 12" in front of Ionizer

±5 Volts Typical

±25 Volts Maximum

(Temperature Range: 65°F to 80°F, RH: 15% to 65%)

Chassis

Stainless steel housing and stand

Dimensions (with stand)

5.3" x 3.5" x 1.7"

(14 cm x 9 cm x 4 cm)

Emitter Points

.050" base diameter

Made of pure tungsten

High Voltage Power Supply

5.5kV DC nominal

Input Power

24 VDC, center positive, 2.5 x 5.5 mm power jack

Ion Emission

Steady-state DC with sense feedback

Mounting

Bench top tilt adjust frame

Ozone

< 0.05 ppm

Weight

1.1 lbs (0.5 kg)

Limited Warranty, Warranty Exclusions, Limit of

Liability and RMA Request Instructions

See the EMIT Warranty -

DescoEMIT.com/Warranty.aspx

This manual suits for next models

2

Table of contents

Popular Other manuals by other brands

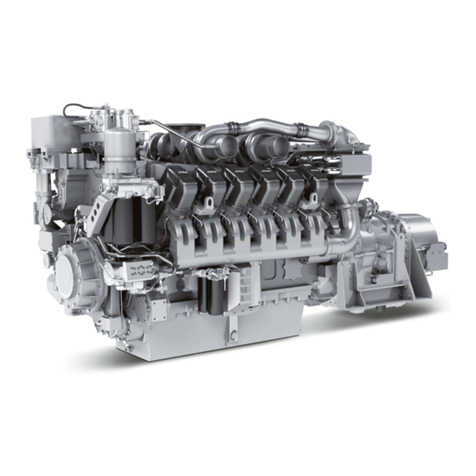

MTU

MTU 12V4000S83 operating instructions

Dataq

Dataq DI-725/E user manual

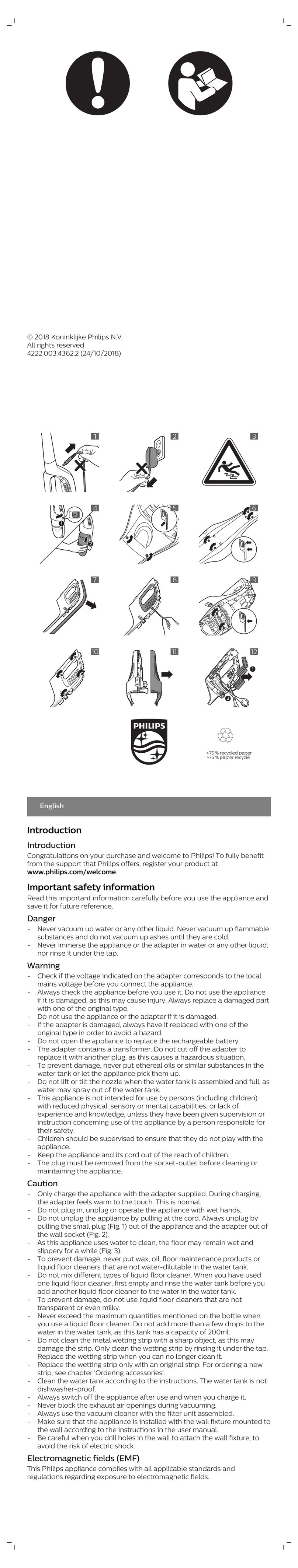

Philips

Philips FC6409 Important information leaflet

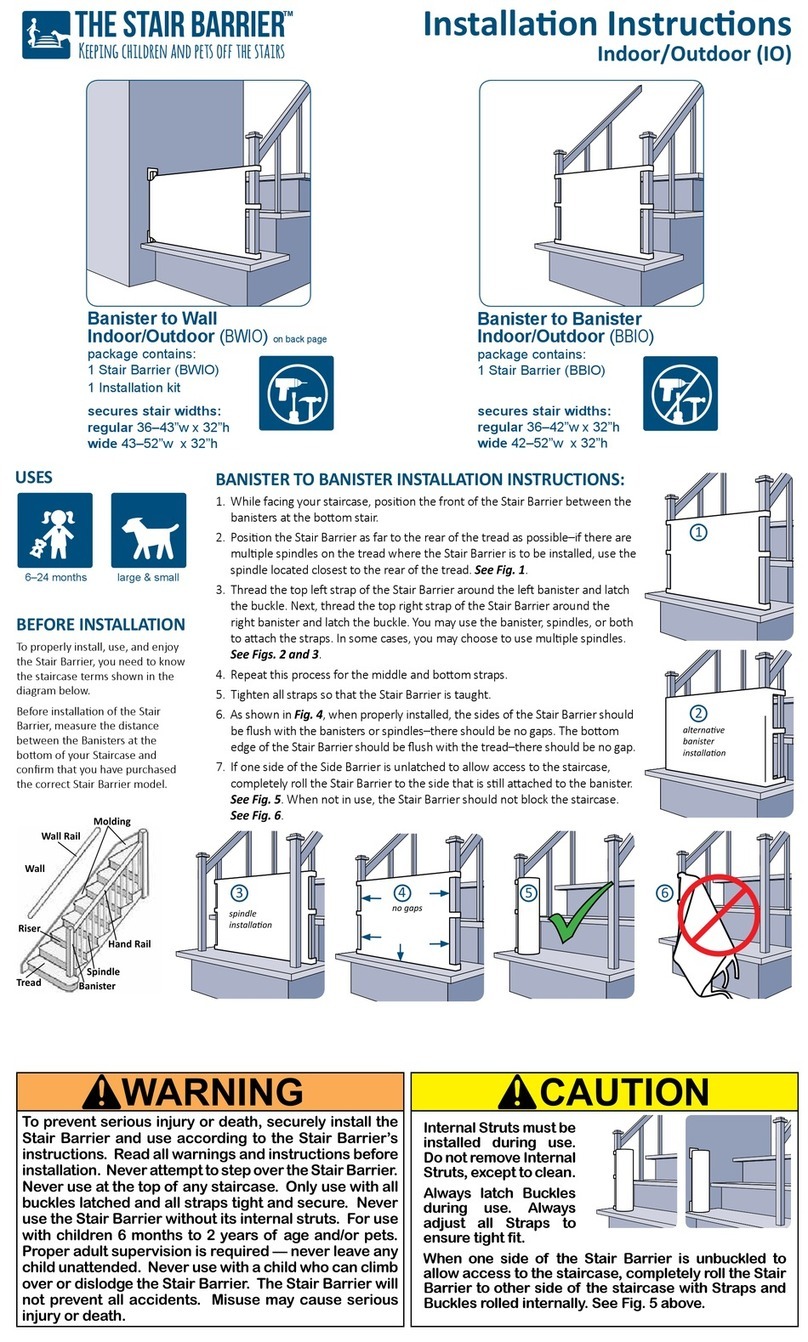

The Stair Barrier

The Stair Barrier BWIO installation instructions

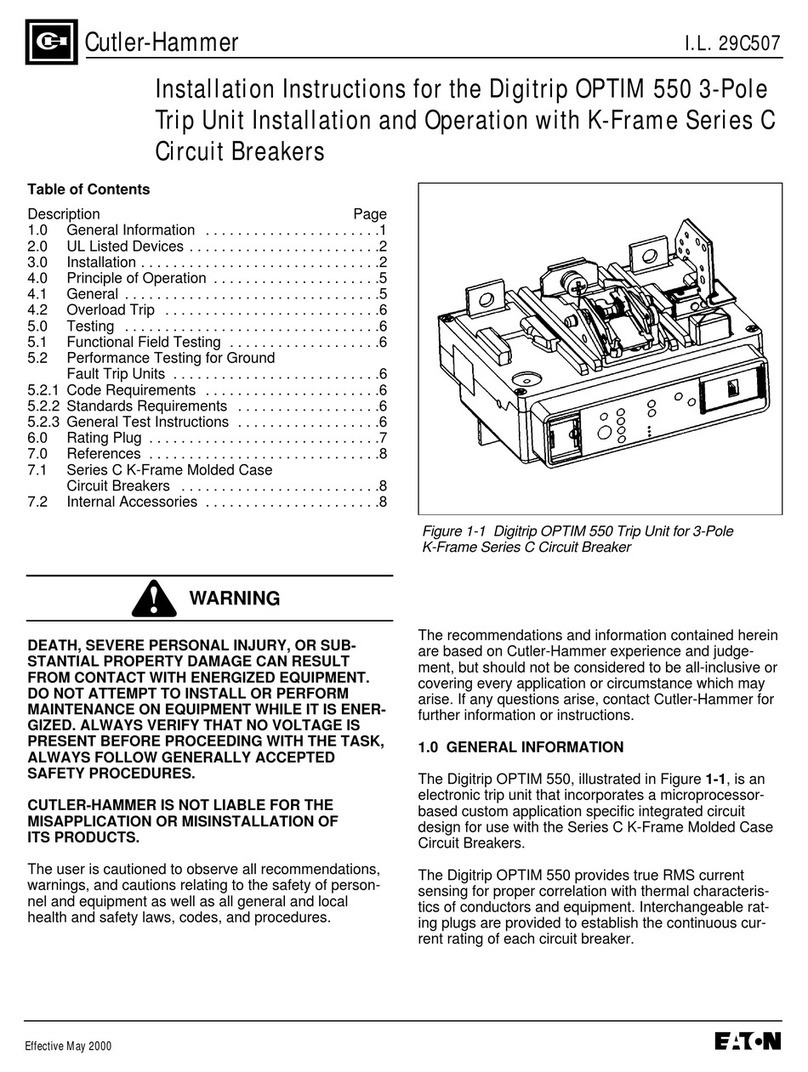

Eaton

Eaton Digitrip OPTIM 550 KEP3125T52 installation instructions

Elaflex

Elaflex ZVG 2 EURO UL Installation and operating manual