Applications:

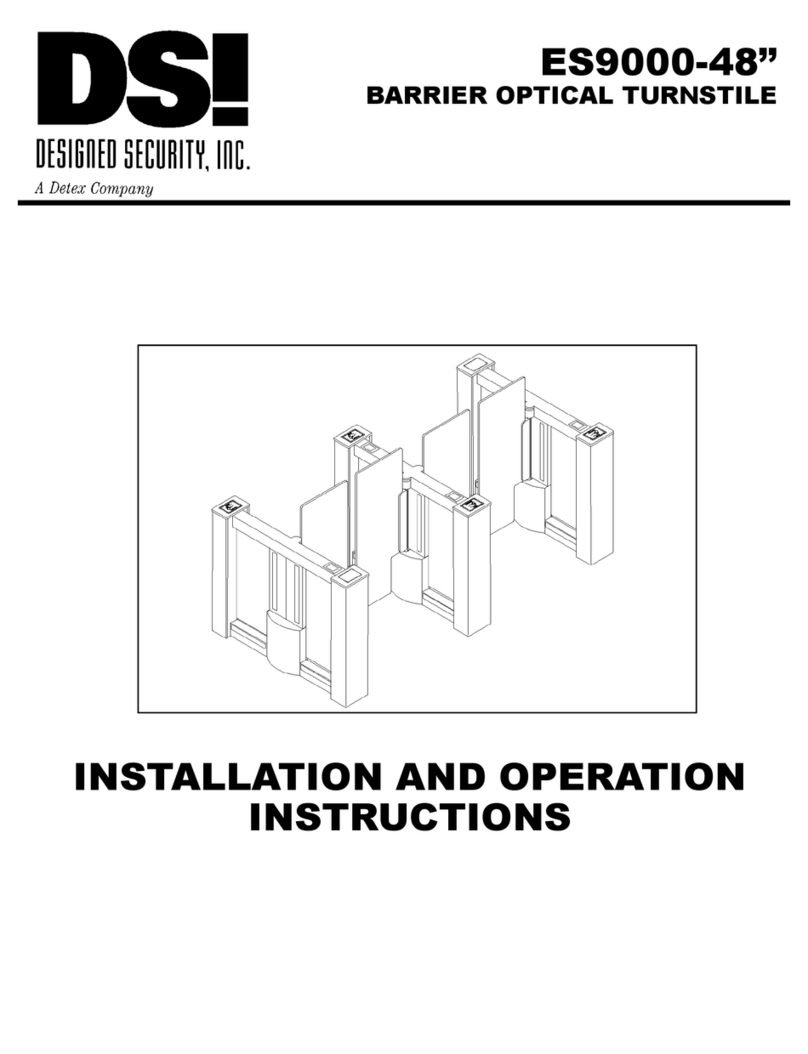

This interior application unit is designed for

embassies and museums.

Product Features:

Materials and Finishes:

• Lid:

choice of 12 standard colors selections.

Custom colors and Corian™ can be quoted

• Cabinet: Our signature 304 stainless steel/

Design & Construction:

• Designed for secure and reliable operation

• Cabinet constructed of 304 stainless steel/

•

•

Dimensions:

• Height:

• Width:

• Depth:

• Arm Length:

Operation Features

6500 Series Control Head:

•

hydraulic shock suppression

• Hardened tool steel locking bars, cam and

roller assemblies

• Permanently lubricated bearings

• Your choice of manual or electronic control on

both directions

• Nearly universal integration to any number of

access control syst ems

• Your choice on each electronic direction of

Options:

• Bi-directional key overrides

•

year lithium battery

•

•

choices outside of our standard selection

• NEW!

available

• Additional options available upon request

* Dimensions are approximate

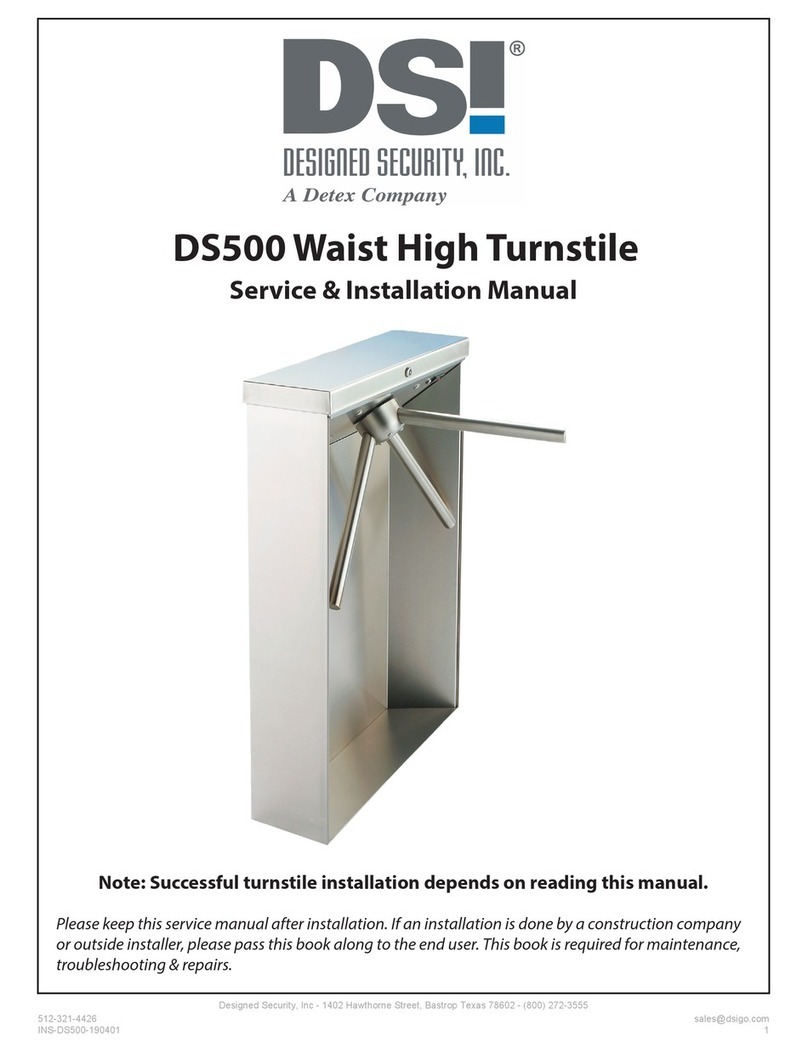

The DS100-R Series Waist-High DS100-R

Round End |Interior Application

Warranty:

defects in materials and

one year from date of delivery.

Input Voltage: 100-240 VAC

Input Current: 1.3 - .55 A

Frequency: 50/60 Hz

Storage Temperature: -40 to 158°F

Operating Temperature: -4 to 131°F

Operating Voltage: 24VDC

Standards and Codes:

Austenitic stainless steel:

ASTM A240, A249, A276

Hot rolled steel:

AISI C-1020, AISI C-1018

All fasteners provided meet IFI ANSI/

ASME Fastener Standards

Standard D 1.1

The 6500 Series Control Head

UL 294, UL 325, UL Subject 2593,

CAN/ULC S319 & CSA C22.2#247

4008027

Our matching ADA gate

(DS100-R-ADA with optional

motorization) is available for

DS100-R Series.

* Dimensions are subject to change without notice

512-321-4426

INS-DS100R-190401

Designed Security, Inc. - 1402 Hawthorne Street, Bastrop Texas 78602 - (800) 272-3555

Electrical Specications: