Revolving door TSA 325 NT

2

Table of contents

Symbols and illustrations ..................................................................................................................................................3

Product liability.....................................................................................................................................................................3

1 Security ......................................................................................................................................................................3

1.1 Intended use.......................................................................................................................................................................................................3

1.2 Safety instructions ...........................................................................................................................................................................................4

1.3 Safety conscious working..............................................................................................................................................................................4

1.4 Inspection of the installed system .............................................................................................................................................................5

1.5 Environmentally conscious working .........................................................................................................................................................5

2 Tools and aids ...........................................................................................................................................................5

2.1 General tool set.................................................................................................................................................................................................5

2.2 Special tools........................................................................................................................................................................................................5

2.3 Consumables......................................................................................................................................................................................................6

3 Structure .....................................................................................................................................................................7

4 Installation..................................................................................................................................................................8

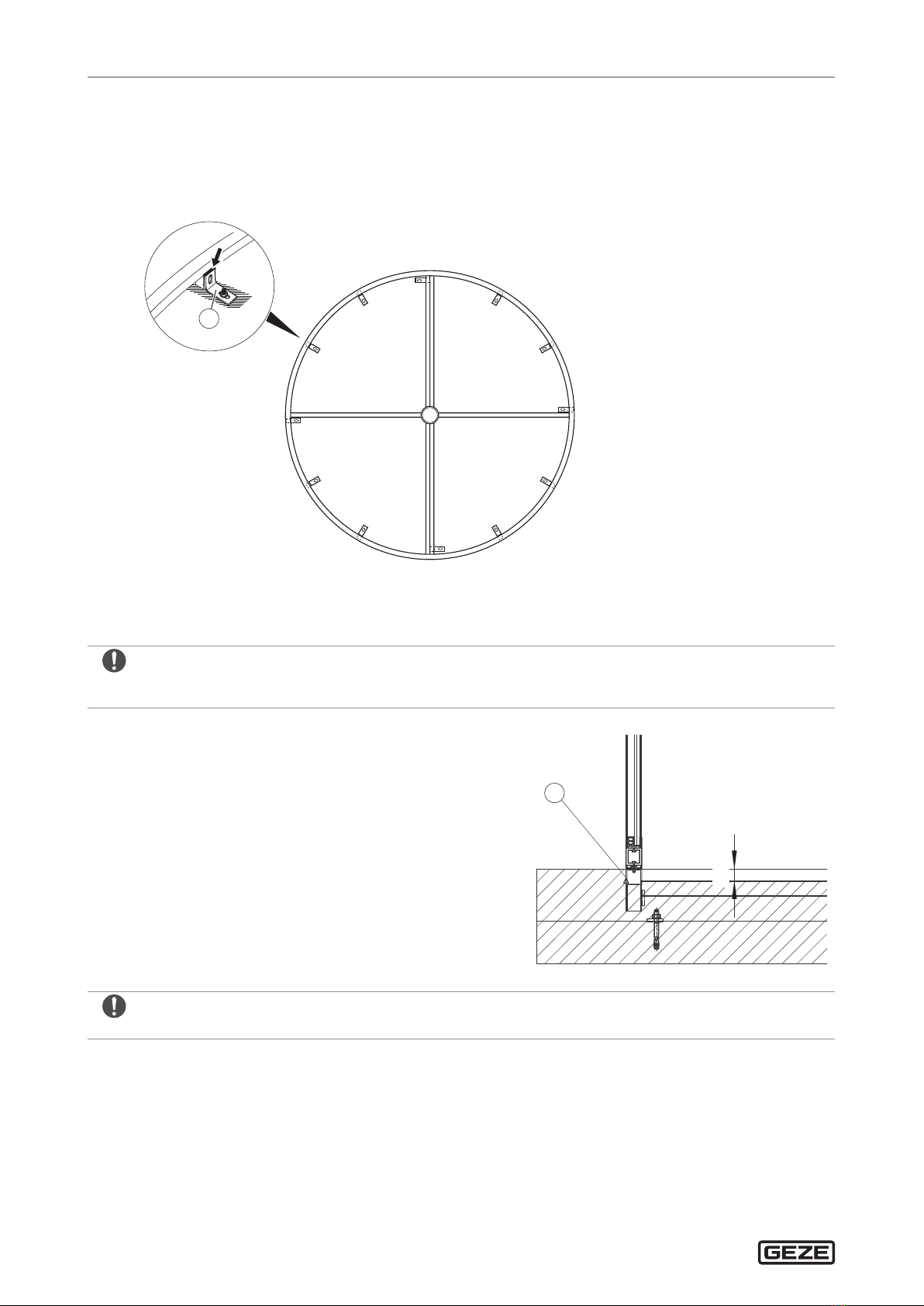

4.1 Preparations to be made on site.................................................................................................................................................................8

4.2 Mounting the revolving door TSA 325 NT...............................................................................................................................................8

4.3 Mounting switch contact strips on the leaves.................................................................................................................................... 22

4.4 Connect the GEZE ST220 diagnostic device/Use GEZEconnects ................................................................................................ 23

4.5 Mount the ceiling panel.............................................................................................................................................................................. 24

4.6 Check list for commissioning and service ........................................................................................................................................... 27

5 Options..................................................................................................................................................................... 28

5.1 Automatic locking system.......................................................................................................................................................................... 28

5.2 Revolving doors with breakout function.............................................................................................................................................. 33

5.3 External night time closer (automatic and manual)..........................................................................................................................41

5.4 Open position monitoring......................................................................................................................................................................... 43

5.5 General installation information for NV tooth-belt tension.......................................................................................................... 44

5.6 Revolving door in all-glass version (TSA 325 NT GG) ....................................................................................................................... 50

5.7 Speed limiter unit for TSA 325 NT ............................................................................................................................................................61

6 Revolving door TSA 325 NT RC 2..................................................................................................................... 64

6.1 Assemblies and parts ................................................................................................................................................................................... 64

6.2 Revolving door TSA 325 NT RC 2.............................................................................................................................................................. 65

6.3 Installing revolving door TSA 325 NT RC 2........................................................................................................................................... 68

6.4 Installation information for NV tooth belt tension RC2 .................................................................................................................. 86

6.5 Mounting the turnstile ................................................................................................................................................................................ 87

6.6 Mounting contact strips on the leaves.................................................................................................................................................. 87

6.7 Mount the RC 2 ceiling panel.................................................................................................................................................................... 87

6.8 Check list for commissioning and service ............................................................................................................................................ 94

7 Revolving door TSA 325 NT, 3-leaf.................................................................................................................. 95

7.1 Assemblies and parts ................................................................................................................................................................................... 95

7.2 Night-time closer drive (AINV).................................................................................................................................................................. 96

7.3 Mounting the TSA 325 NT revolving door, 3-leaf .............................................................................................................................. 97

7.4 Installation information for NV tooth-belt tension.........................................................................................................................108

7.5 Mounting the turnstile ..............................................................................................................................................................................108

7.6 Mounting contact strips on the leaves................................................................................................................................................109

7.7 Mount the RC 2 ceiling panel..................................................................................................................................................................109

7.8 Check list for commissioning and service ..........................................................................................................................................109