Tripod Turnstile Technical Manual

Tripod Turnstile Technical Manual.......................................................................................................... 3

Product description............................................................................................................................. 3

Basic parts ........................................................................................................................................... 4

Wristband Capturer (optional) ....................................................................................................... 4

Antenna with Reader (optional) ..................................................................................................... 4

On the outside ................................................................................................................................ 5

On the inside................................................................................................................................... 5

Mounting set (optional)...................................................................................................................... 6

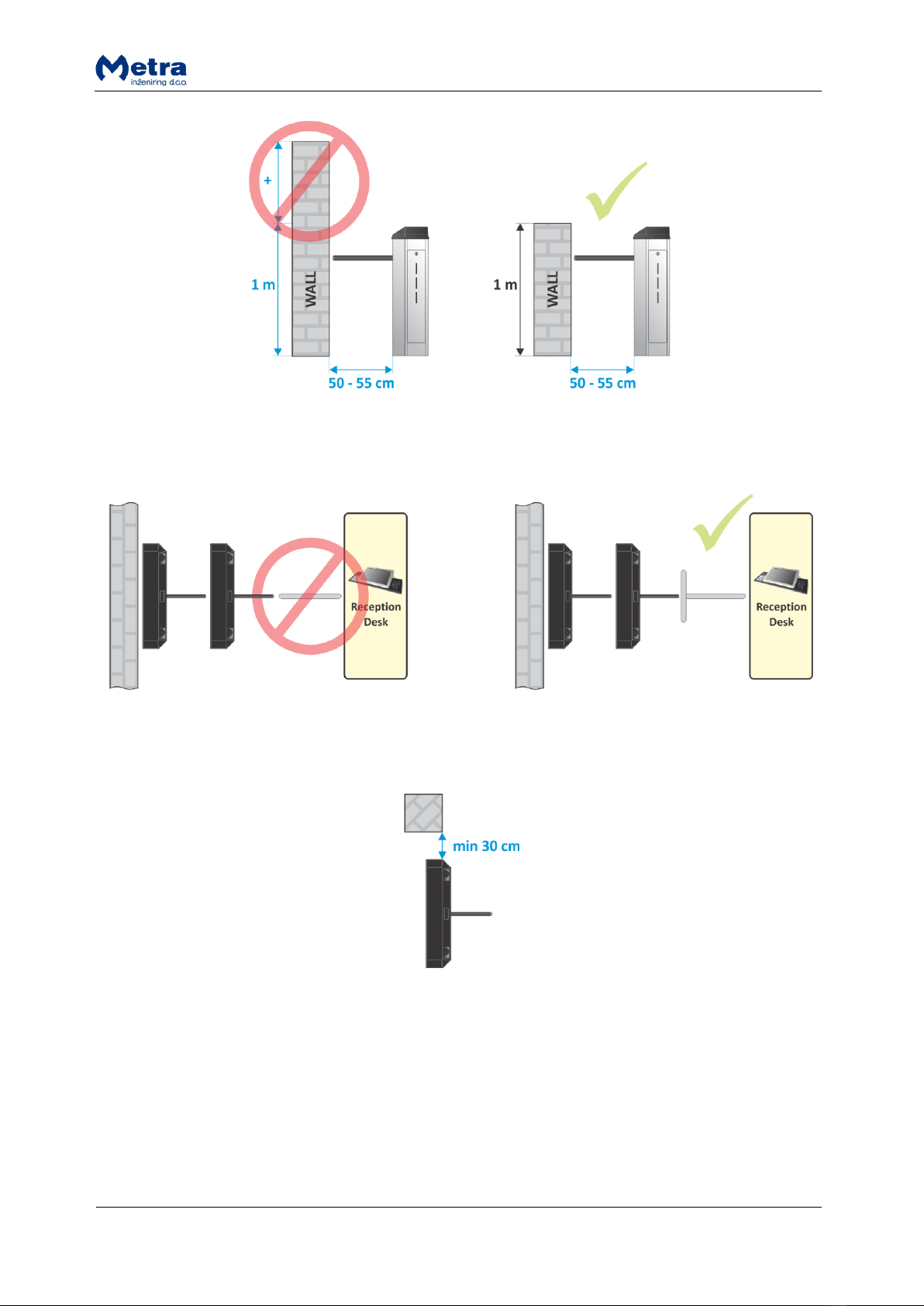

Choosing location for installation ....................................................................................................... 6

Wires installation ................................................................................................................................ 8

Anchor position (orientation) ......................................................................................................... 8

Preparation of wiring...................................................................................................................... 8

Wiring ............................................................................................................................................. 8

Anchor installation.............................................................................................................................. 9

Other installation options ................................................................................................................. 11

Opening cover................................................................................................................................... 11

Connections ...................................................................................................................................... 12

Top................................................................................................................................................ 12

Bottom.......................................................................................................................................... 13

Power supply connection ............................................................................................................. 14

Network connection ..................................................................................................................... 15

DIP switch settings ............................................................................................................................ 16

Operating mode and Network address ........................................................................................ 17

Power-ON.......................................................................................................................................... 17

Spare Fuse..................................................................................................................................... 18

Safety features .................................................................................................................................. 19

Free passage ................................................................................................................................. 19

Special braking fuses (optional).................................................................................................... 19

Barrier calibration ............................................................................................................................. 19

Maintenance ..................................................................................................................................... 20

Cleaning............................................................................................................................................. 20

Technical data ................................................................................................................................... 20

Appendix ........................................................................................................................................... 20