Table of Contents

© 2020 EMP, Inc. 3

Table of Contents

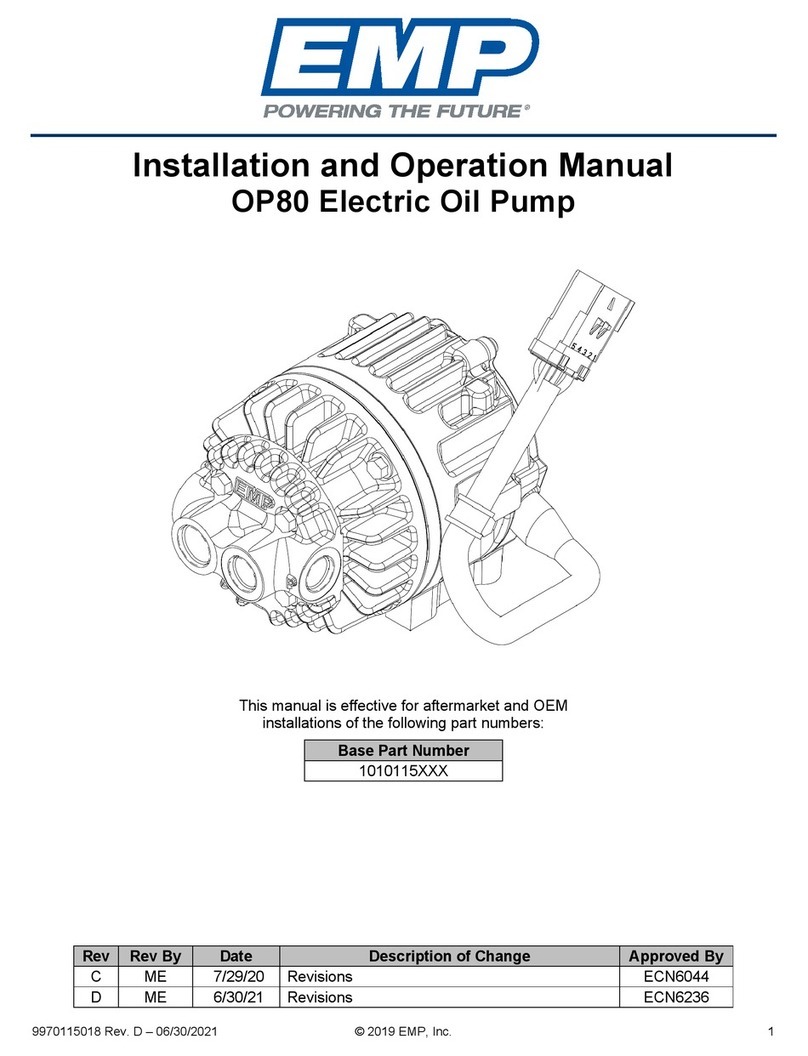

Product Overview ..............................................................................................................................................2

Introduction........................................................................................................................................................4

Purpose .........................................................................................................................................................4

Service Technician Responsibilities ...............................................................................................................4

Liability Disclaimer .........................................................................................................................................4

Additional Information ....................................................................................................................................4

Technical Help ...............................................................................................................................................4

Warnings, Cautions and Notes.......................................................................................................................4

Definition of Terms .........................................................................................................................................4

Product Safety Warnings ...................................................................................................................................5

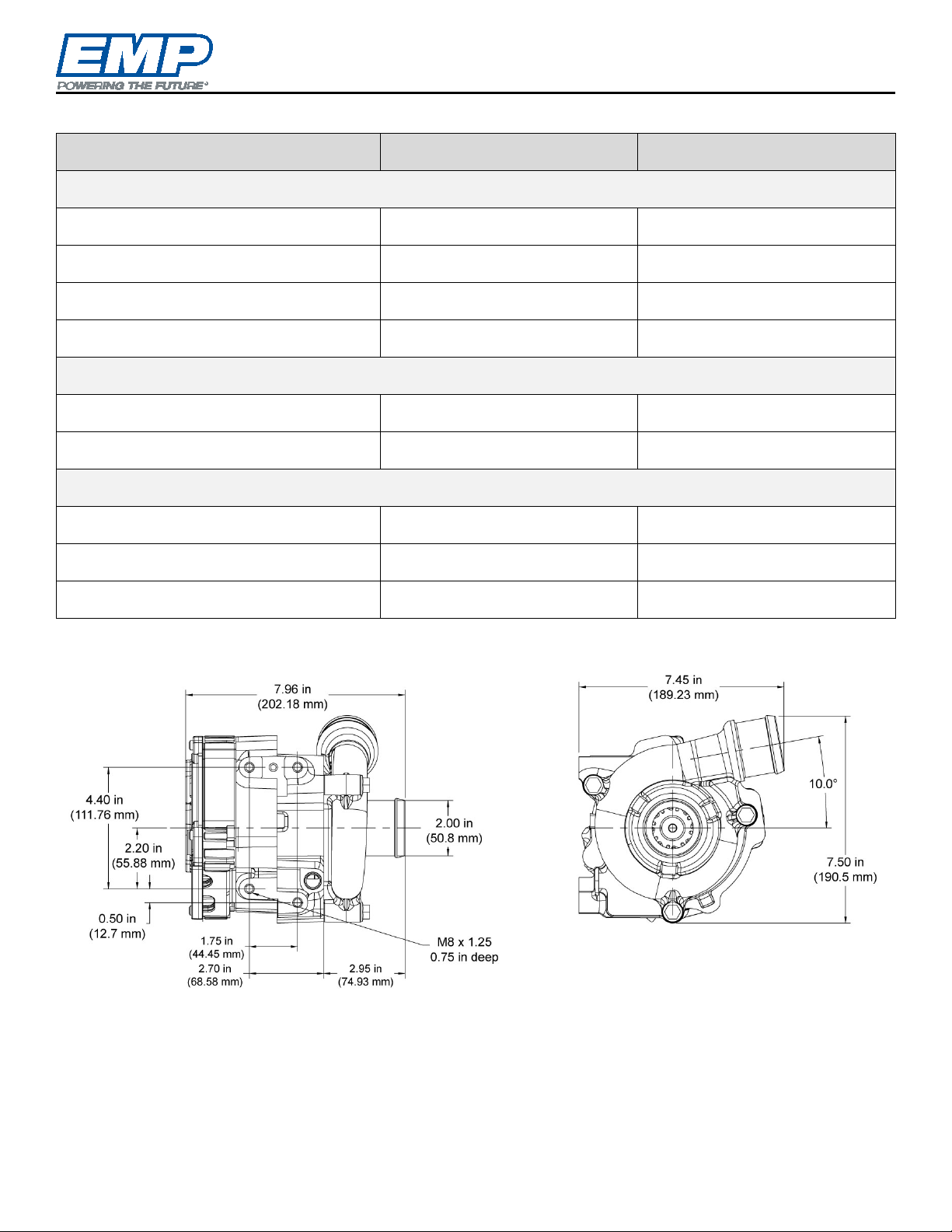

Specifications ....................................................................................................................................................6

Dimensions and Hole Locations/Bolt Spacing ................................................................................................6

Material Listing of Major External and Fluid Contacting Parts.........................................................................7

Operating Limits.............................................................................................................................................7

Identification ......................................................................................................................................................8

Product Label.................................................................................................................................................8

EMP Water Pump Model Codes..................................................................................................................... 9

Installation .......................................................................................................................................................10

Environment.................................................................................................................................................10

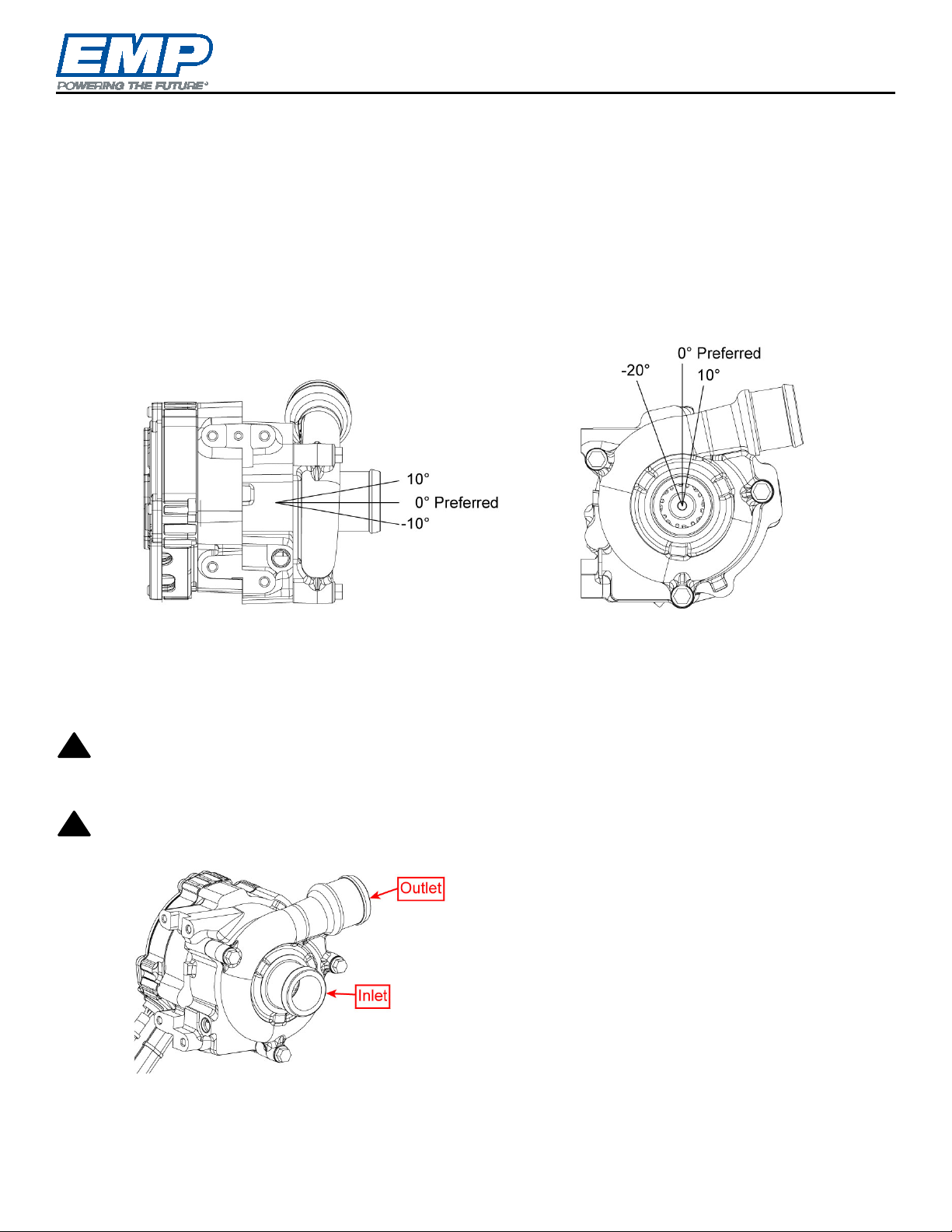

Orientation ...................................................................................................................................................10

Plumbing......................................................................................................................................................10

System Fill Procedure ..................................................................................................................................11

Wiring...........................................................................................................................................................12

Component Connector Information ..............................................................................................................13

Mating Connector Information ......................................................................................................................13

On/Off Single Speed Control........................................................................................................................15

Routine Maintenance.......................................................................................................................................16

Physical Inspection ......................................................................................................................................16

EMPower Connect™ Service Tool ..................................................................................................................17

Diagnostic Outputs.......................................................................................................................................17

Troubleshooting...............................................................................................................................................17