EMIT SmartLog Pro SE Installation and operating instructions

TB-6608 Page 1 of 5 © 2021 DESCO INDUSTRIES INC

Employee Owned

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

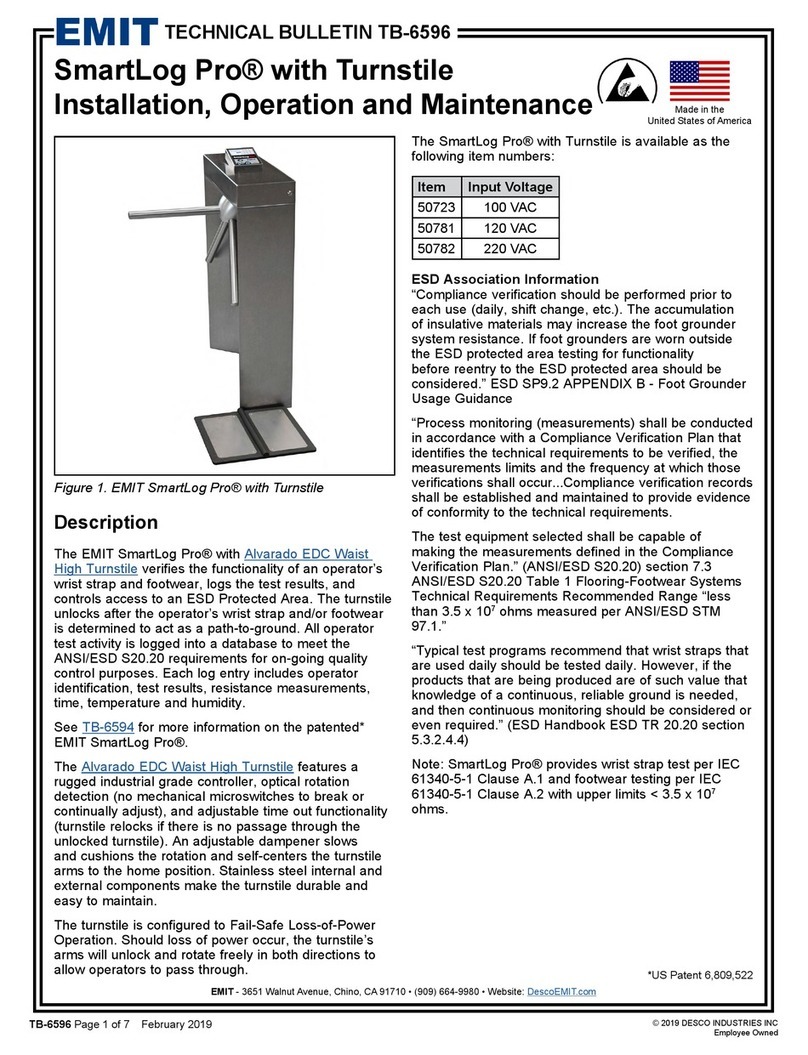

SmartLog Pro® SE with Turnstile

Installation, Operation and Maintenance

Description

The EMIT SmartLog Pro® SE with EDS EDSUKTHH28

Half Height Turnstile verifies the functionality of an

operator’s wrist strap and footwear, logs the test results,

and controls access to an ESD Protected Area. The

turnstile unlocks after the operator’s wrist strap and/or

footwear is determined to act as a path-to-ground. All

operator test activity is logged into a database to meet

the EN 61340-5-1 Compliance Verification and record

keeping requirements. Each log entry includes operator

identification, test results, resistance measurements,

time, temperature and humidity.

See TB-6604 for more information on the EMIT

SmartLog Pro® SE.

The EDS EDSUKTHH28 Half Height Turnstile is a

bidirectional tripod swing turnstile. Both its cabinet and

tripod rotors are composed of stainless steel. LED

passage signs are located at both the entry and exit

sides. A flashing green arrow indicates when to pass,

and a red X indicates when the turnstile is closed.

The turnstile is configured to Fail-Safe Loss-of-Power

Operation. Should loss of power occur, the turnstile’s

arms will unlock and rotate freely in both directions to

allow operators to pass through.

The EMIT 50175 SmartLog Pro® SE with Turnstile has

an input voltage rating of 220 VAC.

June 2021

Figure 1. EMIT 50175 SmartLog Pro® SE with Turnstile

SmartLog Pro® Manager automates the collection of

ESD personnel grounding tests and maintains records

for a Compliance Verification Plan as required by ANSI/

ESD S20.20. It includes functions for tracking employee

leave time, shift and department assignments, and

ESD training accreditation. SmartLog Pro® Manager

generates automated reports that may be e-mailed to

track short term and long term corrective actions. Test

limits and test parameters (wrist strap only, footwear

only, wrist strap and footwear, etc.) may be customized

with the web app to meet special requirements.

SmartLog Pro® Manager is only compatible with

the SmartLog Pro® SE, and it is required for every

SmartLog Pro® SE system installation. Contact Desco

Europe Customer Service to schedule an installation

session.

See technical bulletin TB-6605 for more information.

ESD Association Information

For more information on ESD Control Plan

requirements, please visit the ESD Association website

at esda.org.

Packaging

1 SmartLog Pro® SE with Turnstile

1 Wall Mounting Bracket

1 Dual Independent Foot Plate

1 Allen Wrench, 5/32"

4 M10 x 85 Steel Anchors

4 M10 x 20 Inbus Bolts

4 M10 Washers

2 Turnstile Keys

1 Certificate of Calibration

TECHNICAL BULLETIN TB-6608

Made in the

United States of America and Britain

SmartLog Pro® Manager Web App

TB-6608 Page 2 of 5 © 2021 DESCO INDUSTRIES INC

Employee Owned

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

Installation

Installing the Turnstile

220 VAC and Ethernet access are needed at the

location of every SmartLog Pro® with Turnstile prior to

installation.

Click here to download the EDS EDSUKTHH28

Turnstile Operation Manual and see instructions on

anchoring and wiring the turnstile. Use the included

anchors, bolts and washers when anchoring the turnstile

to the ground.

Setting up the SmartLog Pro® SE

See TB-6604 to learn more about the features and

components of the SmartLog Pro® SE.

1. Open the turnstile’s lid using the included keys.

2. Connect the Ethernet cable to the back of the

SmartLog Pro® SE.

3. Locate the power switch inside the turnstile cabinet,

and set it to ON.

4. Locate the power switch on the back of the

SmartLog Pro® SE, and set it to ON.

5. Locate the foot plate cable at the base of the

turnstile and connect it to the Dual Independent

Foot Plate, so operators can place their feet on it

while performing tests at the turnstile’s entrance.

6. Complete the installation by establishing

communication to the SmartLog Pro® SE via the

Ethernet cable.

Figure 2. Installing the Dual Independent Foot Plate

Operation

NOTE: The SmartLog Pro® SE must first be

programmed with the user ID table using SmartLog

Pro® Manager before being deployed for employee use,

or the default test settings will be applied. See TB-6605

for more information.

If the SmartLog Pro® SE is located near a restroom,

sink or other water source, operators will need to be

instructed to thoroughly dry their hands before testing.

Wet hands may cause inaccurate test results and

damage to the tester.

1. A circling light around the test switch indicates when

the SmartLog Pro® SE is on standby and ready to

perform a test.

2. Initiate the test procedure by identifying yourself to

the SmartLog Pro® SE. This may be done using the

touchscreen keypad, barcode scanner or proximity

reader.

NOTE: Hold the proximity badge in front of the RFID

icon for a full second if using proximity badges. See

Figure 4.

Figure 3. Using the barcode scanner

Figure 4. Holding a proximity badge in front of the RFID

icon on the SmartLog Pro® SE

TB-6608 Page 3 of 5 © 2021 DESCO INDUSTRIES INC

Employee Owned

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

Figure 5. Performing a footwear and wrist strap test

3. Follow the prompt on the SmartLog’s display.

4. When performing a footwear test, be sure to place

both feet on the dual foot plate (one foot per plate).

NOTE: Keep the foot plate clean with 99% isopropyl

alcohol when using the 1 Gigohm high test limit. A

dirty foot plate could yield a false pass.

When performing a wrist strap* test, be sure to

completely plug in the wrist cord into the tester’s

jack.

5. To begin the test, use your finger to bridge the test

switch’s inner and outer contacts. The blue standby

LED will become solid to indicate that the test has

been initiated. Hold your finger down until the test

results are displayed on the touchscreen.

If your finger is removed too early, the tester’s blue

LEDs will blink three times to indicate that the test

was not completed. DO NOT touch any metal other

than the SmartLog Pro® SE or the turnstile while

performing your test as this will affect your results.

Figure 6. Viewing the test results

6. The relay terminal will activate and unlock the

turnstile if the defined tests are passed.

NOTE: Failures may be caused by dry skin or

minimal sweat layer. For wrist straps, try using an

approved dissipative hand lotion such as Reztore™

ESD Hand Lotion prior to use. Footwear test results

can be improved by taking a short walk to build a

sweat layer for better conductivity.

7. Pass through the turnstile. The turnstile will re-lock

after one rotation.

NOTE: The turnstile will remain unlocked until either

the operator passes through or 15 seconds expire.

*The SmartLog Pro® SE may also be used to

test smocks or garments that feature a grounding

mechanism for operators using a coiled cord

connection.

TB-6608 Page 4 of 5 © 2021 DESCO INDUSTRIES INC

Employee Owned

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

Calibration

Frequency of recalibration should be based on the

critical nature of those ESD sensitive items handled and

the risk of failure for the ESD protective equipment and

materials. In general, EMIT recommends that calibration

be performed annually.

Use the EMIT 50424 Limit Comparator and EMIT 50784

5-Pound Electrode to perform periodic verification (once

every 6-12 months) of the SmartLog Pro® SE. The Limit

Comparator can be used to check the test limits of the

SmartLog Pro® SE without removing it from the turnstile

or factory floor.

See TB-6581 for more information.

Figure 7. EMIT 50424 Limit Comparator

Figure 8. EMIT 50784 5-Pound Electrode for Limit

Comparator

Specifications

SmartLog Pro® SE with Turnstile

SmartLog Pro® SE

Input Voltage and

Frequency

(External Adapter)

AC/DC Power Adapter

Power Input:

100-240VAC, 50/60 Hz

Power Output:

5VDC, 3.0A

Cable Length:

5 ft. (1.5 m)

Turnstile

Input Voltage and

Frequency

220VAC, 50/60 Hz

Operating Temperature 70°F to 85°F (21°C to 30°C)

for 1 gigohm test limit

41°F to 85°F (5°C to 30°C)

for all other test limits

Environmental

Requirements

Indoor use only at altitudes

less than 6500 ft. (2 km)

Maximum relative humidity

of 80% up to 85°F (30°C)

decreasing linearly to 50% @

85°F (30°C)

Maximum relative humidity of

50% at 1 gigohm setting

Dimensions (Crated) 47" x 31" x 54"

(119 cm x 78 cm x 137 cm)

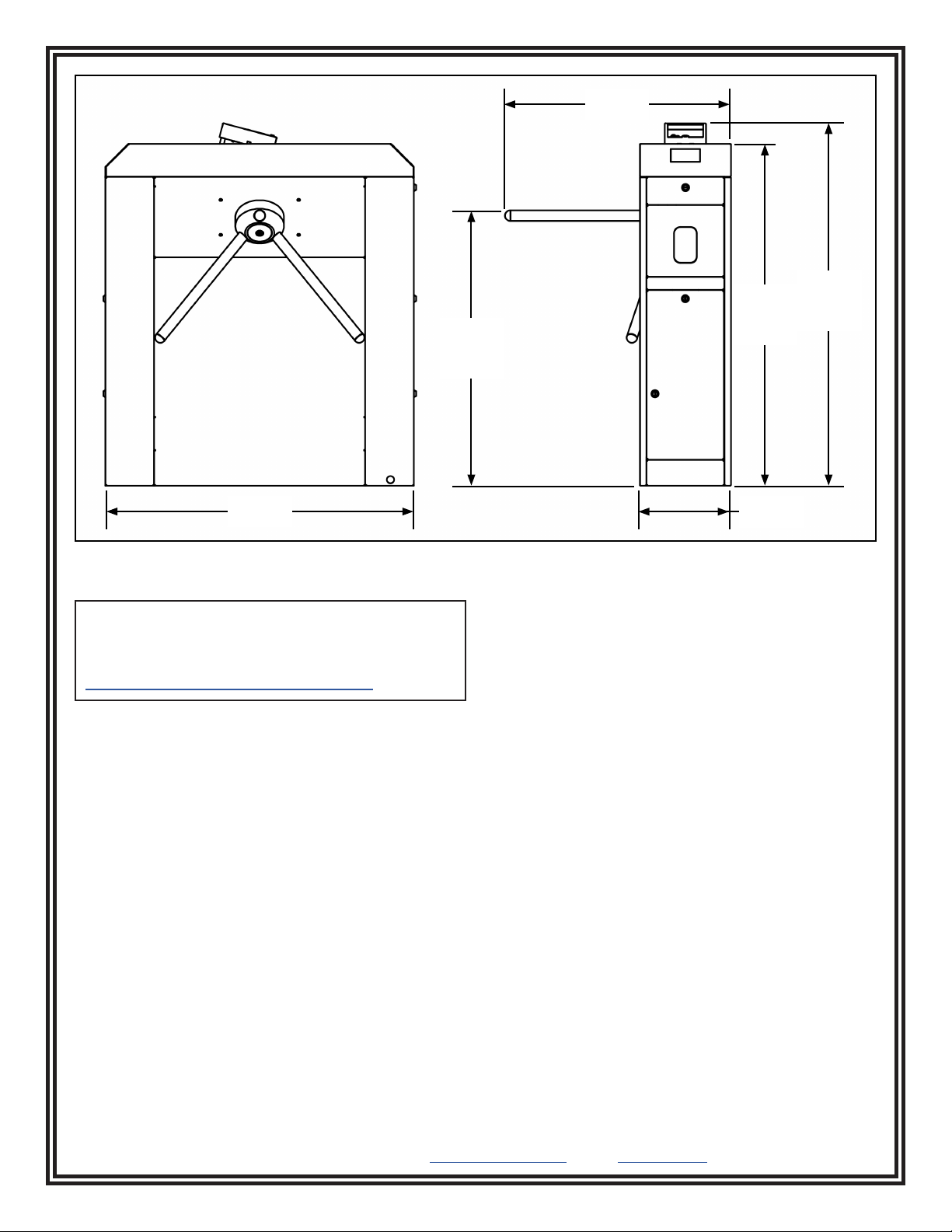

Dimensions (Uncrated) See Figure 9

Weight (Crated) 257 lbs (116 kg)

Weight (Uncrated) 135 lbs (61 kg)

Test Accuracy ±20% for 1 gigohm footwear

test limit

±10% for all other test limits

Test Switch Voltage 5 VDC @ open circuit

Wrist Strap and

Footwear Test Voltage

30 VDC @ open circuit

Test current is limited by

resistors and varies on

the test range setting (100

kilohms - 1 gigohm)

Dual Independent Foot Plate

Dimensions 14.0" x 16.0" x 0.9"

(35.6 cm x 40.1 cm x 2.3 cm)

Weight 7.5 lbs (3.4 kg)

TB-6608 Page 5 of 5 © 2021 DESCO INDUSTRIES INC

Employee Owned

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

Figure 9. Dimensions of the EMIT SmartLog Pro® SE with Turnstile

37.4"

(95 cm)

11.0"

(28 cm)

27.6"

(70 cm)

41.3"

(105 cm)

43.9"

(112 cm)

33.3"

(85 cm)

Limited Warranty, Warranty Exclusions, Limit

of Liability and RMA Request Instructions

See the Desco Europe Warranty -

DescoEurope.com/Limited-Warranty.aspx

Table of contents

Other EMIT Turnstile manuals

Popular Turnstile manuals by other brands

Tansa

Tansa LTT 303 user manual

GEZE

GEZE TSA 325 NT installation instructions

Avantgarde

Avantgarde ALVARADO Supervisor 3500 installation instructions

Turnstiles

Turnstiles AG Series installation manual

PERCo

PERCo TTR-11A Assembly & operation manual

Automatic Systems

Automatic Systems TR450 installation manual