Table of Contents

© 2019 EMP, Inc. 3

Table of Contents

Product Overview ..............................................................................................................................................2

Introduction........................................................................................................................................................4

Purpose .........................................................................................................................................................4

Service Technician Responsibilities ...............................................................................................................4

Liability Disclaimer .........................................................................................................................................4

Additional Information ....................................................................................................................................4

Technical Help ...............................................................................................................................................4

Warranty ........................................................................................................................................................4

About This Document ........................................................................................................................................5

Warnings, Cautions and Notes.......................................................................................................................5

Definition of Terms.........................................................................................................................................5

Product Safety Warnings ...................................................................................................................................6

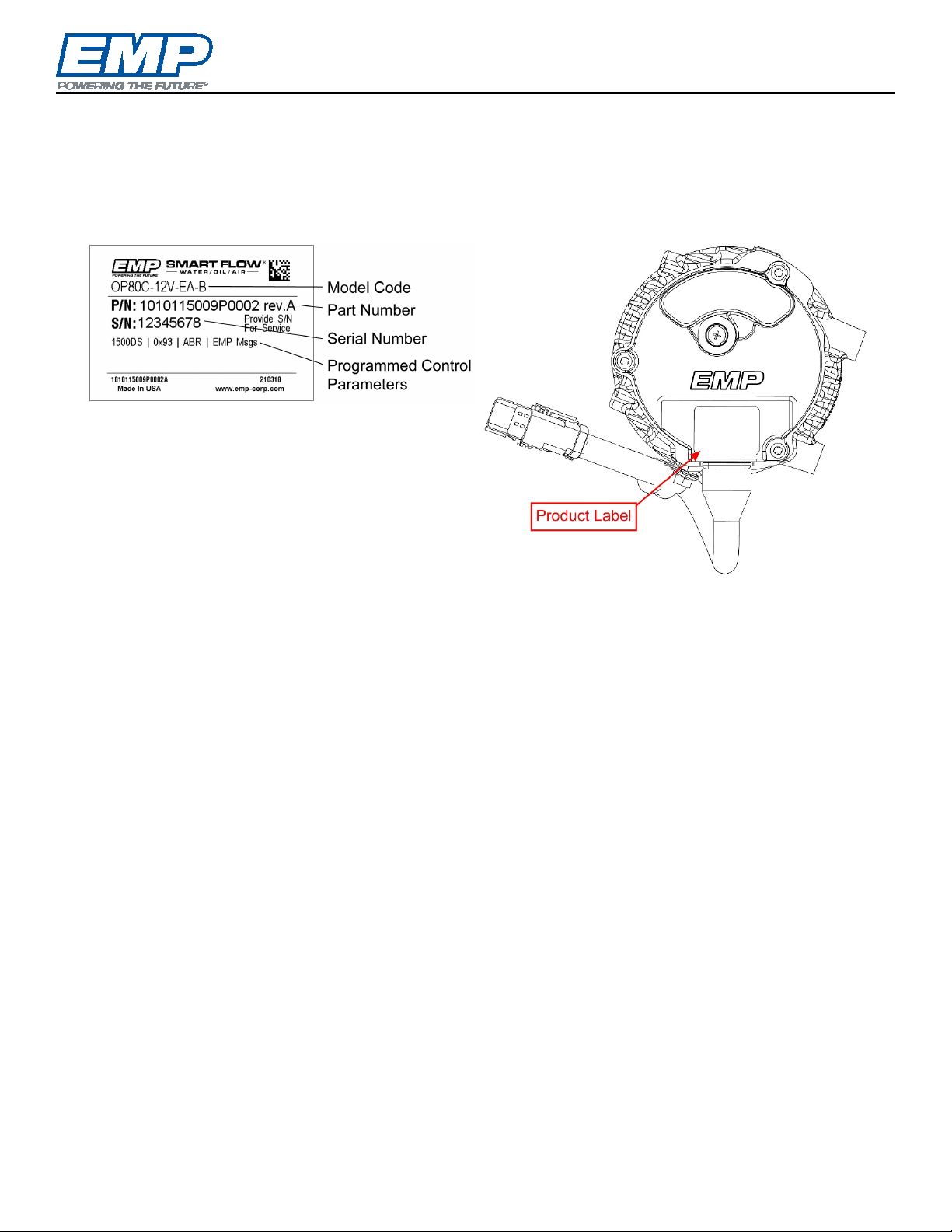

Identification ......................................................................................................................................................7

EMP Oil Pump Model Codes..........................................................................................................................8

Technical Information ........................................................................................................................................9

Operation .......................................................................................................................................................9

Specifications.................................................................................................................................................9

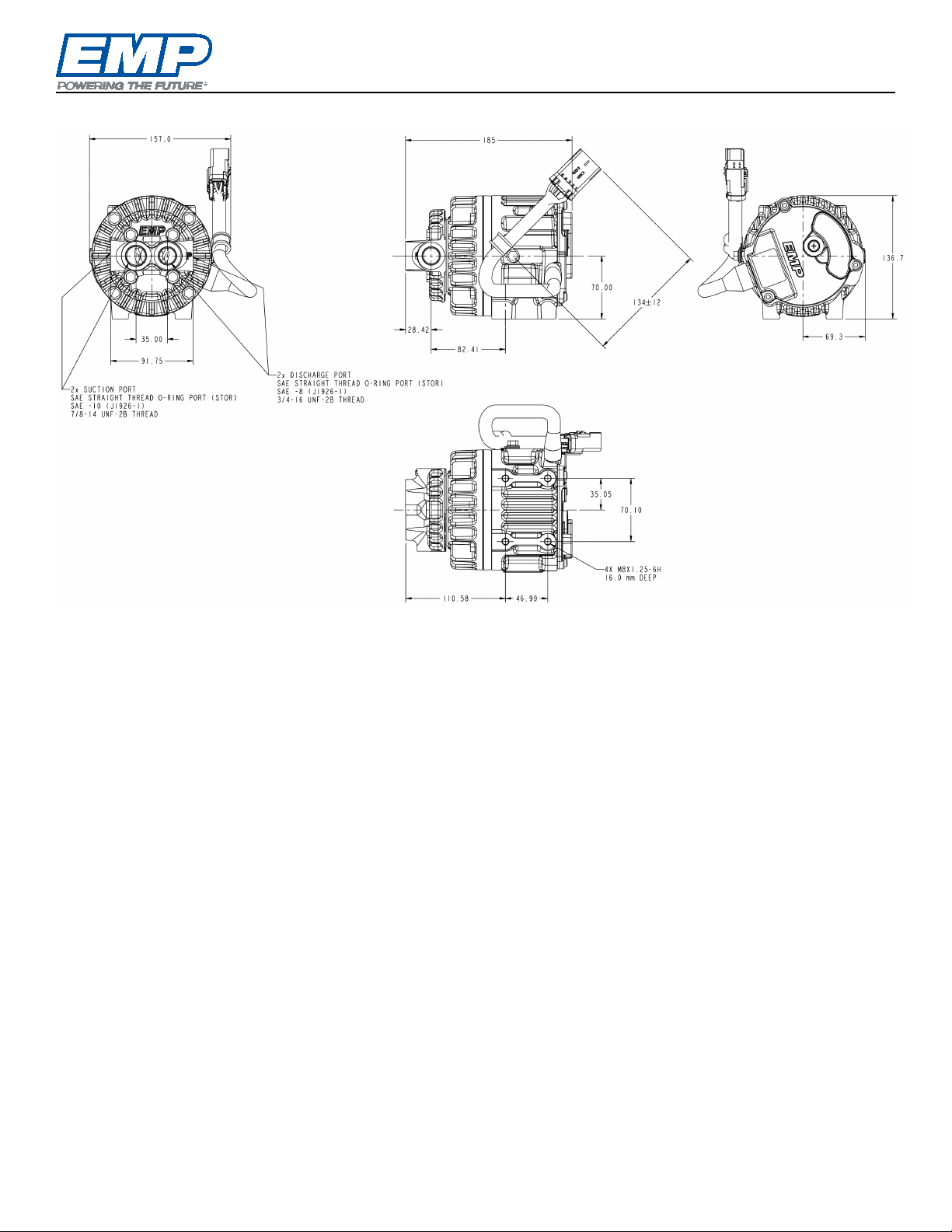

Dimensional and Mounting Details ...............................................................................................................10

Sample Performance Chart..........................................................................................................................11

Installation .......................................................................................................................................................13

Locations/Orientations ................................................................................................................................. 13

Plumbing Considerations .............................................................................................................................13

Wiring Practices ...........................................................................................................................................14

Service Parts Replacement .............................................................................................................................14

Fluids Fill .........................................................................................................................................................15

Final Item Checklist .........................................................................................................................................15

Installation Review Checklist ...........................................................................................................................15

Routine Maintenance.......................................................................................................................................16

Troubleshooting...............................................................................................................................................16

Appendix A ......................................................................................................................................................17

Operation Manual R20L Controller Board ....................................................................................................17

Appendix B ......................................................................................................................................................18

Operation Manual R20C Controller Board....................................................................................................18

Product Warranty Registration Form................................................................................................................ 19