INTRODUCTION

Dear valued customer,

Thank you for choosing our tripod turnstile. We want to offer you the best efficiency.

Please read this manual carefully. This manual contains detailed information on the installation

and maintenance of turnstiles. The information contained in this manual is of great importance

in order to extend the service life of the turnstile and to obtain maximum efficiency.

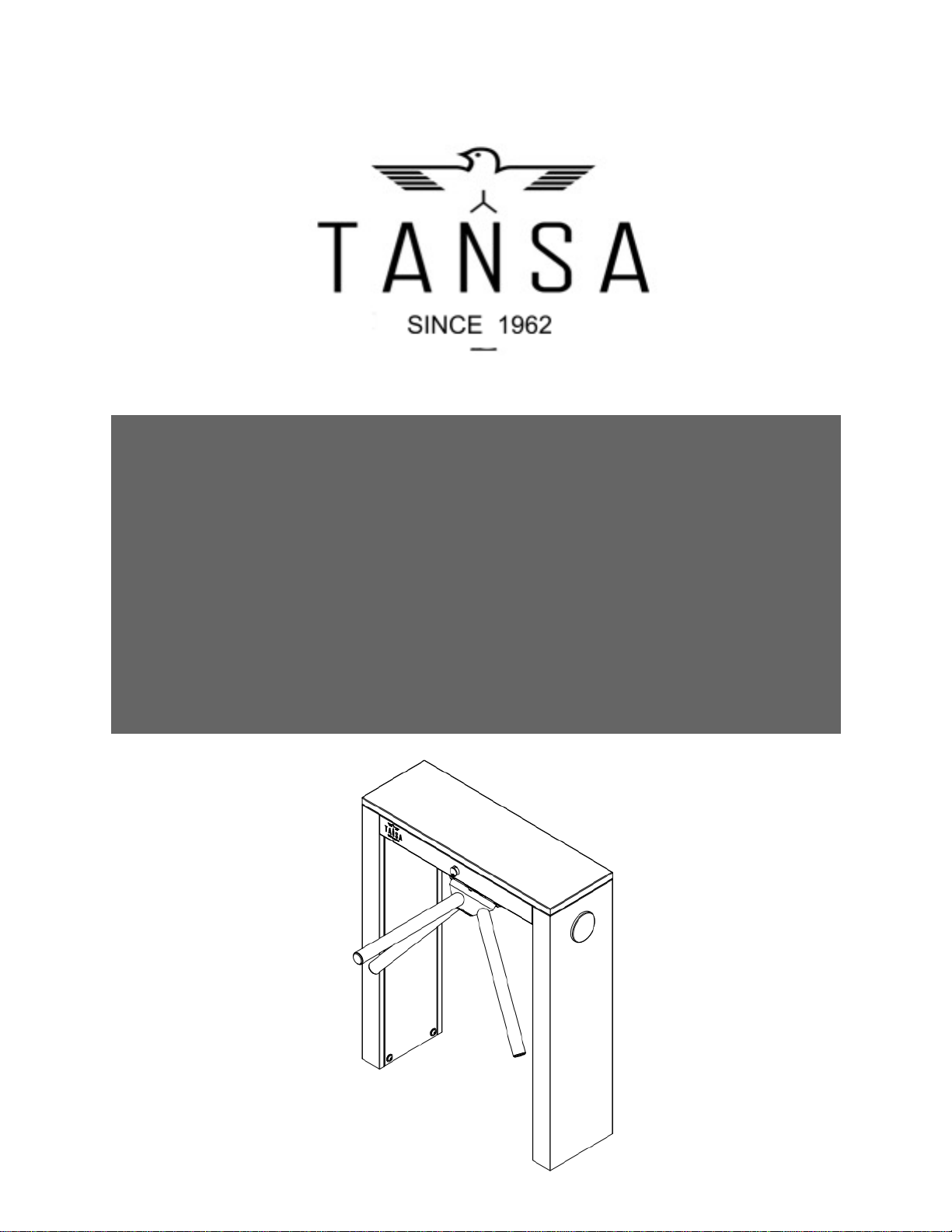

Turnstiles have an active place in our daily lives and are used in many areas. It is possible to

see them in several places such as public transportation stations, business and training centers,

parks, dining halls, stadiums, prisons, etc.

The nature and purpose of the areas where turnstiles are used is the biggest factor in the

design and production of turnstile models. Our products, which are created by taking this factor

into consideration, are grouped into four main categories: Tripod turnstiles (waist high turnstiles),

Swing gate turnstiles (handicapped accessible turnstiles), Full-height turnstiles, and Speed gate

turnstiles. In addition, Full-height turnstiles and the Speed gate turnstiles also have handicapped

accessible versions.

Turnstiles can be produced as stainless steel, galvanized or electrostatic powder-coated

according to customer demands. Optionally, different solutions are available for some product

models.

Turnstiles are compatible with any kind of magnetic, biometric, proximity and similar

readers. In addition, applications such as buttons, coins, remote controls can be integrated and

used with a turnstile.

All materials used in the turnstiles are designed to be water and dust resistant and tested in

accordance with IP44 standards. Mechanical parts of the turnstiles are protected against corrosion

and oxidation with AISI 304 stainless steel and zinc plating.

Turnstiles can work in both directions. The anticipated use per hour is at the level of 1500

persons.

All TANSA brand turnstiles have certificates of compliance with TSE, ISO 9001 and CE

standards.

HEADQUARTER:

Address: Eyüp Sultan Mahallesi. Hoca Nasreddin Caddesi. No: 10

Sancaktepe / İSTANBUL

Phone: +90 (216) 561 96 71-72-73

Fax: +90 (216) 561 96 74-75

| 5 |